THE APPLICATION OF MODIFIED CAM-CLAY MODEL IN DPC PILE-SOIL INTERFACE

-

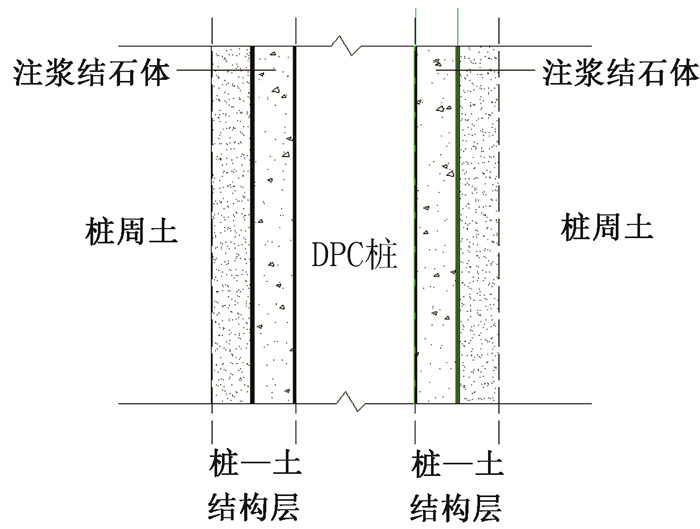

摘要: 针对DPC桩-土结构层开展大型直剪试验,基于试验分析,在考虑DPC桩-土结构层注浆影响上引入临界应力比,构建了可描述应变软化的修正剑桥模型应力应变方程。直剪试验表明DPC桩-土结构层剪切特性表现为剪切软化,具有明显的峰值强度和残余强度,呈现出明显的结构性,其特征与超固结的黏土的剪切应力应变曲线特性类似。推导出的修正剑桥模型能较好的解释实验结果,所得出的结论对DPC桩的设计有一定的指导意义。Abstract: A series of large direct shear tests were carried out for the DPC pile-soil structure layer. Based on the experimental analysis, the critical stress ratio was introduced considering the influence of DPC pile-soil layer grouting, and a modified cam-clay model which can describe the strain softening was constructed. The direct shear tests show that the shear behavior of DPC pile-soil structure layer is shear softening, with obvious peak strength and residual strength, and the structure layer shows structural properties. The results of these tests are well reflected in the modified Cam-clay model. The conclusion has guiding significance for the design of DPC piles.

-

表 1 试验土的基本物理力学参数值

Table 1. The fundamental physical and mechanical parameters of the tested soils

桩周土 最优含

水率/%最大干密度/

(g·cm3)液限

WL塑限

WP粘聚力/

kPa内摩擦角/

(°)粉质黏土 18.5 1.71 24.1 16.53 11.6 31 素填土 14.4 1.88 40.7 25.1 23.1 33 表 2 模型参数值

Table 2. Values of the model parameters

DPC桩—结构层 λ κ e0 v M Mz β η DPC桩—粉质粘土 0.11 0.025 0.66 0.30 0.24 1.7 0.35 1.50 DPC桩—素填土 0.12 0.021 0.58 0.25 0.92 2.3 0.30 1.33 -

[1] Clough G W, Duncan J M. Finite element analysis of retaining wall behavior[J]. Journal of the Soil Mechanics and Foundations Division, 1971, 97(12):1657~1672. [2] 蒲诃夫, 郑俊杰, 章荣军.桩土界面荷载传递模型的改进及其数值实现[J].华中科技大学学报(城市科学版), 2010, 27(1):84~88. doi: 10.3969/j.issn.2095-0985.2010.01.019PU Hefu, ZHENG Junjie, ZHANG Rongjun. Improvement on the load transfer model of pile-soil interface and its numerical simulation[J]. Journal of Huazhong University of Science and Technology (Urban Science Edition), 2010, 27(1):84~88. (in Chinese with English abstract) doi: 10.3969/j.issn.2095-0985.2010.01.019 [3] 曹卫平.桩土界面荷载传递双曲线模型的改进及其应用[J].岩石力学与工程学报, 2009, 28(1):144~151. doi: 10.3321/j.issn:1000-6915.2009.01.019CAO Weiping. An improved load transfer hyperbolic model for pile-soil interface and its application[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(1):144~151. (in Chinese with English abstract) doi: 10.3321/j.issn:1000-6915.2009.01.019 [4] Brandt J R T. Behaviour of soil-concrete interfaces[D]. Alberta, Canada: The University of Alberta, 1985. [5] Desai C S, Ma Y Z. Modelling of joints and interfaces using the disturbed-state concept[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 1992, 16(9):623~652. doi: 10.1002/(ISSN)1096-9853 [6] 胡黎明, 濮家骝.土与结构物接触面损伤本构模型[J].岩土力学, 2002, 23(1):6~11. doi: 10.3969/j.issn.1000-7598.2002.01.002HU Liming, PU Jialiu. Damage model of soil-structure interface[J]. Rock and Soil Mechanics, 2002, 23(1):6~11. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2002.01.002 [7] 王伟, 卢廷浩.土与水工结构接触面模型研究[J].水力水电学报, 2012, 31(1):68~71. http://d.old.wanfangdata.com.cn/Periodical/slfdxb201201013WANG Wei, LU Tinghao. Study on constitutive law of soil-hydraulic structure interface[J]. Journal of Hydroelectric Engineering, 2012, 31(1):68~71. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/slfdxb201201013 [8] 李赛, 汪优, 秦志浩, 等.基于统计损伤本构模型的改进接触面模型研究[J].铁道科学与工程学报, 2016, 13(7):1247~1252. doi: 10.3969/j.issn.1672-7029.2016.07.004LI Sai, WANG You, QIN Zhihao, et al. Research on improved contact surface constitutive model based on statistical da mage constitutive model[J]. Journal of Railway Science and Engineering, 2016, 13(7):1247~1252. (in Chinese with English abstract) doi: 10.3969/j.issn.1672-7029.2016.07.004 [9] 张嘎, 张建民.土与结构接触面弹塑性损伤模型用于单桩与地基相互作用分析[J].工程力学, 2006, 23(2):72~77. doi: 10.3969/j.issn.1000-4750.2006.02.013ZHANG Ga, ZHANG Jianmin. Elastoplastic damage model of soil-structure interface in single pile-soil interaction analysis[J]. Engineering Mechanics, 2006, 23(2):72~77. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-4750.2006.02.013 [10] Chen X B, Zhang J S, Xiao Y J, et al. Effect of roughness on shear behavior of red clay-concrete interface in large-scale direct shear tests[J]. Canadian Geotechnical Journal, 2015, 52(8):1122~1135. doi: 10.1139/cgj-2014-0399 [11] 石熊, 张家生, 邓国栋, 等.循环荷载作用下红黏土与混凝土接触面剪切特性试验研究[J].铁道科学与工程学报, 2014, 11(3):88~93. doi: 10.3969/j.issn.1672-7029.2014.03.015SHI Xiong, ZHANG Jiasheng, DENG Guodong, et al. Experimental research on shearing property of red clay-concrete interface under cyclic loading[J]. Journal of Railway Science and Engineering, 2014, 11(3):88~93. (in Chinese with English abstract) doi: 10.3969/j.issn.1672-7029.2014.03.015 [12] Zheng G, Peng S Y, Ng C W W, et al. Excavation effects on pile behaviour and capacity[J]. Canadian Geotechnical Journal, 2012, 49(12):1347~1356. doi: 10.1139/t2012-095 [13] Ebrahimian B, Bauer E. Numerical simulation of the effect of interface friction of a bounding structure on shear deformation in a granular soil[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2012, 36(12):1486~1506. doi: 10.1002/nag.v36.12 [14] Kwak C W, Park I J, Park J B. Dynamic shear behavior of concrete-soil interface based on cyclic simple shear test[J]. KSCE Journal of Civil Engineering, 2014, 18(3):787~793. doi: 10.1007/s12205-014-0360-2 [15] Liu J K, Lv P, Cui Y H, et al. Experimental study on direct shear behavior of frozen soil-concrete interface[J]. Cold Regions Science and Technology, 2014, 104~105:1~6. http://www.sciencedirect.com/science/article/pii/S0165232X14000949 [16] Xiao S G, Suleiman M T, McCartney J S. Shear behavior of silty soil and soil-structure interface under temperature effects[A]. American Society of Civil Engineers Geo-Congress 2014[C]. Atlanta, Georgia: American Society of Civil Engineers, 2014. [17] 吕鹏, 刘建坤, 崔颖辉.冻土-混凝土接触面动剪强度研究[J].岩土力学, 2013, 34(S2):180~183 http://d.old.wanfangdata.com.cn/Periodical/ytlx2013z2029LÜ Peng, LIU Jiankun, CUI Yinghui. A study of dynamic shear strength of frozen soil-concrete contact interface[J]. Rock and Soil Mechanics, 2013, 34(S2):180~183. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/ytlx2013z2029 [18] Yu Y, Damians I P, Bathurst R J. Influence of choice of FLAC and PLAXIS interface models on reinforced soil-structure interactions[J]. Computers and Geotechnics, 2015, 65:164~174. doi: 10.1016/j.compgeo.2014.12.009 [19] 唐孟雄.大直径随钻跟管桩的研制及工程化[J].广州建筑, 2009, 37(5):3~7. doi: 10.3969/j.issn.1671-2439.2009.05.001TANG Mengxiong. The development and engineering of drilling with PHC pipe cased pile[J]. Guangzhou Archtecture, 2009, 37(5):3~7. (in Chinese with English abstract) doi: 10.3969/j.issn.1671-2439.2009.05.001 [20] 甄文战, 孙德安, 段博.不同应力路径下超固结黏土试样变形局部化分析[J].岩土力学, 2011, 32(1):293~298. doi: 10.3969/j.issn.1000-7598.2011.01.046ZHEN Wenzhan, SUN Dean, DUAN Bo. Analysis of strain localization in overconsolidated clay specimens along different stress paths[J]. Rock and Soil Mechanics, 2011, 32(1):293~298. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2011.01.046 [21] Schofield A N, Wroth P. Critical State Soil Mechanics[M]. London:McGraw-Hill, 1968. [22] Nakai T, Kikumoto M, Kyokawa H, et al. A simple method to consider density and bonding effects in modeling of geomaterials[A]. Wan R, Alsaleh M, Labuz J. Bifurcations, Instabilities and Degradations in Geomaterials[M]. Berlin, Heidelberg: Springer, 2011, 91~111. [23] 徐连民, 祁德庆, 高云开.用修正剑桥模型研究超固结土的变形特性[J].水利学报, 2008, 39(3):313~317. doi: 10.3321/j.issn:0559-9350.2008.03.009XU Lianmin, QI Deqing, GAO Yunkai. Study on characteristics of over-consolidated soils with modified Cam Clay Model[J]. Journal of Hydraulic Engineering, 2008, 39(3):313~317. (in Chinese with English abstract) doi: 10.3321/j.issn:0559-9350.2008.03.009 [24] 姚仰平. UH模型系列研究[J].岩土工程学报, 2015, 37(2):193~217. http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201502001YAO Yangping. Advanced UH models for soils[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(2):193~217. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/ytgcxb201502001 -

下载:

下载: