Water inrush mechanism and the minimum safety thickness of the rock wall of a tunnel crossing a fault fracture zone

-

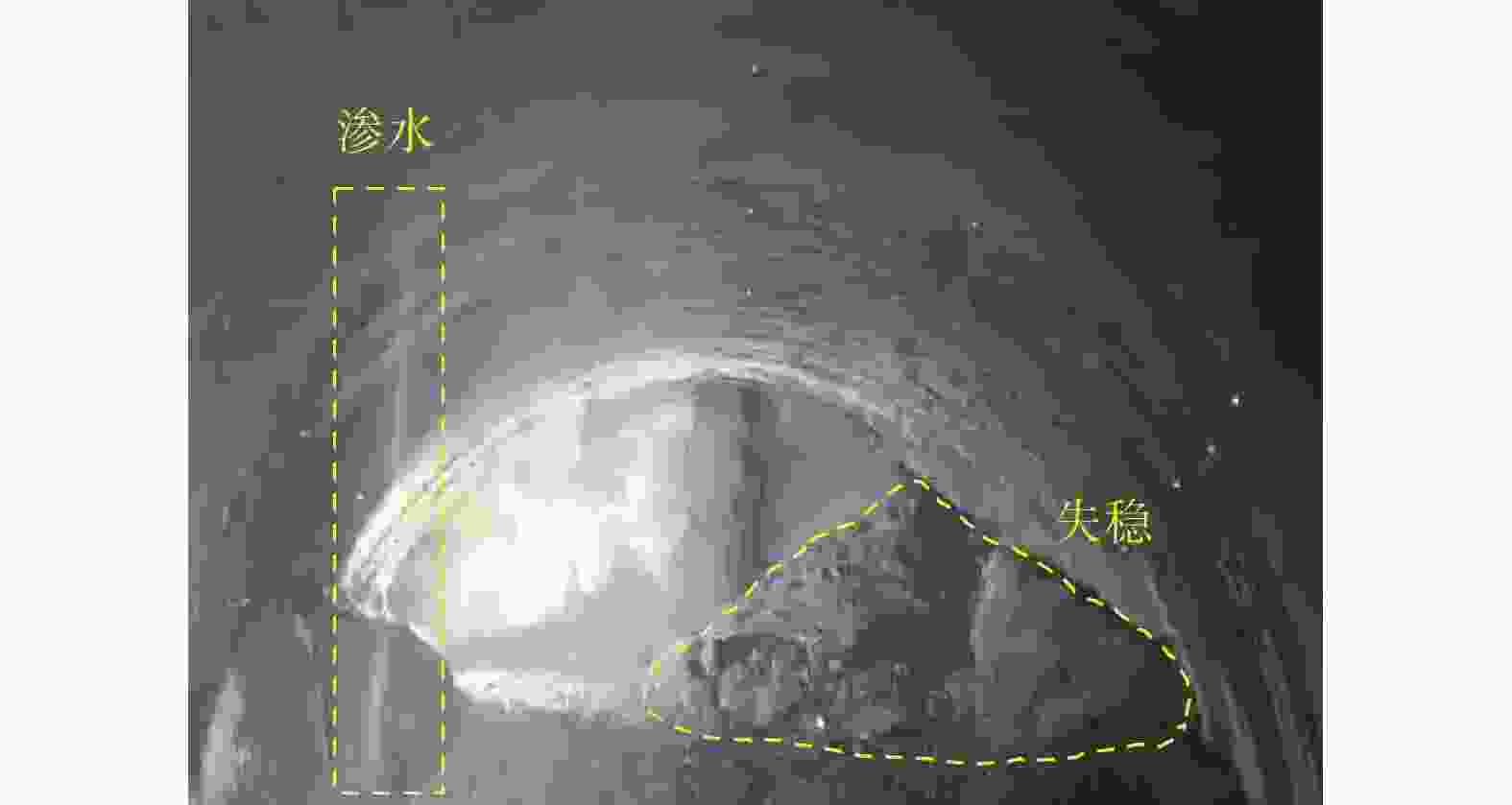

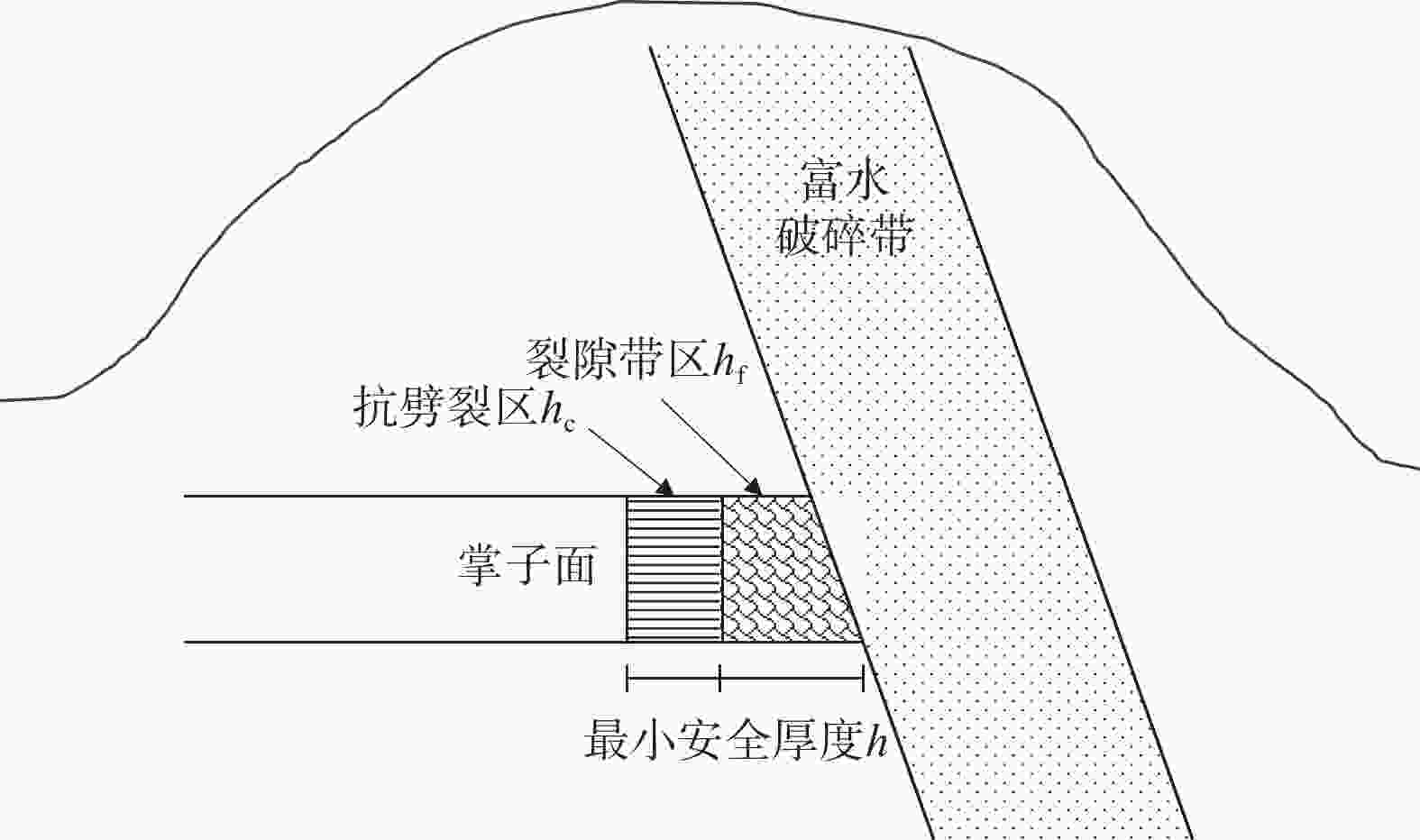

摘要: 隧道穿越富水断层破碎带时,掌子面前方的隔水岩体在高渗压作用下容易发生水力劈裂破坏,诱发围岩塌方突水等灾害。基于翼裂纹模型,文章从断裂力学角度分析了岩体含水裂纹扩展及岩桥贯通破坏机理,并且重点考虑了隧道开挖扰动导致岩体损伤弱化,提出了临近断层隔水岩体的最小抗劈裂厚度计算方法。通过对不同影响因素的敏感性分析,发现岩体抗劈裂厚度随隧道断面尺寸、断层水压力、开挖扰动因子的增大而增大,随隧道竖向应力和岩体强度的增大而减小;同时开挖扰动损伤对于岩体抗劈裂厚度的计算结果影响最为显著。最后,以临近雅拉河断裂的川西某隧道为例,考虑实际工程扰动和断层水压力因素,计算了现场施工风险防控岩盘厚度,进一步为类似工程提供理论借鉴。Abstract:

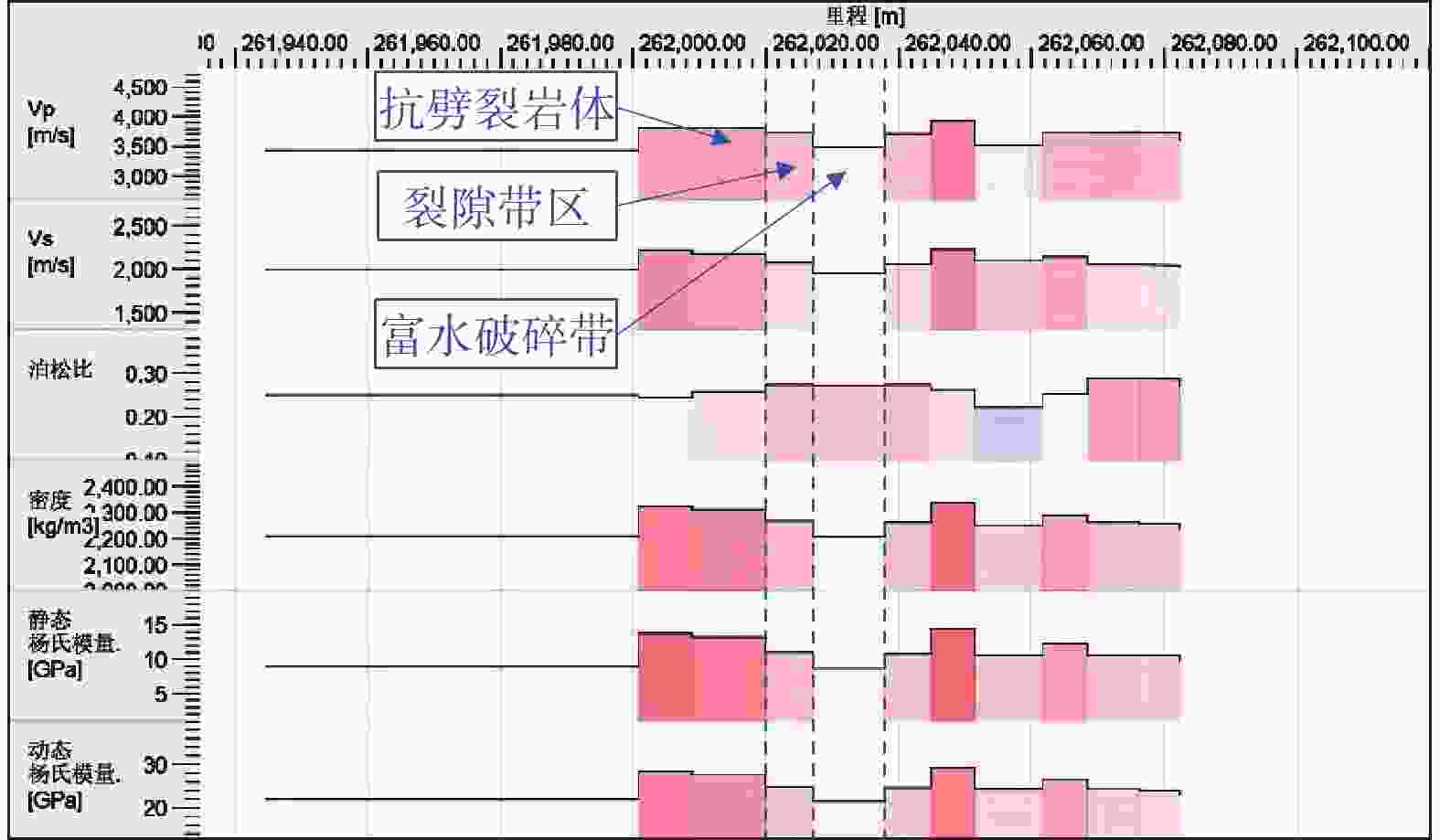

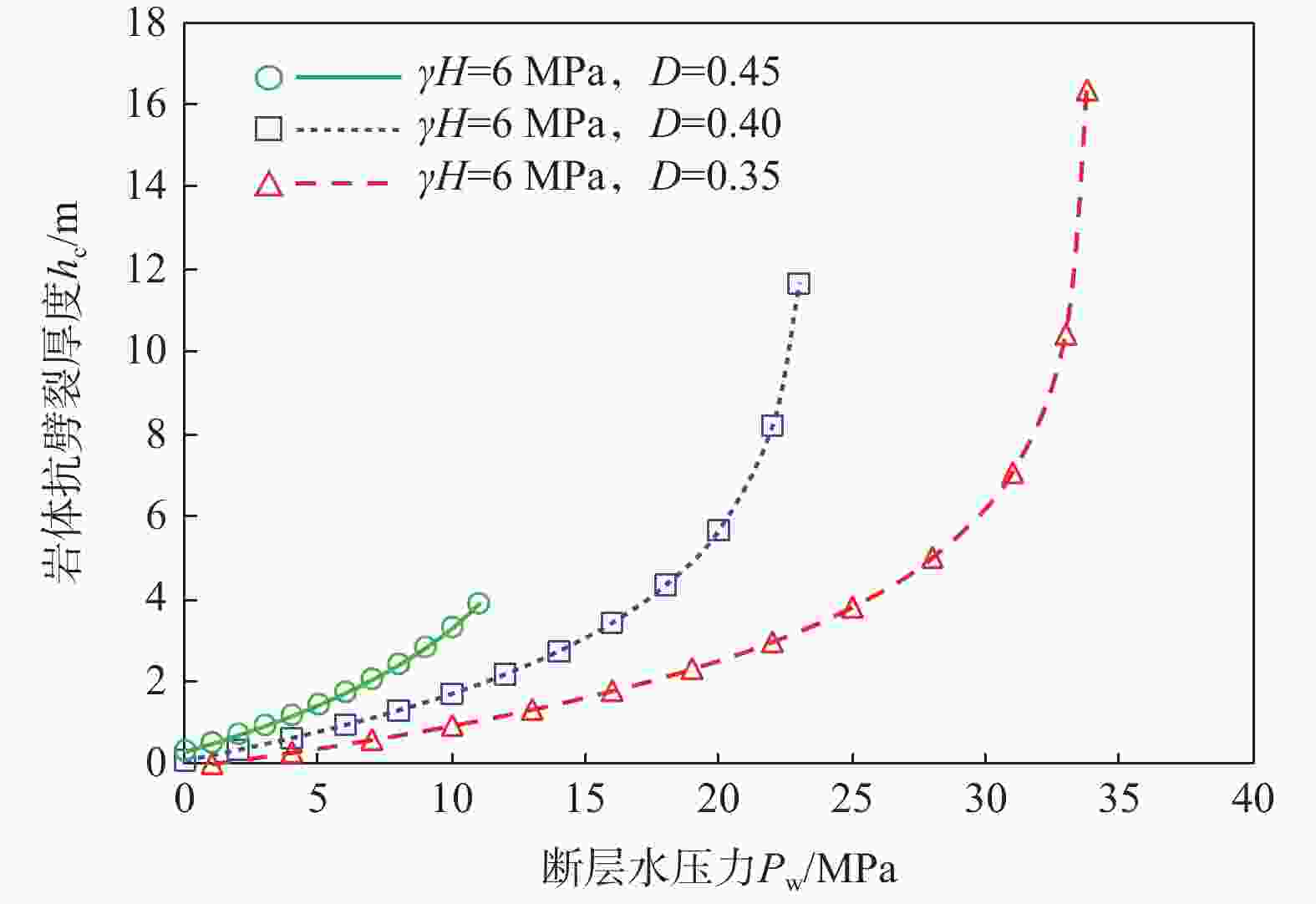

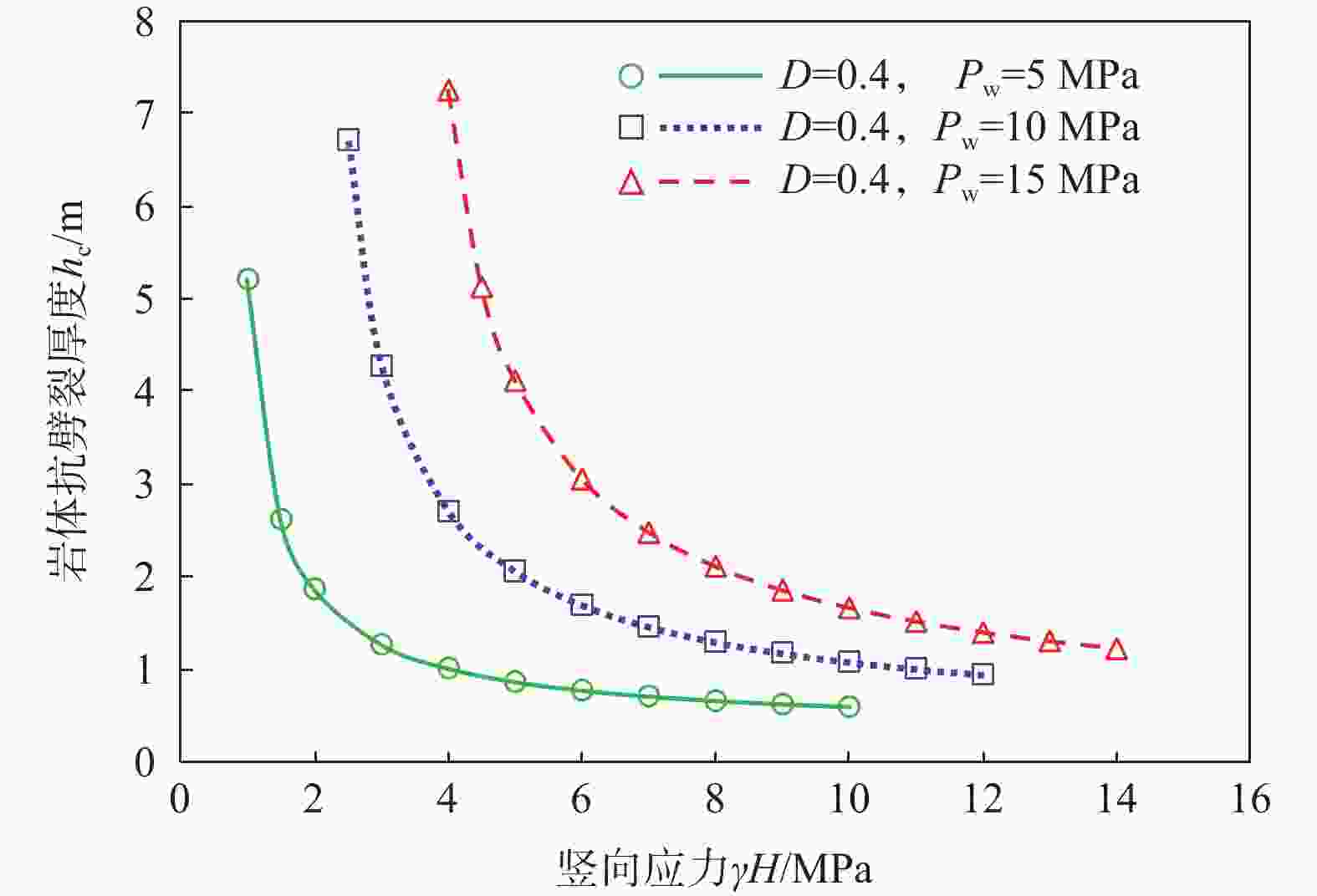

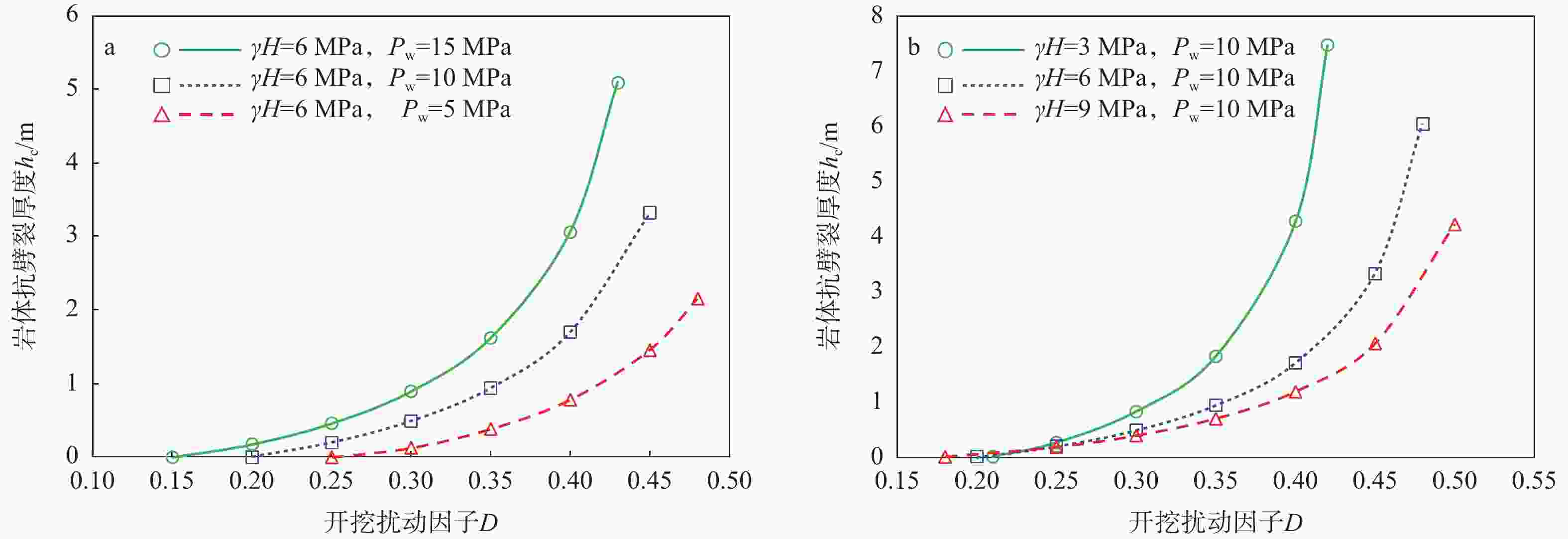

Objective With the relocation of major national strategic plans to western China, railway construction has gradually focused on the complex and dangerous mountainous regions of Yunnan, Sichuan, and Xizang Provinces, where the proportion of tunnels along the railway is very high. When a tunnel passes through a water-rich fault fracture zone, the rock mass in front of the palm face is prone to hydraulic fracturing and damage under high osmotic pressure, leading to disasters such as rock collapse and water inrush. Methods The wing crack model is introduced to fully account for the initiation and propagation of secondary wing cracks in water-saturated fractures, as well as the impact of excavation disturbances. The effective tensile stress and rock bridge size between intermittent fractures in the rock are revised. The tensile-shear failure mechanism of the water-insulating rock mass in front of the tunnel face is analyzed, and the critical water pressure for hydraulic fracturing of the water-insulating rock mass is derived. The minimum safety thickness for the tunnel face against water inrush in the proximity of a fault fracture zone is proposed. Results The theoretical formulas indicate that the anti-splitting thickness of the water-insulating rock mass is related to factors such as tunnel section size, fault water pressure, excavation disturbance, in-situ stress, rock mass strength, crack size, and fracture parameters. Through analysis of the sensitivity of the different influencing factors, it is found that the anti-splitting thickness of the rock mass increases with the increase of the tunnel section size, the fault water pressure, and the excavation disturbance factor, but decreases with the increase of the vertical tunnel stress and the rock mass strength. At the same time, the excavation disturbance damage has the most significant impact on the calculated anti-splitting thickness of the rock mass. Conclusion In practical engineering, there are certain empirical judgments and errors in obtaining excavation disturbance factors via rock integrity assessment and rock wave velocity testing. Therefore, this method requires accurate acquisition of the damage conditions of the rock mass in front of the tunnel face. Various assessment methods can be used for comparison and selection, and a conservative approach can be adopted by using a larger value for the excavation disturbance factor. Significance Finally, taking a tunnel in western Sichuan near the Yalahe fault as an example and considering the actual engineering disturbance and fault water pressure, the minimum safety thickness of the rock wall at the tunnel face is calculated to verify the engineering applicability of the proposed method. This research can effectively guide on-site risk prediction and plan formulation; it provides a theoretical basis for the prevention and control of water inrush in tunnels crossing water-rich fault fracture zones. -

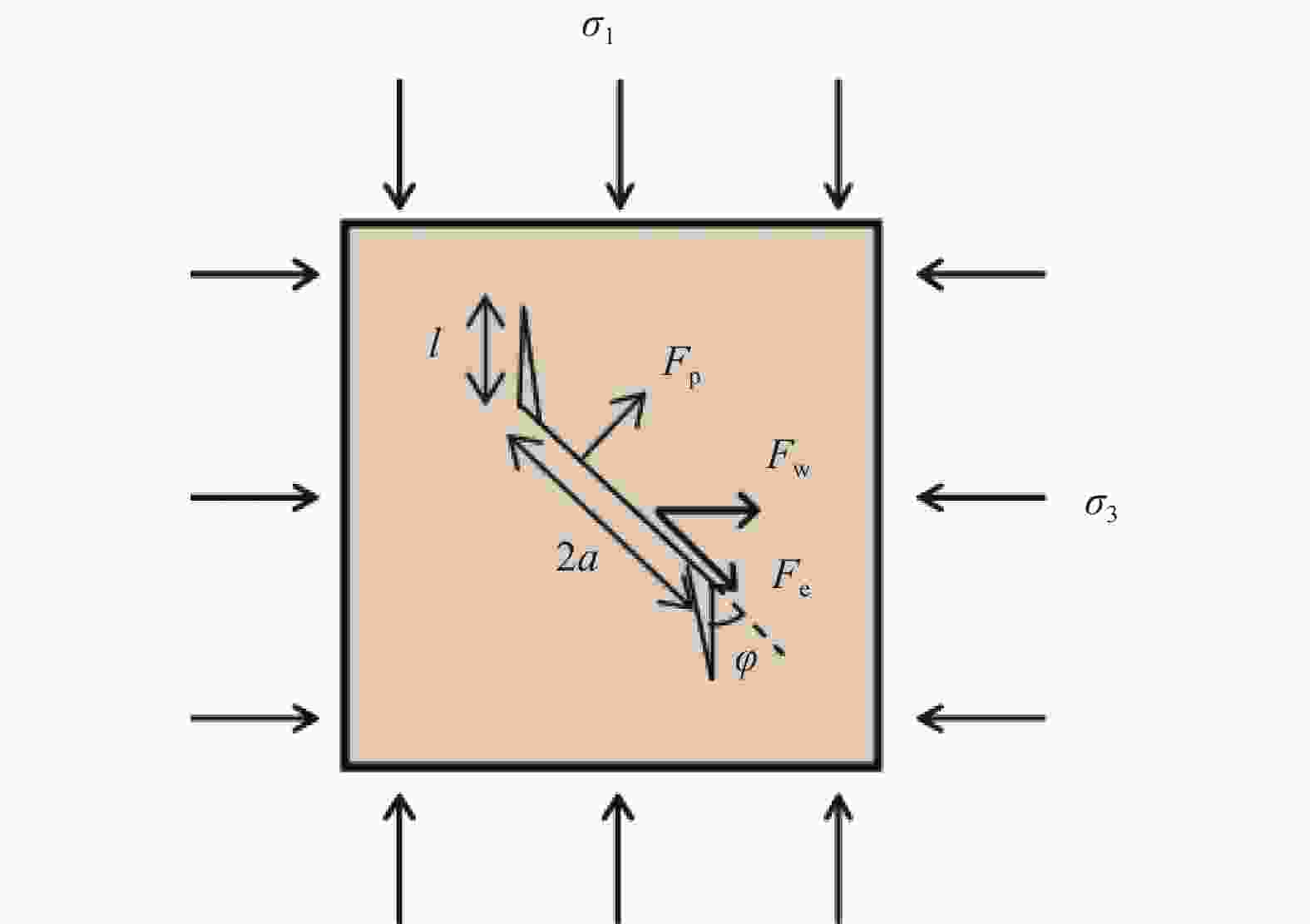

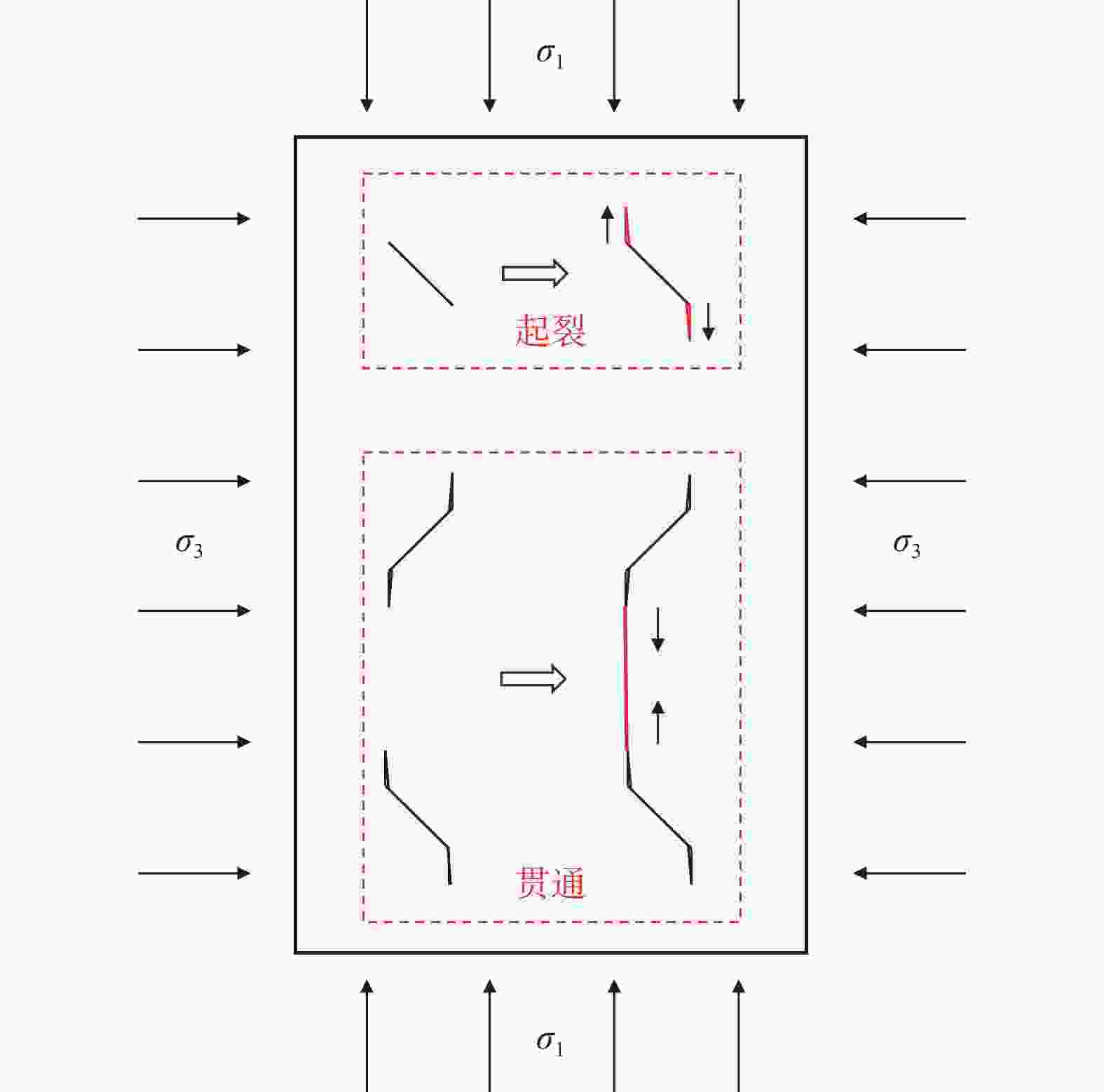

图 2 渗压−应力作用下微裂纹起裂示意图

${\sigma _1}$—最大主应力,MPa;${\sigma _3}$—最小主应力,MPa;$l$—翼裂纹长度,m;$a$—裂纹半径,m;${F_{\mathrm{p}}}$—裂纹有效法向力,N;${F_{\mathrm{e}}}$—裂纹有效切向力,N;${F_{\mathrm{w}}}$—楔入力,N;$\varphi $—裂纹与最大主应力方向的夹角

Figure 2. Schematic diagram of microcrack initiation under osmotic pressure stress

${\sigma _1}$−maximum principal stress, MPa; ${\sigma _3}$−minimum principal stress, MPa; $l$−wing crack length, m; $a$−crack radius, m; ${F_{\mathrm{p}}}$−effective normal force of the crack, N; ${F_{\mathrm{e}}}$−effective tangential force of the crack, N; ${F_{\mathrm{w}}}$−wedging force, N; $\varphi $−angle between the crack and the direction of the maximum principal stress

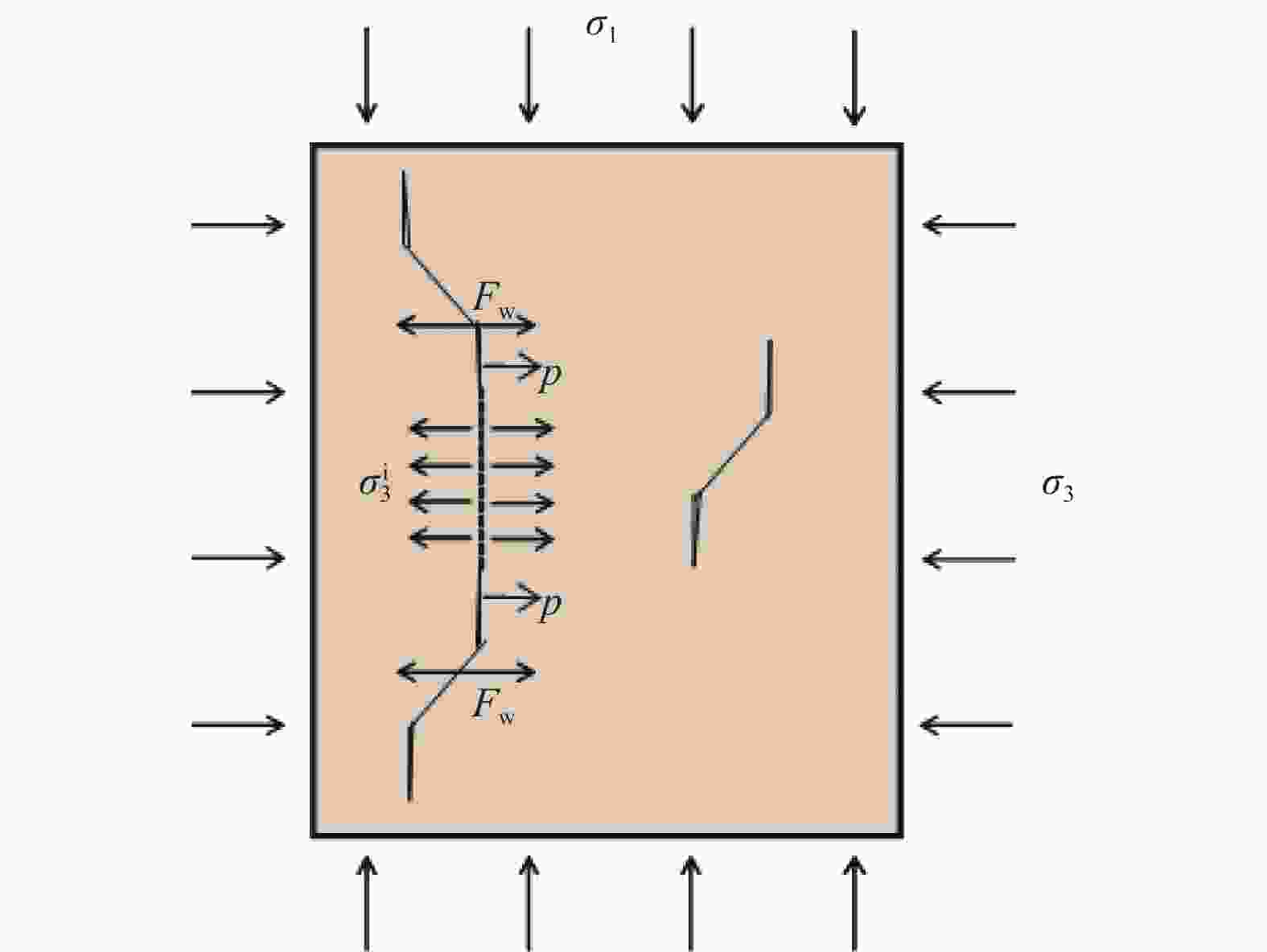

图 3 渗压−应力环境下翼型裂纹扩展贯通示意图

${\sigma _1}$—最大主应力,MPa;${\sigma _3}$—最小主应力,MPa;${F_{\mathrm{w}}}$—楔入力,MPa;$p$—渗压,MPa;$\sigma _3^{\,\mathrm{i}} $—有效张拉应力,MPa

Figure 3. Schematic diagram of wing crack propagation and penetration under an osmotic stress environment

${\sigma _1}$−maximum principal stress, MPa; ${\sigma _3}$−minimum principal stress, MPa; ${F_{\mathrm{w}}}$−wedge force, N; $p$−osmotic pressure, MPa; $\sigma _3^{\mathrm{i}} $−effective tensile stress

图 9 开挖扰动因子对岩体抗劈裂厚度的影响

$\gamma $—岩层容重,N/m3;H—隧道埋深,m;${p_{\mathrm{w}}}$—断层水压力,MPaa—不同断层水压力条件下;b—不同竖向应力条件下

Figure 9. The influence of the excavation disturbance factor on the anti-splitting thickness of a rock mass

(a) Under different fault water pressures; (b) Under different vertical stresses $\gamma $−rock unit weight, N/m3; H −tunnel burial depth, m; ${p_{\mathrm{w}}}$−fault water pressure, MPa

表 1 地质条件计算基本参数表

Table 1. Basic parameters for the geological condition calculation

地应力环境 地下水 掌子面岩体特征 水平应

力/MPa竖向应

力/MPa侧压力

系数地下水

压力/MPa原生裂纹

半径a/m裂纹与最大主

应力夹角φ/(°)翼裂纹

长度l/m裂隙面

摩擦系数岩石单轴抗压

强度/MPa岩石单轴抗拉

强度/MPa完整性

系数7.48 5.81 1.44 0.97 0.8 35 0.1 0.577 9.9 3.8 0.5 -

[1] ASHBY M F, HALLAM S D, 1986. The failure of brittle solids containing small cracks under compressive stress states[J]. Acta Metallurgica, 34(3): 497-510. doi: 10.1016/0001-6160(86)90086-6 [2] ASHBY M F, SAMMIS C G, 1990. The damage mechanics of brittle solids in compression[J]. Pure and Applied Geophysics, 133(3): 489-521. doi: 10.1007/BF00878002 [3] CAI Z Y, QIAO S F, LIU Y Q, 2024. Analysis of disaster mechanism and influence of water inrush in tunnel construction under complex environment[J]. Journal of Railway Science and Engineering, 21(12): 5140-5150. (in Chinese with English abstract [4] GAN K R, YANG Y, LI J S, 2007. Analysis on karst water inflow mechanisms and determination of thickness of safe rock walls: case study on a tunnel[J]. Tunnel Construction, 27(3): 13-16, 50. (in Chinese with English abstract [5] GUO C B, ZHANG Y S, WANG T, et al., 2017. Discussion on geological hazards and major engineering geological problems in the middle part of the north-south active tectonic zone, China[J]. Journal of Geomechanics, 23(5): 707-722. (in Chinese with English abstract [6] GUO J Q, 2011. Study on against-inrush thickness and waterburst mechanism of karst tunnel[D]. Beijing: Beijing Jiaotong University. (in Chinese with English abstract [7] GUO J Q, QIAO C S, 2012. Study on water-inrush mechanism and safe thickness of rock wall of karst tunnel face[J]. Journal of the China Railway Society, 34(3): 105-111. (in Chinese with English abstract [8] GUO J Q, CHEN J X, CHEN F, et al., 2018. Water inrush criterion and catastrophe process of a karst tunnel face with non-persistent joints[J]. China Journal of Highway and Transport, 31(10): 118-129. (in Chinese with English abstract [9] HE C H, 2022. Study on the safe thickness of water-resisting rock mass and water inrush mechanism of water-filling karst cave tunnel[D]. Chongqing: Chongqing University. (in Chinese with English abstract [10] JIANG H M, LI L, RONG X L, et al., 2017. Model test to investigate waterproof-resistant slab minimum safety thickness for water inrush geohazards[J]. Tunnelling and Underground Space Technology, 62: 35-42. doi: 10.1016/j.tust.2016.11.004 [11] KONG F M, 2022. Hazard-causing mechanism of dynamic water and mud inrush triggered by deep buried tunnel of Sichuan-Tibet railway crossing active fault[D]. Ji’nan: Shandong University. (in Chinese with English abstract [12] LI J, LU H, XIA Y P, 2014. Survey and research on estimation method of against-inrush safe thickness of rock strata in karst tunnels[J]. Tunnel Construction, 34(9): 862-872. (in Chinese with English abstract [13] LI L, RONG X L, WANG M Y, et al., 2016. Development and application of 3D model test system for water inrush geohazards in long and deep tunnels[J]. Chinese Journal of Rock Mechanics and Engineering, 35(3): 491-497. (in Chinese with English abstract [14] LI L P, ZHU Y Z, ZHOU Z Q, et al. , 2020. Calculation methods of rock thickness for preventing water inrush in tunnels and their applicability evaluation[J]. Rock and Soil Mechanics, 41(S1): 41-50, 170. (in Chinese with English abstract [15] LI S C, YUAN Y C, LI L P, et al., 2015. Water inrush mechanism and minimum safe thickness of rock wall of karst tunnel face under blast excavation[J]. Chinese Journal of Geotechnical Engineering, 37(2): 313-320. (in Chinese with English abstract [16] LI S C, WANG J, LI L P, et al., 2019. The theoretical and numerical analysis of water inrush through filling structures[J]. Mathematics and Computers in Simulation, 162: 115-134. doi: 10.1016/j.matcom.2018.12.014 [17] LI X P, LI Y N, 2014. Research on risk assessment system for water inrush in the karst tunnel construction based on GIS: case study on the diversion tunnel groups of the Jinping II Hydropower Station[J]. Tunnelling and Underground Space Technology, 40: 182-191. doi: 10.1016/j.tust.2013.10.005 [18] LI X Z, QI C Z, SHAO Z S, 2020. Study on strength weakening model induced by microcrack growth in rocks[J]. Chinese Journal of Underground Space and Engineering, 16(1): 26-34. (in Chinese with English abstract [19] LI X Z, ZHANG Q S, CAI B C, et al., 2023. A static creep fracture model after dynamic damage in brittle rocks[J]. Chinese Journal of Theoretical and Applied Mechanics, 55(4): 903-914. (in Chinese with English abstract [20] LUO L R, LIU Z G, 2009. Influence of fault crush belts on the stability of tunnel rock[J]. Journal of Geomechanics, 15(3): 226-232. (in Chinese with English abstract [21] MA J F, LI X Q, ZHANG C C, et al., 2022. Characterization of karst development and groundwater circulation in the middle part of the Jinshajiang fault zone[J]. Journal of Geomechanics, 28(6): 956-968. (in Chinese with English abstract [22] SUN L J, ZHAO Z B, PAN J W, et al., 2021. The stress and strain state of Yalahe fault in the Kangding segment of the Xianshuihe fault zone and its seismogenic environment[J]. Acta Petrologica Sinica, 37(10): 3225-3240. (in Chinese with English abstract doi: 10.18654/1000-0569/2021.10.15 [23] WANG J, CUI J Y, CHEN Z L, et al., 2021. Prediction formula of critical safety thickness of tunnel water inrush in water-rich fault zone[J]. Tunnel Construction, 41(S1): 256-264. (in Chinese with English abstract [24] WU Z S, LI S, TU Y L, et al. , 2020. Study on safety thickness theory of palm surface outburst prevention based on unified strength theory[J]. Chinese Journal of Underground Space and Engineering, 16(6): 1705-1710, 1721. (in Chinese with English abstract [25] XIAO K, ZHANG Z T, ZHA E S, et al., 2023. A non-linear creep model considering disturbance damage at different depths[J]. Thermal Science, 27(5A): 3863-3868. [26] XIAO Q F, LI W L, FU W X, et al., 2022. Analytical solution to the minimum safe thickness of circular tunnel anti-inrushing structure in water-rich area[J]. Advanced Engineering Sciences, 54(3): 159-168. (in Chinese with English abstract [27] XIAO X, ZHAO X Y, ZHANG J F, et al., 2022. Classification of water inrush failure mode and rock thickness for preventing water inrush in karst tunnels[J]. Journal of Engineering Geology, 30(2): 459-474. (in Chinese with English abstract [28] YANG Z H, YANG X L, XU J S, et al., 2017. Two methods for rock wall thickness calculation in karst tunnels based on upper bound theorem[J]. Rock and Soil Mechanics, 38(3): 801-809. (in Chinese with English abstract [29] ZENG Y, 2015. Study on the calculation method of safe thickness of rock masses in karst tunnels and the mechanism of water inrush disasters[D]. Chengdu: Southwest Petroleum University. (in Chinese t [30] ZHA E S, 2022. Seepage-creep behavior of marble under environments with disturbance conditions corresponding to different depths[D]. Chengdu: Sichuan University. (in Chinese with English abstract [31] ZHANG A L, XIE H P, ZHANG Z T, et al., 2024. Mechanical responses in rocks with different lithologies under mining loading–unloading: an insight by energy damage and ultrasonic characterization[J]. Rock Mechanics and Rock Engineering, 57(11): 10047-10069. doi: 10.1007/s00603-024-04081-4 [32] ZHENG X Y, SHI C H, WANG Z X, et al., 2023. Calculation method for safe thickness of water insulation rock in tunnelling based on timoshenko beam theory[J]. Modern Tunnelling Technology, 60(4): 14-22. (in Chinese with English abstract [33] ZHOU Z Q, LI L P, SHI S S, et al., 2020. Study on tunnel water inrush mechanism and simulation of seepage failure process[J]. Rock and Soil Mechanics, 41(11): 3621-3631. (in Chinese with English abstract [34] ZHU C Y, YU S C, 2001. Study on the criterion of rockmass damage caused by blasting[J]. Engineering Blasting, 7(1): 12-16. (in Chinese with English abstract [35] 蔡子勇,乔世范,刘屹颀,2024. 复杂环境下隧道施工涌水致灾机理及影响分析[J]. 铁道科学与工程学报,21(12):5140-5150. [36] 干昆蓉,杨毅,李建设,2007. 某隧道岩溶突水机理分析及安全岩墙厚度的确定[J]. 隧道建设,27(3):13-16,50. doi: 10.3969/j.issn.1672-741X.2007.03.004 [37] 郭长宝,张永双,王涛,等,2017. 南北活动构造带中段地质灾害与重大工程地质问题概论[J]. 地质力学学报,23(5):707-722. doi: 10.3969/j.issn.1006-6616.2017.05.008 [38] 郭佳奇,2011. 岩溶隧道防突厚度及突水机制研究[D]. 北京:北京交通大学. [39] 郭佳奇,乔春生,2012. 岩溶隧道掌子面突水机制及岩墙安全厚度研究[J]. 铁道学报,34(3):105-111. doi: 10.3969/j.issn.1001-8360.2012.03.018 [40] 郭佳奇,陈建勋,陈帆,等,2018. 岩溶隧道断续节理掌子面突水判据及灾变过程[J]. 中国公路学报,31(10):118-129. doi: 10.3969/j.issn.1001-7372.2018.10.011 [41] 贺辰昊,2022. 充水溶洞隧道掌子面隔水岩体安全厚度及突水机理研究[D]. 重庆:重庆大学. [42] 孔凡猛,2022. 川藏铁路深埋隧道穿越活动断裂动力突水突泥致灾机理研究[D]. 济南:山东大学. [43] 李集,卢浩,夏沅谱,2014. 岩溶隧道防突安全厚度研究综述及估算方法探讨[J]. 隧道建设,34(9):862-872. [44] 李浪,戎晓力,王明洋,等,2016. 深长隧道突水地质灾害三维模型试验系统研制及其应用[J]. 岩石力学与工程学报,35(3):491-497. [45] 李利平,朱宇泽,周宗青,等,2020. 隧道突涌水灾害防突厚度计算方法及适用性评价[J]. 岩土力学,41(S1):41-50,170. [46] 李术才,袁永才,李利平,等,2015. 钻爆施工条件下岩溶隧道掌子面突水机制及最小安全厚度研究[J]. 岩土工程学报,37(2):313-320. [47] 李晓照,戚承志,邵珠山,2020. 岩石裂纹扩展诱发的强度弱化模型研究[J]. 地下空间与工程学报,16(1):26-34. [48] 李晓照,张骐烁,柴博聪,等,2023. 动力损伤后的脆性岩石静力蠕变断裂模型研究[J]. 力学学报,55(4):903-914. doi: 10.6052/0459-1879-22-597 [49] 罗利锐,刘志刚,2009. 断层对隧道围岩稳定性的影响[J]. 地质力学学报,15(3):226-232. doi: 10.3969/j.issn.1006-6616.2009.03.004 [50] 马剑飞,李向全,张春潮,等,2022. 金沙江断裂带中段岩溶发育和地下水循环特征[J]. 地质力学学报,28(6):956-968. [51] 孙丽静,赵中宝,潘家伟,等,2021. 鲜水河断裂带康定段雅拉河断裂深部应力应变状态及其孕震环境[J]. 岩石学报,37(10):3225-3240. [52] 王军,崔江余,陈泽龙,等,2021. 富水断层带隧道突水临界安全厚度预测公式研究[J]. 隧道建设(中英文),41(S1):256-264. [53] 吴祖松,李松,涂义亮,等,2020. 统一强度理论下掌子面防突安全厚度理论研究[J]. 地下空间与工程学报,16(6):1705-1710,1721. [54] 肖前丰,李文龙,符文熹,等,2022. 富水构造区圆形隧道抗突体最小安全厚度解析解[J]. 工程科学与技术,54(3):159-168. [55] 肖喜,赵晓彦,张巨峰,等,2022. 岩溶隧道涌突水破坏模式分类及防突厚度研究[J]. 工程地质学报,30(2):459-474. [56] 杨子汉,杨小礼,许敬叔,等,2017. 基于上限原理的两种岩溶隧道岩墙厚度计算方法[J]. 岩土力学,38(3):801-809. [57] 曾艺,2015. 岩溶隧道岩盘安全厚度计算方法及突水灾害发生机理研究[D]. 成都:西南石油大学. [58] 查尔晟,2022. 不同深度环境及扰动条件下大理岩渗流-蠕变力学行为研究[D]. 成都:四川大学. [59] 郑晓悦,施成华,王祖贤,等,2023. 基于Timoshenko梁理论的隧道隔水岩体安全厚度计算方法[J]. 现代隧道技术,60(4):14-22. [60] 周宗青,李利平,石少帅,等,2020. 隧道突涌水机制与渗透破坏灾变过程模拟研究[J]. 岩土力学,41(11):3621-3631. [61] 朱传云,喻胜春,2001. 爆破引起岩体损伤的判别方法研究[J]. 工程爆破,7(1):12-16. -

下载:

下载: