NUMERICAL SIMULATION OF THE STRAIN LOCALIZATION OF A CIRCULAR TUNNEL AT DIFFERENT ELASTIC MODULI

-

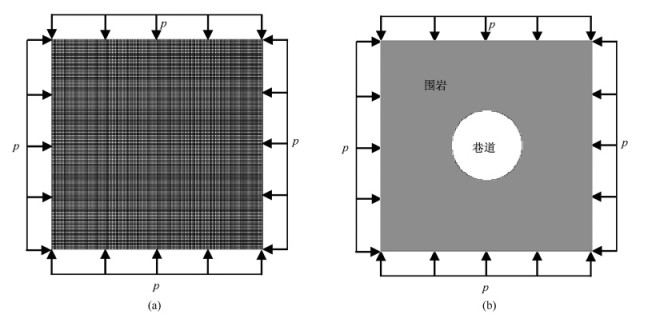

摘要: 利用基于运动方程求解的FLAC程序模拟了不同弹性模量时圆形巷道的应变局部化过程。在计算中, 采用了"先加载, 后挖洞"方式。模拟结果表明, 在弹性模量中等或较小的条件下, 由于开挖卸荷而产生的围岩向空腔内部的"涌入"(运动)现象比较明显, 进而围岩中诱发了较多的破坏、V形坑或短剪切带式破坏。在上述条件下, 基于静力平衡的解析及数值方法不再适用, 而且是偏于不安全的。弹性模量越小, 开挖之后, 围岩维持其均匀周向(或环向)变形的能力越差, 这种轴对称变形越容易被打破, 也被打破得越早。尽管随着弹性模量的增加, 破坏单元数的变化并不是单调的, 但是在总体上, 随着弹性模量的增加, 破坏单元数目降低, 最大剪切应变增量急剧单调下降。Abstract: Strain localization processes of a circular tunnel at different elastic moduli are modeled by use of FLAC where the solution is based on equations of motion. In the present calculation, the tunnel is excavated after the model is loaded to reach a static equilibrium state. The numerical results show that at low and moderate elastic moduli, the movement of the surrounding rock toward the center of the tunnel is apparent once the tunnel is excavated, generating many fracture bands, V-shaped notches and shorter shear bands. The analyses and numerical simulations based on static equilibrium, which may yield unsafe solutions, cannot be applied to these cases. When the elastic modulus is lower, the capacity of the surrounding rock maintaining uniform circumferential or loop deformation is worse, and the axially-symmetrical deformation mode is easier to be broken and broken earlier. Although the failed number of elements is not monotonic with an increase of the elastic modulus, in general, as the elastic modulus is increased, the failed number of elements decreases, and the maximum shear strain increment is decreased monotonically and rapidly.

-

Key words:

- circular tunnel /

- strain localization /

- shear band /

- elastic modulus /

- shear strain /

-

-

[1] Wang Xue-bin.Temperature distribution in adiabatic shear band for ductile metal based Johnson-Cook and gradient plasticity models[J].Trans Nonferrous Met Soc China, 2006, 16 (2): 333~338. doi: 10.1016/S1003-6326(06)60057-5 [2] Wang X B.Effects of temperature and strain rate on the evolution of thickness of transformed adiabatic shear band[J].Solid State Phenomena, 2008, 138: 385~392. doi: 10.4028/www.scientific.net/SSP.138 [3] Wang Xue-bin.A method for calculating the damage evolution in the adiabatic shear band of Titanium alloy[J].Trans Nonferrous Met Soc China, 2009, 19 (5): 1280~1285. doi: 10.1016/S1003-6326(08)60439-2 [4] Martin C D.The effect of cohesion loss and stress path on brittle rock strength[J].Can Geotech, 1997, 34: 698~725. doi: 10.1139/t97-030 [5] Hajiabdolmajid V, Kaiser P K, Martin C D.Modelling brittle failure of rock[J].International Journal of Rock Mechanics and Mining Sciences, 2002, 39 (6): 731~741. doi: 10.1016/S1365-1609(02)00051-5 [6] 陆家佑, 王昌明.根据岩爆反分析岩体应力研究[J].长江科学院院报, 1994, 11 (3): 27~30. http://d.old.wanfangdata.com.cn/Conference/333786Lu Jia-you, Wang Chang-ming.Study on back analysis for stress of rock mass from information of rockbursts[J].Journal of Yangtze River Scientific Research Institute, 1994, 11 (3): 27~30. http://d.old.wanfangdata.com.cn/Conference/333786 [7] Guenot A.Borehole breakout and stress fields[J].Int J Rock Mech Min Sci, 1989, 26: 185~195. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0228607071/ [8] Vardoulakis I G, Papanastasiou P C.Bifurcation analysis of deep boreholes: I.Surface instabilities[J].International Journal for Numerical and Analytical Methods in Geomechanics, 1988, 12: 379~399. doi: 10.1002/(ISSN)1096-9853 [9] 王学滨.不同强度岩石的破坏过程及声发射数值模拟[J].北京科技大学学报, 2008, 30 (8): 837~843. doi: 10.3321/j.issn:1001-053X.2008.08.001Wang Xue-bin.Numerical simulation of failure processes and acoustic emissions of rock specimens with different strengths [J].Journal of University of Science and Technology Beijing, 2008, 30 (8): 837~843. doi: 10.3321/j.issn:1001-053X.2008.08.001 [10] 王学滨.扩容角对初始随机材料缺陷岩石试样破坏过程及力学行为的影响[J].中国有色金属学报, 2007, 17 (7): 1063~1071. doi: 10.3321/j.issn:1004-0609.2007.07.007Wang Xue-bin.Effects of dilation angle on failure process and mechanical behavior for rock specimen with random material imperfections[J].The Chinese Journal of Nonferrous Metals, 2007, 17 (7): 1063~1071. doi: 10.3321/j.issn:1004-0609.2007.07.007 [11] 王学滨.应变软化扩容对含随机缺陷岩石的渐进变形及破坏前兆特征的影响[J].地质力学学报, 2008, 14 (2): 158~167. doi: 10.3969/j.issn.1006-6616.2008.02.007Wang Xue-bin.Effects of strain-softening dilatancy on progressive deformations and precursors to failure of rock with initial random imperfections[J].Journal of Geomechanics, 2008, 14 (2): 158~167. doi: 10.3969/j.issn.1006-6616.2008.02.007 [12] 王学滨.强度参数对初始随机缺陷岩样全部变形的影响[J].地质力学学报, 2009, 15 (4): 321~329. doi: 10.3969/j.issn.1006-6616.2009.04.001Wang Xue-bin.Influence of strength parameters on overall deformations of rock specimen with initially random material imperfections[J].Journal of Geomechanics, 2009, 15 (4): 321~329. doi: 10.3969/j.issn.1006-6616.2009.04.001 [13] Wang Xue-bin, Pan Yi-shan. Numerical simulation of size effect in circular tunnel rockburst[A]. Seventh International Symposium on Rockburst and Seismicity in Mines Peoceedings: Controlling Seismic Hazard and Sustainable Development of Deep Mines[C]. New York/New Jersey: Rinton Press, 2009, 137~142. [14] 王学滨, 潘一山, 王玮.不同围压条件下圆形巷道岩爆过程模拟[J].防灾减灾工程学报, 2009, 29 (6): 597~603. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzxk200906001Wang Xue-bin, Pan Yi-shan, Wang Wei.Numerical simulation of rockburst processes of a circular tunnel at different confining pressures[J].Journal of Disaster Prevention and Mitigation Engineering, 2009, 29 (6): 597~603. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzxk200906001 [15] 王学滨, 潘一山, 张智慧.扩容角对圆形巷道岩爆过程的影响[J].中国工程科学, 2010, 12 (2): 40~46. doi: 10.3969/j.issn.1009-1742.2010.02.007Wang Xue-bin, Pan Yi-shan, Zhang Zhi-hui.Numerical simulation of the rockburst processes of a circular tunnel at different dilation angles[J].Engineering Sciences, 2010, 12 (2): 40~46. doi: 10.3969/j.issn.1009-1742.2010.02.007 -

下载:

下载: