NUMERICAL SIMULATION STUDY ON THE INFLUENCE OF PARTICLE PROPORTION ON ROCK MECHANICS CHARACTERISTICS

-

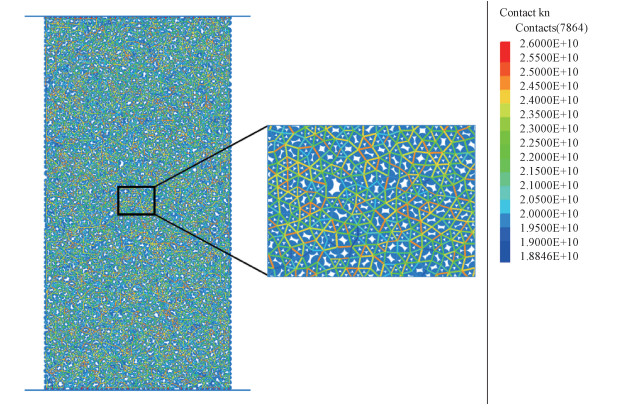

摘要: 岩石是矿物颗粒的集合体同时也是一种重要的非均质材料,了解它的力学特征对岩土工程及矿产开采都具有重要的指导作用。作为典型的颗粒材料,颗粒单元体的粒径分布配比必然影响着岩石的宏观力学表现。通过设置不同体积配比下的颗粒材料单元体,利用PCF2D软件模拟了相同颗粒材料单元体不同配比下岩石模型的力学特征。模拟结果表明颗粒单元体配比对岩石的力学特征有明显的影响。在模拟过程中大颗粒的配比显著影响着岩石的抗压强度,大颗粒含量相对越高,抗压强度越大。而细颗粒的配比影响着岩石的抗拉强度,细颗粒含量相对越高,抗拉强度越大,但是过多的细颗粒会降低岩石的抗拉强度。考虑岩石压缩过程中裂缝形态的影响。结果表明均匀分布、5:2:3、7:2:1的颗粒配比形成了贯穿裂缝,而1:2:7和3:2:5的颗粒配比未能形成贯穿裂缝,且细颗粒配比越高,裂缝数目出现高值的概率也越大。Abstract: Rock is a collection of mineral particles and an important heterogeneous material. Understanding its mechanical characteristics plays an important role in guiding geotechnical engineering and mining. As a typical granular material, the proportion of particle size distribution in granular element body certainly affects the macroscopic mechanical behavior of rock. PCF2D software was used to simulate the mechanical characteristics of rock models with different proportions of the same granular material element body by setting the granular material element bodies with different volume proportions. The simulation results show that the proportion of particle elements has obvious influence on the mechanical characteristics of rock. In the simulation process, the proportion of large particles significantly affects the compressive strength of rocks. The higher the content of large particles is, the greater the compressive strength is. The proportion of fine particles affects the tensile strength of rocks. The higher the content of fine particles is, the greater the tensile strength will be; however, excessive fine particles will reduce the tensile strength of rocks. Considering the influence of fracture morphology in the process of rock mass compression, penetrating fractures are formed by rock model with particle proportions of 1:1:1, 5:2:3 and 7:2:1, while those of 1:2:7 and 3:2:5 fail to form penetrating fractures. Moreover, the higher the proportion of fine particles is, the higher the probability of high number of fractures is.

-

Key words:

- particle proportion /

- particle flow /

- compressive strength /

- tensile strength /

- failure morphology

-

图 2 平行黏结模型示意图及破坏包络线

a—平行黏结示意图;b—平行黏结模型破坏包络线

$\overline{{{k}_{\text{s}}}} $ —黏结切向刚度;$ \overline{{{k}_{\text{n}}}}$ —黏结法向刚度;$\overline{{{\sigma }_{\text{c}}}} $ —拉伸强度;$ \bar{\tau }/\overline{{{\tau }_{\text{c}}}}$ —剪切强度;$ (\bar{c}, \bar{\varphi })$ —粘聚力和摩擦角;μ—摩擦系数;gs—黏结激活间隙;kn—法向刚度;ks—切向刚度Figure 2. Schematic diagram and failure envelope of the parallel bond model

表 1 不同颗粒配比试验结果

Table 1. Results of different particle proportion

颗粒配比 均匀分布 1:2:7 3:2:5 5:2:3 7:2:1 颗粒数目/个 3161 2774 3233 3681 4126 接触个数/个 7860 6901 8050 9198 10356 压缩裂缝/条 1145 1199 1383 1920 1318 抗压强度/MPa 26.65 31.12 29.39 29.37 28.31 抗拉强度/MPa 5.89 5.49 5.92 6.30 5.02 表 2 不同颗粒配比数值模型中颗粒配位数统计图

Table 2. Statistical analysis of particle proportions in numerical model of different particle proportions

颗粒配比 均匀分布 1:2:7 3:2:5 5:2:3 7:2:1 大颗粒配位数 5.84 5.19 5.47 5.68 5.84 中颗粒配位数 5.38 4.78 5.04 5.16 5.38 细颗粒配位数 4.85 4.31 4.51 4.67 4.85 -

[1] 王连山, 孙东生, 郑秀华, 等.三种典型岩石单轴抗压强度的尺寸效应试验研究[J].地质力学学报, 2017, 23(2):327-332. http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20170216&journal_id=dzlxxbWANG Lianshan, SUN Dongsheng, ZHENG Xiuhua, et al. Size effect experiment of uniaxial compressive strength of three typical rocks[J]. Journal of Geomechanics, 2017, 23(2):327-332. (in Chinese with English abstract) http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20170216&journal_id=dzlxxb [2] 王佳运, 石小亚.陡倾层状斜向岩层视向溃屈机制力学分析:以陕西山阳滑坡为例[J].地质力学学报, 2018, 24(4):482-489. http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180405&journal_id=dzlxxbWANG Jiayun, SHI Xiaoya. Mechanical analysis of apparent dip Buckling mechanism of steep stratified oblique rock:a case study of Shanyang rockslide in Shaanxi province[J]. Journal of Geomechanics, 2018, 24(4):482-489. (in Chinese with English abstract) http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180405&journal_id=dzlxxb [3] 王学滨, 白雪元, 祝铭泽.基于连续-非连续方法的地质体材料变形-拉裂过程模拟:以岩样紧凑拉伸试验为例[J].地质力学学报, 2018, 24(3):332-340. http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180305&journal_id=dzlxxbWANG Xuebin, BAI Xueyuan, ZHU Mingze. Modeling of deformation-cracking processes of geomaterials based on a continuum-discontinuum method:a case study of compact tension test[J]. Journal of Geomechanics, 2018, 24(3):332-340. (in Chinese with English abstract) http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180305&journal_id=dzlxxb [4] 李响, 荣冠, 彭俊, 等.考虑黏聚力损失的岩石残余强度模型与数值验证[J].水利水电技术, 2018, 49(11):173-178. http://d.old.wanfangdata.com.cn/Periodical/slsdjs201811024LI Xiang, RONG Guan, PENG Jun, et al. Cohesive force loss-considered rock residual strength model and its numerical verification[J]. Water Resources and Hydropower Engineering, 2018, 49(11):173-178. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/slsdjs201811024 [5] 赵二平, 贾小兵, 龚章龙, 等.水压循环作用下砂岩损伤本构模型研究[J].水利水电技术, 2018, 49(9):1-7. http://d.old.wanfangdata.com.cn/Periodical/slsdjs201809002ZHAO Erping, JIA Xiaobing, GONG Zhanglong, et al. Study on damage constitutive model of sandstone under hydro-pressure cycle effect[J]. Water Resources and Hydropower Engineering, 2018, 49(9):1-7. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/slsdjs201809002 [6] 廖烟开, 刘继滨, 蔡建华, 等.隧道围岩级别快捷判定技术及配套仪器研究[J].铁道勘察, 2017, 43(5):1-5. http://d.old.wanfangdata.com.cn/Periodical/tlhc201705001LIAO Yankai, LIU Jibin, CAI Jianhua, et al. Research on rapid determination technology of surrounding rock classification and the supporting equipment[J]. Railway Investigation and Surveying, 2017, 43(5):1-5. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/tlhc201705001 [7] 陈曦, 曾亚武, 刘伟.岩体基本质量指标BQ图解法讨论[J].铁道标准设计, 2018, 62(11):155-160. http://d.old.wanfangdata.com.cn/Periodical/tdbzsj201811032CHEN Xi, ZENG Yawu, LIU Wei. Discussion on graphic method of rock mass basic quality index BQ[J]. Railway Standard Design, 2018, 62(11):155-160. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/tdbzsj201811032 [8] 孙其诚, 程晓辉, 季顺迎, 等.岩土类颗粒物质宏-细观力学研究进展[J].力学进展, 2011, 41(3):351-371. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxjz201103007SUN Qicheng, CHENG Xiaohui, JI Shunying, et al. Advances in the micro-macro mechanics of granular soil materials[J]. Advances in Mechanics, 2011, 41(3):351-371. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxjz201103007 [9] 贺续文, 刘忠, 廖彪, 等.基于离散元法的节理岩体边坡稳定性分析[J].岩土力学, 2011, 32(7):2199-2204. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201107046HE Xuwen, LIU Zhong, LIAO Biao, et al. Stability analysis of jointed rock slopes based on discrete element method[J]. Rock and Soil Mechanics, 2011, 32(7):2199-2204. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201107046 [10] 刘传奇, 孙其诚, 王光谦.颗粒介质结构与力学特征研究综述[J].力学与实践, 2014, 36(6):716-721. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxysj201406002LIU Chuanqi, SUN Qicheng, WANG Guangqian. Structure and thermodynamics of granular materials[J]. Mechanics in Engineering, 2014, 36(6):716-721. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxysj201406002 [11] 秦岩, 刘春, 张晓宇, 等.基于MatDEM的砂土侧限压缩试验离散元模拟研究[J].地质力学学报, 2018, 24(5):676-681. http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180510&journal_id=dzlxxbQIN Yan, LIU Chun, ZHANG Xiaoyu, et al. Discrete element simulation of sand confined compression test based on MatDEM[J]. Journal of Geomechanics, 2018, 24(5):676-681. (in Chinese with English abstract) http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20180510&journal_id=dzlxxb [12] 丛宇, 王在泉, 郑颖人, 等.基于颗粒流原理的岩石类材料细观参数的试验研究[J].岩土工程学报, 2015, 37(6):1031-1040. http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201506010CONG Yu, WANG Zaiquan, ZHENG Yingren, et al. Experimental study on microscopic parameters of brittle materials based on particle flow theory[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(6):1031-1040. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201506010 [13] 李坤蒙, 李元辉, 徐帅, 等. PFC2D数值计算模型微观参数确定方法[J].东北大学学报(自然科学版), 2016, 37(4):563-567. http://d.old.wanfangdata.com.cn/Periodical/dbdxxb201604023LI Kunmeng, LI Yunhui, XU Shuai, et al. Method to determine microscopic parameters of PFC2D numerical model[J]. Journal of Northeastern University (Natural Science), 2016, 37(4):563-567. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/dbdxxb201604023 [14] 邓树新, 郑永来, 冯利坡, 等.试验设计法在硬岩PFC3D模型细观参数标定中的应用[J].岩土工程学报, 2019, 41(4):655-664. http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201904008DENG Shuxin, ZHENG Yonglai, FENG Lipo, et al. Application of design of experiments in microscopic parameter calibration for hard rocks of PFC3D model[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4):655-664. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201904008 [15] 陈鹏宇, 孔莹, 余宏明.岩石单轴压缩PFC2D模型细观参数标定研究[J].地下空间与工程学报, 2018, 14(5):1240-1249. http://d.old.wanfangdata.com.cn/Periodical/dxkj201805013CHEN Pengyu, KONG Ying, YU Hongming. Research on the calibration method of microparameters of a uniaxial compression PFC2D model for rock[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(5):1240-1249. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/dxkj201805013 [16] 陈鹏宇. PFC2D模拟裂隙岩石裂纹扩展特征的研究现状[J].工程地质学报, 2018, 26(2):528-539. http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201802032CHEN Pengyu. Research progress on PFC2D simulation of crack propagation characteristics of cracked rock[J]. Journal of Engineering Geology, 2018, 26(2):528-539. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201802032 [17] 李士斌, 李磊, 张立刚.清水压裂多场耦合下裂缝扩展规律数值模拟分析[J].石油化工高等学校学报, 2014, 27(1):42-47. http://d.old.wanfangdata.com.cn/Periodical/syhggdxx201401008LI Shibin, LI Lei, ZHANG Ligang. The numerical simulation analysis of crack propagation law under Riverfrac treatment multi-field coupling[J]. Journal of Petrochemical Universities, 2014, 27(1):42-47. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/syhggdxx201401008 [18] 郑力会, 刘皓, 曾浩, 等.流量替代渗透率评价破碎性储层工作流体伤害程度[J].天然气工业, 2019, 39(12):75-80.ZHENG Lihui, LIU Hao, ZENG Hao, et al. Using flow rate instead of permeability to evaluate the degree of formation damage by working fluids in fractured reservoirs[J]. Natural Gas Industry, 2019, 39(12):75-80. (in Chinese with English abstract) [19] 朱方辉, 李明星, 贺炳成, 等.碳酸盐岩储层压井液漏失影响因素研究[J].钻井液与完井液, 2019, 36(4):522-528. http://d.old.wanfangdata.com.cn/Periodical/zjyywjy201904023ZHU Fanghui, LI Mingxing, HE Bingcheng, et al. Factors affecting loss of kill mud used in carbonate rock reservoirs[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):522-528. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/zjyywjy201904023 [20] BILLAUX D, DEDECKER F, CUNDALL P. A novel approach to studying rock damage:the three-dimensional adaptive continuum/discontimuum code[J]. Rock Engineering, 2004:723-728. [21] 冯兴波, 奚悦, 宋丹青, 等.基于PFC2D岩石颗粒破碎强度和能量的分形模型[J].工程地质学报, 2016, 24(4):629-634. http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201604019FENG Xingbo, XI Yue, SONG Danqing, et al. PFC2D based fractal model for tensile strength and breakage energy of rock particle crushing[J]. Journal of Engineering Geology, 2016, 24(4):629-634. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201604019 [22] 黄丹, 李小青.基于微裂纹发育特性的大理岩特征强度数值模拟研究[J].岩土力学, 2017, 38(1):253-262. http://d.old.wanfangdata.com.cn/Periodical/ytlx201701032HUANG Dan, LI Xiaoqing. Numerical simulation research on characteristic strength of marble based on development of microcrack[J]. Rock and Soil Mechanics, 2017, 38(1):253-262. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/ytlx201701032 [23] 田佳杰, 孙金山.岩石蠕变效应颗粒流模拟中弹簧与黏壶参数对变形特征的影响[J].安全与环境工程, 2019, 26(2):202-206.TIAN Jiajie, SUN Jinshan. Influence of spring and sticky kettle parameters on deformation features in particle flow numerical simulation of rock creep[J]. Safety and Environmental Engineering, 2019, 26(2):202-206. (in Chinese with English abstract) [24] 周天白, 杨小彬, 韩心星.煤岩单轴压缩破坏PFC2D数值反演模拟研究[J].矿业科学学报, 2017, 2(3):260-266. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20172017072600033718ZHOU Tianbai, YANG Xiaobin, HAN Xinxing. Numerical inversion simulation of coal and rock under uniaxial compression failure in PFC2D[J]. Journal of Mining Science and Technology, 2017, 2(3):260-266. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20172017072600033718 [25] 周博, 汪华斌, 赵文锋, 等.黏性材料细观与宏观力学参数相关性研究[J].岩土力学, 2012, 33(10):3171-3178. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201210045ZHOU Bo, WANG Huabin, ZHAO Wenfeng, et al. Analysis of relationship between particle mesoscopic and macroscopic mechanical parameters of cohesive materials[J]. Rock and Soil Mechanics, 2012, 33(10):3171-3178. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201210045 [26] 赵国彦, 戴兵, 马驰.平行黏结模型中细观参数对宏观特性影响研究[J].岩石力学与工程学报, 2012, 31(7):1491-1498. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201207024ZAHO Guoyan, DAI Bing, MA Chi. Study of effects of microparameters on macroproperties for parallel bonded model[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(7):1491-1498. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201207024 [27] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8):1329-1364. http://d.old.wanfangdata.com.cn/Periodical/lxxb-e201804011 [28] DING X B, ZHANG L Y, ZHU H H, et al. Effect of model scale and particle size distribution on PFC3D simulation results[J]. Rock Mechanics and Rock Engineering, 2014, 47(6):2139-2156. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=34496779e3ac08d5ac2ebad114188ba9 [29] YANG B D, JIAO Y, LEI S T. A study on the effects of microparameters on macroproperties for specimens created by bonded particles[J]. Engineering Computations, 2006, 23(6):607-631. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f7e8967883719b5ea2a709d26fa4ea60 -

下载:

下载: