Estimation of the rock mechanics and in-situ stress parameters of carbonate reservoirs using array sonic logging: A case study of Shunbei No.4 block

-

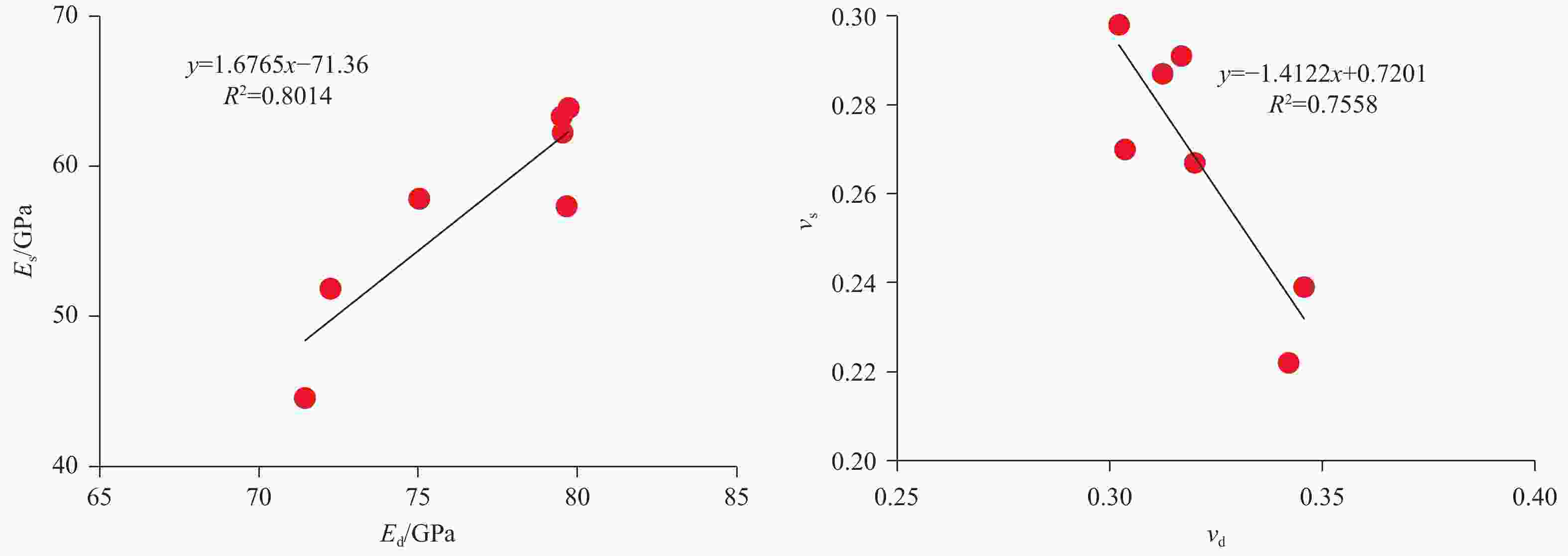

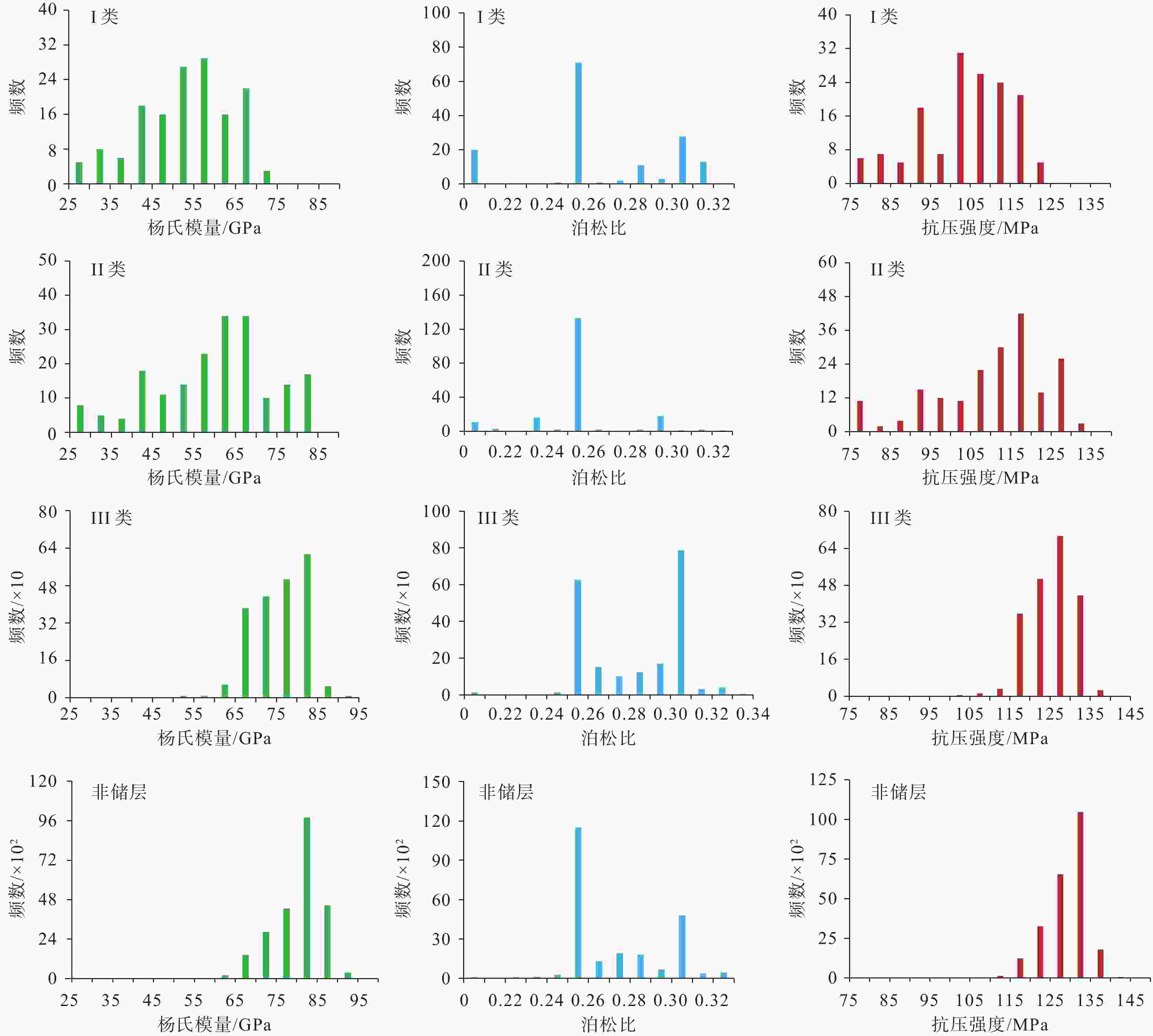

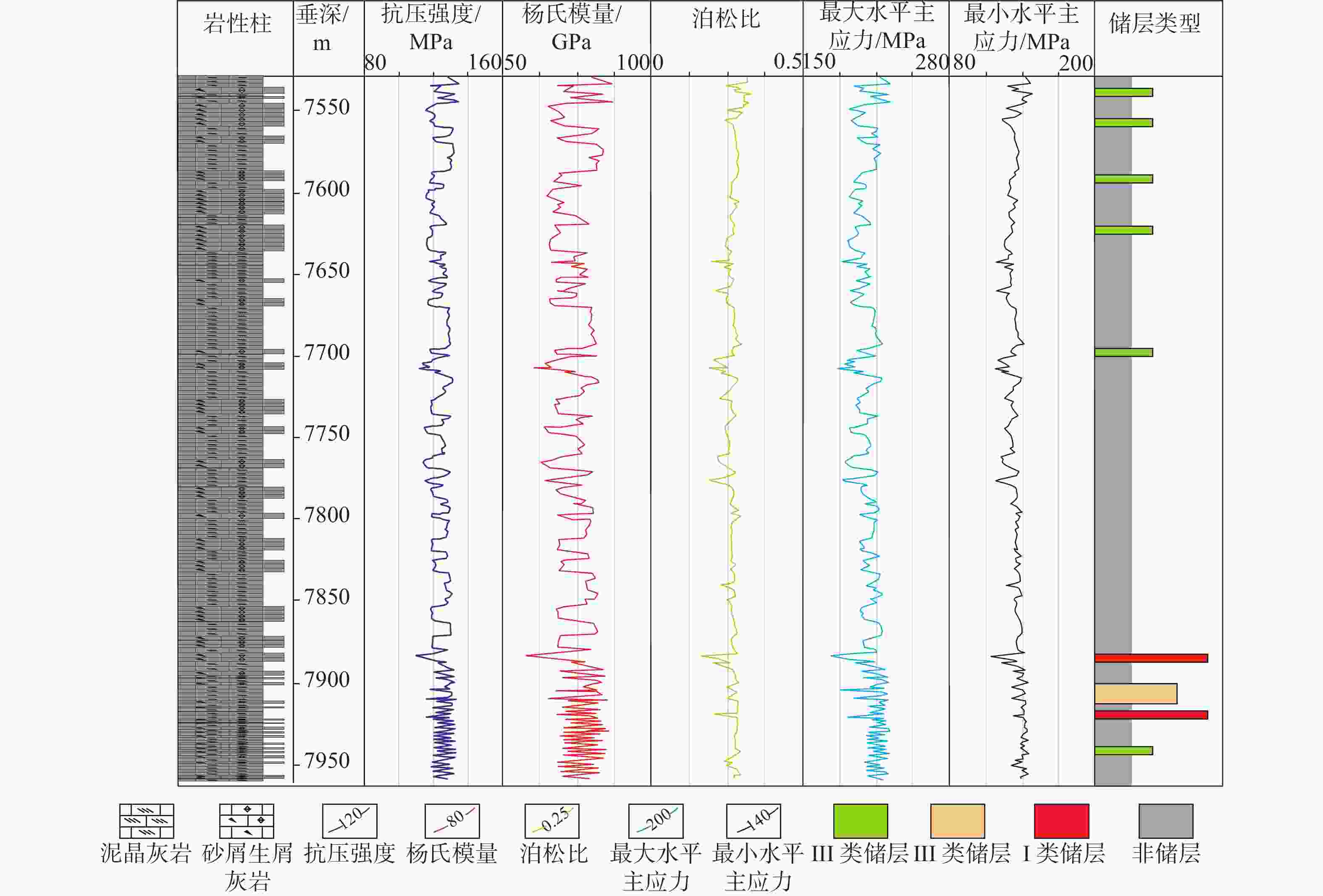

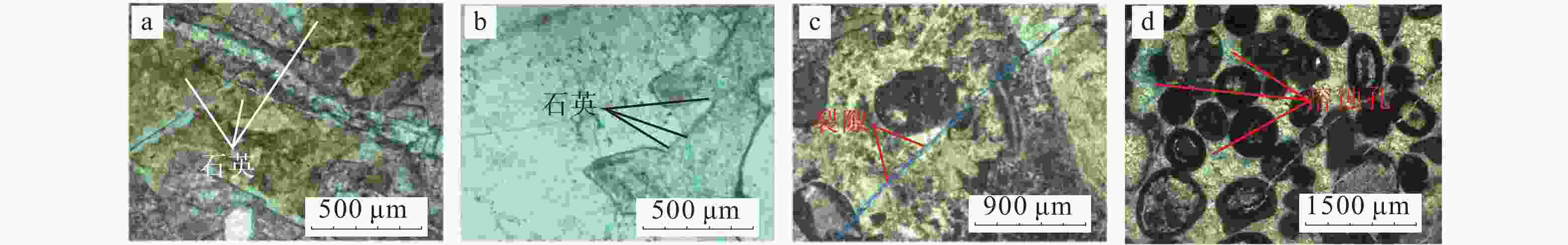

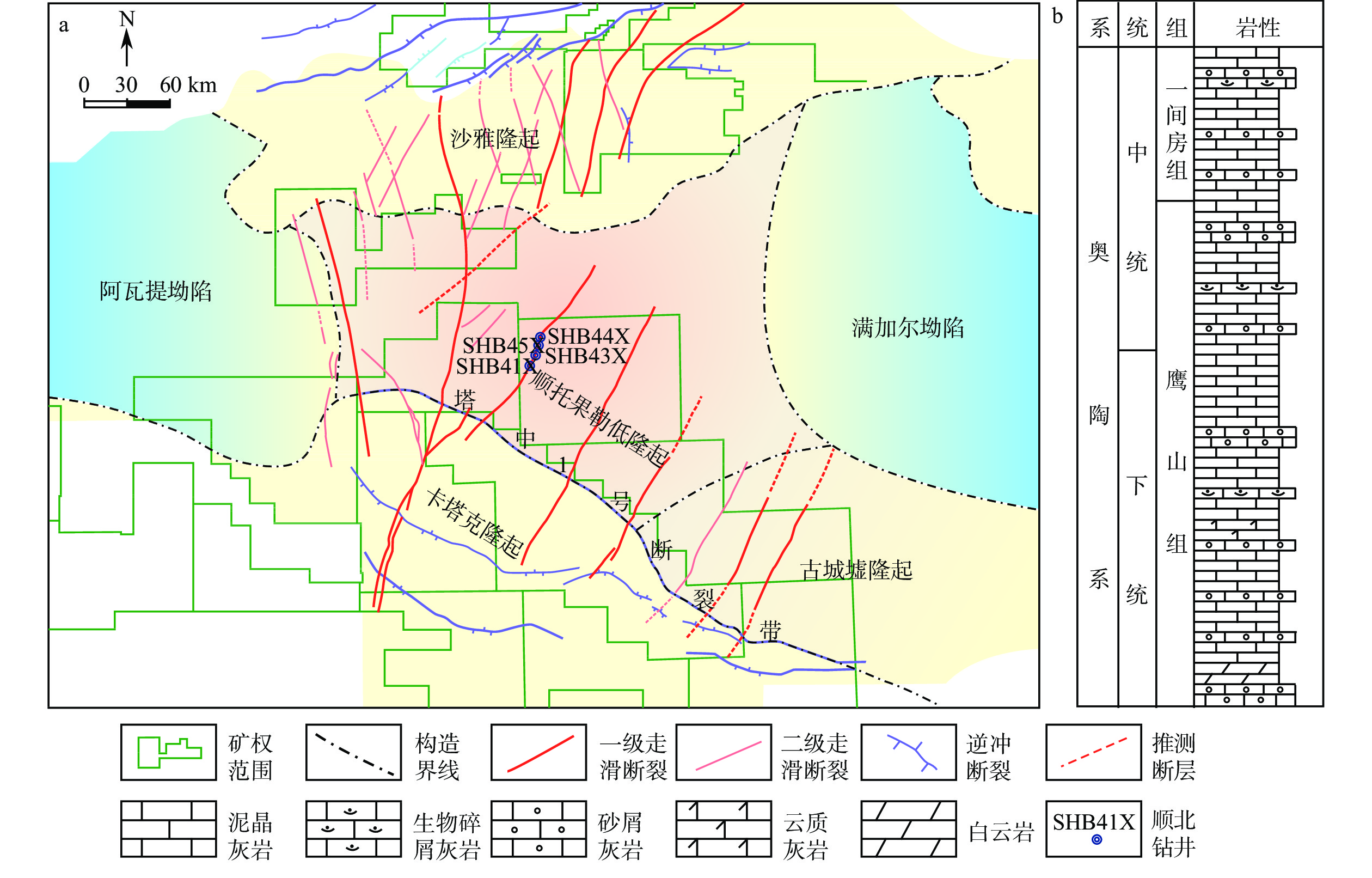

摘要: 地质力学分析在油气藏勘探开发过程中发挥着重要作用,顺北油气田中—下奥陶统一间房组—鹰山组储层地应力研究相对滞后。对比分析了顺北4号带下古生界中—下奥陶统一间房组—鹰山组碳酸盐岩不同类型储层的岩石力学和地应力特征,同时探讨了微观颗粒结构对碳酸盐岩储层地应力和岩石力学参数的控制作用,为顺北地区超深层碳酸盐岩储层评价提供了基础地质依据。基于弹簧组合模型,通过岩石力学实验和阵列声波测井确定了岩石力学和地应力特征,通过铸体薄片和X射线CT扫描表征碳酸盐岩的微观孔隙结构。研究结果表明:顺北4号带一间房组—鹰山组杨氏模量分布在50~89 GPa,抗压强度在99~136 MPa,泊松比在0.25~0.32;地层最大水平主应力为200~225 MPa,最小水平主应力为125~160 MPa。一间房组—鹰山组碳酸盐岩不同类型储层的岩石力学参数和地应力存在明显差异,从I类、II类、III类到非储层段碳酸盐岩的杨氏模量、抗压强度和最大水平主应力明显增大,而泊松比和最小水平主应力变化不大。相比于一间房组—鹰山组泥晶灰岩,砂屑−生屑灰岩方解石颗粒较大,颗粒黏结程度降低,导致岩石抗压强度和杨氏模量减小;砂屑−生屑灰岩部分方解石颗粒呈次圆状或圆状,颗粒三维空间球度较大,颗粒之间咬合作用减弱,使得岩石的抗压强度和杨氏模量减小;砂屑−生屑灰岩存在大量的孔隙和裂缝,灰岩易沿着潜在的微裂缝面或者颗粒接触面摩擦滑动甚至破裂,同样导致岩石抗压强度和杨氏模量减小。此外,一间房组—鹰山组泥晶灰岩受热液作用影响,部分白云石交代为石英,导致泥晶灰岩的抗压强度和杨氏模量增加。岩石的宏观力学特征和岩石力学参数受岩石微观颗粒结构的制约,一间房组—鹰山组杨氏模量、抗压强度和最大水平主应力低值区即为顺北4号带优势储层发育区带。Abstract:

Objective Geomechanical analysis plays a crucial role in exploring and developing oil and gas reservoirs. However, the study of in-situ stress in the Yijianfang–Yingshan formations of the Middle to Lower Ordovician in the Shunbei oilfield has lagged behind. This paper compares and analyzes the rock mechanics and in-situ stress characteristics of different types of carbonate reservoirs in the Yijianfang-Yingshan formations of the Lower Paleozoic Ordovician in the Shunbei No. 4 block, and explores the control effect of micro-grain structures on the in-situ stress and rock mechanics parameters of carbonate reservoirs. It aims to provide fundamental geological data for the evaluating of ultra-deep carbonate reservoirs in the Shunbei area. Methods This study, based on the spring combination model, determined the rock mechanics and in-situ stress characteristics through rock mechanics experiments and array acoustic logging, and characterized the micro-pore structure of the limestone using casting thin sections and X-ray μ-computed tomography analysis. Results The results indicate that the Young's modulus of the Yijianfang–Yingshan formations ranges from 50 to 89 GPa, the compressive strength from 99 to 136 MPa, and the Poisson's ratio from 0.25 to 0.32. The maximum horizontal principal stress of the formations ranges from 200 to 225 MPa, while the minimum horizontal principal stress ranges from 125 to 160 MPa. Conclusion Significant differences in rock mechanics parameters and in-situ stress exist among different types of carbonate reservoirs in the Yijianfang–Yingshan formations. From Type I to Type III and non-reservoir carbonate rocks, the Young's modulus, compressive strength, and maximum horizontal principal stress increase dramatically, while the Poisson's ratio and minimum horizontal principal stress show little change. Compared to micritic limestone, sandy–bioclastic limestone has larger calcite particles and reduced particle cohesion, resulting in decreased compressive strength and Young's modulus. Some calcite particles appear sub-rounded or rounded with higher three-dimensional particle sphericity, also leading to weaker intergranular engagement and further reduction in compressive strength and Young's modulus. The presence of numerous pores and fractures in sandy-bioclastic limestone facilitates frictional sliding and potential failure along microfractures or particle interfaces, contributing to lower compressive strength and Young's modulus as well. In addition, micritic limestones in the Yijianfang–Yingshan formations are affected by hydrothermal activity, with some dolomite being replaced by quartz, which increases the compressive strength and Young's modulus. The macroscopic mechanical characteristics and rock mechanics parameters of the rock are constrained by the micro-grain structures. The low-value zones of the Young's modulus, compressive strength, and maximum horizontal principal stress in the Yijianfang–Yingshan formations are identified as the advantageous reservoir development zones in the Shunbei No. 4 block. -

Key words:

- Shunbei No. 4 block /

- carbonate rock /

- rock mechanic parameters /

- in-situ stress

-

图 6 SHB45X井一间房组灰岩类型

a—含硅质泥晶灰岩,SHB45X井7722 m;b—泥晶灰岩,SHB45X井7724 m;c—生屑灰岩,SHB45X井7725 m;d—鲕粒灰岩,SHB45X井7727 m

Figure 6. Limestone types of the Yijianfang Formation in well SHB45

(a) Siliceous micritic limestone, at 7722 m in well SHB45X; (b) Micritic limestone, at 7724 m in well SHB45X; (c) Bioclastic limestone, at 7725 m in well SHB45X; (d) Oolitic limestone, at 7727 m in well SHB45X

图 7 不同类型储层裂缝CT成像

a—非储层段灰岩CT切片,SHB43X井7570.25 m;b—非储层段灰岩柱塞CT成像,SHB43X井7570.25 m,;c—III类储层灰岩CT切片SHB41X井,7543.3 m;d—III类储层灰岩柱塞CT成像,SHB41X井7543.3 m

Figure 7. CT images of fractures in different reservoirs

(a) CT slice of limestone in the non-reservoir section, at 7570.25 m in well SHB43X; (b) CT image of limestone plug in the non-reservoir section, at 7570.25 m in well SHB43X; (c) CT slice of limestone in Type III reservoir, at 7543.3 m in well SHB41X; (d) CT image of limestone plug in Type III reservoir, at 7543.3 m in well SHB41X

表 1 动、静态岩石力学参数

Table 1. The dynamic and static rock mechanics parameters from geomechanical experiments

井号 井深/m Es/GPa vs Ed/GPa vd σh/MPa σH/MPa SHB41X 7543.30 52 0.222 72.24 0.342 7543.18 58 0.287 75.04 0.312 147 200 SHB43X 7570.05 62 0.267 79.53 0.32 143 213 7570.25 64 0.239 79.73 0.346 SHB43X 7572.24 63 0.291 79.51 0.317 SHB44X 7632.79 57 0.270 79.67 0.304 149 212 SHB44X 7634.66 45 0.298 71.44 0.302 注:Es—静态杨氏模量,GPa;vs—静态泊松比,无量纲;Ed—动态杨氏模量,GPa;vd—动态泊松比,无量纲;σh—最小水平主应力,MPa;σH—最大水平主应力,MPa 表 2 顺北4号带地破实验参数和地层压力

Table 2. The LOT parameters and formation pressure for the Shunbei No. 4 block

井名 地破层位 地破深度/m 地破当量密度/(g/cm3) 地破压力 深度/m 地层压力/MPa SHB41X 库车组 1500 1.97 29.0 7500 90.67 卡拉沙依组 4349 1.55 66.1 7984 92.51 SHB42X 吉迪克组 2009 1.96 38.6 却尔却克组 6140 1.74 104.7 SHB43X 库车组 1505 1.84 27.1 2500 64.21 卡拉沙依组 4441 1.55 67.5 7944 91.97 SHB44X 库车组 1509 2.18 32.2 7431 88.44 卡拉沙依组 4430 1.72 74.7 7882 90.55 -

[1] BILLAUX D, DEDECKER F, CUNDALL P, 2004. A novel approach to studying rock damage: the three dimensional adaptive continuum/discontinuum code[J]. Rock Engineering, 723-728. [2] Bowers G. L. Pore pressure estimation from velocity data: accounting for overpressure mechanisms besides undercompaction[J]. SPE Drilling & Completion, 1995, 10(2): 89-95. [3] BU X Q, WANG L Y, ZHU L H, et al, 2023. Characteristics and reservoir accumulation model of Ordovician fault-controlled fractured-vuggy reservoirs in Shunbei oil and gas field, Tarim Basin[J]. Lithologic Reservoirs, 35(3): 152-160. (in Chinese with English abstract [4] CHEN P, NENG Y, WU X, et al, 2023. Stratification and segmentation characteristics and tectonic evolution of Shunbei No. 5 strike-slip fault zone in Tarim Basin[J]. Xinjiang Petroleum Geology, 44(1): 33-42. (in Chinese with English abstract [5] CHEN S J, GUO Y H, HUANG W P, et al, 2017. Experimental study of influence regularity and mechanism of particle size on mechanical properties of red sandstone[J]. Journal of Shandong University of Science and Technology (Natural Science), 36(6): 8-14. (in Chinese with English abstract [6] CHEN Y L, TANG J, 2022. Well logging evaluation of fractures and Vugs of carbonate reservoirs in Tuofutai area of Tarim Basin, Xinjiang, China[J]. Chinese Journal of Engineering Geophysics, 19(5): 689-698. (in Chinese with English abstract [7] DENG S, LI H L, ZHANG Z P, et al, 2018. Characteristics of differential activities in major strike-slip fault zones and their control on hydrocarbon enrichment in Shunbei area and its surroundings, Tarim Basin[J]. Oil & Gas Geology, 39(5): 878-888. (in Chinese with English abstract [8] DING W L, YIN S, WANG X H, et al, 2015. Assessment method and characterization of tight sandstone gas reservoir fractures[J]. Earth Science Frontiers, 22(4): 173-187. (in Chinese with English abstract [9] DODDS J S, 2003. Particle shape and stiffness: effects on soil behavior[D]. Atlanta: Georgia Institute of Technology. [10] ELIYAHU M, EMMANUEL S, DAY-STIRRAT R J, et al, 2015. Mechanical properties of organic matter in shales mapped at the nanometer scale[J]. Marine and Petroleum Geology, 59: 294-304. doi: 10.1016/j.marpetgeo.2014.09.007 [11] EZATI M, AZIZZADEH M, RIAHI M A, et al, 2020. Wellbore stability analysis using integrated geomechanical modeling: a case study from the Sarvak reservoir in one of the SW Iranian oil fields[J]. Arabian Journal of Geosciences, 13(4): 149. doi: 10.1007/s12517-020-5126-1 [12] FU H C, ZHANG C S, ZHAO L X, et al, 2006. Identificaton of the reservoir space types of the carbonate reservoir in Lunnan area of Tarim Basin by means of logging data[J]. Journal of Xi’an Shiyou University (Natural Science Edition), 21(5): 38-41. (in Chinese with English abstract [13] GAO C Y, ZHAO F H, GAO L F, et al, 2023. The methods of fracture prediction based on structural strain analysis and its application[J]. Journal of Geomechanics, 29(1): 21-33. (in Chinese with English abstract [14] GB/T 50266—2013. 2013. Standard for testing methods for engineering rock masses[S]. Beijing, China Planning Press.(in Chinese) [15] GE H K, LIN Y S, WANG S C, 1998. In situ stresses determination technique and its applications in petroleum exploration and development[J]. Journal of the University of Petroleum (Edition of Natural Science), 22(1): 94-99. (in Chinese with English abstract [16] GE H K, CHEN Y, LIN Y S, 2001. Microscopic mechanism of difference between static and dynamic elastic parameters of rock[J]. Journal of China University of Petroleum (Edition of Natural Science), 25(4): 34-36. (in Chinese with English abstract [17] GUO S Q, 2020. Rock mechanical parameter modeling of Fuyu tight oil reservoir in Well Block T30 of Daqing Oilfield[J]. Petroleum Geology & Oilfield Development in Daqing, 39(5): 169-174. (in Chinese with English abstract [18] GUO Y X, QIN Y, WANG H, et al, 2022. Physical modelling of particle size on mechanical properties of broken rock[J]. Science Technology and Engineering, 22(11): 4489-4496. (in Chinese with English abstract [19] HAN Q, YUN L, JIANG H S, et al, 2021. Marine oil and gas filling and accumulation process in the north of Shuntuoguole area in northern Tarim basin[J]. Journal of Jilin University (Earth Science Edition), 51(3): 645-658. (in Chinese with English abstract [20] HAN Z H, ZHANG L Q, ZHOU J, et al, 2019. Uniaxial compression test and numerical studies of grain size effect on mechanical properties of granite[J]. Journal of Engineering Geology, 27(3): 497-504. (in Chinese with English abstract [21] HOU L F, YANG C H, GUO Y T, et al, 2020. Simulation study on crack steering of near-wellbore in crack-hole type carbonate rock[J]. Science Technology and Engineering, 20(27): 11080-11086. (in Chinese with English abstract [22] HU G Q, BAI B Z, KE K, 2017. Analysis on borehole instability mechanism of diabase in Shunbei Block[J]. China Offshore Oil and Gas, 29(5): 119-125. (in Chinese with English abstract [23] HUANG R Z, BAI J Z, ZHOU Y H, et al, 1993. The relationship between the location and direction of tensile cracks on the wellbore wall of inclined vertical wells and wellbore pressure[J]. Oil Drilling & Production Technology, 15(5): 7-11. (in Chinese) [24] ISRAELI Y, EMMANUEL S, 2018. Impact of grain size and rock composition on simulated rock weathering[J]. Earth Surface Dynamics, 6(2): 319-327. doi: 10.5194/esurf-6-319-2018 [25] JIA Y R, SHI J T, LI X H, et al, 2021. Classification and evaluation methods for low-permeability tight gas wells in the Zizhou gas field of Changqing[J]. Geology and Exploration, 2021, 57(3): 647-655. (in Chinese with English abstract [26] JIANG M J, BAI R P, LIU J D, et al, 2013. Experimental study of inter-granular particles bonding behaviors for rock microstructure[J]. Chinese Journal of Rock Mechanics and Engineering, 32(6): 1121-1128. (in Chinese with English abstract [27] JIAO F Z, 2018. Significance and prospect of ultra-deep carbonate fault-karst reservoirs in Shunbei area, Tarim Basin[J]. Oil & Gas Geology, 39(2): 207-216. (in Chinese with English abstract [28] JIN F, ZHU X X, YU Y X, et al, 2023. Structural geometry and evolution of the No. 13 strike-slip fault zone in the Shunbei Area, Tarim Basin[J]. Geotectonica et Metallogenia, 47(1): 54-65. (in Chinese with English abstract [29] JOHANSSON E, 2011. Technological properties of rock aggregates[D]. Luleå: University of Technology. [30] KANG H, 2013. Experimental study on mechanical characteristics of Triaxial compression of sandstone in different sizes[J]. Subgrade Engineering(6): 94-96, 101. (in Chinese with English abstract [31] KOCK I, HUHN K, 2007. Influence of particle shape on the frictional strength of sediments: A numerical case study[J]. Sedimentary Geology, 196(1-4): 217-233. doi: 10.1016/j.sedgeo.2006.07.011 [32] KONG L, PENG R, 2011. Particle flow simulation of influence of particle shape on mechanical properties of quasi-sands[J]. Chinese Journal of Rock Mechanics and Engineering, 30(10): 2112-2119 (in Chinese with English abstract [33] KUMAR V, CURTIS M E, GUPTA N, et al , 2012. Estimation of elastic properties of organic matter and woodford shale through nano-indentation measurements[C]//Proceedings of SPE Canadian unconventional resources conference. Calgary, Canada: SPE. [34] LI S B, JIANG W, ZHANG X G, et al, 2019. The main controlling factors and evolutionary sequence of Ordovician fracture in H gas field of Bachu uplift, Tarim Basin[J]. Journal of Geomechanics, 25(4): 518-526. (in Chinese with English abstract [35] LI Z W, LUO Y H, LIU S G, et al, 2005. The main controlling factors and evolutionary sequence of ordovician fracture in H gas field of Bachu uplift, Tarim basin[J]. Journal of Mineralogy and Petrology, 25(4): 52-60. (in Chinese with English abstract [36] LINDQVIST J E, ÅKESSON U, MALAGA K, 2007. Microstructure and functional properties of rock materials[J]. Materials Characterization, 58(11-12): 1183-1188. doi: 10.1016/j.matchar.2007.04.012 [37] LIU B Z, 2020. Analysis of main controlling factors of oil and gas differential accumulation in Shunbei area, Tarim Basin - taking Shunbei No. 1 and No. 5 strike slip fault zones as examples[J]. China Petroleum Exploration, 25(3): 83-95. (in Chinese with English abstract [38] LIU G, RONG G, PENG J, et al, 2013. Mechanical behaviors of rock affected by mineral particle shapes[J]. Chinese Journal of Geotechnical Engineering, 35(3): 540-550. (in Chinese with English abstract [39] LIU J Z, CAI Z X, TENG C Y, et al, 2023. Coupling relationship between formation of calcite veins and hydrocarbon charging in Middle-Lower Ordovician reservoirs in strike-slip fault zones within craton in Shunbei area, Tarim Basin[J]. Oil & Gas Geology, 44(1): 125-137. (in Chinese with English abstract [40] LIU R H, FENG W G, LONG L, et al, 2008. Experimental studies on the mechanics and acoustics of tight carbonate rock[J]. Petroleum Geology & Oilfield Development in Daqing, 27(6): 131-135. (in Chinese with English abstract [41] LIU S X, WANG Z X, ZHANG L Y, et al, 2018. Micromechanics properties analysis of shale based on nano-indentation[J]. Journal of Experimental Mechanics, 33(6): 957-968. (in Chinese with English abstract [42] LIU S X, WANG Z X, ZHANG L Y, et al, 2019. Effects of microstructure characteristics of shale on development of complex fracture network[J]. Journal of Mining and Safety Engineering, 36(2): 420-428. (in Chinese with English abstract [43] LIU Z, KANG Z H, ZHOU L, et al, 2014. Distribution model of remaining oil of fractured-vuggy carbonate reservoir in 6-7 Area, Tahe Oilfield[J]. Geoscience, 28(2): 369-378. (in Chinese with English abstract [44] LU X B, HU W G, WANG Y, et al, 2015. Characteristics and development practice of fault-karst carbonate reservoirs in Tahe area, Tarim Basin[J]. Oil & Gas Geology, 36(3): 347-355. (in Chinese with English abstract [45] LÜ H T, HAN J, ZHANG J B, et al, 2021. Development characteristics and formation mechanism of ultra-deep carbonate fault-dissolution body in Shunbei area, Tarim Basin[J]. Petroleum Geology & Experiment, 43(1): 14-22. (in Chinese with English abstract [46] MA N B, MA X P, DU W W, et al, 2019. Developmental characteristics for the carbonate reservoir in Ordovician in first area of SHUNBEI[J]. Inner Mongolia Petrochemical Industry, 45(7): 106-112. (in Chinese) [47] MA Q F, QIN Y P, ZHOU T B, et al, 2019. Constitutive model of rock compaction stage based on contact theory[J]. Journal of Central South University (Science and Technology), 50(8): 1941-1948. (in Chinese with English abstract [48] MA Y S, HE Z L, ZHAO P R, et al, 2019. A new progress in formation mechanism of deep and ultra-deep carbonate reservoir[J]. Acta Petrolei Sinica, 40(12): 1415-1425. (in Chinese with English abstract [49] NING C Z, SUN L D, HU S Y, et al, 2021. Karst types and characteristics of the Ordovician fracture-cavity type carbonate reservoirs in Halahatang oilfield, Tarim Basin[J]. Acta Petrolei Sinica, 42(1): 15-32. (in Chinese with English abstract [50] POTYONDY D O, CUNDALL P A, 2004. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 41(8): 1329-1364. doi: 10.1016/j.ijrmms.2004.09.011 [51] PŘIKRYL R, 2001. Some microstructural aspects of strength variation in rocks[J]. International Journal of Rock Mechanics and Mining Sciences, 38(5): 671-682. doi: 10.1016/S1365-1609(01)00031-4 [52] QI L X, 2020. Characteristics and inspiration of ultra-deep fault-karst reservoir in the Shunbei area of the Tarim Basin[J]. China Petroleum Exploration, 25(1): 102-111. (in Chinese with English abstract [53] QI L X, DING Y, 2023. Differences in marine hydrocarbon accumulation between the eastern and western parts of Shunbei area, Tarim Basin[J]. Petroleum Geology & Experiment, 45(1): 20-28. (in Chinese with English abstract [54] SHANG K, GUO N, CAO Z C, et al, 2017. Main controlling factors of reservoir in Ordovician Yijianfang Formation on the northern slope of Middle Tarim Basin[J]. Marine Origin Petroleum Geology, 22(1): 39-46. (in Chinese with English abstract [55] SHI J T, HAO J M, WANG X L, 2022. Reservoir characteristics and controlling factors of Lower-Middle Ordovician Yingshan Formation in Tahe area[J]. Journal of Jilin University (Earth Science Edition), 52(2): 348-362. (in Chinese with English abstract [56] SHINOHARA K, OIDA M, GOLMAN B, 2000. Effect of particle shape on angle of internal friction by triaxial compression test[J]. Powder Technology, 107(1-2): 131-136. doi: 10.1016/S0032-5910(99)00179-5 [57] SHU H L, QIU K B, LI Q F, et al, 2021. A method for evaluating the geomechanical characteristics of shale gas: the geomechanical characteristics of the mountain shale in the intensively reworked marine area of South China[J]. Natural Gas Industry, 41(S1): 1-13. (in Chinese with English abstract [58] SONG G, LI H Y, YE N, et al, 2022. Types and features of diagenetic fluids in Shunbei No. 4 strike-slip fault zone in Shuntuoguole Low Uplift, Tarim Basin[J]. Petroleum Geology & Experiment, 44(4): 603-612. (in Chinese with English abstract [59] SONG Q, MA Q, DONG X J, et al, 2016. Sequence stratigraphic framework and sedimentary evolution of the Ordovician in northern Tarim Basin[J]. Journal of Palaeogeography, 18(5): 731-742. (in Chinese with English abstract [60] SONG Q, MA Q, LIU Y, et al, 2018. Sedimentary characteristics and distribution regularities of Ordovician carbonate grainstone shoals in Tabei area, NW China[J]. Lithologic Reservoirs, 30(1): 46-54. (in Chinese with English abstract [61] SONG Z P, LIU H K, ZHENG F, et al,2023. Mechanical behavior and failure response characteristics of hard sandstones considering bedding dip angles[J]. Coal Geology & Exploration,51(12):167-175. (in Chinese with English abstract [62] SUN D S, LV H T, WANG L J, et al, 2018. Determination of the in-situ stress state at 7 km depth under Tarim Basin by ASR and DITH methods[J]. Chinese Journal of Rock Mechanics and Engineering, 37(2): 383-391. (in Chinese with English abstract [63] WALLS J D, DVORKIN J, 1994. Measured and calculated horizontal stresses in the Travis Peak Formation[J]. SPE Formation Evaluation, 9(4): 259-263. doi: 10.2118/21843-PA [64] WANG B, ZHAO Y Q, HE S, et al, 2020. Hydrocarbon accumulation stages and their controlling factors in the northern Ordovician Shunbei 5 fault zone, Tarim Basin[J]. Oil & Gas Geology, 41(5): 965-974. (in Chinese with English abstract [65] WANG W B, FU H, LÜ L R, et al, 2021. Sequence model of Ordovician carbonate strata in Shunbei area, Tarim basin, and its significance[J]. Acta Sedimentologica Sinica, 39(6): 1451-1465. (in Chinese with English abstract [66] WANG W J, LI D Q, JIN J B, et al, 2022. Technical problems and measures of wellbore stability of broken formation in Shunbei oil and gas field[J]. Science Technology and Engineering, 22(13): 5205-5212. (in Chinese with English abstract [67] WANG Y W, CHEN H H, CAO Z C, et al, 2023. Controlling effects of fluid activity on reservoir formation in Shunbei area[J]. Fault-block Oil & Gas Field, 30(1): 44-51. (in Chinese with English abstract [68] WANG Y X, WANG B, GU Y, et al, 2023. Coupling relationship between fluid transformation and oil and gas filling of middle lower Ordovician in Shunbei area of Tarim Basin[J]. Science Technology and Engineering, 23(1): 66-76. (in Chinese with English abstract [69] WONG R H C, CHAU K T, WANG P, 1996. Microcracking and grain size effect in Yuen Long marbles[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 33(5): 479-485. [70] WU B L, 2001. Boit’s effective stress coefficient evaluation: static and dynamic approaches[C]//Proceedings of the ISRM International Symposium - 2nd Asian Rock Mechanics Symposium. Beijing: ISRM: 369-372. [71] WU Q Q, LI J R, CAO F, et al, 2019. Characteristics of fault-karst carbonate reservoirs in the Shunbei No. 1 well block, Tarim basin[J]. Carsologica Sinica, 38(3): 444-449. (in Chinese with English abstract [72] XIA Z L, LIU S G, SHI H X, et al, 2008. Experimental analysis of the rock mechanical properties of the fractured reservoir under formation conditions in the Central Iran Basin[J]. Petroleum Geology & Experiment, 30(1): 86-93. (in Chinese with English abstract [73] YANG H B, WU Y Y, 2011. The experimental analysis of microstructure and mechanical properties of tight reservoir rocks[J]. Complex Hydrocarbon Reservoirs, 4(3): 10-15. (in Chinese with English abstract [74] YANG Q, SUN J, JIA Y X, et al, 2017. Experimental study on rock mechanics of reservoir Nanchang 8 in Ordos Basin[J]. Petroleum Geology and Engineering, 31(4): 100-103. (in Chinese with English abstract [75] YE G Q, CAO H, GAO Q, et al, 2019. Numerical simulation study on the influence of particle proportion on rock mechanics characteristics[J]. Journal of Geomechanics, 25(6): 1129-1137. (in Chinese with English abstract [76] YIN X Y, MA N, MA Z Q, et al, 2018. Review of in-situ stress prediction technology[J]. Geophysical Prospecting for Petroleum, 57(4): 488-504. (in Chinese with English abstract [77] ZENG L B, LI Z X, SHI C E, et al, 2007. Characteristics and origin of fractures in the extra low-permeability sandstone reservoirs of the Upper Triassic Yanchang Formation in the Ordos basin[J]. Acta Geologica Sinica, 81(2): 174-180. (in Chinese with English abstract [78] ZHANG G S, 2005. Characteristics of fractures in the tight sandstone reservoirs of Xujiahe Formation in West Sichuan Depression[J]. Natural Gas Industry, 25(7): 11-13, 26. (in Chinese with English abstract [79] ZHANG Y Y, LI D Q, GAO S Y, et al, 2022. Analysis on influencing factors of wellbore instability of Ordovician fractured formation in Shunbei Oil and Gas Field[J]. Fault-Block Oil & Gas Field, 29(2): 256-260. (in Chinese with English abstract [80] ZHANG Y, MAO Q Y, LI H Y, et al, 2023. Characteristics and practical application of ultra-deep fault-controlled fractured-cavity type reservoir in central Shunbei area[J]. China Petroleum Exploration, 28(1): 1-13. (in Chinese with English abstract [81] ZHAO J Y, JI D S, WU J, et al, 2022. Research on rock mechanics parameters of the Jurassic-Cretaceous reservoir in the Sikeshu sag, Junggar Basin, China[J]. Journal of Geomechanics, 28(4): 573-582. (in Chinese with English abstract [82] ZHAO N, WANG L, ZHANG L, et al , 2022. Mechanical properties and fracturing characteristics of tight sandstones based on granularity classification: a case study of Permian Lower Shihezi Formation, Ordos Basin[J]. Petroleum Geology & Experiment, 44(4): 720-729, 738. (in Chinese with English abstract [83] ZHAO R, ZHAO T, LI H L, et al, 2019. Fault-controlled fracture-cavity reservoir characterization and main-controlling factors in the Shunbei Hydrocarbon Field of Tarim Basin[J]. Special Oil and Gas Reservoirs, 26(5): 8-13. (in Chinese with English abstract [84] ZHAO Y Q, 2022. The fourth-order sequence stratigraphic division and geological significance of Ordovician Yingshan Formation in Shunbei—Shunnan area, Tarim Basin, China[J]. Journal of Chengdu University of Technology (Science & Technology Edition), 49(4): 454-467. (in Chinese with English abstract [85] ZHAO Z H, LIU Z N, PU H, et al, 2018. Effect of thermal treatment on brazilian tensile strength of granites with different grain size distributions[J]. Rock Mechanics and Rock Engineering, 51(4): 1293-1303. doi: 10.1007/s00603-018-1404-6 [86] ZHU X X, ZHAO R, ZHAO T, 2023. Characteristics and control effect on reservoir and accumulation of strike-slip segments in Shunbei No. 1 fault zone, Tarim Basin[J]. Lithologic Reservoirs, 35(5): 131-138. (in Chinese with English abstract [87] 卜旭强,王来源,朱莲花,等,2023. 塔里木盆地顺北油气田奥陶系断控缝洞型储层特征及成藏模式[J]. 岩性油气藏,35(3):152-160. [88] 陈平,能源,吴鲜,等,2023. 塔里木盆地顺北5号走滑断裂带分层分段特征及构造演化[J]. 新疆石油地质,44(1):33-42. [89] 陈绍杰,郭宇航,黄万朋,等,2017. 粒度对红砂岩力学性质影响规律与机制试验研究[J]. 山东科技大学学报(自然科学版),36(6):8-14. [90] 陈雨霖,唐军,2022. 新疆塔里木盆地托甫台地区碳酸盐岩储层缝洞测井评价[J]. 工程地球物理学报,19(5):689-698. [91] 邓尚,李慧莉,张仲培,等,2018. 塔里木盆地顺北及邻区主干走滑断裂带差异活动特征及其与油气富集的关系[J]. 石油与天然气地质,39(5):878-888. [92] 丁文龙,尹帅,王兴华,等,2015. 致密砂岩气储层裂缝评价方法与表征[J]. 地学前缘,22(4):173-187. [93] 傅海成,张承森,赵良孝,等,2006. 塔里木盆地轮南奥陶系碳酸盐岩储层类型测井识别方法[J]. 西安石油大学学报(自然科学版),21(5):38-41. [94] 高晨阳,赵福海,高莲凤,等,2023. 基于构造应变分析的裂缝预测方法及其应用[J]. 地质力学学报,29(1):21-33. [95] GB/T 50266—2013. 2013. 工程岩体试验方法标准[S]. 北京,中国计划出版社. [96] 葛洪魁,林英松,王顺昌,1998. 地应力测试及其在勘探开发中的应用[J]. 石油大学学报(自然科学版),22(1):94-99. [97] 葛洪魁,陈颙,林英松,2001. 岩石动态与静态弹性参数差别的微观机理[J]. 石油大学学报(自然科学版),25(4):34-36. [98] 郭思强,2020. 大庆油田T30井区扶余油层致密储层岩石力学参数建模[J]. 大庆石油地质与开发,39(5):169-174. [99] 郭禹希,秦严,王海,等,2022. 粒径对破碎岩石力学性质影响模型试验研究[J]. 科学技术与工程,22(11):4489-4496. [100] 韩强,云露,蒋华山,等,2021. 塔里木盆地顺北地区奥陶系油气充注过程分析[J]. 吉林大学学报(地球科学版),51(3):645-658. [101] 韩振华,张路青,周剑,等,2019. 矿物粒径对花岗岩单轴压缩特性影响的试验与模拟研究[J]. 工程地质学报,27(3):497-504. [102] 侯龙飞,杨春和,郭印同,等,2020. 缝洞型碳酸盐岩近井筒裂缝转向模拟研究[J]. 科学技术与工程,20(27):11080-11086. doi: 10.3969/j.issn.1671-1815.2020.27.015 [103] 胡广强,白彬珍,柯珂,2017. 顺北区块辉绿岩井段井壁稳定性分析[J]. 中国海上油气,29(5):119-125. [104] 黄荣樽,白家祉,周煜辉,等,1993. 斜直井井壁张性裂纹的位置及走向与井眼压力的关系[J]. 石油钻采工艺,15(5):7-11. [105] 贾焰然,石军太,李星浩,等,2021. 低渗致密气井分类评价方法研究:以长庆子洲气田为例[J]. 地质与勘探,57(3):647-655. [106] 蒋明镜,白闰平,刘静德,等,2013. 岩石微观颗粒接触特性的试验研究[J]. 岩石力学与工程学报,32(6):1121-1128. [107] 焦方正,2018. 塔里木盆地顺北特深碳酸盐岩断溶体油气藏发现意义与前景[J]. 石油与天然气地质,39(2):207-216. [108] 金峰,朱秀香,余一欣,等,2023. 塔里木盆地顺北地区13号走滑断裂带发育特征[J]. 大地构造与成矿学,47(1):54-65. [109] 康瀚,2013. 不同粒径砂岩三轴压缩力学特性试验研究[J]. 路基工程(6):94-96,101. [110] 孔亮,彭仁,2011. 颗粒形状对类砂土力学性质影响的颗粒流模拟[J]. 岩石力学与工程学报,30(10):2112-2119. [111] 李树博,姜伟,张效恭,等,2019. 塔里木盆地巴楚凸起H气田奥陶系裂缝主控因素及演化序列研究[J]. 地质力学学报,25(4):518-526. [112] 李智武,罗玉宏,刘树根,等,2005. 川东北地区地层条件下致密储层力学性质实验分析[J]. 矿物岩石,25(4):52-60. [113] 刘宝增,2020. 塔里木盆地顺北地区油气差异聚集主控因素分析:以顺北1号、顺北5号走滑断裂带为例[J]. 中国石油勘探,25(3):83-95. [114] 刘广,荣冠,彭俊,等,2013. 矿物颗粒形状的岩石力学特性效应分析[J]. 岩土工程学报,35(3):540-550. [115] 刘建章,蔡忠贤,滕长宇,等,2023. 塔里木盆地顺北地区克拉通内走滑断裂带中-下奥陶统储集体方解石脉形成及其与油气充注耦合关系[J]. 石油与天然气地质,44(1):125-137. [116] 刘荣和,冯文光,龙玲,等,2008. 致密碳酸盐岩石力学与声学实验研究[J]. 大庆石油地质与开发,27(6):131-135. [117] 刘圣鑫,王宗秀,张林炎,等,2018. 基于纳米压痕的页岩微观力学性质分析[J]. 实验力学,33(6):957-968. [118] 刘圣鑫,王宗秀,张林炎,等,2019. 页岩微观组构特征对复杂裂缝网络形成的影响[J]. 采矿与安全工程学报,36(2):420-428. [119] 柳洲,康志宏,周磊,等,2014. 缝洞型碳酸盐岩油藏剩余油分布模式:以塔河油田六七区为例[J]. 现代地质,28(2):369-378. [120] 鲁新便,胡文革,汪彦,等,2015. 塔河地区碳酸盐岩断溶体油藏特征与开发实践[J]. 石油与天然气地质,36(3):347-355. doi: 10.11743/ogg20150301 [121] 吕海涛,韩俊,张继标,等,2021. 塔里木盆地顺北地区超深碳酸盐岩断溶体发育特征与形成机制[J]. 石油实验地质,43(1):14-22. [122] 马乃拜,马新平,杜伟维,等,2019. 顺北一区奥陶系碳酸盐岩储层发育特征与预测[J]. 内蒙古石油化工,45(7):106-112. [123] 马秋峰,秦跃平,周天白,等,2019. 基于颗粒接触理论的岩石压密阶段本构模型[J]. 中南大学学报(自然科学版),50(8):1941-1948. [124] 马永生,何治亮,赵培荣,等,2019. 深层—超深层碳酸盐岩储层形成机理新进展[J]. 石油学报,40(12):1415-1425. [125] 宁超众,孙龙德,胡素云,等,2021. 塔里木盆地哈拉哈塘油田奥陶系缝洞型碳酸盐岩储层岩溶类型及特征[J]. 石油学报,42(1):15-32. [126] 漆立新,2020. 塔里木盆地顺北超深断溶体油藏特征与启示[J]. 中国石油勘探,25(1):102-111. doi: 10.3969/j.issn.1672-7703.2020.01.010 [127] 漆立新,丁勇,2023. 塔里木盆地顺北地区东西部海相油气成藏差异[J]. 石油实验地质,45(1):20-28. [128] 尚凯,郭娜,曹自成,等,2017. 塔里木盆地塔中北坡奥陶系一间房组储集层主控因素分析[J]. 海相油气地质,22(1):39-46. [129] 史江涛,郝君明,王小雷,2022. 塔河地区奥陶系鹰山组储层特征及其主控因素[J]. 吉林大学学报(地球科学版),52(2):348-362. [130] 舒红林,仇凯斌,李庆飞,等,2021. 页岩气地质力学特征评价方法:中国南方海相强改造区山地页岩地质力学特征[J]. 天然气工业,41(S1):1-13. [131] 宋刚,李海英,叶宁,等,2022. 塔里木盆地顺托果勒低隆起顺北4号走滑断裂带成岩流体类型及活动特征[J]. 石油实验地质,44(4):603-612. [132] 宋倩,马青,董旭江,等,2016. 塔里木盆地北部地区奥陶系层序地层格架与沉积演化[J]. 古地理学报,18(5):731-742. [133] 宋倩,马青,刘莹,等,2018. 塔北地区奥陶系碳酸盐岩颗粒滩沉积特征及分布规律[J]. 岩性油气藏,30(1):46-54. [134] 宋战平,刘洪珂,郑方,等,2023. 考虑层理倾角的硬质砂岩力学行为及破裂响应特征[J]. 煤田地质与勘探,51(12):167-175 [135] 孙东生,吕海涛,王连捷,等,2018. ASR 和DITF 法综合确定塔里木盆地7 km深部地应力状态[J]. 岩石力学与工程学报,37(2):383-391. [136] 王斌,赵永强,何生,等,2020. 塔里木盆地顺北5号断裂带北段奥陶系油气成藏期次及其控制因素[J]. 石油与天然气地质,41(5):965-974. [137] 王伟吉,李大奇,金军斌,等,2022. 顺北油气田破碎性地层井壁稳定技术难题与对策[J]. 科学技术与工程,22(13):5205-5212. [138] 王文博,傅恒,闾廖然,等,2021. 塔里木盆地顺北地区奥陶系碳酸盐岩层序模式及其意义[J]. 沉积学报,39(6):1451-1465. [139] 王玉伟,陈红汉,曹自成,等,2023. 顺北地区流体活动对储层形成的控制作用[J]. 断块油气田,30(1):44-51. [140] 王昱翔,王斌,顾忆,等,2023. 塔里木盆地顺北地区中下奥陶统流体改造与油气充注耦合关系[J]. 科学技术与工程,23(1):66-76. [141] 伍齐乔,李景瑞,曹飞,等,2019. 顺北1井区奥陶系断溶体油藏岩溶发育特征[J]. 中国岩溶,38(3):444-449. [142] 夏在连,刘树根,时华星,等,2008. 中伊朗盆地地层条件下裂缝性储层岩石力学性质实验分析[J]. 石油实验地质,30(1):86-93. [143] 杨海博,武云云,2011. 致密储层岩石的微观结构和力学性质试验分析[J]. 复杂油气藏,4(3):10-15. [144] 杨琦,孙洁,贾昱昕,等,2017. 鄂尔多斯盆地南部长8储层岩石力学实验研究[J]. 石油地质与工程,31(4):100-103. [145] 叶功勤,曹函,高强,等,2019. 颗粒配比对岩石力学特征影响的数值模拟研究[J]. 地质力学学报,25(6):1129-1137. [146] 印兴耀,马妮,马正乾,等,2018. 地应力预测技术的研究现状与进展[J]. 石油物探,57(4):488-504. [147] 曾联波,李忠兴,史成恩,等,2007. 鄂尔多斯盆地上三叠统延长组特低渗透砂岩储层裂缝特征及成因[J]. 地质学报,81(2):174-180. [148] 张贵生,2005. 川西坳陷须家河组致密砂岩储层裂缝特征[J]. 天然气工业,25(7):11-13,26. [149] 张亚云,李大奇,高书阳,等,2022. 顺北油气田奥陶系破碎性地层井壁失稳影响因素分析[J]. 断块油气田,29(2):256-260. [150] 张煜,毛庆言,李海英,等,2023. 顺北中部超深层断控缝洞型油气藏储集体特征与实践应用[J]. 中国石油勘探,28(1):1-13. [151] 赵进雍,冀冬生,吴见,等,2022. 准噶尔盆地四棵树凹陷侏罗系—白垩系储层岩石力学参数研究[J]. 地质力学学报,28(4):573-582. [152] 赵宁,王亮,张磊,等,2022. 基于粒径分类的致密砂岩力学特性及破坏特征研究:以鄂尔多斯盆地二叠系下石盒子组为例[J]. 石油实验地质,44(4):720-729,738. [153] 赵锐,赵腾,李慧莉,等,2019. 塔里木盆地顺北油气田断控缝洞型储层特征与主控因素[J]. 特种油气藏,26(5):8-13. [154] 赵永强,2022. 塔里木盆地顺北—顺南地区鹰山组四级层序地层划分及地质意义[J]. 成都理工大学学报(自然科学版),49(4):454-467. [155] 朱秀香,赵锐,赵腾,2023. 塔里木盆地顺北1号断裂带走滑分段特征与控储控藏作用[J]. 岩性油气藏,35(5):131-138. -

下载:

下载: