Research and development of a volumetric mining-induced stress monitoring sensor and its application

-

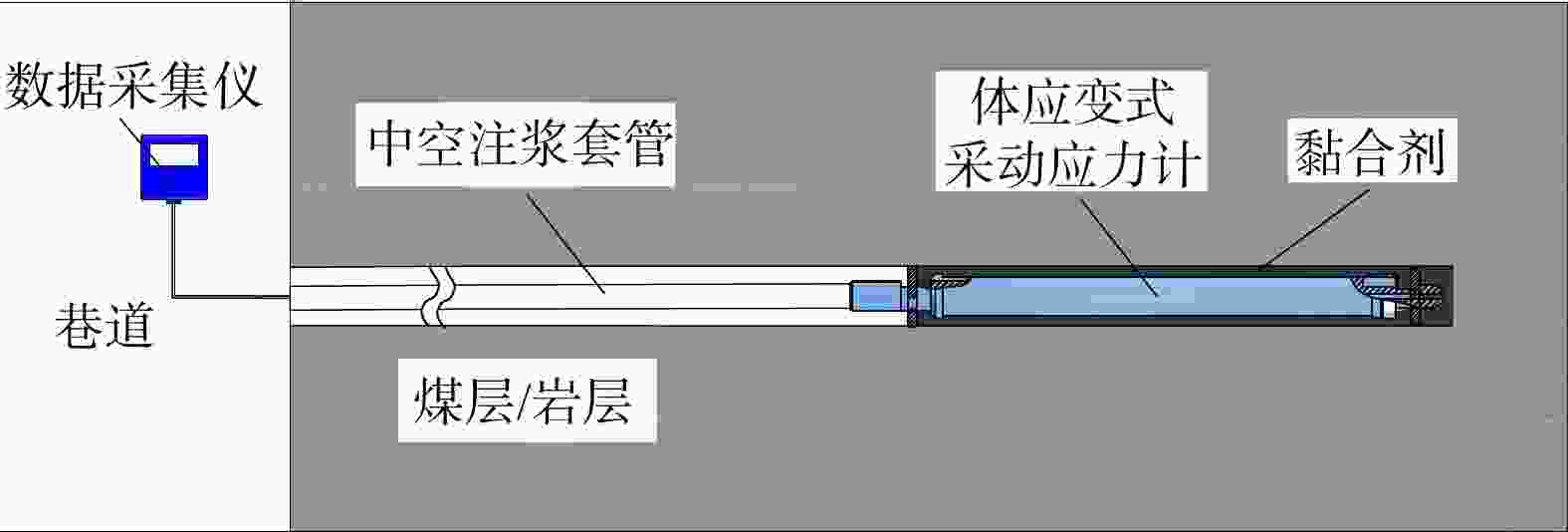

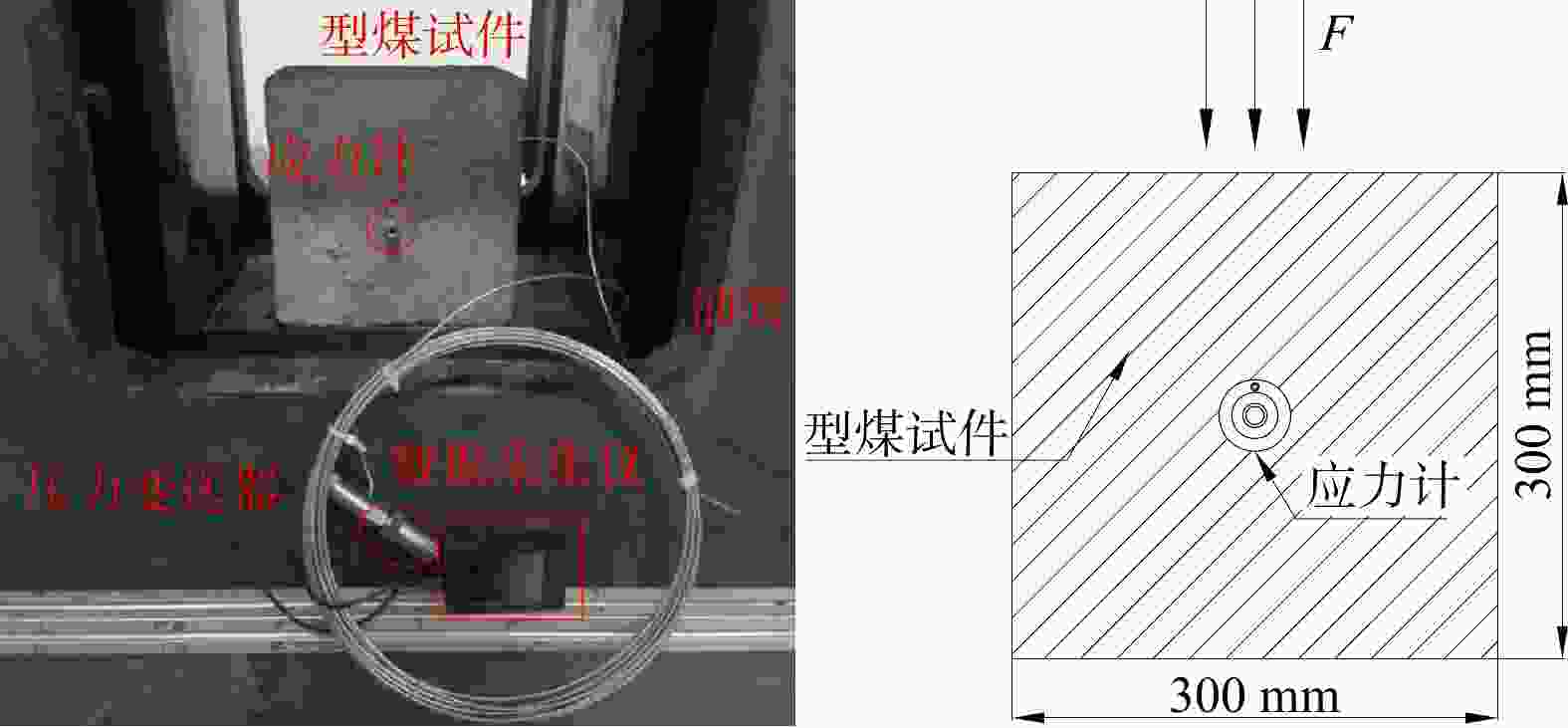

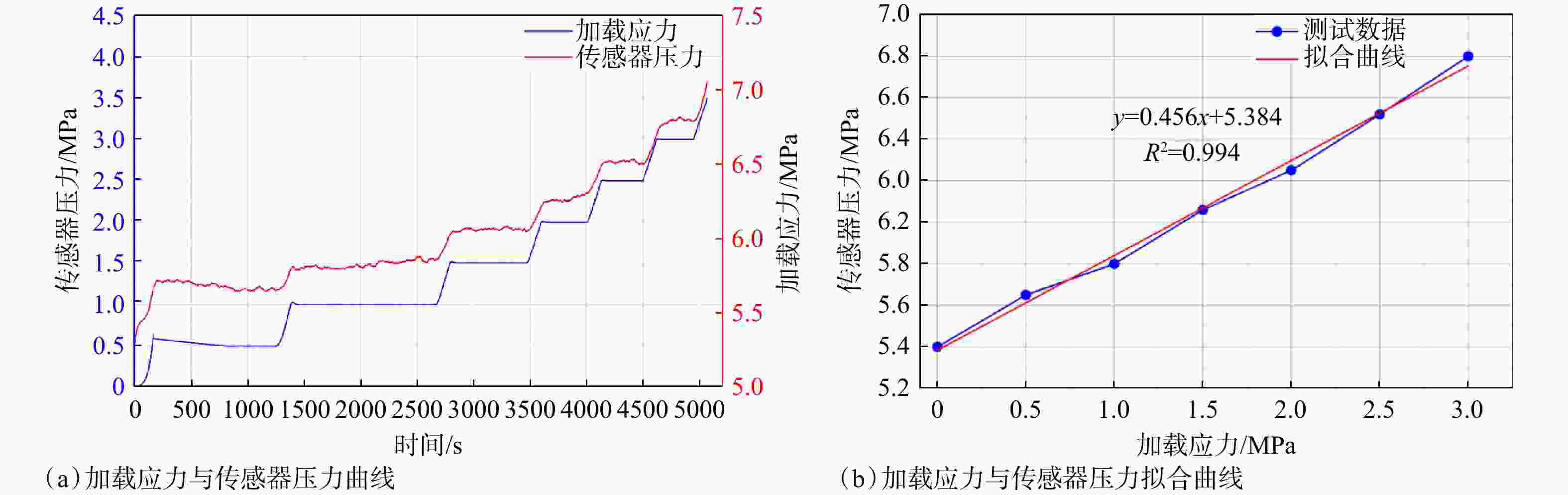

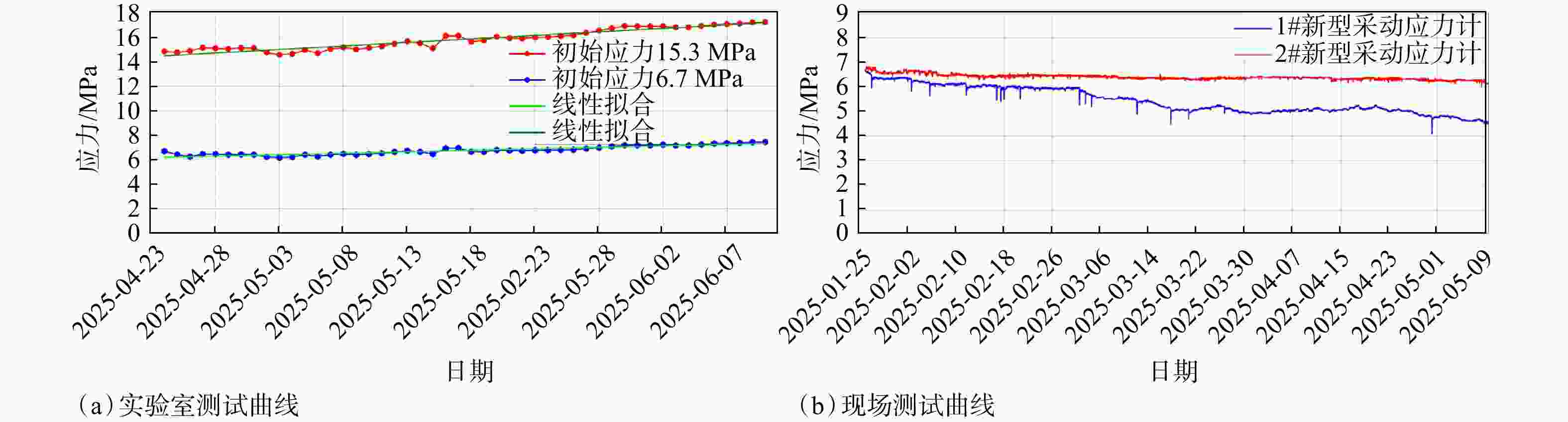

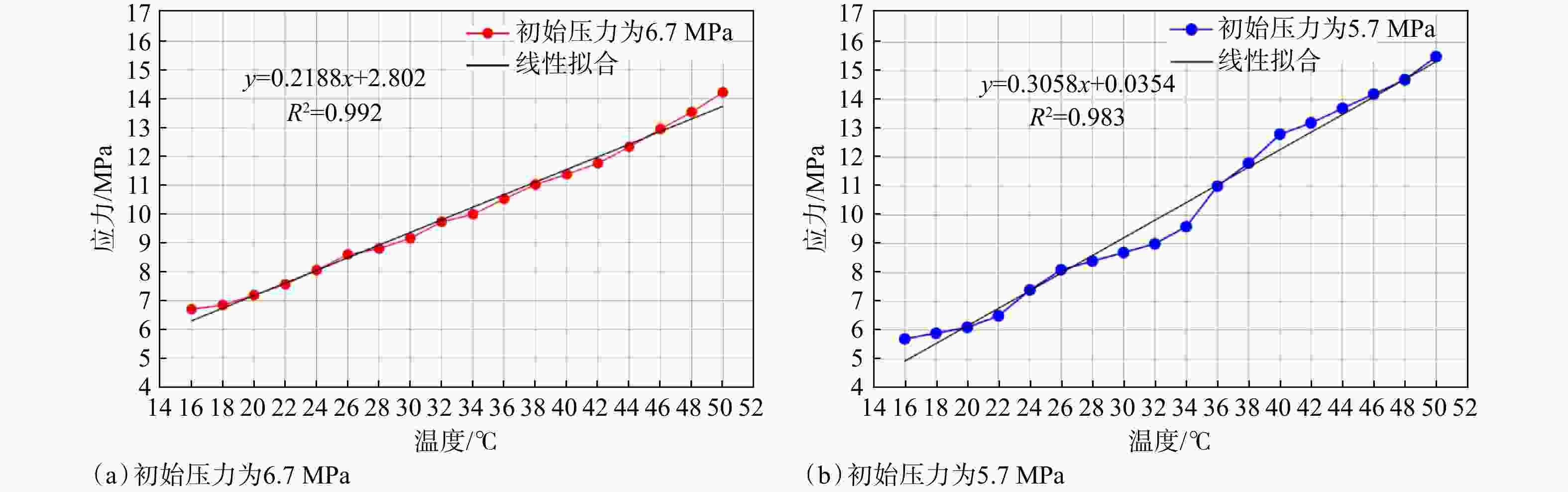

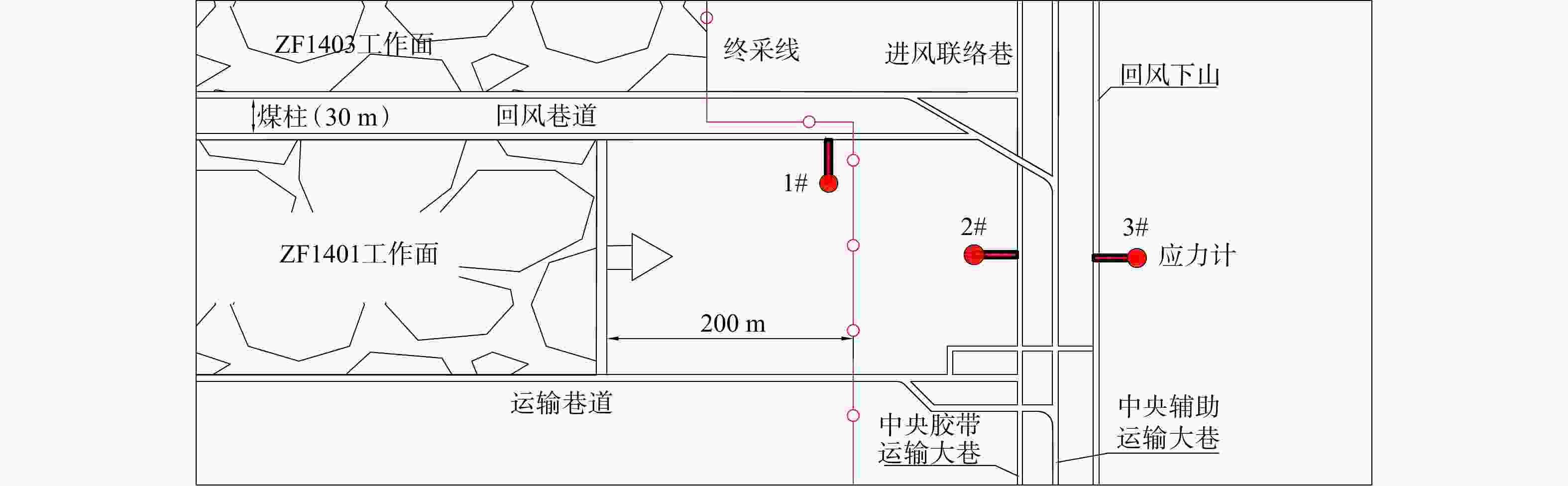

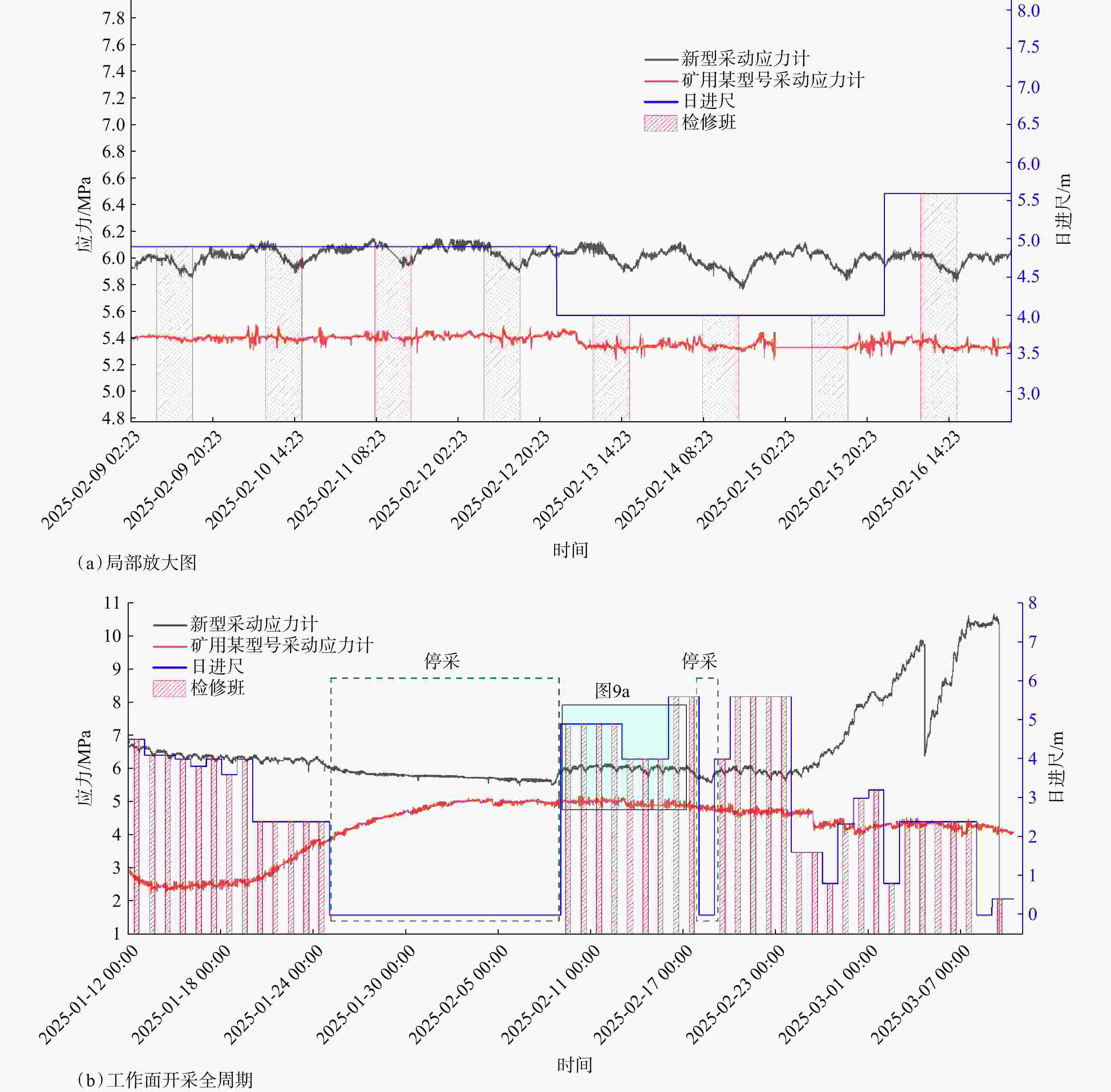

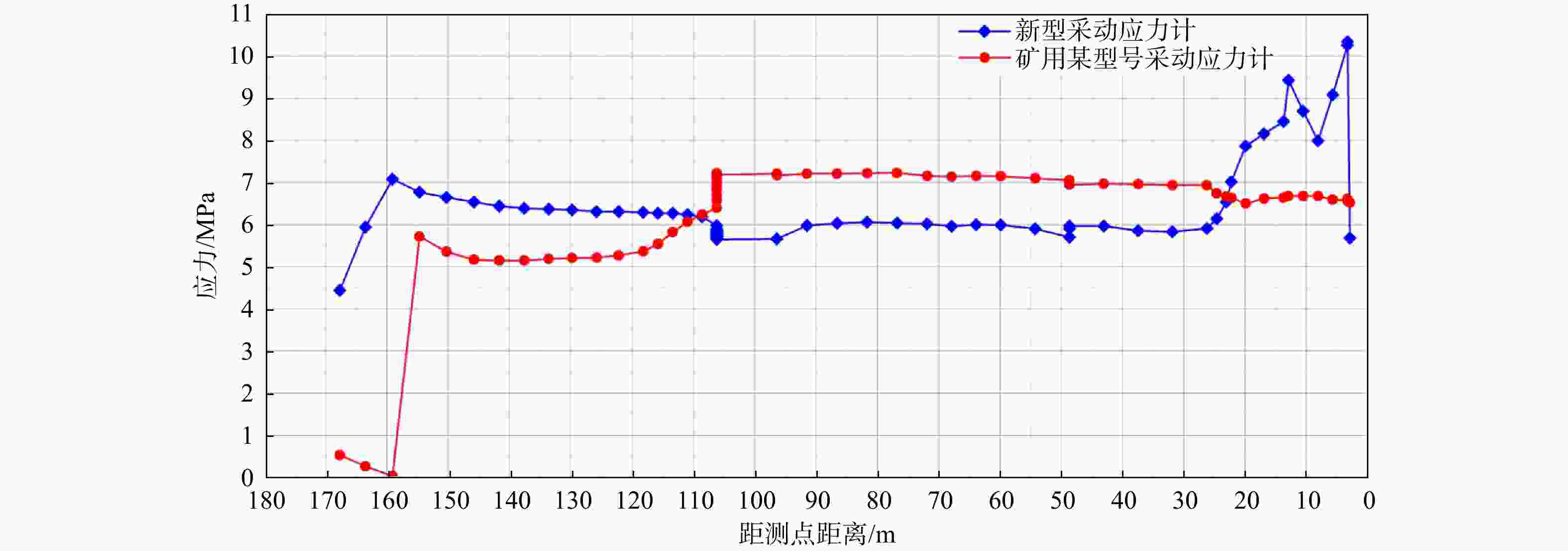

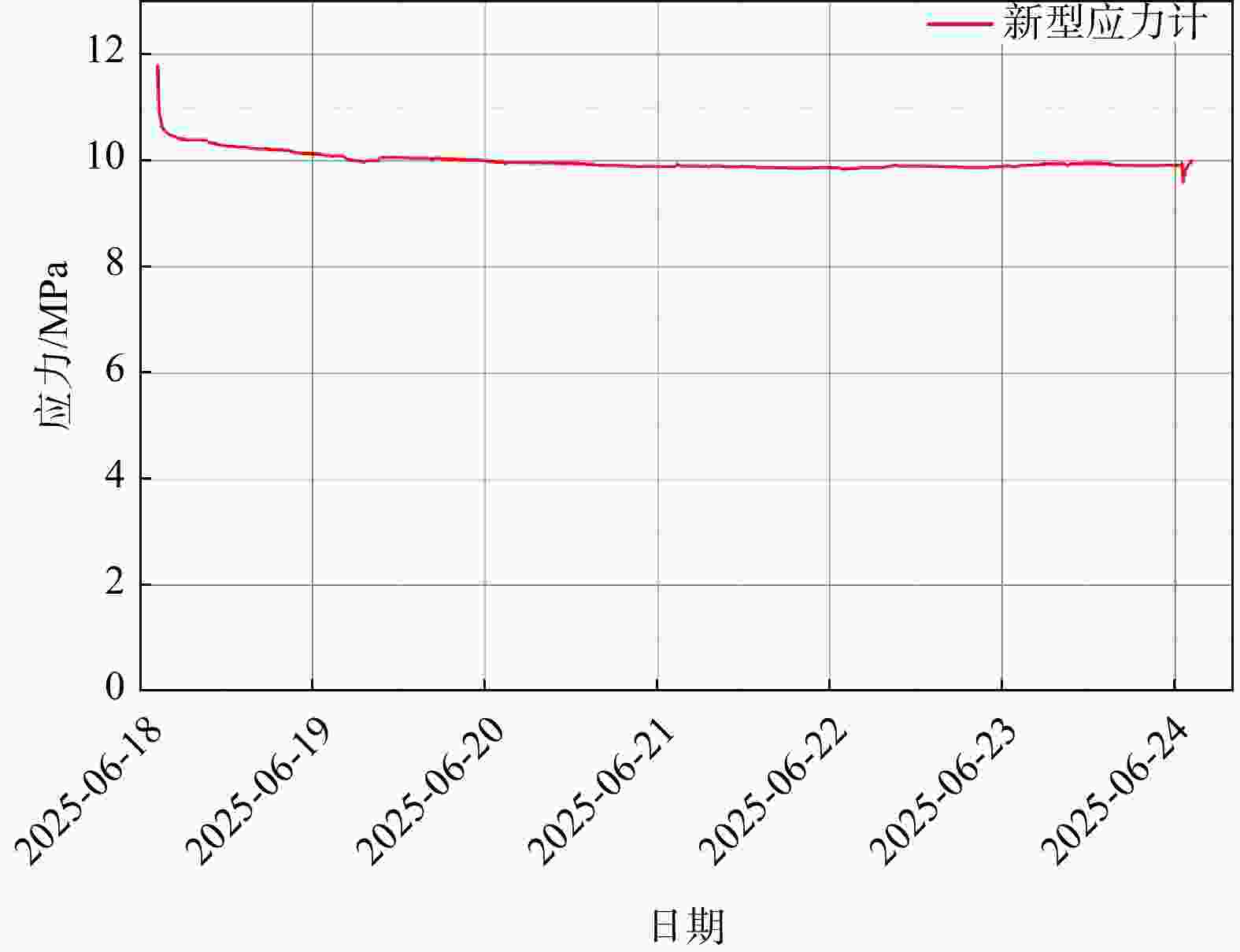

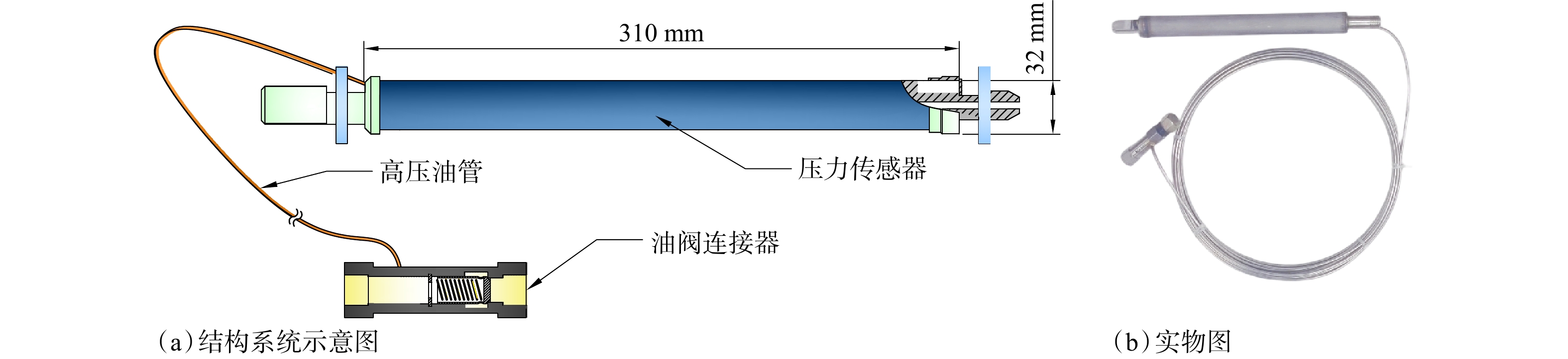

摘要: 随着煤矿开采深度持续向千米级推进,采动应力场的动态演化特征成为深部围岩稳定性控制与动力灾害预警的核心难题。为此,文章研发了一种新型体积式采动应力监测传感器,其通过圆柱形传感结构与钻孔围岩完全耦合,突破了传统设备的单轴测量局限,可实时监测围岩体微小变形引起的采动应力变化,显著提升了煤岩体等非均质介质中的采动应力监测敏感性与长期稳定性。实验室测试结果显示,传感器输出压力变化与轴向应力呈高度线性关系,灵敏度达0.456,优于传统应力计。在长期稳定性测试中,高、低应力环境下的压力波动均未出现持续漂移或数据跳变;温度特性实验揭示了温度与压力变化的线性关系,验证了温度补偿公式的普适性。在陕西彬长矿区雅店煤矿的现场应用中,该传感器成功捕捉到回采过程中与开采周期同步的应力波动;在顶板断裂等突发应力事件中,其响应速度与精度显著优于传统设备,且与微震监测数据具有强相关性;在金属矿山硬岩环境测试中,传感器亦展现出长期稳定的监测能力。试验及应用结果表明,该技术可高效捕捉动力灾害前兆信息,在深埋矿山采动应力监测及深埋隧道迟滞型岩爆预警等领域具有广阔应用前景。Abstract:

Objective As coal mining depth continuously advancing to the kilometer level, the dynamic evolution characteristics of mining-induced stress fields have become a crucial challenge for deep surrounding rock stability control and dynamic disaster early warning. Existing traditional monitoring equipment is limited by uniaxial measurement, and suffers from insufficient monitoring sensitivity and poor long-term stability in heterogeneous media such as coal and rock masses, failing to meet the precise monitoring needs of deep mining. Methods This study proposes a new type of volumetric mining-induced stress monitoring sensor. Through complete coupling between its cylindrical sensing structure and the surrounding rock of the borehole, it breaks through the uniaxial measurement limitation of traditional equipment, enabling real-time monitoring of mining-induced stress changes caused by micro-deformations of surrounding rock masses. Results Laboratory tests, field tests, and application results show the following: (1) In laboratory tests, the pressure change output by the sensor shows a highly linear relationship with axial stress, with a sensitivity of 0.456, which is better than that of traditional stress gauges; (2) Long-term stability tests indicate that under high and low stress environments, the sensor’s pressure fluctuations show no continuous drift or data jumps, demonstrating good long-term monitoring stability; (3) Temperature characteristic experiments reveal a linear relationship between temperature and pressure changes, verifying the universality of the temperature compensation formula; (4) In the field application at Yadian Coal Mine in Binchang Mining Area, Shaanxi Province, the sensor successfully captured stress fluctuations synchronized with the mining cycle. In sudden stress events, such as roof fractures, its response speed and accuracy were significantly better than those of traditional equipment, and the monitoring data showed a strong correlation with microseismic monitoring results; (5) Tests in hard rock environments in metal mines also confirmed the sensor's long-term stable monitoring capability. Conclusion (1) The new volumetric mining-induced stress monitoring sensor overcomes the uniaxial measurement limitation of traditional equipment, significantly improving monitoring sensitivity and long-term stability in heterogeneous media; (2) Laboratory tests verify its linear response characteristics, high sensitivity, and temperature adaptability, while field applications prove that it can effectively capture the dynamic evolution characteristics of mining-induced stress; (3) The sensor can work stably in different mining environments such as coal mines and metal mines, showing strong applicability. Significance This research solves the key problems of insufficient monitoring sensitivity and poor long-term stability of mining-induced stress in deep heterogeneous media. It provides reliable technical support for capturing precursor information of dynamic disasters in deep mines and early warning of delayed rockbursts in tunnels, with important scientific value and application innovation. -

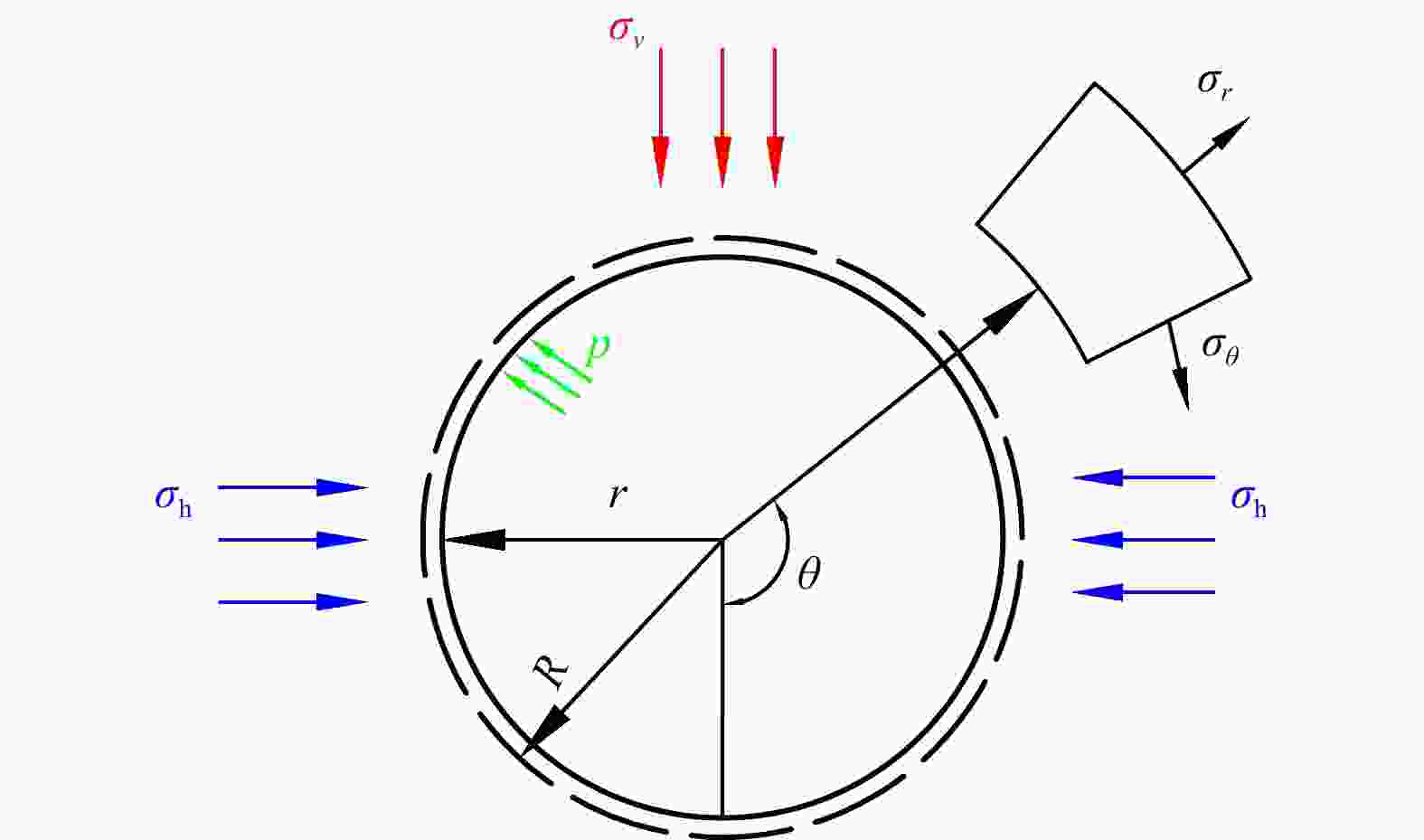

图 3 新型应力计施加均匀应力状态时的应力分布

σv—竖直方向应力,σh—水平方向应力,p—应力计内部压力;R—应力计受压变化前的半径;r—应力计受压变化后的半径;σr—径向应力;σθ—环向应力;σh—水平方向应力

Figure 3. Stress distribution of the novel stress gauge under uniform stress state

σv—vertical stress; σh—horizontal stress; p—internal pressure of the stress gauge; R—radius of the stress gauge before compression; r—radius of the stress gauge after compression; σr—ridial stress; σθ—hoop stress;σh—horizontal stress

表 1 雅店煤矿4号煤层特征综合表

Table 1. Comprehensive table of characteristics of No. 4 coal seam in Yadian Coal Mine

特征类别 参数指标 详细说明 厚度特征 平均厚度 11.85~12.07 m(特厚煤层) 夹矸特征 局部含泥岩夹矸1~2层,单层厚0.2~0.66 m 力学性质 单轴抗压强度 11.80~16.36 MPa(中硬煤层) 弹性模量 2.54 GPa 泊松比 0.3 地应力特征 水平应力主导(最大主应力15.89 MPa) 裂隙发育特征 构造背景 单斜构造(倾角<5°),无大型断层 导水裂隙带高度 205~214 m(裂采比≤20) -

[1] AMADEI B, 1985. Applicability of the theory of hollow inclusions for overcoring stress measurements in rock[J]. Rock Mechanics and Rock Engineering, 18(2): 107-130. doi: 10.1007/BF01019601 [2] BRADY B H G, BROWN E T, 2006. Rock mechanics: for underground mining[M]. 3rd ed. Dordrecht: Springer. [3] BROYLES L W, CASSAN J T, 1968. Bulk modulus investigation – hydraulic fluid stiffness (AFAPL-TR-68-14)[R]. Wright-Patterson AFB, OH: Air Force Aero Propulsion Laboratory. [4] CAI M F, QIAO L, LI H B, 1995. Principles and techniques of in situ stress measurement[M]. Beijing: Science Press: 1-27. (in Chinese with English abstract) [5] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China, 2015. Test methods of the performances for pressure transducer/sensor: GB/T 15478-2015 [S]. Beijing: China Standard Press. [6] GILLEY J L, SPOREIC R, ZONA A, 1964. Progress in the application of encapsulated cells in a coal mine subject to coal bursts[C]//Proceedings of the 6th U. S. symposium on rock mechanics. Rolla: University of Missouri: 649-667. [7] KELLER C, LOWRY W, 1990. The use of the CALIP gauge for those difficult measurements of rock stress[M]//HUSTRULID W, JOHNSON G A. Rock mechanics contributions and challenges. London: CRC Press: 573-577. [8] KUTZ M, 2015. Mechanical engineers' handbook: energy and power[M]. Hoboken: Wiley. [9] LIU W J, LIU Y, PAN G H, 2019. Study on the method of determining the stopping line of working face based on stress monitoring system[J]. Coal Engineering, 51(6): 112-115. (in Chinese with English abstract) [10] LU P H, 1981. Determination of ground pressure existing in a viscoelastic rock mass by use of hydraulic borehole pressure cells[C]//Proceedings of the ISRM international symposium. Tokyo: ISRM: 459-465. [11] LU P H, 1984. Mining-induced stress measurement with hydraulic borehole pressure cells[C]//Proceedings of the 25th U. S. symposium on rock mechanics. Evanston: American Rock Mechanics Association. [12] MA J J, LI H L, 2021. Development of miniaturized volume borehole strain instrument[J]. Journal of Geodesy and Geodynamics, 41(2): 217-220. (in Chinese with English abstract) [13] National Coal Mining Safety Administration, 2018. Notification on issuing the "regulations on the prevention and control of impact ground pressure in coal mines": coal mine safety supervision equipment (2018) 8[EB/OL]. Beijing: National Coal Mine Safety Administration, (2018-05-02)[2025-05-16]. https://www.gov.cn/zhengce/zhengceku/2019-12/09/content_5459585.htm. (in Chinese with English abstract) [14] NEWMAN D A, 1989. In situ yield behaviour of a coal pillar[J]. International Journal of Mining and Geological Engineering, 7(2): 163-170. doi: 10.1007/BF01554344 [15] OBERT L, DUVAL W I, 1967. Rock mechanics and the design of structures in rock[M]. New York: Wiley. [16] PANEK L A, HORNSEY E E, LAPPI R L, 1964. Determination of the modulus of rigidity of rock by expanding a cylindrical pressure cell in a drillhole[C]//Proceedings of the 6th U. S. symposium on rock mechanics. Rolla: ARMA: 351-365. [17] PANEK L A, STOCK J A, 1964. Development of a rock stress monitoring station based on the flat slot method of measuring existing rock stress[R]. Washington: United States Department of the Interior, Bureau of Mines. [18] PANEK L A, 1973. Solution of mine structure problems through field measurements and theoretical analysis[C]//Proceedings of the rock mechanics instrumentation for mine design. Washington: U. S. Bureau of Mines: 23-34. [19] SALVINI R, ERMINI A, DE LUCIA V, et al., 2022. Stress–strain investigation of the rock mass based on overcoring with CSIRO HI cell test and numerical modeling: a case study from an Italian underground marble quarry[J]. Geosciences, 12(12): 441. doi: 10.3390/geosciences12120441 [20] SONG G D, LIU T Y, WANG C, 2012. Deep dynamic disaster prediction technologies based on mining-induced stress monitoring[J]. China Mining Magazine, 21(S1): 520-522. (in Chinese with English abstract) [21] SU K Z, 2003. Status and developments of borehole strain observations in China[J]. Seismological and Geomagnetic Observation and Research, 24(1): 65-69. (in Chinese with English abstract) [22] SWOLFS H S, BRECHTEL C E, 1977. The direct measurement of long-term stress variations in rock[C]//Proceedings of the 18th U. S. symposium on rock mechanics. Golden: ARMA: 4C5-1-4C5-3. [23] WOROTNICKI G, 1993. CSIRO triaxial stress measurement cell[M]//HUDSON J A. Rock testing and site characterization: principles, practice and projects. Amsterdam: Elsevier: 329-394. [24] XIA F Q, WEI Q D, GUO Y M, et al., 2020. Design and application of flexible borehole stressmeter[J]. Coal Engineering, 52(4): 161-165. (in Chinese with English abstract) [25] ZHANG Z G, ZHANG Q H, LIU J, 2024. Research progress and prospects of coal and gas outburst and composite dynamic disaster warning systems in China[J]. Journal of China Coal Society, 49(S2): 911-923. (in Chinese with English abstract) [26] 蔡美峰, 乔兰, 李华斌, 1995. 地应力测量原理和技术[M]. 北京: 科学出版社: 1-27. [27] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 2015. 压力传感器性能试验方法: GB/T 15478—2015[S]. 北京: 中国标准出版社. [28] 国家煤矿安监局, 2018. 防治煤矿冲击地压细则: 煤安监技装[2018]8号[EB/OL]. 北京: 国家煤矿安全监察局, (2018-05-02)[2025-05-16]. https: //www.gov.cn/zhengce/zhengceku/2019-12/09/content_5459585.htm. [29] 刘伟建, 刘晔, 潘贵豪. 基于应力监测系统的工作面终采线确定方法研究[J]. 煤炭工程, 2019, 51(6): 112-115. [30] 马京杰, 李海亮, 2021. 小型化体积式钻孔应变仪的研制[J]. 大地测量与地球动力学, 41(2): 217-220. doi: 10.14075/j.jgg.2021.02.020 [31] 宋广东, 刘统玉, 王昌, 2012. 基于采动应力监测的深部动力灾害预测技术[J]. 中国矿业, 21(S1): 520-522. [32] 苏恺之, 2003. 我国钻孔应变观测的回顾与展望[J]. 地震地磁观测与研究, 24(1): 65-69. doi: 10.3969/j.issn.1003-3246.2003.01.011 [33] 夏方迁, 魏全德, 郭延淼, 等, 2020. 柔性钻孔应力计设计及实验应用研究[J]. 煤炭工程, 52(4): 161-165. doi: 10.11799/ce202004030 [34] 张志刚, 张庆华, 刘军, 2024. 我国煤与瓦斯突出及复合动力灾害预警系统研究进展及展望[J]. 煤炭学报, 49(S2): 911-923. -

下载:

下载: