Comparative study of excavation schemes for underground plant caverns based on in-situ stress field inversion

-

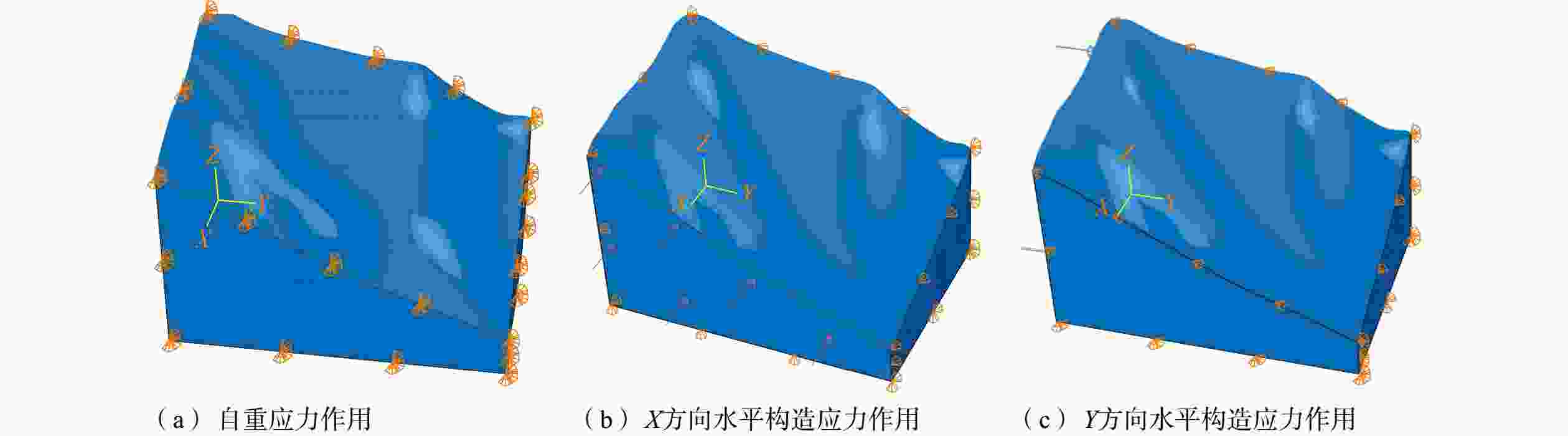

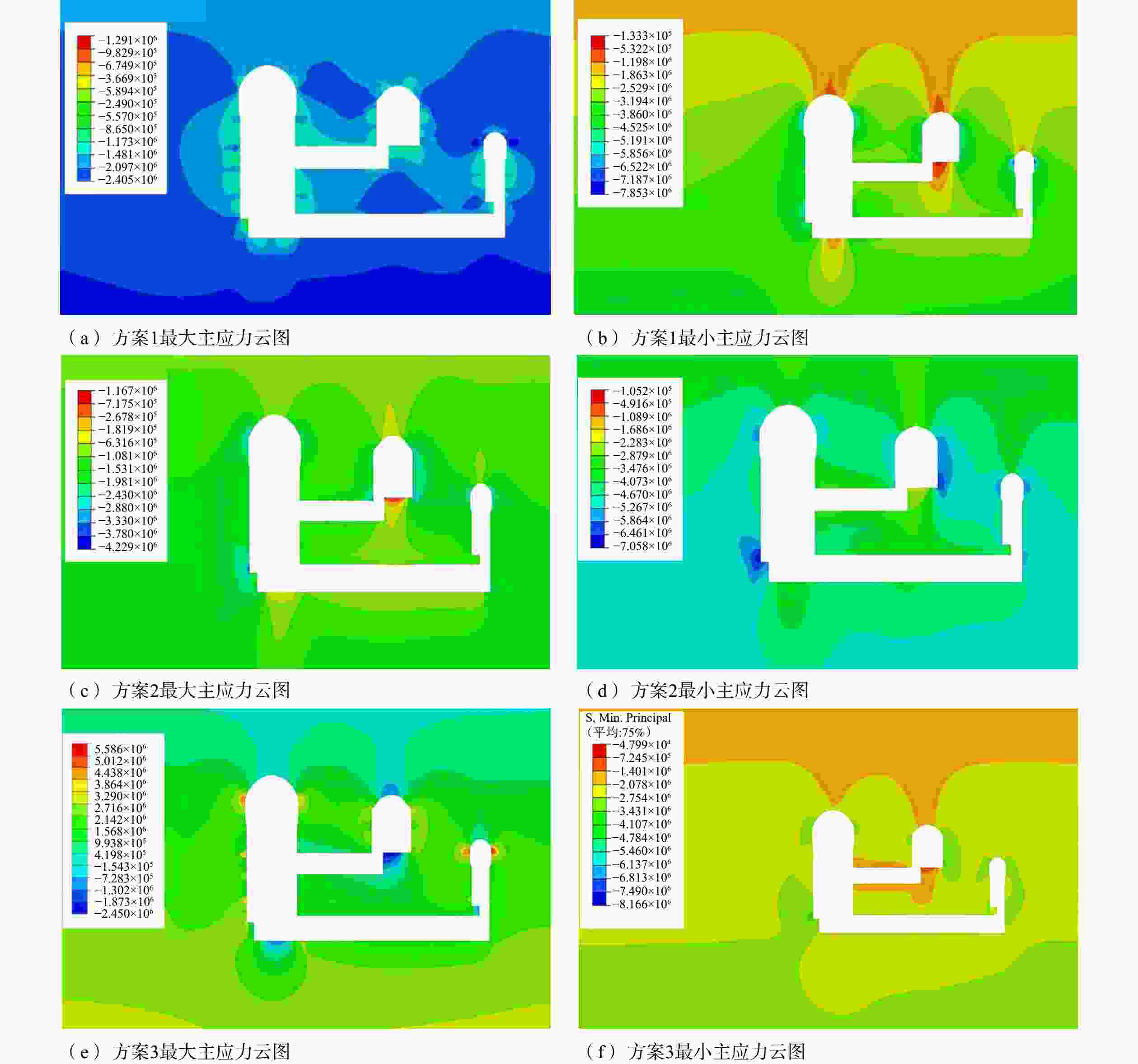

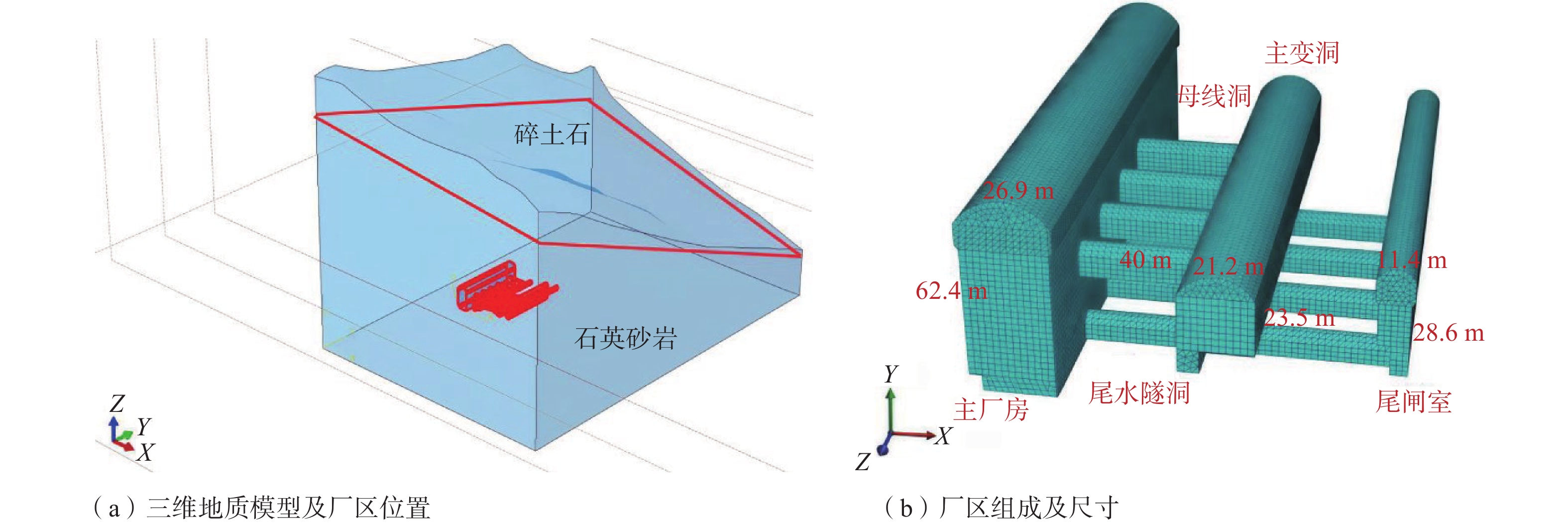

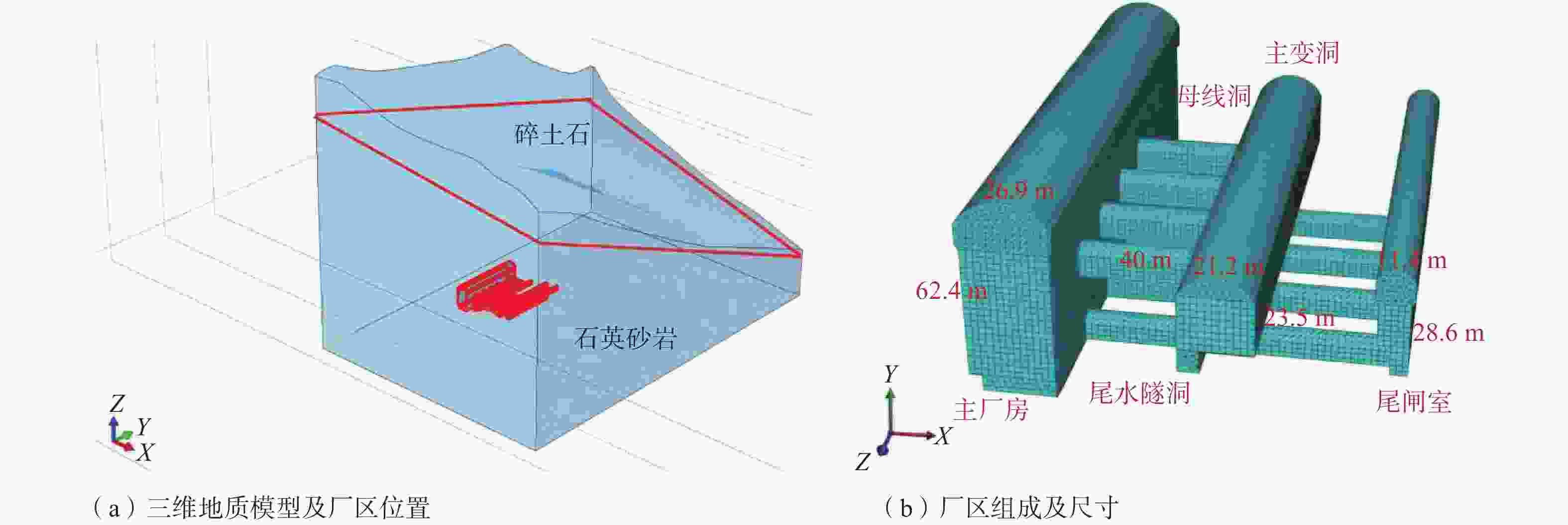

摘要: 地下厂房作为抽水蓄能电站工程的核心枢纽,围岩稳定性直接关系工程安全与全生命周期效益,其开挖控制是抽水蓄能电站安全高效建设的关键挑战。为保障厂区安全开挖以及合理支护,文章设计3种不同顺序的开挖方案,利用熵权−Topsis法综合比选,所得结果对地下厂房开挖方案设计以及优化提供了理论参考。文章依据地质勘察及地下厂房设计资料,建立三维地质模型,通过反演初始地应力场得到地应力平衡;设计3种开挖顺序,模拟开挖过程,观察主应力、位移、塑性区3个主要方面的围岩力学响应;基于开挖模拟得到的比选指标原始数据,应用熵权法赋予主应力、位移、塑性区分布3个主要方面的指标权重,客观评价围岩稳定性,再用Topsis评价体系计算各方案相对贴近度,选出最优开挖顺序方案。对大雅河抽水蓄能电站开展研究,对比3种开挖方案,方案1整体开挖效果要比另外2种方案效果好:围岩所受压应力较小且不容易发生受拉破坏,围岩整体应力分布较均匀;位移量控制效果最佳,且具有明显的位移变化规律;塑性区发育范围最小,表现出较好的围岩自稳能力。计算相对贴近度,方案1(0.82)大于方案2(0.36)、方案3(0.41),比选其为最优开挖方案。由应力、位移和塑性区分布的熵权权重可以看出,位移因素尤其是水平方向位移在施工过程中占据着较大比重。在后续支护以及开挖优化时应细化设计,保障施工期间围岩稳定性。通过熵权−Topsis法计算各方案综合效果评分,可以减小某一单一指标带来的经验类比误差,更直观地得出比选结果,评价结果的优劣与模拟开挖时围岩力学响应相符合。为后续的支护设计和施工开挖提供了依据,也为类似复杂地质条件下厂区开挖方案设计提供了重要的理论参考和实践案例。

-

关键词:

- 地应力测量 /

- 数值模拟反演 /

- 熵权−Topsis评价 /

- 开挖方案比选

Abstract:Objective As the core hub of pumped storage power station projects, the stability of the surrounding rock of underground powerhouses directly affects engineering safety and lifecycle benefits. The control of its excavation poses a key challenge for the safe and efficient construction of such stations. To ensure safe excavation and rational support design, three excavation sequences were designed and comprehensively compared using the entropy-weighted Topsis method. The results provide a theoretical reference for the design and optimization of excavation schemes for underground powerhouses. Methods Based on geological survey data and underground powerhouse designdocumentation, a three-dimensional geological model was established. Initial in-situ stress equilibrium was achieved through inversion of the stress field. Three excavation sequences were simulated to observe the mechanical responses of the surrounding rock in terms of principal stress, displacement, and plastic zone distribution. Using raw indicator data obtained from the simulations, the entropy weight method was applied to assign weights to these three key indicators, enabling an objective evaluation of surrounding rock stability. The Topsis evaluation system was then used to calculate the relative closeness degree of each scheme, thereby identifying the optimal excavation sequence. Results A case study of the Daya River Pumped Storage Power Station showed that Scheme I outperformed the other two schemes in overall excavation effectiveness: (1) The surrounding rock experienced lower compressive stress with reduced susceptibility to tensile failure, and the stress distribution was more uniform; (2) displacement control was the most effective, with clear and consistent displacement trends; (3) the plastic zone developed within the smallest range, indicating a superior self-stabilizing capacity of the surrounding rock. The calculated relative closeness degrees were 0.82 for Scheme I, significantly higher than those for Scheme II (0.36) and Scheme III (0.41), confirming Scheme I as the optimal excavation scheme. Conclusion The entropy weights assigned to stress, displacement, and plastic zone distribution indicate that displacement, particularly in the horizontal direction, plays a dominant role during construction. Subsequent support design and excavation optimization should emphasize detailed planning to ensure surrounding rock stability. The comprehensive scoring of each scheme via the entropy-weighted Topsis method reduces empirical analogy errors caused by overreliance on any single indicator, providing a more intuitive and reliable comparison. The evaluation results align well with the mechanical response patterns observed during excavation simulation. Significance This study provides a basis for subsequent support design and construction excavation, while also offering valuable theoretical reference and a practical case for the design of excavation schemes under similar complex geological conditions. -

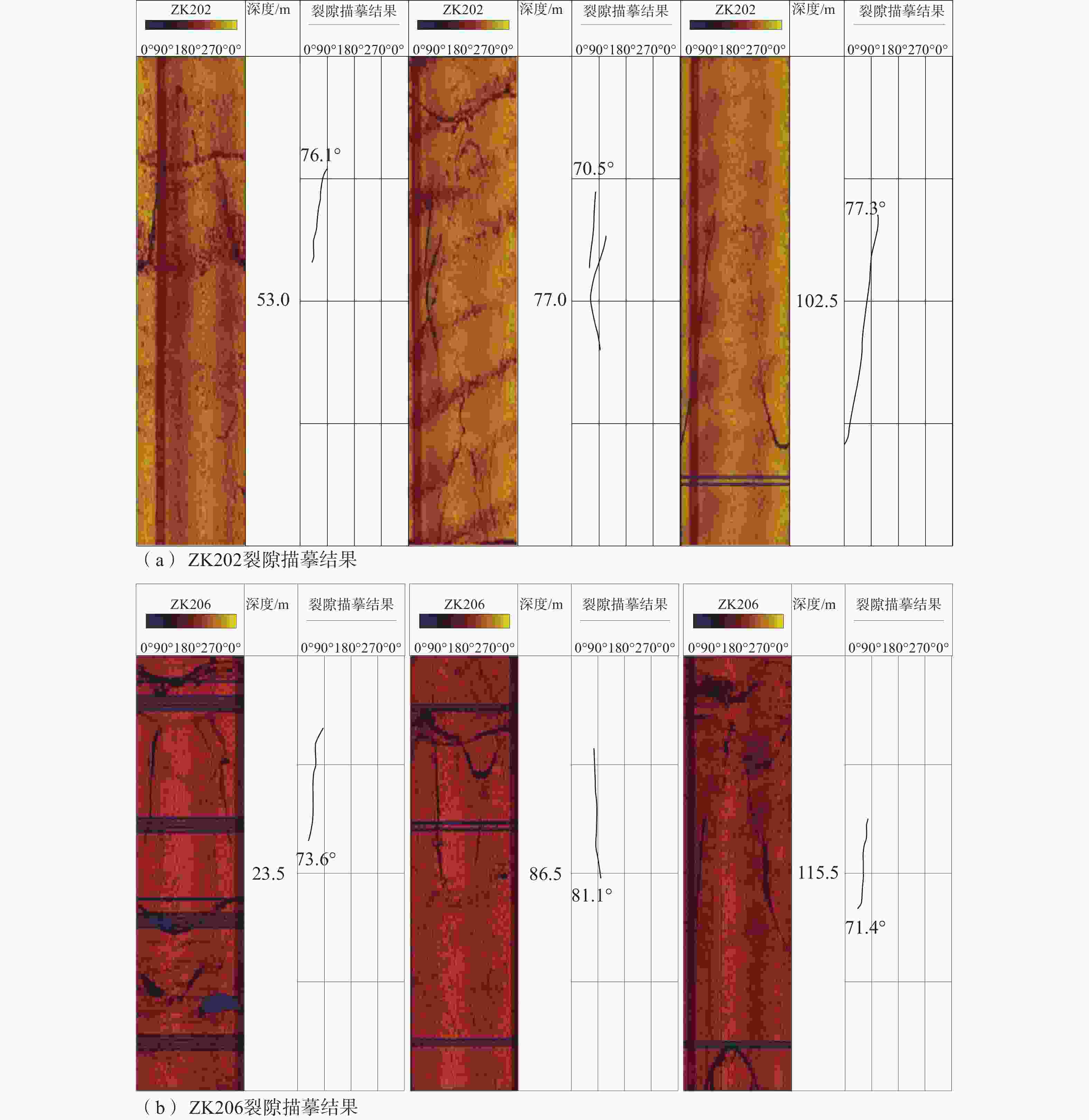

图 2 主应力方向描摹结果

图中色卡代表裂隙的发育程度,颜色越深则岩体越破碎,裂隙越深

Figure 2. Results of principal stress orientation determination

(a) Directional tracing results of borehole televiewer for fractures in ZK202; (b) Directional tracing results of borehole televiewer for fractures in ZK206 The color palette in the figure represents the development degree of fractures; the darker the color, the more fragmented the rock mass and the deeper the fractures.

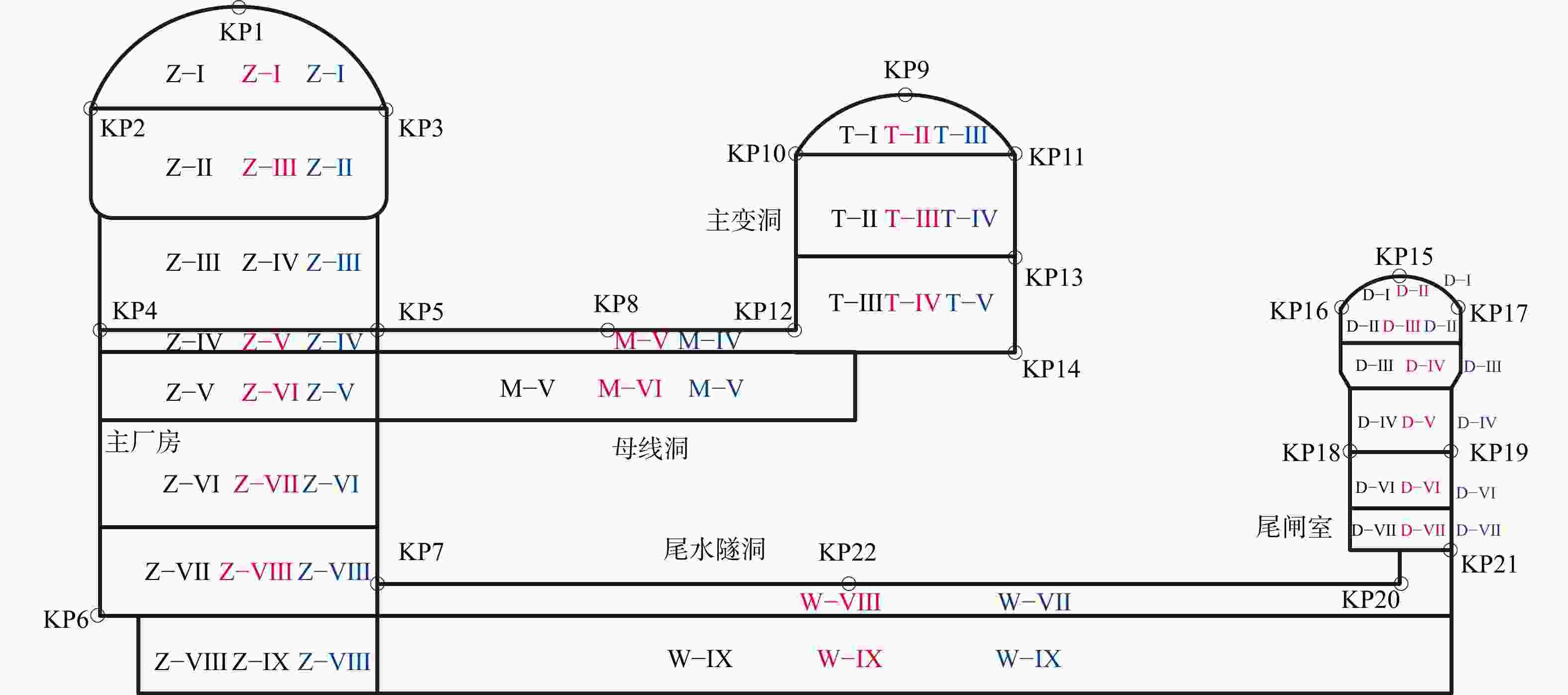

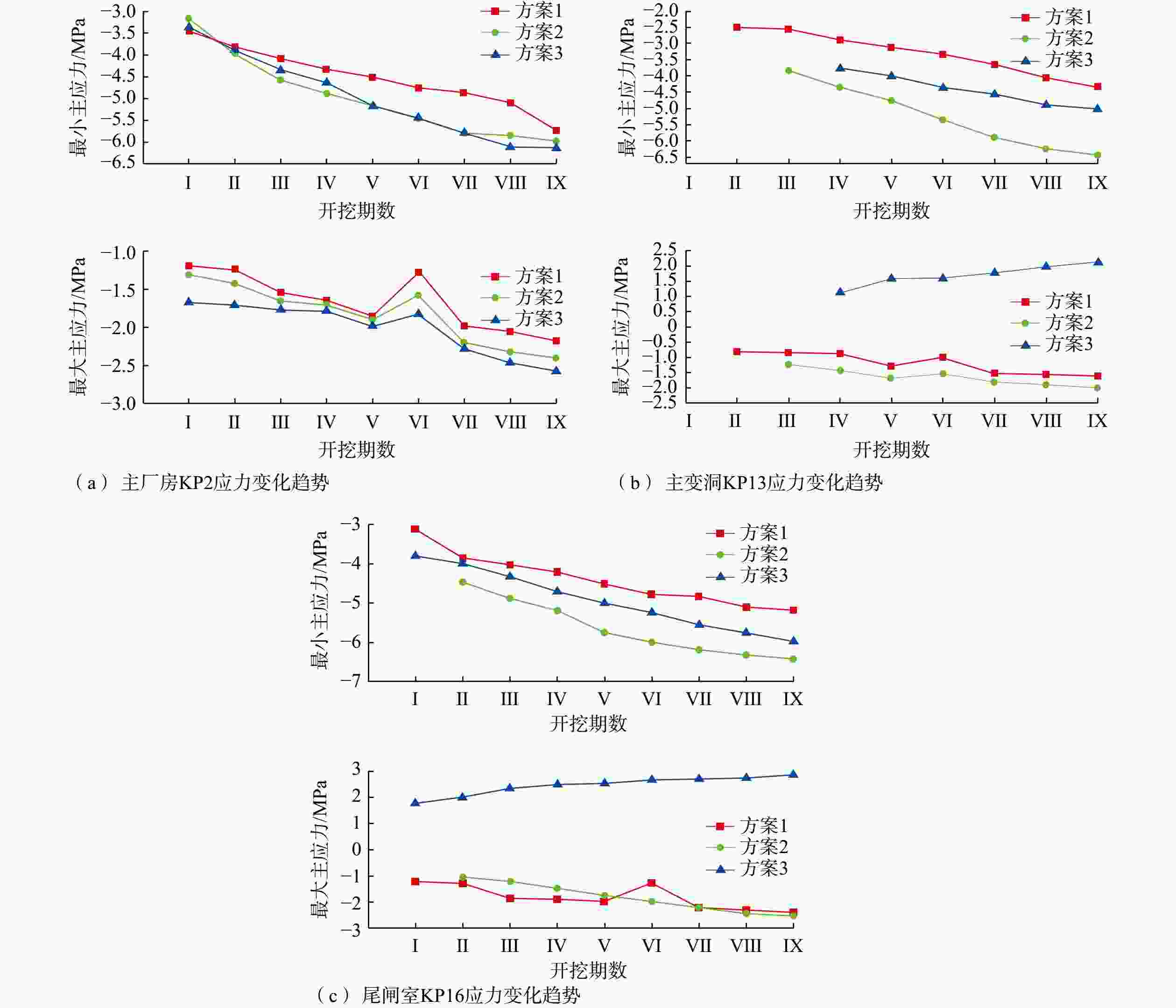

图 4 地下厂房开挖分区示意及关键点布置

Z、T、D、M、W分别代表主厂房、主变洞、尾闸室、母线洞和尾水隧洞开挖;黑色代表方案1,红色代表方案2,蓝色代表方案3;KP是关键点,代表塑性区分布位置;I—IX为开挖期数

Figure 4. Schematic diagram of excavation zoning and key point layout in underground powerhouse

Z, T, D, M, W denote the excavation of the main powerhouse, main transformer tunnel, tailgate chamber, busbar tunnel, and tailrace tunnel, respectively; Black, red, and blue indicate Scheme Ⅰ, Scheme Ⅱ, and Scheme Ⅲ, respectively; KP are key points indicating the distribution of plastic zones; I—IX are the excavation phase numbers.

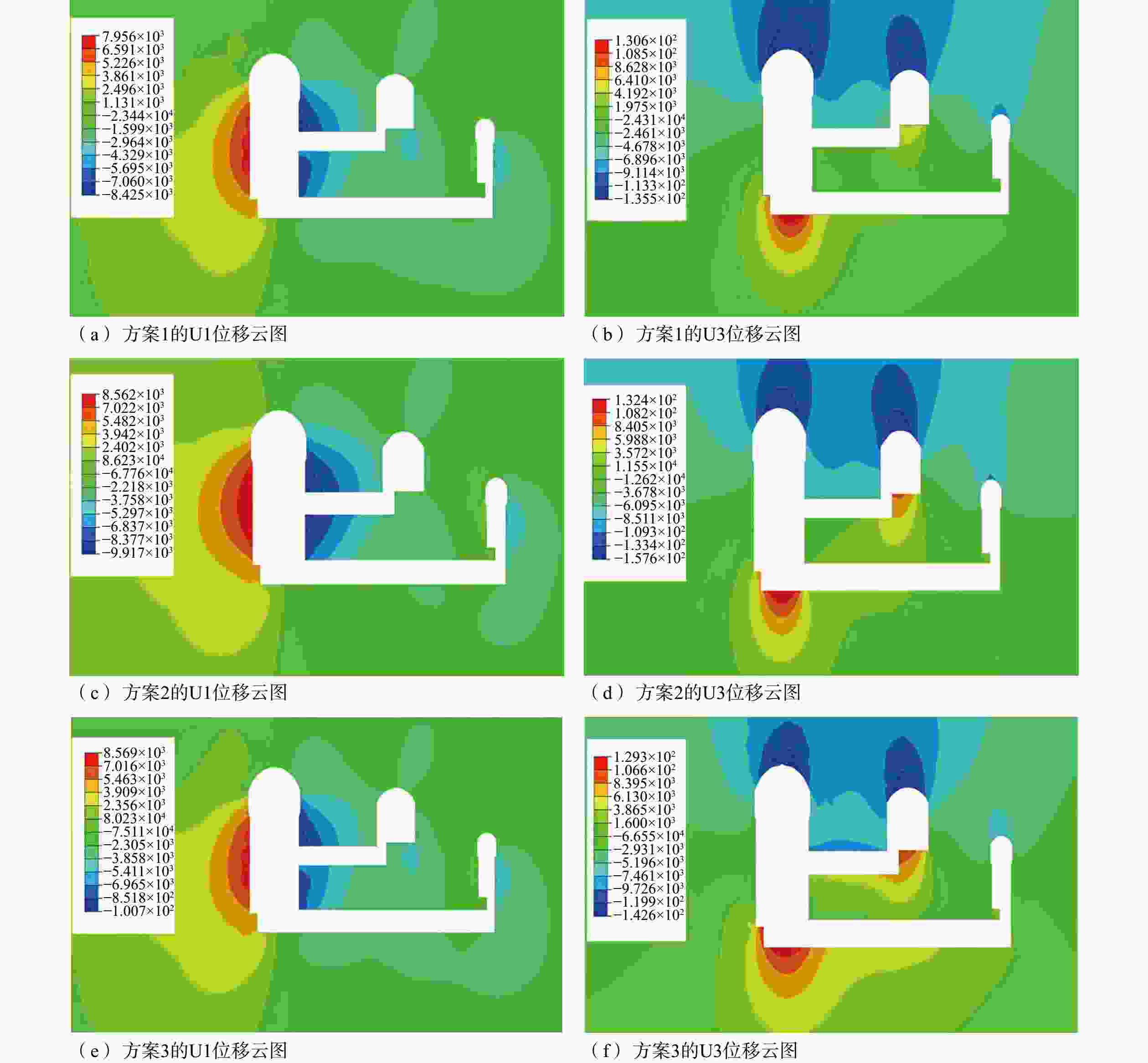

图 5 各方案最大、最小应力云图

Figure 5. Principal stress contour plots for each scheme

(a) Maximum principal stress for Scheme Ⅰ; (b) Minimum principal stress for Scheme Ⅰ; (c) Maximum principal stress for Scheme Ⅱ; (d) Minimum principal stress for Scheme Ⅱ; (e) Maximum principal stress for Scheme Ⅲ; (f) Minimum principal stress for Scheme Ⅲ

表 1 岩土体主要物理力学参数

Table 1. Primary physico-mechanical parameters of the rock and soil masses

围岩分类 干密度/(g/cm3) 弹性模量/GPa 变形模量/GPa 泊松比 凝聚力/MPa 内摩擦角/(°) 碎土石 2.40 1.20 0.06 0.17 0.01 23 Ⅱ类石英砂岩 2.63 22.0 15.0 0.23 1.50 33 表 2 钻孔主应力数据

Table 2. Drill hole principal stress data

观测点 测段深度/ m 压裂参数/ MPa 主应力值/ MPa 破裂方位/(°) $ {P_{\text{b}}} $ $ {P_{\text{r}}} $ $ {P_{\text{S}}} $ $ {P_{\text{0}}} $ T ${S_{\text{H}}}$ ${S_{\text{h}}}$ ${S_{\text{V}}}$ ZK202-1 52.61~53.46 17.42 10.97 10.81 4.79 6.45 16.66 10.81 12.95 N76.1°E ZK202-2 77.20~78.05 19.24 12.07 11.52 5.06 7.17 17.42 11.52 13.68 N70.5°E ZK202-3 102.69~103.54 19.01 12.58 11.99 5.28 6.43 18.10 11.99 14.28 N77.3°E ZK206-1 22.16~23.01 13.85 9.30 7.93 3.22 4.55 11.27 7.93 10.42 N73.6°E ZK206-2 85.90~86.75 18.02 11.12 10.14 3.84 6.90 15.46 10.14 12.11 N81.1°E ZK206-3 115.23~116.08 20.57 12.40 11.13 4.13 8.17 16.86 11.13 12.89 N71.4°E 注:$ {P_{\text{b}}} $—初始破裂压力,$ {P_{\text{r}}} $—破裂重张压力,$ {P_{\text{S}}} $—瞬时闭合压力,$ {P_{\text{0}}} $—孔隙水压,T—时间,$ S_{\mathrm{H}} $—最大水平主应力,$ S\mathrm{_h} $—最小水平主应力,$ S\mathrm{_V} $—垂直主应力 表 3 各钻孔应力分量实测值与反演值比较

Table 3. Comparison between measured and inverted stress components in individual boreholes

观测点 数值类别 ${S_{\text{H}}}$/MPa ${S_{\text{h}}}$/MPa ${S_{\text{V}}}$/MPa 破裂方位/(°) ZK202-1 实测值 16.66 10.81 12.95 N76.1E 反演值 15.38 9.56 10.56 N73.1E 误差 1.28 1.25 2.39 3.0 ZK202-2 实测值 17.42 11.52 13.68 N70.5E 反演值 15.72 10.50 11.20 N75.0E 误差 1.70 1.02 2.48 4.5 ZK202-3 实测值 18.10 11.99 14.28 N77.3E 反演值 16.39 12.01 12.55 N79.5E 误差 1.71 –0.02 1.73 –2.2 ZK206-1 实测值 11.27 7.93 10.42 N73.6°E 反演值 11.63 8.01 9.64 N69.7E 误差 –0.36 –0.08 0.78 3.9 ZK206-2 实测值 15.46 10.14 12.11 N81.1°E 反演值 15.93 11.21 11.74 N79.6E 误差 −0.47 −1.07 0.37 1.5 ZK206-3 实测值 16.86 11.13 12.89 N71.4°E 反演值 16.91 11.96 13.28 N72.4E 误差 –0.05 –0.83 –0.39 –1.0 表 4 不同开挖方案下塑性区深度范围

Table 4. Depth range of plastic zones under different excavation schemes

洞室名称 塑性区位置

(分布见图4)塑性区深度/m 方案1 方案2 方案3 主厂房 KP2 11.6 11.9 10.2 KP3 12.1 13.5 9.9 KP4 9.4 11.8 11.3 KP5 5.3 4.9 5.9 母线洞 KP8 2.3 2.4 4.6 主变洞 KP12 6.2 7.8 6.8 KP13 6.5 8.1 7.0 尾闸室 KP18 0 3.8 10.4 KP19 0 4.2 11.2 表 5 评价指标标准化

Table 5. Indicator standardization

评价方面 评价指标($ x_{ij} $) 方向性 开挖方案1 开挖方案2 开挖方案3 主应力 $ \dfrac{最大压应力}{岩体抗压强度}\times 100\% $ 负向指标 1.60 2.82 1.63 $ \dfrac{最大拉应力}{岩体抗拉强度}\times 100\% $ 负向指标 8.61 7.78 37.24 位移 $ \dfrac{\text{U1}}{允许阈值}\times 100\% $ 负向指标 18.71 22.02 22.22 $ \dfrac{\text{U3}}{允许阈值}\times 100\% $ 负向指标 42.89 45.03 40.74 塑性区 $ \dfrac{各方案最大塑性区深度}{总塑性区最大深度} $ 负向指标 0.90 1.00 0.84 注:$ {x_{ij}} $—第$ i $个开挖方案的第$ j $个比选指标;U1—最大水平位移;U3—最大垂直位移 表 6 各指标熵权计算结果

Table 6. Results of entropy weight calculation for all indicators

评价指标 ${y_{ij}}$ ${e_j}$ ${\omega _j}$ $ \dfrac{最大压应力}{岩体抗压强度}\times 100\% $ 1.0010 0.0010 0.9764 0.3890 0.1815 $ \dfrac{最大拉应力}{岩体抗拉强度}\times 100\% $ 0.9728 1.0010 0.0010 0.3890 0.1815 $ \dfrac{\text{U1}}{允许阈值}\times 100\% $ 1.0010 0.0580 0.0010 0.1226 0.2606 $ \dfrac{\text{U3}}{允许阈值}\times 100\% $ 0.4998 0.0010 1.0010 0.3580 0.1907 $ \dfrac{各方案最大塑性区深度}{总塑性区最大深度} $ 0.6260 0.0010 1.0010 0.3745 0.1858 注:${y_{ij}}$—各比选指标原始数据标准化;${e_j}$—各指标熵值;${\omega _j}$—各指标权重 表 7 Topsis计算综合得分

Table 7. Comprehensive score calculation by Topsis

方案 $ d_i^ + $ $d_{\text{i}}^ - $ ${C_i}$ 排名 1 0.08945 0.41961 0.82428 1 2 0.34604 0.19108 0.35576 3 3 0.33635 0.23173 0.40791 2 注:$ d_i^ + $、$d_{\text{i}}^ - $—各指标与正负理想解的欧氏距离,${C_i}$—与最优对象的相对贴近度 -

[1] BAI J P, DONG Y A, GAN J, et al., 2023. In-situ stress state in critical areas of the Taiyuan pumped storage power station and its application in pivot project layout[J]. Journal of Geomechanics, 29(3): 375-387. (in Chinese with English abstract) [2] CHEN N, WANG C H, GAO G Y, et al., 2021. Characteristics of in-situ stress field in the powerhouse area on the right bank of Baihetan based on stress polygon and borehole breakout method[J]. Rock and Soil Mechanics, 42(12): 3376-3384. (in Chinese with English abstract) [3] CHEN Q C, FAN T Y, LI X S, et al., 2014. In situ measurements and comprehensive research on the present crustal stress of northern South China Sea[J]. Chinese Journal of Geophysics, 57(8): 2518-2529. (in Chinese with English abstract) [4] CHEN W Z, LI S C, ZHU W S, et al., 2004. Excavation and optimization theory for giant underground caverns constructed in high dipping laminar strata[J]. Chinese Journal of Rock Mechanics and Engineering, 23(19): 3281-3287. (in Chinese with English abstract) [5] CHEN X F, CHEN W T, LUO J M, et al., 2018. Application of entropy weight Topsis method in the quality evaluation of underground cavern rock[J]. Industrial Safety and Environmental Protection, 44(3): 20-23. (in Chinese with English abstract) [6] CHENG Z Y, LIU R, ZHANG J F, et al, 2023. Study on Seepage Mechanism Characteristics of A Single Fracture Based on Fracture Deformation Under Different ConfiningPressures[J]. Geoscience, 37(4): 972-976. (in Chinese with English abstract) [7] DONG Y, ZHANG Y, XI C H, 2018. Study on rock burst prediction based on combination weighting—Topsis theory[J]. Pearl River, 39(9): 87-91. (in Chinese with English abstract) [8] DUAN S Q, FENG X T, JIANG Q, et al., 2017. Failure modes and mechanisms for rock masses with staggered zones of Baihetan underground caverns under high geostress[J]. Chinese Journal of Rock Mechanics and Engineering, 36(4): 852-864. (in Chinese with English abstract) [9] GAO G Y, WANG C H, ZHOU H, et al., 2023. Analysis of in-situ stress characteristics in southern Sichuan basin based on multi-source data[J]. Chinese Journal of Underground Space and Engineering, 19(2): 550-559. (in Chinese with English abstract) [10] GUO H Z, MA Q C, XUE X C, et al., 1983. The analytical method of the initial stress field for rock masses[J]. Chinese Journal of Geotechnical Engineering, 5(3): 64-75. (in Chinese with English abstract) [11] HONG W B, ZHOU L Y, WANG G Y, 2024. Influence analysis on Liaoning Dayahe pumped storage power station on Dayahe reservoir[J]. Water Resources & Hydropower of Northeast China, 42(10): 46-49. (in Chinese with English abstract) [12] LI C R , TANG M G , ZHOU J, et al , 2025. Distribution and impoundment response law of landslides in the reservoir area of Wudongde Hydropower Station [J]. Water Resources and Hydropower Engineering, 56(4): 35-51. DOI: 10.13928/j.cnki.wrahe.2025.04.004. (in Chinese with English abstract) [13] LI R J, JIANG H, SU G S, et al., 2025. Optimization of excavation and support schemes for underground caverns of pumped-storage power station[J]. Water Power, 51(4): 54-61. (in Chinese) [14] LI T, FENG X T, WANG R, et al., 2019. Characteristics of rockburst location deflection and its microseismic activities in a deep tunnel[J]. Rock and Soil Mechanics, 40(7): 2847-2854. (in Chinese with English abstract) [15] LI Z J, ZHOU J, PENG F X, 2025. Comprehensive evaluation of integrated development of pumped storage power stations and photovoltaic systems based on entropy weight Topsis method[J]. Water Resources and Power, 43(3): 205-209, 195. (in Chinese with English abstract) [16] LI Z Z, YANG W C, ZHANG P, et al., 2023. In-situ stress measurement and inversion analysis of a large hydropower project in southeast Tibet[J]. Journal of Geomechanics, 29(3): 442-452. (in Chinese with English abstract) [17] LIU J, XIA Y, JIANG Q, et al., 2025. Surrounding rock deformation and failure characteristics of Yingliangbao hydropower station in highly tectonic region and response analysis to Luding earthquake in underground caverns[J]. Rock and Soil Mechanics, 46(7): 2265-2280. (in Chinese with English abstract) [18] SHA P, GUO Q L, WANG C H, 2014. Application of hydraulic fracturing method in the construction of deep buried tunnels in western China[C]//Proceedings of the 2014 national conference on engineering geology. Taiyuan: Engineering Geology Committee of the Geological Society of China: 119-125. (in Chinese) [19] SONE H, ZOBACK M D, 2014. Viscous relaxation model for predicting least principal stress magnitudes in sedimentary rocks[J]. Journal of Petroleum Science and Engineering, 124: 416-431. doi: 10.1016/j.petrol.2014.09.022 [20] SU D D, FAN Y, WU J G, et al., 2024. Research progress on failure mechanism of surrounding rock in deep cavern blasting excavation crossing fault fracture zone[J]. Journal of China Three Gorges University (Natural Sciences), 46(4): 25-34. (in Chinese with English abstract) [21] SU G S, FENG X T, JIANG Q, et al., 2007. Intelligent method of combinatorial optimization of excavation sequence and support parameters for large underground caverns under condition of high geostress[J]. Chinese Journal of Rock Mechanics and Engineering, 26(S1): 2800-2808. (in Chinese with English abstract) [22] TAN Z, LI B, LI P, et al., 2024. Study on the formation mechanism of excavation damage zone of surrounding rock of the underground powerhouse under high geostress[J]. Chinese Journal of Underground Space and Engineering, 20(6): 1979-1990. (in Chinese with English abstract) [23] WANG C H, GUO Q L, DING L F, et al., 2009. High in-situ stress criteria for engineering area and a case analysis[J]. Rock and Soil Mechanics, 30(8): 2359-2364. (in Chinese with English abstract) [24] WANG C H, GAO G Y, WANG H, et al., 2020. Integrated determination of principal stress and tensile strength of rock based on the laboratory and field hydraulic fracturing tests[J]. Journal of Geomechanics, 26(2): 167-174. (in Chinese with English abstract) [25] XIE H P, 2019. Research review of the state key research development program of China: deep rock mechanics and mining theory[J]. Journal of China Coal Society, 44(5): 1283-1305. (in Chinese with English abstract) [26] YANG Q, PAN Y W, CHENG L, et al., 2015. Mechanism of valley deformation of high arch dam and effective stress principle for unsaturated fractured rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 34(11): 2258-2269. (in Chinese with English abstract) [27] ZHANG X F, WANG J M, ZHANG P, et al. , 2025. Analysis on the three-dimensional in-situ stress state and underground cavern stability of a pumped storage hydropower project area in Xinjiang Uygur autonomous region[J/OL]. Journal of Geomechanics. [2025-11-30]. https://link.cnki.net/urlid/11.3672.P.20250910.1652.002. (in Chinese with English abstract) [28] ZHOU Z J, CHEN H J, LUO T, et al., 2024. A simple inversion method for initial ground stress of underground powerhouses based on FLAC3D[J]. Engineering Journal of Wuhan University, 57(S2): 11-15. (in Chinese with English abstract) [29] 白金朋, 董延安, 甘俊, 等, 2023. 太原抽水蓄能电站关键部位地应力状态及其在枢纽工程布设中的应用[J]. 地质力学学报, 29(3): 375-387. doi: 10.12090/j.issn.1006-6616.20232907 [30] 陈念, 王成虎, 高桂云, 等, 2021. 基于应力多边形与钻孔崩落的白鹤滩右岸厂房区地应力场特征研究[J]. 岩土力学, 42(12): 3376-3384. doi: 10.16285/j.rsm.2021.0380 [31] 陈群策, 范桃园, 李绪深, 等, 2014. 中国南海海域北部地区现今地应力实测及综合分析研究[J]. 地球物理学报, 57(8): 2518-2529. [32] 陈卫忠, 李术才, 朱维申, 等, 2004. 急倾斜层状岩体中巨型地下洞室群开挖施工理论与优化研究[J]. 岩石力学与工程学报, 23(19): 3281-3287. doi: 10.3321/j.issn:1000-6915.2004.19.012 [33] 陈雪锋, 陈文涛, 罗建梅, 等, 2018. 熵权Topsis模型在地下工程岩体质量评价中的应用[J]. 工业安全与环保, 44(3): 20-23. doi: 10.3969/j.issn.1001-425X.2018.03.006 [34] 程智余, 刘瑞, 张金锋, 等, 2023. 围压变化作用下基于水力开度变化的单裂隙渗流特性研究[J]. 现代地质, 37(4): 972-976. [35] 董源, 张引, 习朝辉, 2018. 基于组合赋权-Topsis理论的岩爆预测研究[J]. 人民珠江, 39(9): 87-91. [36] 段淑倩, 冯夏庭, 江权, 等, 2017. 高地应力下白鹤滩地下洞室群含错动带岩体破坏模式及机制研究[J]. 岩石力学与工程学报, 36(4): 852-864. doi: 10.13722/j.cnki.jrme.2015.1236 [37] 高桂云, 王成虎, 周昊, 等, 2023. 基于多源应力数据的川南地区地应力特征分析[J]. 地下空间与工程学报, 19(2): 550-559. [38] 郭怀志, 马启超, 薛玺成, 等, 1983. 岩体初始应力场的分析方法[J]. 岩土工程学报, 5(3): 64-75. [39] 洪文彬, 周立洋, 王冠宇, 2024. 辽宁大雅河抽水蓄能电站对大雅河水库影响分析[J]. 东北水利水电, 42(10): 46-49. [40] 李超瑞, 汤明高, 周剑, 等2025. 乌东德水电站库区滑坡发育分布及蓄水响应规律[J]. 水利水电技术(中英文) , 56(4): 35-51. DOI: 10.13928/j.cnki.wrahe.2025.04.004 [41] 李仁杰, 江浩, 苏国韶, 等, 2025. 抽水蓄能电站地下洞室群开挖支护方案优化研究[J]. 水力发电, 51(4): 54-61. [42] 李桐, 冯夏庭, 王睿, 等, 2019. 深埋隧道岩爆位置偏转及其微震活动特征[J]. 岩土力学, 40(7): 2847-2854. doi: 10.16285/j.rsm.2018.0470 [43] 李征征, 杨文超, 张鹏, 等, 2023. 藏东南某大型水电站工程区地应力状态及反演分析[J]. 地质力学学报, 29(3): 442-452. doi: 10.12090/j.issn.1006-6616.20232912 [44] 李梓嘉, 周佳, 彭方旭, 2025. 基于熵权Topsis法的抽水蓄能电站与光伏配套开发综合评价[J]. 水电能源科学, 43(3): 205-209, 195. doi: 10.20040/j.cnki.1000-7709.2025.20240761 [45] 刘健, 夏勇, 江权, 等, 2025. 强烈构造区硬梁包水电站地下洞室群围岩变形破坏特征与泸定地震响应分析[J]. 岩土力学, 46(7): 2265-2280. doi: 10.16285/j.rsm.2024.1557 [46] 沙鹏, 郭啟良, 王成虎, 2014. 水压致裂法在西部深埋隧道工程建设中的应用[C]//2014年全国工程地质学术大会论文集. 太原: 中国地质学会工程地质专委会: 119-125. [47] 苏都都, 范勇, 吴进高, 等, 2024. 穿越断层破碎带深埋洞室爆破开挖围岩破坏机理研究进展[J]. 三峡大学学报(自然科学版), 46(4): 25-34. doi: 10.13393/j.cnki.issn.1672-948X.2024.04.004 [48] 苏国韶, 冯夏庭, 江权, 等, 2007. 高地应力下大型地下洞室群开挖顺序与支护参数组合优化的智能方法[J]. 岩石力学与工程学报, 26(S1): 2800-2808. doi: 10.3321/j.issn:1000-6915.2007.z1.032 [49] 谭洲, 李彪, 李鹏, 等, 2024. 高地应力地下厂房围岩开挖损伤区形成机理研究[J]. 地下空间与工程学报, 20(6): 1979-1990. doi: 10.20174/j.JUSE.2024.06.24 [50] 王成虎, 高桂云, 王洪, 等, 2020. 利用室内和现场水压致裂试验联合确定地应力与岩石抗拉强度[J]. 地质力学学报, 26(02): 167-174. doi: 10.12090/j.issn.1006-6616.2020.26.02.016 [51] 王成虎, 郭啟良, 丁立丰, 等, 2009. 工程区高地应力判据研究及实例分析[J]. 岩土力学, 30(8): 2359-2364. doi: 10.3969/j.issn.1000-7598.2009.08.029 [52] 谢和平, 2019. 深部岩体力学与开采理论研究进展[J]. 煤炭学报, 44(5): 1283-1305. [53] 杨强, 潘元炜, 程立, 等, 2015. 高拱坝谷幅变形机制及非饱和裂隙岩体有效应力原理研究[J]. 岩石力学与工程学报, 34(11): 2258-2269. doi: 10.13722/j.cnki.jrme.2015.0972 [54] 张晓飞, 王继明, 张鹏, 等, 2025. 新疆某抽蓄电站深部岩体地应力赋存规律及地下硐室稳定性分析[J/OL]. 地质力学学报. [2025-09-09]. DOI: 10.12090/j.issn.1006-6616.2025076 [55] 周佐健, 陈焕杰, 罗滔, 等, 2024. 地下厂房初始地应力简易FLAC3D反演方法[J]. 武汉大学学报(工学版), 57(S2): 11-15. -

下载:

下载: