Analysis on the application prospect of ASR in-situ stress measurement method in underground mine

-

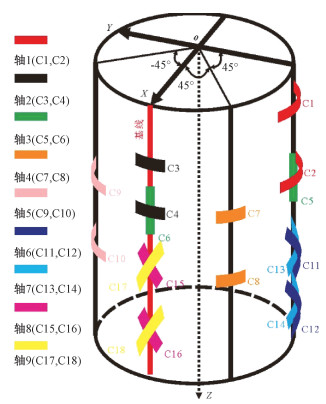

摘要: 现今地应力状态是井下矿山建设、巷道稳定性分析和冲击地压(煤与瓦斯突出)预测等方面的重要基础数据。目前井下矿山地应力测试主要以空芯包体解除法为主,实践中发现空芯包体解除应力计安装过程中,易出现不能与孔壁完全黏贴的情况,导致测试成功率较低且劳动强度较大。文章介绍了一种基于定向岩芯卸荷后非(滞)弹性恢复变形测量的近原位地应力测试方法(简称ASR法),并通过与水压致裂地应力测试结果对比,验证了ASR地应力测试方法的有效性。ASR法的可重复性结果表明,同一测点ASR地应力测量结果平均差系数最大为6.29%,验证了ASR地应力测量方法的可靠性。预期ASR法以其安全、高效且不受测量深度和测试环境限制等优点,在井下矿山地应力测试中具有广阔的应用前景。Abstract: Present in-situ stress state is an important data for the underground construction, tunnel stability analysis and rock burst (coal and gas burst) prediction in underground mine. At present, in-situ stress measurement in underground mine is mainly based on hollow inclusion gauge method. In practice, it is found that the stress meter of hollow inclusion gauge often fails to fully adhere to the borehole wall, which brings the low success rate and high labor intensity. In this paper, the anelastic strain recovery (ASR in short) in-situ stress measurement method based on the oriented cores is introduced. The effectiveness of ASR method are analyzed by comparing the test results with that obtained through the hydraulic fracturing method. The reliability of the ASR method is also analyzed by the repeatable test results. The results show that the maximum value of mean deviation parameter is 6.29%. The ASR method will have broad application prospects on in-situ stress measurement in underground mine with the advantages of safety, high efficiency and immunity to the limitation of depth and measurement environment.

-

表 1 ASR法与水压致裂法地应力测量结果对比

Table 1. Comparison of in-situ measurement results from the ASR method and the hydraulic fracturing method

岩芯编号 深度/m σH/MPa σh/MPa σv/MPa ASR法 1260.00 42.03 29.09 33.40 水压致裂法 1267.00 50.79 32.52 33.58 均值 1263.50 46.41 30.81 33.49 注:σH-最大水平主应力;σh-最小水平主应力;σv-垂向应力;σv根据上覆岩层重量计算(岩石密度取2.65 g/cm3)。 表 2 ASR法地应力重复测量结果

Table 2. Repeated measurement results through the ASR method

岩芯编号 深度/m σ1/MPa σ2/MPa σ3/MPa σH/MPa σh/MPa σv/MPa ASR1 3620.9 120.6 79.3 69.2 112.3 79.1 97.7 ASR2 3621.1 126.4 89.0 78.5 117.2 78.9 97.8 均值 2621.0 123.5 84.2 73.9 114.8 79 97.8 平均差系数 — 2.35% 5.76% 6.29% 2.13% 0.13% 0.05% 注:σ1-最大主应力;σ2-最大主应力;σ3-中间主应力;σH-最大水平主应力;σh-最小水平主应力;σv-垂向应力;σv根据上覆岩层重量计算(岩石密度取2.70 g/cm3)。平均差系数采用常用的统计学公式计算 -

CAI M F, QIAO L, YU B, et al., 1999. Results and analysis of in-situ stress measurement at deep position of No. 2 mining area of Jinchuan Nichkel mine[J]. Chinese Journal of Rock Mechanics and Engineering, 18(4):414-418. (in Chinese with English abstract) http://en.cnki.com.cn/Article_en/CJFDTOTAL-YSLX904.011.htm CHEN Q C, SUN D S, CUI J J, et al., 2019. Hydraulic fracturing stress measurements in Xuefengshan deep borehole and its significance[J]. Journal of Geomechanics, 25(5):853-865. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/dzlxxb201905015 LIN W R, 2008. A core-based method to determine three-dimensional in-situ stress in deep drilling wells:anelastic strain recovery technique[J]. Chinese Journal of Rock Mechanics and Engineering, 27(12):2387-2394. (in English with Chinese abstract) doi: 10.3321/j.issn:1000-6915.2008.12.002 LIN W R, KWASNIEWSKI M, IMAMURA T, et al., 2006. Determination of three-dimensional in situ stresses from anelastic strain recovery measurement of cores at great depth[J]. Tectonophysics, 426(1-2):221-238. doi: 10.1016/j.tecto.2006.02.019 MATSUKI K, 2008. Anelastic strain recovery compliance of rocks and its application to in situ stress measurement[J]. International Journal of Rock Mechanics and Mining Sciences, 45(6):952-965. doi: 10.1016/j.ijrmms.2007.10.005 MATSUKI K, TAKEUCHI K, 1993. Three-dimensional in situ stress determination by anelastic strain recovery of a rock core[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 30(7):1019-1022. SUN D S, 2018. Calculation software of ASR in-situ stress measurement method[PELVRES] 1. 0: No. 2976423[CP]. 2018-05-02. (in Chinese) SUN D S, LIN W R, CUI J W, et al., 2014. Three-dimensional in situ stress determination by anelastic strain recovery and its application at the Wenchuan Earthquake Fault Scientific Drilling Hole-1(WFSD-1)[J]. Science China Earth Sciences, 57(6):1212-1220. doi: 10.1007/s11430-013-4739-6 SUN D S, SONE H, LIN W R, et al., 2017. Stress state measured at~7 km depth in the Tarim Basin, NW China[J]. Scientific Reports, 7:4503. doi: 10.1038/s41598-017-04516-9 SUN D S, WANG L J, ZHAO W H, et al., 2010. The application of in-situ stress measurement to the study of coal and gas outburst in coal mines[J]. Geology in China, 37(1):223-228. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgdizhi201001026 VOIGHT B, 1968. Determination of the virgin state of stress in the vicinity of a borehole from measurements of a partial inelastic strain tensor in drill cores[J]. Felsmechanik und Ingenieurgeologie. 6:201-215 WANG L J, LIAO C T, OU M Y, et al., 1988. KX-81 triaxial hollow inclusion gauges for in-situ stress[M]//Institute of Geomechanics, Chinese Academy of Geosciences. Bulletin of the Institute of Geomechanics CAGS. Beijing: Geological Publishing House: 127-136. (in Chinese) WANG L J, PAN L Z, LIAO C T, 1991. Crustal stress measurements and their application in engineering[M]. Beijing:Geological Publishing House:110-145. (in Chinese) WANG L J, SUN D S, LIN W R, et al., 2012. Anelastic strain recovery method to determine in-situ stress and application example[J]. Chinese Journal of Geophysics, 55(5):1674-1681. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dqwlxb201205024 WANG L J, SUN D S, ZHANG L R, et al., 2009. Application of in-situ stress measurement on bursts disasters of rock and CO2 in coal mine[J]. Journal of China Coal Society, 34(1):28-32. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtxb200901006 XIAN X F, XU J, WANG H T, 2001. Predication of potential danger region (zone) of coal and gas outburst[J]. Engineering Science, 3(2):39-46, 51. (in Chinese with English abstract) doi: 10.3969/j.issn.1009-1742.2001.02.009 YANG X C, WANG L J, 2000. Error processing and precision estimation for rock stress measurement[J]. Journal of Geomechanics, 6(2):53-63. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzlxxb200002009 ZHAO W H, SUN D S, WANG H C, et al., 2008. Measurement of rock stress of Hongling coal mine[J]. Journal of Geomechanics, 14(3):286-291. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzlxxb200803010 蔡美峰, 乔兰, 于波, 等, 1999.金川二矿区深部地应力测量及其分布规律研究[J].岩石力学与工程学报, 18(4):414-418. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb199904011 陈群策, 孙东生, 崔建军, 等, 2019.雪峰山深孔水压致裂地应力测量及其意义[J].地质力学学报, 25(5):853-865. http://journal.geomech.ac.cn/ch/reader/view_abstract.aspx?flag=1&file_no=20190514&journal_id=dzlxxb 林为人, 2008.基于岩芯非弹性应变恢复量测定的深孔三维地应力测试方法[J].岩石力学与工程学报, 27(12):2387-2394. doi: 10.3321/j.issn:1000-6915.2008.12.002 孙东生, 王连捷, 赵卫华, 等, 2010.地应力测量在煤与瓦斯突出灾害研究中的应用[J].中国地质, 37(1):223-228. doi: 10.3969/j.issn.1000-3657.2010.01.026 孙东生, 2018. ASR法地应力计算软件[PELVRES] 1.0: 软著登字第2976423号[CP]. 2018-05-02. 王连捷, 廖椿庭, 区明益, 等, 1988. KX-81型空芯包体三轴地应力计[M]//中国地质科学院地质力学研究所.地质力学文集第八集.北京: 地质出版社: 127-136. 王连捷, 潘立宙, 廖椿庭, 1991.地应力测量及其在工程中的应用[M].北京:地质出版社:110-145. 王连捷, 孙东生, 张利容, 等, 2009.地应力测量在岩石与CO2突出灾害研究中的应用[J].煤炭学报, 34(1):28-32. doi: 10.3321/j.issn:0253-9993.2009.01.006 王连捷, 孙东生, 林为人, 等, 2012.地应力测量的非弹性应变恢复法及应用实例[J].地球物理学报, 55(5):1674-1681. http://d.old.wanfangdata.com.cn/Periodical/dqwlxb201205024 鲜学福, 许江, 王宏图, 2001.煤与瓦斯突出潜在危险区(带)预测[J].中国工程科学, 3(2):39-46, 51. doi: 10.3969/j.issn.1009-1742.2001.02.009 杨小聪, 王连捷, 2000.地应力测量的误差处理及精度评定[J].地质力学学报, 6(2):53-63. doi: 10.3969/j.issn.1006-6616.2000.02.009 赵卫华, 孙东生, 王红才, 等, 2008.沈阳红菱煤矿地应力测量[J].地质力学学报, 14(3):286-291. doi: 10.3969/j.issn.1006-6616.2008.03.010 -

下载:

下载: