Analysis of soaking deformation characteristics of large-thickness discontinuous collapsible loess

-

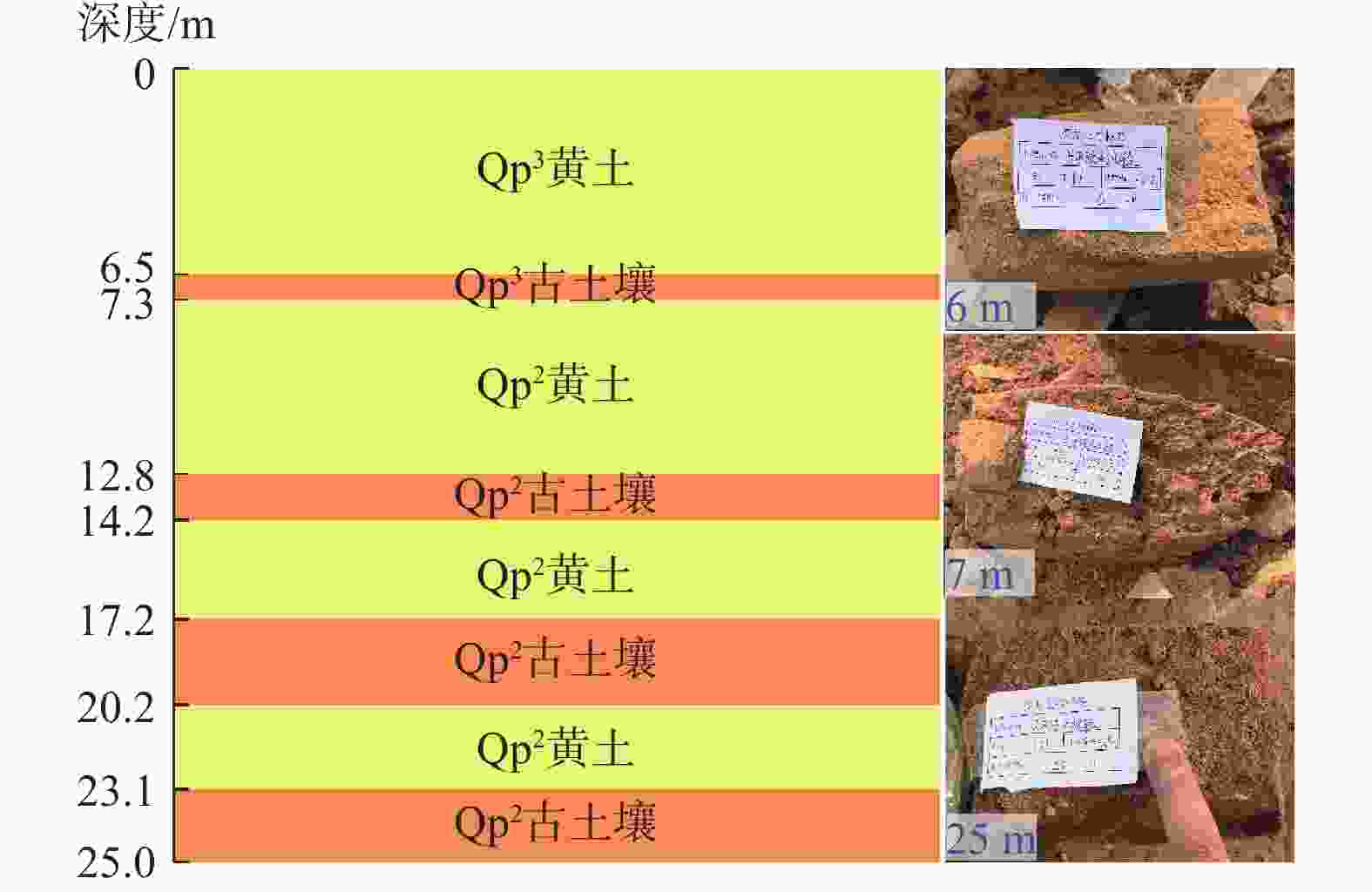

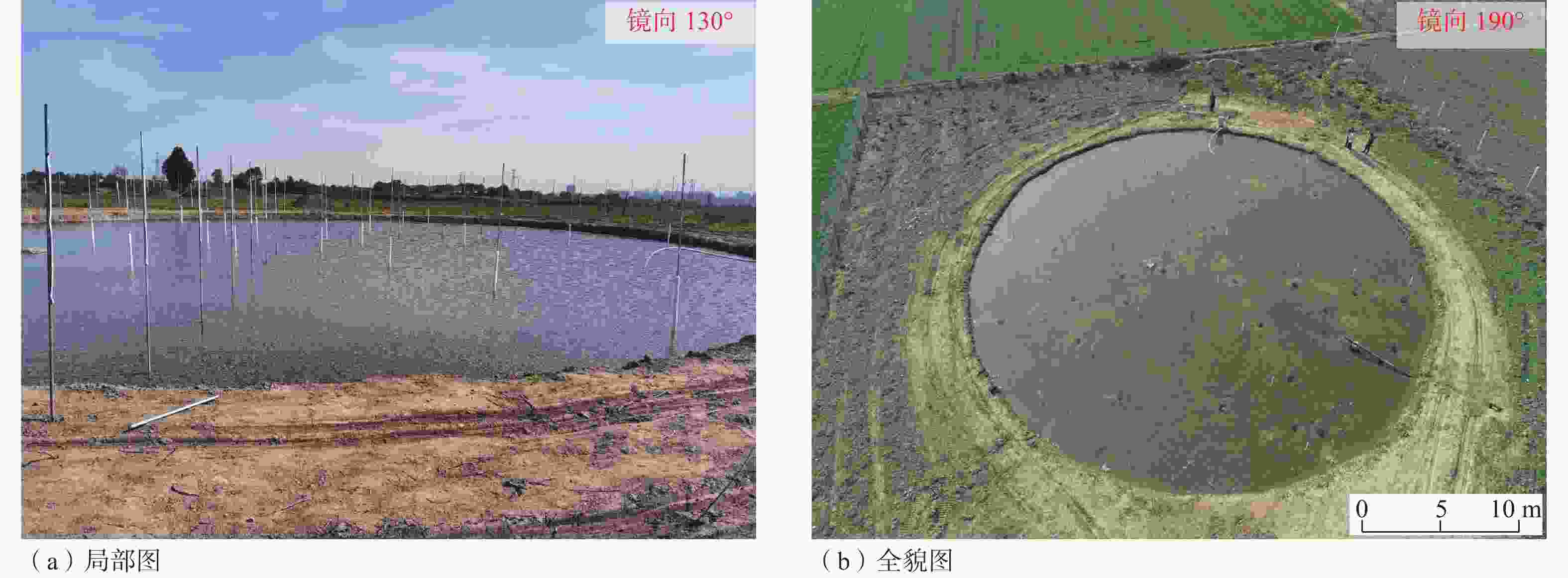

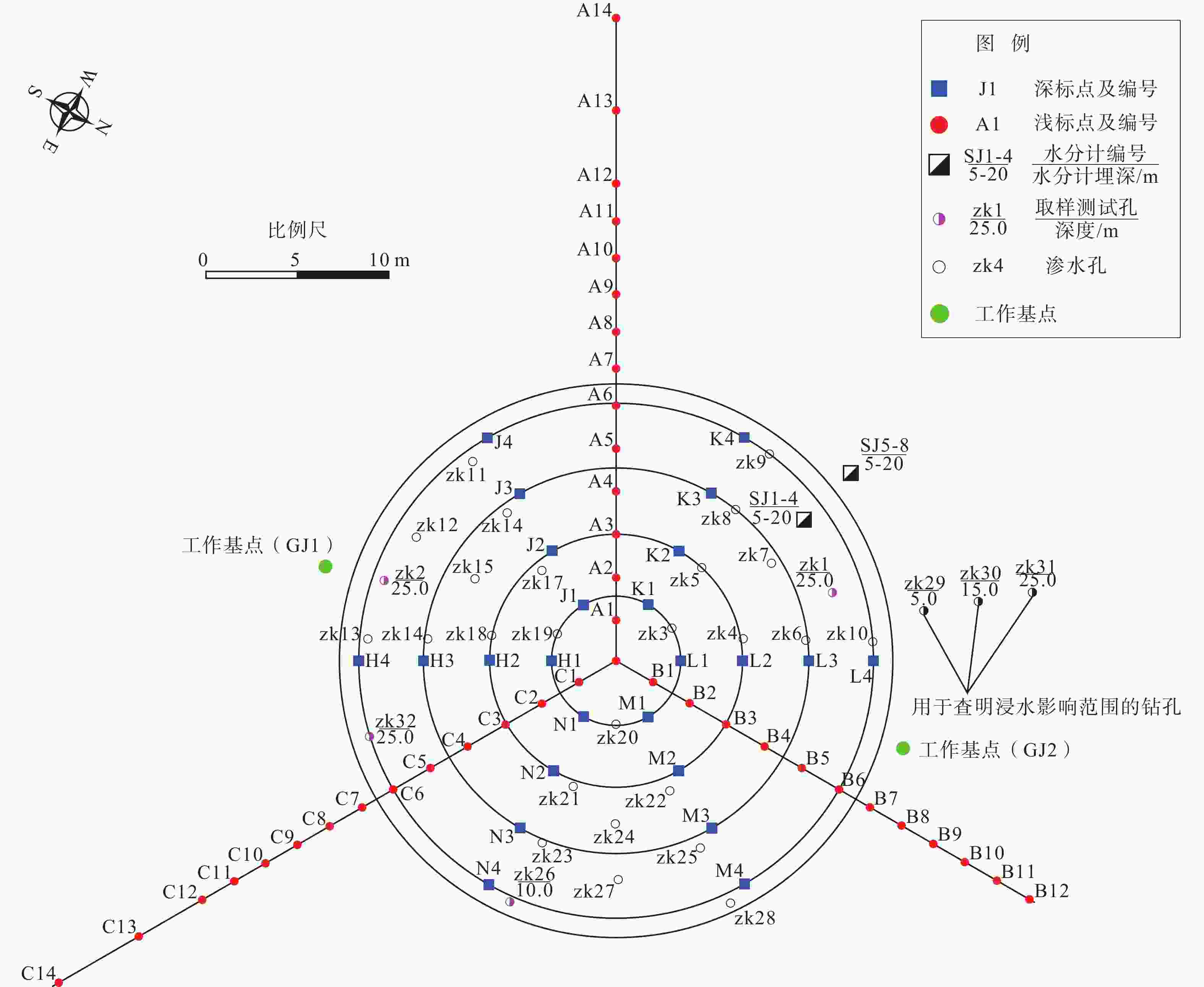

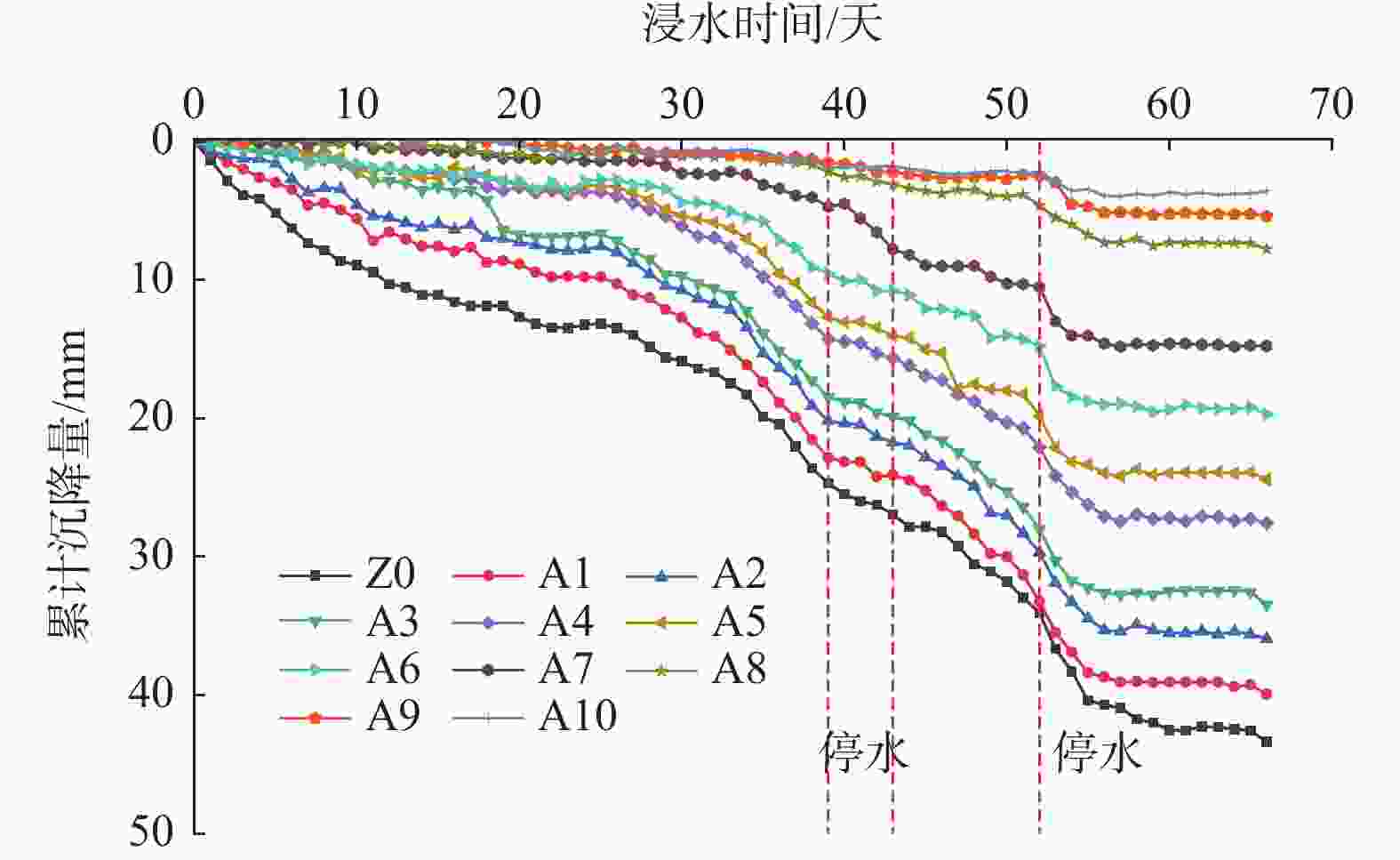

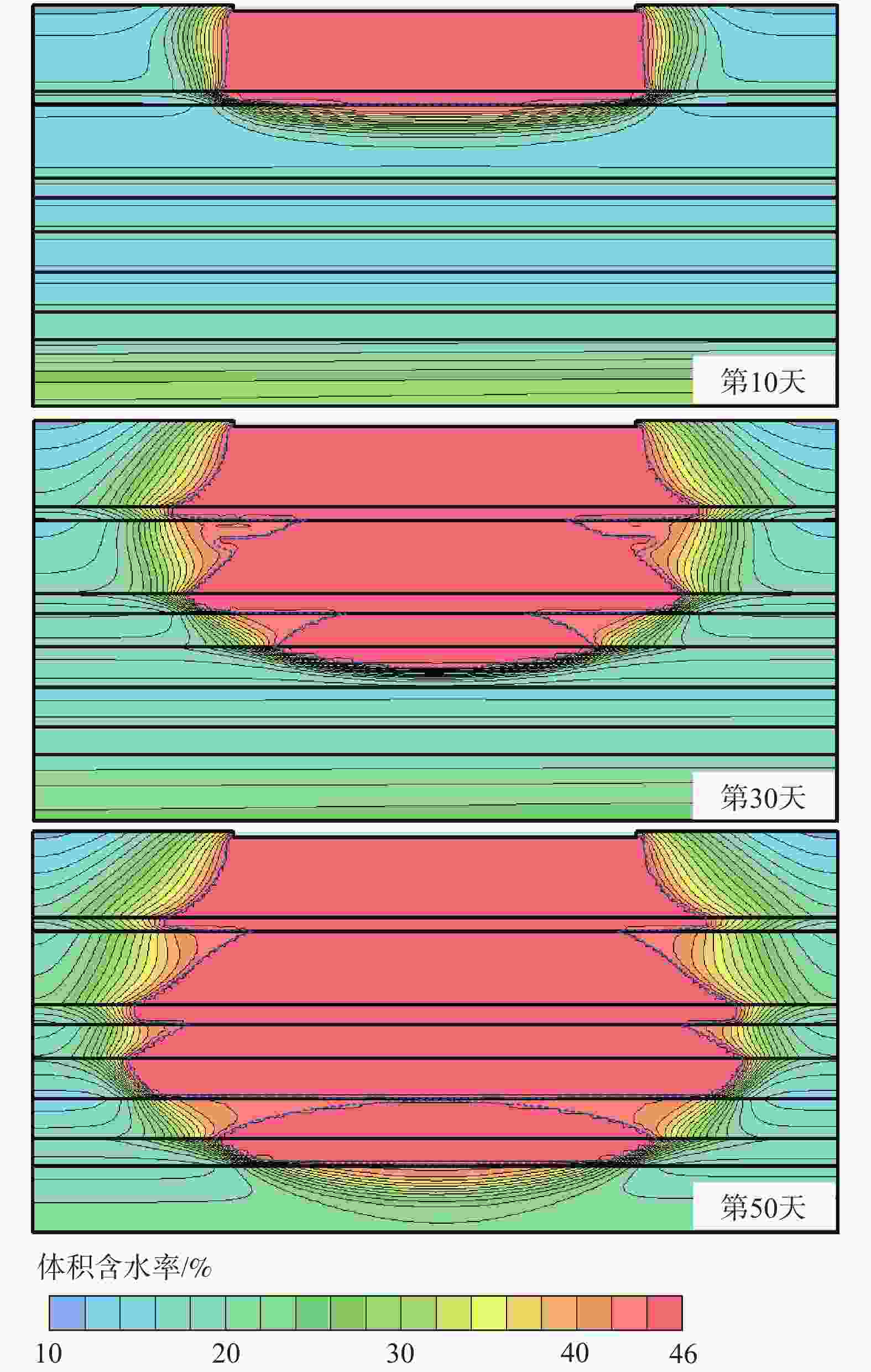

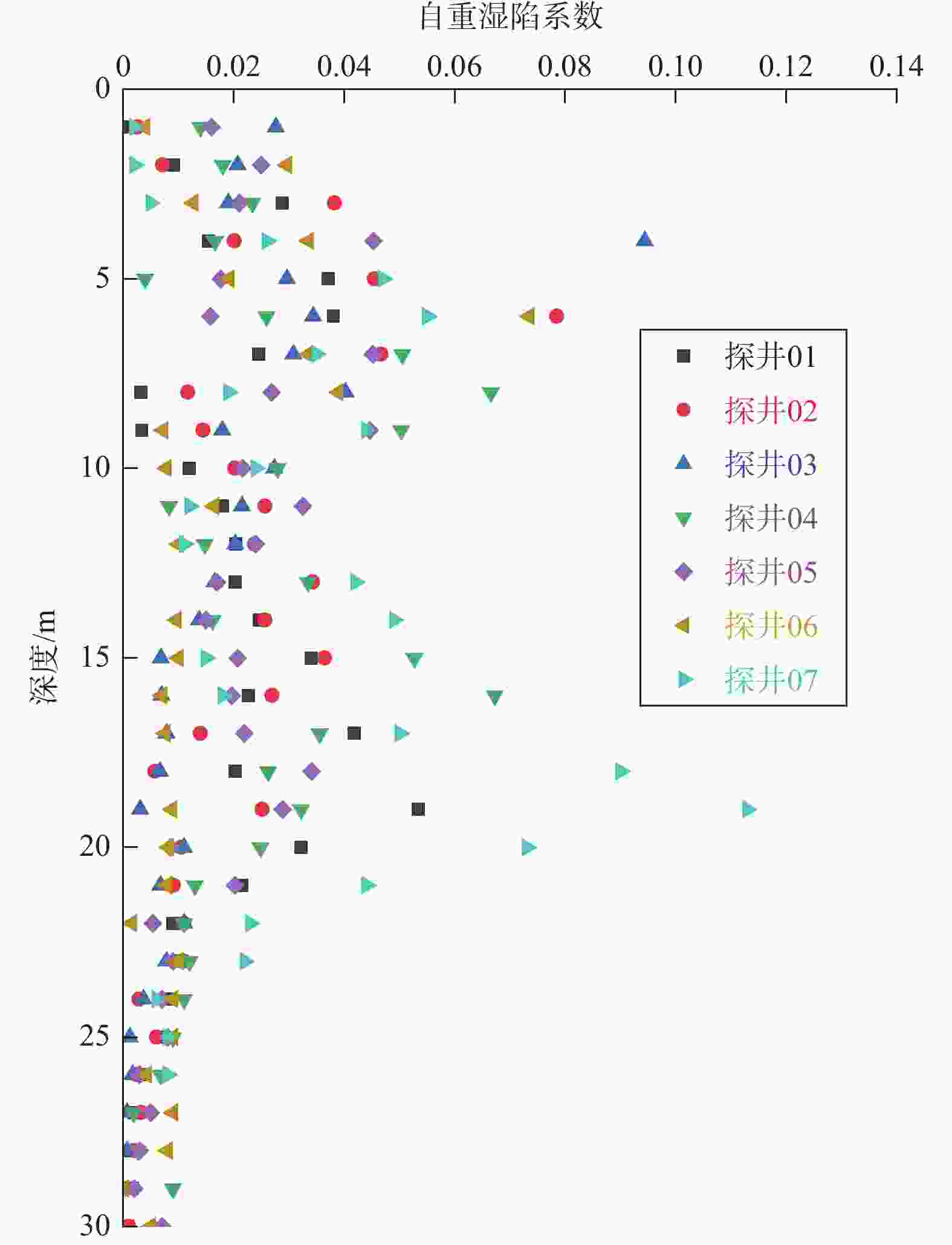

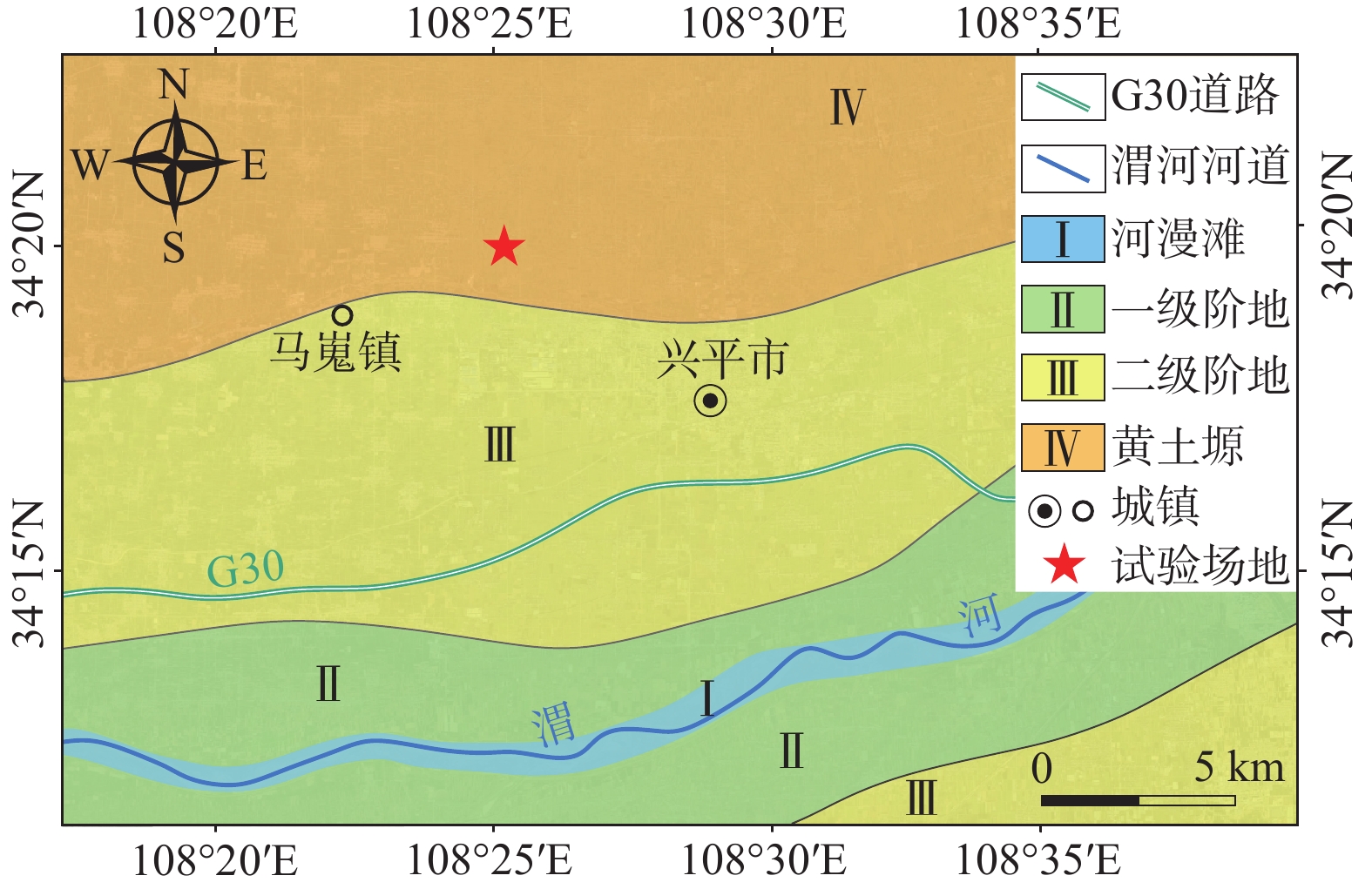

摘要: 非连续分布的黄土地层在中国关中平原地区广泛分布,由于其特殊的地层结构,在评价地基湿陷性时自重湿陷量的室内计算值与现场实测值有较大的差异。为此,文章以关中盆地渭河北岸黄土塬地层为研究对象,开展了室内湿陷性试验和现场大型试坑浸水试验,对比了现场与室内湿陷量差异的影响因素。同时在结合数值计算的基础上,分析了现场浸水试验的渗流特征。研究结果显示:场地现场试验和室内试验的自重湿陷量比值小于0.1,产生此差异的原因包括黄土地层的非连续性和不均匀性、室内试验的取样扰动因素以及现场试验的浸水条件差异;黄土的非连续性形成的层拱效应是造成室内试验与现场试验差异的主要原因,其削弱了部分向上传递的变形、阻碍了向下传递的自重应力,同时造成渗流过程的不连续;计算自重湿陷量时,可采用根据地层时代分层的计算方法,该方法可为该地区未来的工程建设提供理论指导。Abstract:

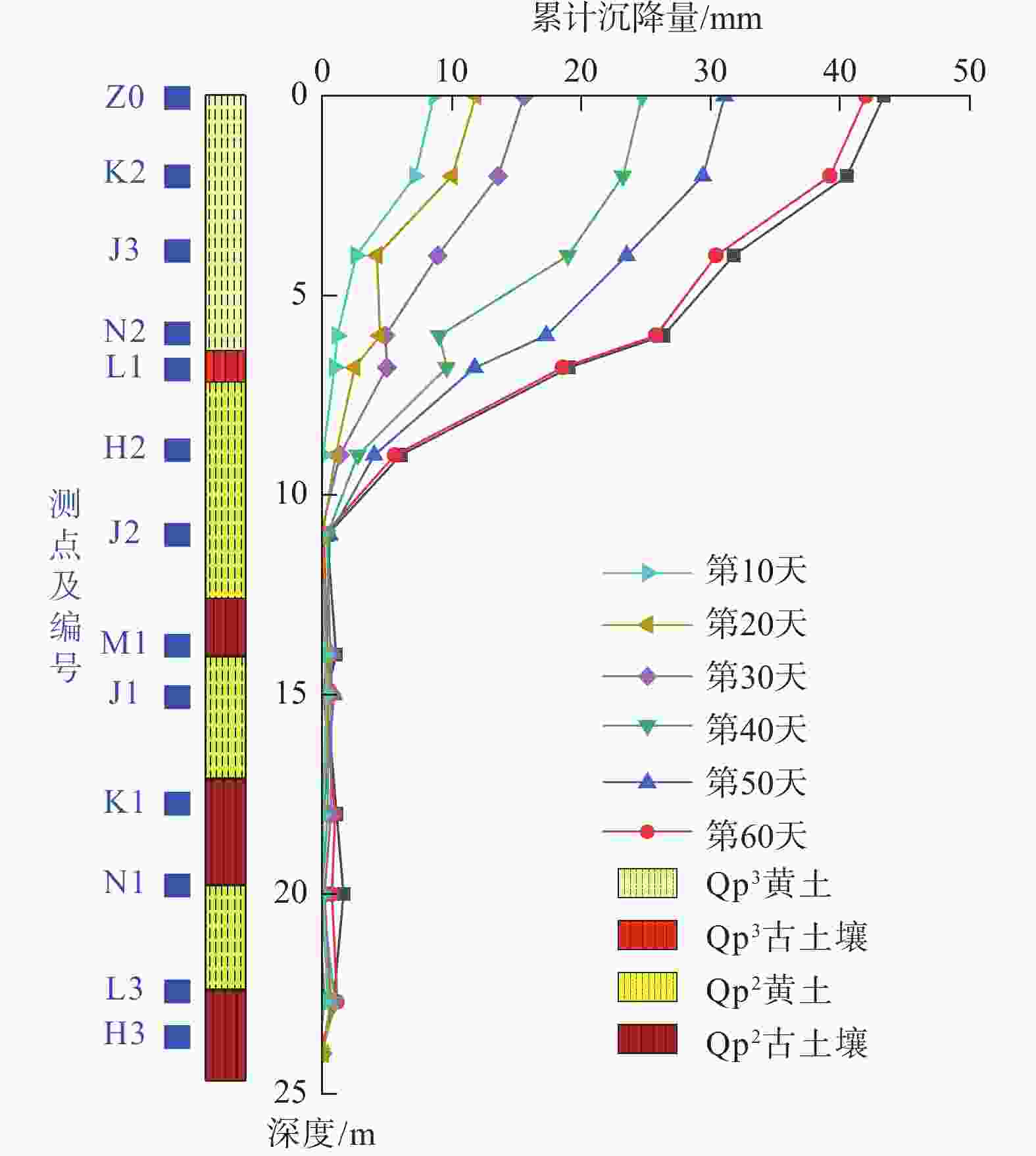

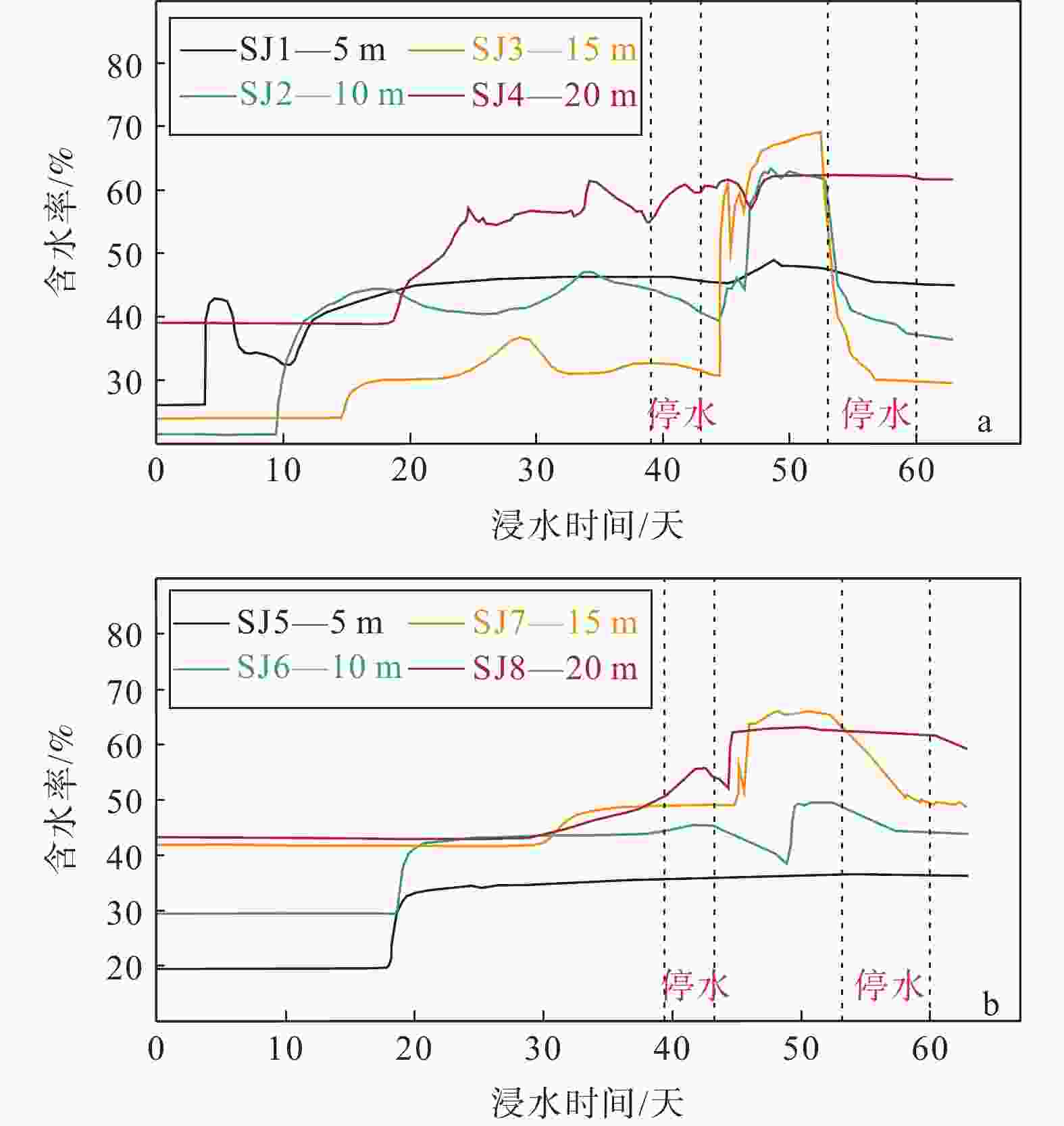

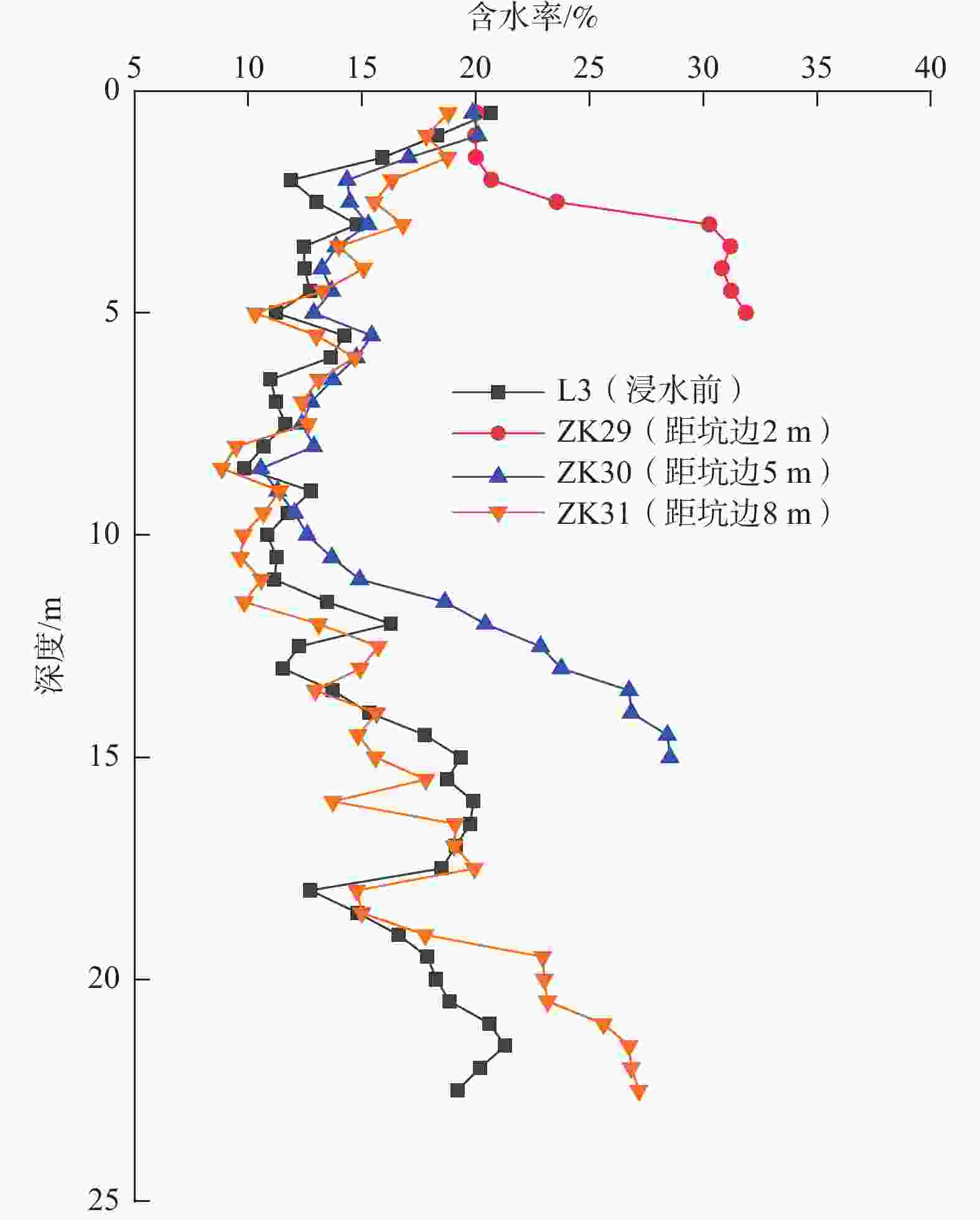

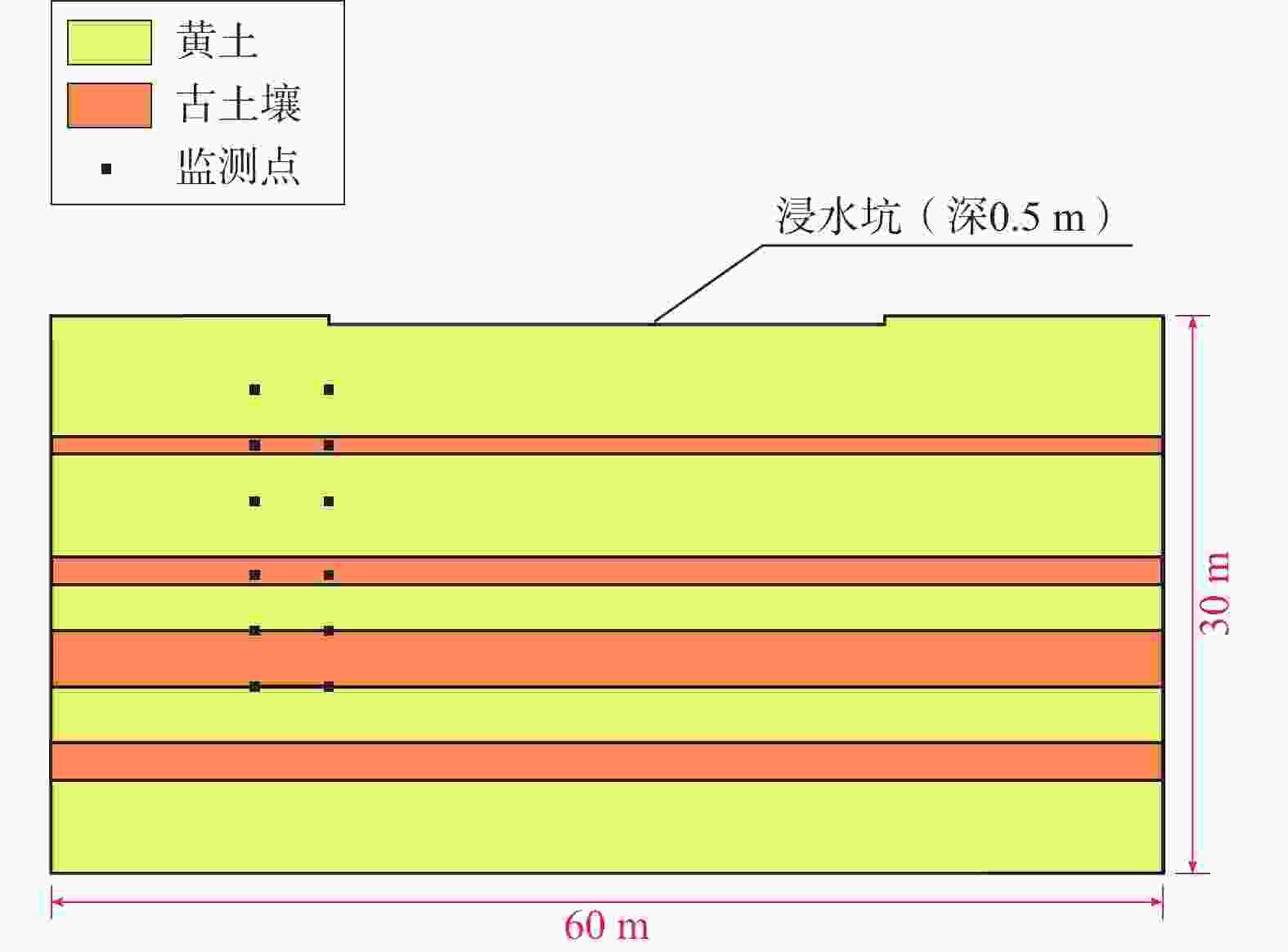

Objective The unique stratigraphic structure of the widely distributed discontinuous loess stratum in the Guanzhong Plain area of China results in significant differences between the indoor calculated values and field-measured values of the self-weight wetting amount for evaluating the foundation’s wetting property. Methods Indoor wetting tests and large-scale test pit immersion tests were carried out on-site to compare the factors influencing the difference between on-site and indoor wetting amounts, with the loess stratum on the north bank of the Weihe River as the research object. Results The following results were obtained from the study: (1) The ratio of self-weight wet depressions between field and indoor test was less than 0.1. This discrepancy was due to the discontinuity and inhomogeneity of loess layers, sampling disturbances in indoor tests, and differing immersion conditions in field test. (2) The “layer bow effect” caused by the discontinuity of loess was the main reason for the difference between the indoor and field tests. This effect weakened upward-transmitted deformation, hindered downward-transmitted gravity stress, and caused discontinuity in the percolation process. (3) Stratification calculations for the four test sites showed that most of the gravitational self-wetting in the field tests occurred in the Qp3 soil layer, while the Qp2 loess layer showed large difference between the field-measured and indoor test values. Thus, the Qp2 loess layer has little to no wetting effect. Conclusion The shape of the saturated zone range obtained through numerical simulation was consistent with the field test results, and the numerical simulation method was more advantageous for observing the experimental results. When calculating wet subsidence by self-weight, a stratification method based on the strata age can be used. For the Qp3 stratum, the correction coefficient method specified in the guidelines was chosen, while the Qp2 loess stratum was determined by an on-site pit immersion test. Significance The research methodology used in this study provides theoretical guidance for future engineering constructions on the Guanzhong Plain. -

表 1 试验场地黄土物理力学指标

Table 1. Loess physical index of the test site

取土深

度/m地层

岩性含水率/% 天然密度/

(g·cm−3)孔隙比 自重湿

陷系数取土深

度/m地层

岩性含水率/% 天然密度/

(g·cm−3)孔隙比 自重湿

陷系数1 Qp3黄土 18.7 1.49 1.167 0.003 14 Qp2古土壤 8.9 1.44 1.049 0.051 2 Qp3黄土 17.9 1.64 0.948 0.003 15 Qp2黄土 17.1 1.75 0.820 0.016 3 Qp3黄土 16.2 1.43 1.202 0.009 16 Qp2黄土 19.7 1.76 0.850 0.020 4 Qp3黄土 15.0 1.39 1.250 0.018 17 Qp2黄土 12.0 1.42 1.137 0.051 5 Qp3黄土 10.9 1.41 1.131 0.041 18 Qp2古土壤 11.9 1.41 1.151 0.097 6 Qp3黄土 11.3 1.40 1.154 0.057 19 Qp2古土壤 11.9 1.44 1.114 0.105 7 Qp3古土壤 14.3 1.51 1.059 0.033 20 Qp2古土壤 11.3 1.44 1.095 0.081 8 Qp2黄土 10.1 1.52 0.963 0.017 21 Qp2黄土 11.6 1.54 0.964 0.041 9 Qp2黄土 11.0 1.42 1.118 0.040 22 Qp2黄土 20.6 1.68 0.945 0.023 10 Qp2黄土 12.1 1.46 1.081 0.024 23 Qp2黄土 23.3 1.68 0.989 0.021 11 Qp2黄土 15.0 1.68 0.855 0.011 24 Qp2古土壤 19.7 1.86 0.750 0.006 12 Qp2黄土 14.9 1.70 0.838 0.018 25 Qp2古土壤 18.3 1.79 0.798 0.010 13 Qp2古土壤 12.2 1.50 1.027 0.040 26 Qp2古土壤 19.1 1.84 0.761 0.008 表 2 数值模拟参数统计表

Table 2. Statistics of the numerical simulation parameters

材料介质 水平渗透系数/(cm∙s−3) 竖直渗透系数/(cm∙s−3) 黄土 2.3×10−4 6.9×10−4 古土壤 1.4×10−4 4.0×10−4 表 3 考虑地层时代的修正系数β值

Table 3. Values of correction factor β considering stratigraphic age

序号 地层时代 土层厚度

/m现场实测值

/mm室内试验值

/mm修正系数

β数据来源 1 Qp3 7.0 32.3 154.0 0.21 文中试验场地 Qp2 16.0 11.0 556.1 0.02 2 Qp3 16.5 181.7 177.0 1.03 西安市东郊浐河西岸(王庆满等,2022) Qp2 10.0 27.0 351.0 0.08 3 Qp3 15.2 285.4 268.0 1.07 西安地铁6号线项目田家湾站(王庆满等,2022) Qp2 3.3 0 36.0 0 4 Qp3 10.0 380.5 179.0 1.91 西安城际铁路项目咸阳机场附近(杨喆等,2022) Qp2 9.0 0 129.0 0 注:β为现场实测值与室内试验值得比值 -

[1] CHEN J L, NI W K, WANG H M, et al. 2024. Correlation between soil-water characteristic curves and wet subsidence of in situ loess[J]. Chinese Journal of Geologic Hazards and Prevention, 35(02): 107-114. (in Chinese with English abstract) [2] CHEN Z H, LIU Z D, 1986. Mechanism of collapsible deformation of loess[J]. Chinese Journal of Geotechnical Engineering, 8(2): 1-12. (in Chinese with English abstract [3] FAN W, WEI Y N, YU B, et al., 2022. Research progress and prospect of loess collapsible mechanism in micro-level[J]. Hydrogeology and Engineering Geology, 49(5): 144-156. (in Chinese with English abstract [4] HUANG X F, YANG X H, 2013. A study progress on in-situ soaking test on collapsible loess[J]. Rock and soil Mechanics, 34(S2): 222-228. (in Chinese with English abstract [5] KRABBENHOFT K, LYAMIN A V, HJIAJ M, et al., 2005. A new discontinuous upper bound limit analysis formulation[J]. International Journal for Numerical Methods in Engineering, 63(7): 1069-1088. doi: 10.1002/nme.1314 [6] KYUMA K, WANG Y Y, TULAPHITAK T, et al. , 1984. Paleosols in Luochuan loess section[M]//SASAJIMA S, WANG Y Y. The recent research of loess in China. Kyoto: Kyoto Institute of Natural History. [7] LENG Y Q, 2018. Study on the water-sensitive characteristics and disasters of loess[D]. Xi'an: Chang'an University. (in Chinese with English abstract [8] LI B, 2009. Research on formation evolution mechanism of multiple rotational loess landslides[D]. Xi'an: Chang'an University. (in Chinese with English abstract [9] LI D Z, HE Y H, SUI G X, 1993. Study and test on immersion of Q2 loess in Large area[J]. Chinese Journal of Geotechnical Engineering, 15(2): 1-11. (in Chinese with English abstract [10] LI K C, WANG Q M, 2017. Discussion on the causes of the discrepancy between the internal and external test values of self-weight loess collapsibility content[J]. Shanxi Architecture, 43(3): 47-48. (in Chinese with English abstract [11] LIANG Q G, FANG J, ZHANG J D, et al., 2018. In-situ soaking test on the disturbed loess site at Lanzhou metro, Gansu province, China[J]. Journal of Geomechanics, 24(6): 803-812. (in Chinese with English abstract [12] LU J, 2020. Study on engineering characteristics of loess-paleosol[D]. Xi'an: Xi'an University of Architecture and Technology. (in Chinese with English abstract [13] MU H D, SUN P, LI R J, et al., 2017. Dynamic damping characteristics and evolution law of Pan’an structural loess[J]. Journal of Geomechanics, 23(6): 935-942. (in Chinese with English abstract [14] National Standard of the People's Republic of China. 2018. Building code for wet subsided loess areas (GB50025-2018) [S]. Beijing: China Construction Industry Press. (in Chinese) [15] PENG J B, LIN H Z, WANG Q Y, et al., 2014. The critical issues and creative concepts in mitigation research of loess geological hazards[J]. Journal of Engineering Geology, 22(4): 684-691. (in Chinese with English abstract [16] QI L, QIAO Y S, LIU Z X, et al., 2021. Geochemical characteristics of the Tertiary and Quaternary eolian deposits in eastern Gansu province: implications for provenance and weathering intensity[J]. Journal of Geomechanics, 27(3): 475-490. (in Chinese with English abstract [17] SHAO S J, LONG J Y, YANG S, et al., 2006. Analysis of structural deformation properties of collapsible loess[J]. Rock and Soil Mechanics, 27(10): 1668-1672. (in Chinese with English abstract [18] SHAO S J, LI J, LI G L, et al., 2015. Evaluation method for self-weight collapsible deformation of large thickness loess foundation[J]. Chinese Journal of Geotechnical Engineering, 37(6): 965-978. (in Chinese with English abstract [19] SHI H Q, 2008. In-situ immersion test and analysis of Pleistocene Epoch Q2 loess at Xi'an tableland[D]. Xi'an: Xi'an University of Architecture and Technology. (in Chinese with English abstract [20] SLOAN S W, KLEEMAN P W, 1995. Upper bound limit analysis using discontinuous velocity fields[J]. Computer Methods in Applied Mechanics and Engineering, 127(1-4): 293-314. doi: 10.1016/0045-7825(95)00868-1 [21] SU R, ZHANG H R, ZHANG W J, et al., 2020. Immersion tests on self-weight collapsible loess site with large depth of Lanzhou metro line[J]. China Civil Engineering Journal, 53(S1): 186-193. (in Chinese with English abstract [22] SUN P, LI R J, LIU J D, et al., 2016. Structural index and dynamic strength attenuation characteristics of structural loess in Pan'an[J]. Science & Technology Review, 34(5): 74-78. (in Chinese with English abstract [23] WANG Q M, FAN H G, LIU Y, et al., 2022. Study on field immersion test of large thickness self-weight collapsible loess sites[J]. Geotechnical Engineering Technique, 36(5): 409-416. (in Chinese with English abstract [24] WANG X J, MI W J, XIONG Z W, et al., 2012. Water immersion field tests of collapsibility of loess foundation of Zhengzhou-Xi’an passenger dedicated line[J]. Journal of the China Railway Society, 34(1): 83-90. (in Chinese with English abstract [25] WANG Y H, ZHANG X H, YUAN Q G, 2013. Analysis and study on self-weight collapsible test of big thickness loess under overburden Pressure[J]. Site Investigation Science and Technology(3): 5-8. (in Chinese with English abstract [26] WANG Z J, PAN J Y, MA Y, et al., 2016. Immersion test on the self-weight collapsible loess in the Dongzhiyuan area[J]. Hydrogeology & Engineering Geology, 43(2): 75-82. (in Chinese with English abstract [27] WANG Z Q, 2022. Experimental study on structural and engineering mechanical properties of paleosail in loess stratum[D]. Xi'an: Xi'an University of Technology. (in Chinese with English abstract [28] WU X P, CHU H D, QU Y H, et al., 2011. Discussion on judging methods for the maximum depth of collapsible loess under overburden pressure[J]. Northwestern Seismological Journal, 33(S1): 218-222. (in Chinese with English abstract [29] XU L, DAI F C, 2009. Discussion on the further research in loess hydrocompaction[J]. Journal of Geomechanics, 15(1): 88-94, 104. (in Chinese with English abstract [30] XU X J, FAN J T, YUAN K J, et al. 2023. Field immersion test on large thickness of wet subsidence loess[J]. Journal of Xi'an University of Architecture and Technology (Natural Science Edition), 55(06): 849-857. (in Chinese with English abstract) [31] YANG Z, WANG J D, LI K C, et al, 2022. Field test pit immersion test study on loess plateau section of Xi'an North to Airport Intercity Railway[J]. Journal of Railway, 44(06): 107-115. (in Chinese with English abstract) [32] ZHANG T L, LIU D, LI Q, et al, 2023. Research on rapid evaluation method of wet subsidence of deep self-weighted loess site based on static touch test[J]. Journal of Engineering Geology, 31(05): 1767-1773. (in Chinese with English abstract) [33] ZHAO J G, LYU Y Q, CHAO J, et al. , 2020. The law of soaking infiltration and collapse deformation in typical loess-paleosol series[J]. Coal Geology & Exploration, 48(3): 152-159, 168. (in Chinese with English abstract [34] ZHAO M, TAN B R, DENG R, et al. 2022. Influence of “Agglomeration” Degree of Clay Minerals in Railway Subgrade Body on Mechanical Properties[J]. Railway Investigation and Surveying, 48(6): 59-65. [35] ZHENG J G, DENG G H, LIU Z H, et al., 2015. Influence of discontinuous distribution of collapsible loess on its deformation[J]. Chinese Journal of Geotechnical Engineering, 37(1): 165-170. (in Chinese with English abstract [36] ZHOU Y L, WU X P, FANG J H, et al., 2018. Comparative study on field and laboratory tests for collapsibility characteristics of large thickness loess[J]. Railway Engineering, 58(1): 114-117. (in Chinese with English abstract [37] 陈家乐,倪万魁,王海曼,等,2024. 原状黄土土-水特征曲线与湿陷性的相关性[J]. 中国地质灾害与防治学报,35(02):107-114. [38] 陈正汉,刘祖典,1986. 黄土的湿陷变形机理[J]. 岩土工程学报,8(2):1-12. doi: 10.3321/j.issn:1000-4548.1986.02.001 [39] 范文,魏亚妮,于渤,等,2022. 黄土湿陷微观机理研究现状及发展趋势[J]. 水文地质工程地质,49(5):144-156. [40] 黄雪峰,杨校辉,2013. 湿陷性黄土现场浸水试验研究进展[J]. 岩土力学,34(S2):222-228. [41] 冷艳秋,2018. 黄土水敏特性及其灾变机制研究[D]. 西安:长安大学. [42] 李滨,2009. 多级旋转型黄土滑坡形成演化机理研究[D]. 西安:长安大学. [43] 李大展,何颐华,隋国秀,1993. Q2黄土大面积浸水试验研究[J]. 岩土工程学报,15(2):1-11. doi: 10.3321/j.issn:1000-4548.1993.02.001 [44] 李开超,王庆满,2017. 黄土自重湿陷量室内外试验值差异原因探讨[J]. 山西建筑,43(3):47-48. doi: 10.3969/j.issn.1009-6825.2017.03.024 [45] 梁庆国,房军,张晋东,等,2018. 兰州轨道交通扰动场地黄土浸水试验研究[J]. 地质力学学报,24(6):803-812. doi: 10.12090/j.issn.1006-6616.2018.24.06.083 [46] 鲁洁,2020. 黄土地区古土壤工程特性研究[D]. 西安:西安建筑科技大学. [47] 慕焕东,孙萍,李荣建,等,2017. 磐安结构性黄土动阻尼特征及其演化规律研究[J]. 地质力学学报,23(6):935-942. [48] 彭建兵,林鸿州,王启耀,等,2014. 黄土地质灾害研究中的关键问题与创新思路[J]. 工程地质学报,22(4):684-691. [49] 綦琳,乔彦松,刘宗秀,等,2021. 陇东新近纪红粘土与第四纪黄土地球化学特征及其物源和风化指示意义[J]. 地质力学学报,27(3):475-490. doi: 10.12090/j.issn.1006-6616.2021.27.03.043 [50] 邵生俊,龙吉勇,杨生,等,2006. 湿陷性黄土结构性变形特性分析[J]. 岩土力学,27(10):1668-1672. doi: 10.3969/j.issn.1000-7598.2006.10.005 [51] 邵生俊,李骏,李国良,等,2015. 大厚度自重湿陷黄土湿陷变形评价方法的研究[J]. 岩土工程学报,37(6):965-978. doi: 10.11779/CJGE201506001 [52] 石怀清,2008. 西安塬区中更新世Q2黄土场地浸水试验与研究[D]. 西安:西安建筑科技大学. [53] 苏忍,张恒睿,张稳军,等,2020. 兰州地铁大厚度湿陷性黄土地层的现场浸水试验研究[J]. 土木工程学报,53(S1):186-193. [54] 孙萍,李荣建,刘军定,等,2016. 磐安结构性黄土的构度及动强度衰减特性[J]. 科技导报,34(5):74-78. [55] 王庆满,范寒光,刘艺,等,2022. 大厚度自重湿陷性黄土场地现场浸水试验研究[J]. 岩土工程技术,36(5):409-416. doi: 10.3969/j.issn.1007-2993.2022.05.012 [56] 王小军,米维军,熊治文,等,2012. 郑西客运专线黄土地基湿陷性现场浸水试验研究[J]. 铁道学报,34(1):83-90. doi: 10.3969/j.issn.1001-8360.2012.01.015 [57] 王延辉,张希宏,袁勤刚,2013. 大厚度黄土自重湿陷性试验分析研究[J]. 勘察科学技术(3):5-8. [58] 王治军,潘俊义,马闫,等,2016. 董志塬大厚度自重湿陷性黄土场地浸水试验研究[J]. 水文地质工程地质,43(2):75-82. [59] 王志强,2022. 黄土地层古土壤的结构性及工程力学特性试验研究[D]. 西安:西安理工大学. [60] 武小鹏,楚华栋,屈耀辉,等,2011. 自重湿陷性黄土下限深度判定方法探讨[J]. 西北地震学报,33(S1):218-222. [61] 许领,戴福初,2009. 黄土湿陷机理研究现状及有关问题探讨[J]. 地质力学学报,15(1):88-94,104. doi: 10.3969/j.issn.1006-6616.2009.01.008 [62] 徐西久,范江涛,袁可佳,等,2023. 大厚度湿陷性黄土现场浸水试验研究[J]. 西安建筑科技大学学报(自然科学版),55(06):849-857. [63] 杨喆,王家鼎,李开超,等,2022. 西安北至机场城际铁路黄土塬段现场试坑浸水试验研究[J]. 铁道学报,44(06):107-115. doi: 10.3969/j.issn.1001-8360.2022.06.013 [64] 张天林,刘德仁,李青,等,2023. 基于静力触探测试的深厚自重黄土场地湿陷性快速评价方法研究[J]. 工程地质学报,31(05):1767-1773. [65] 赵金刚,吕远强,晁军,等,2020. 典型黄土-古土壤系列浸水渗透及湿陷变形规律[J]. 煤田地质与勘探,48(3):152-159,168. doi: 10.3969/j.issn.1001-1986.2020.03.022 [66] 赵蒙,谭博仁,邓瑞,等. 2022. 铁路路基本体中黏土矿物“团块化”程度对力学特性的影响[J]. 铁道勘察,48(6):59-65. [67] 郑建国,邓国华,刘争宏,等,2015. 黄土湿陷性分布不连续对湿陷变形的影响研究[J]. 岩土工程学报,37(1):165-170. doi: 10.11779/CJGE201501020 [68] 中华人民共和国国家标准. 2018. 湿陷性黄土地区建筑规范(GB50025—2018)[S]. 北京:中国建筑工业出版社. [69] 周有禄,武小鹏,房建宏,等,2018. 大厚度黄土湿陷特性现场及室内试验对比研究[J]. 铁道建筑,58(1):114-117. doi: 10.3969/j.issn.1003-1995.2018.01.29 -

下载:

下载: