In-situ stress state in critical areas of the Taiyuan pumped storage power station and its application in pivot project layout

-

摘要:

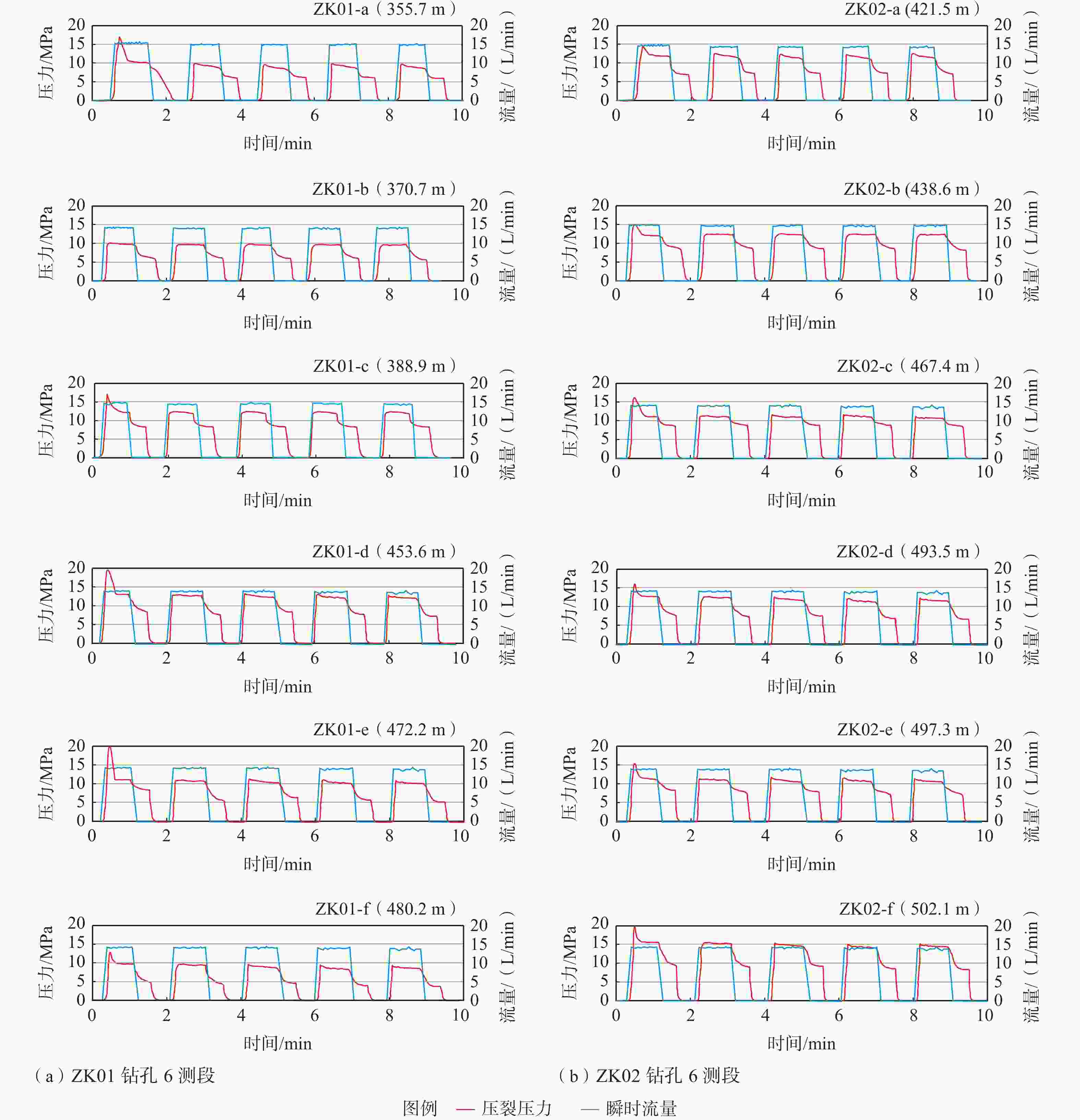

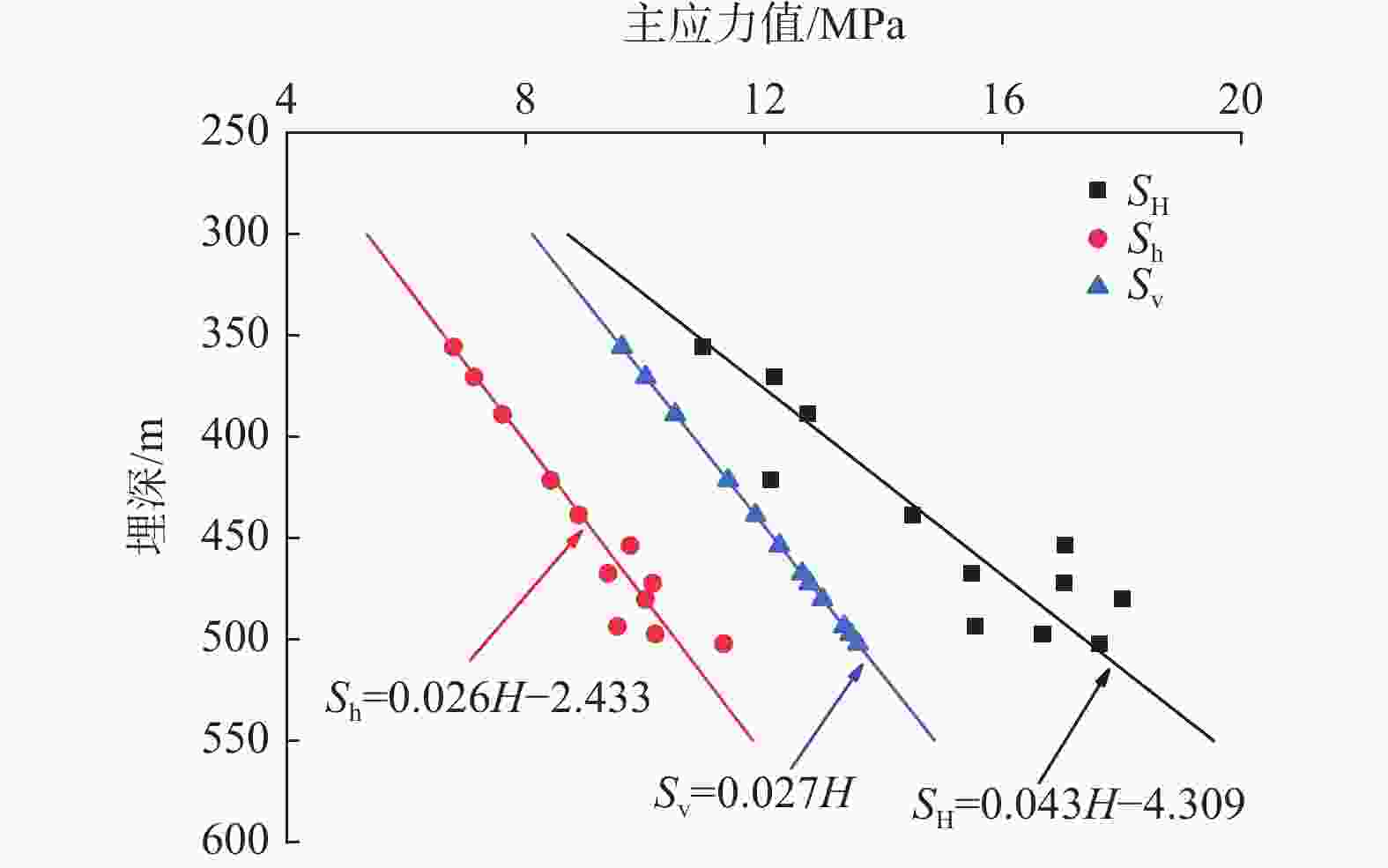

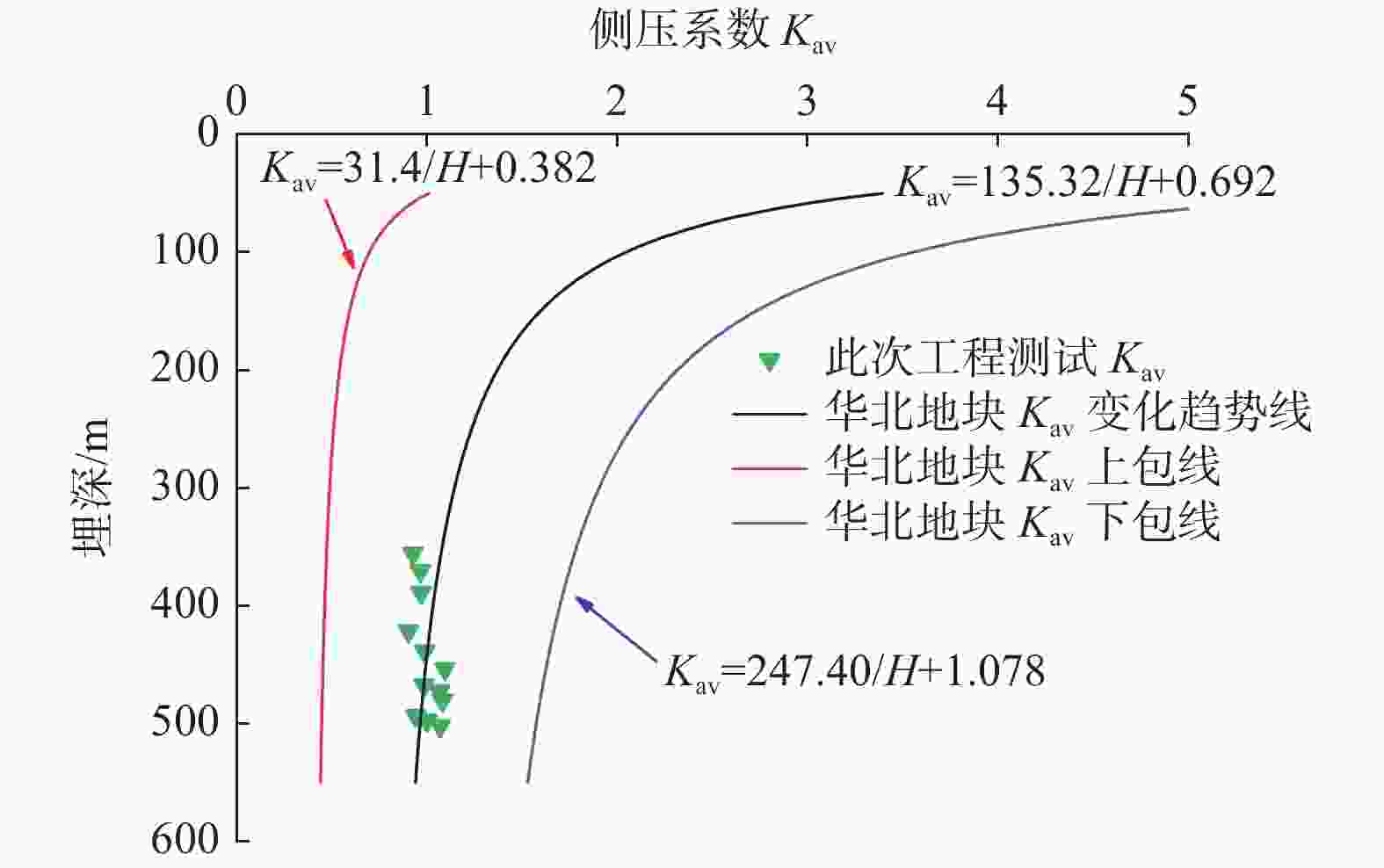

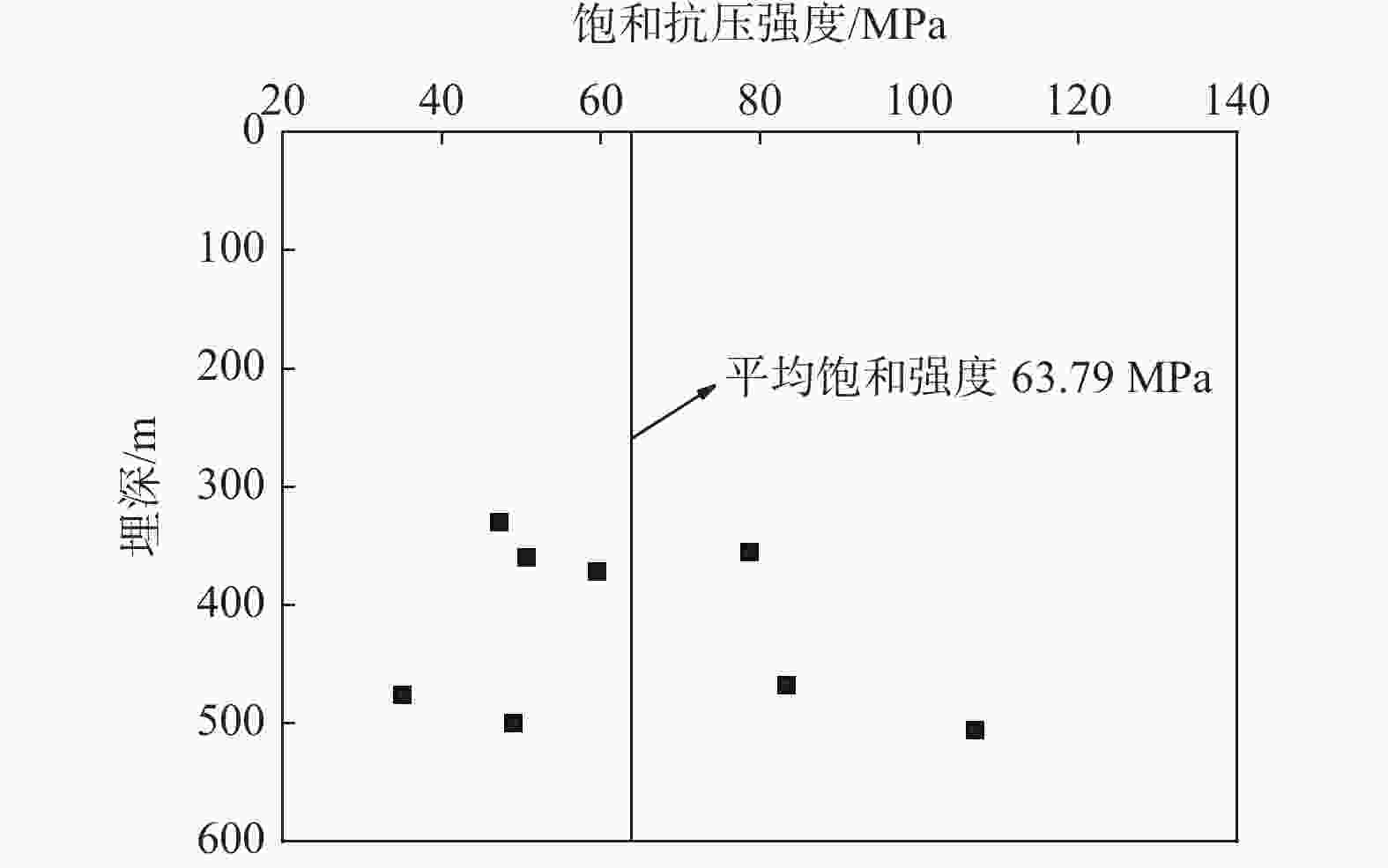

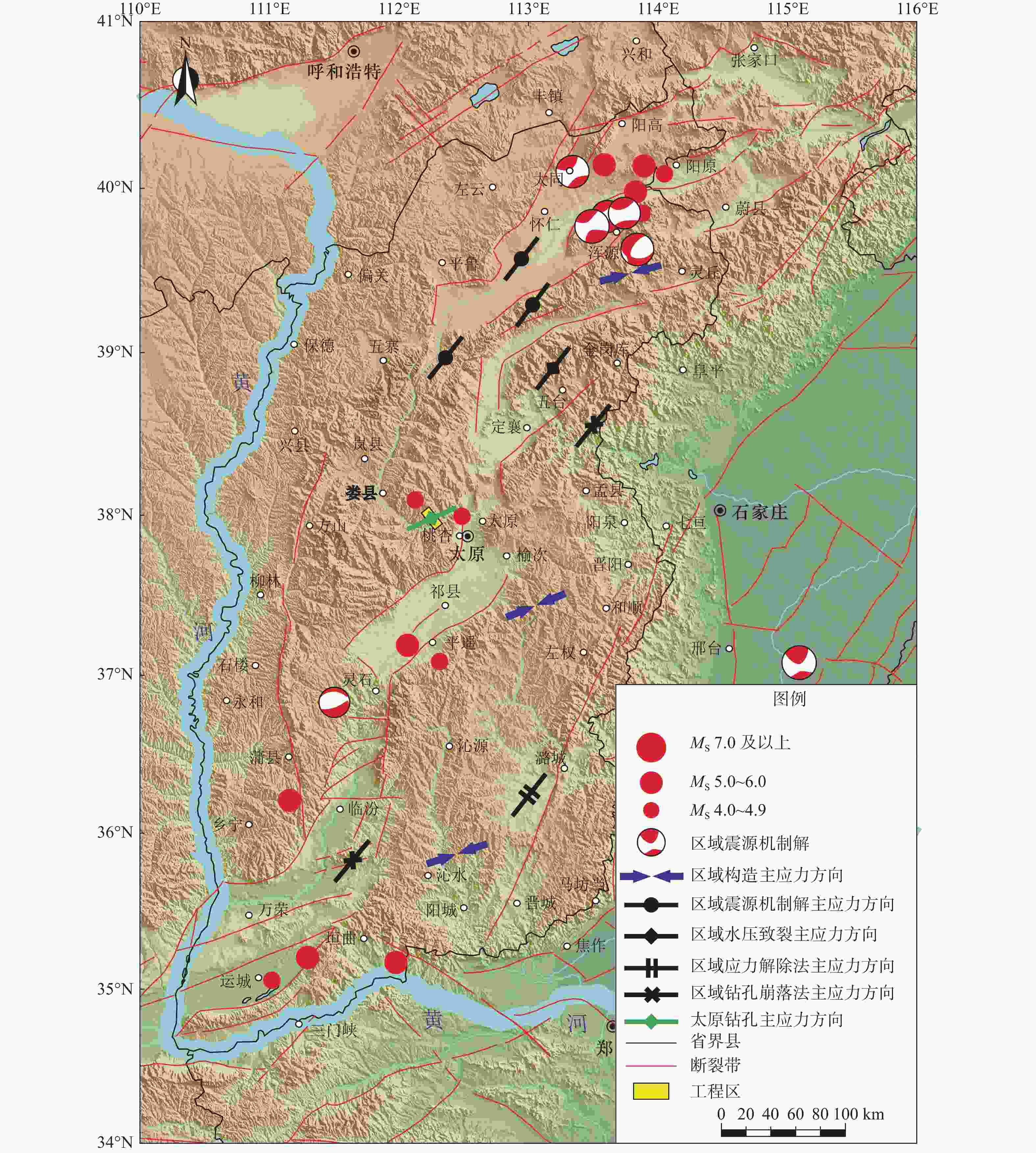

采用水压致裂地应力测试技术,开展了山西太原抽水蓄能电站工程2个孔(孔深500 m和520 m)的地应力测试工作,获得了工程区关键部位地应力状态,分析了工程区的地应力水平、地下建筑布设方式和衬砌形式。结果表明:工程区最大水平主应力为10.98~18.09 MPa,最小水平主应力为6.79~11.32 MPa,垂直主应力9.61~13.57 MPa;与山西省南北两端“南高北低”地应力值相比,此次测值处于两者之间,与沁水盆地地应力场模拟值相比,测试结果基本一致;垂直应力介于最大水平主应力和最小水平主应力之间(SH>Sv>Sh),即测点的最大水平应力即最大主应力,且处于走滑型应力状态,其侧压系数Kav为0.92~1.09,反映出工程区构造作用不强烈;2个钻孔330 ~506 m范围内岩石饱和单轴抗压强度(Rb)为35.00~107.00 MPa,平均为63.79 MPa,岩石饱和单轴抗压强度与最大主应力比值(Rb/σm)为3.54~5.81,属于中—高应力水平;工程区最大水平主应力方向为NE 43°—NE 70.5°,平均为NE 59.5°,与区域震源机制解、GPS位移资料研究结果一致;从地应力方位考虑,地下厂房长轴线方向位于NE 29.5°—NE 89.5°之间,有利于厂房的围岩稳定;地下枢纽工程最大水头PH约为4.62 MPa,小于最小主应力值σ3(6.79~11.32 MPa),基于水力劈裂准则可知,岩体本身具有足够抵抗最大内水压力能力,输水隧洞采用钢筋混凝土衬砌,能够满足输水隧洞的稳定性。该研究成果可在抽水蓄能电站工程勘察、设计中推广使用。

Abstract:The hydraulic fracturing in-situ stress testing technology was used to test two boreholes (500-meter and 520-meter deep) at the Taiyuan pumped storage power station in Shanxi Province. The in-situ stress state of critical areas was obtained, and the ground stress level, underground building layout, and lining form in the project area were analyzed. The results show that the maximum horizontal principal stress ranges from 10.98 to 18.09 MPa, the minimum horizontal principal stress from 6.79 to 11.32 MPa, and the vertical principal stress from 9.61 to 13.57 MPa. Compared with the high and low in-situ stress values at the north and south ends of Shanxi Province, respectively, the measured values are between; Compared with the simulated in-situ stress field in the Qinshui Basin, the test results are basically consistent. The vertical stress values are between the maximum horizontal principal stress values and the minimum horizontal principal stress values (SH>Sv>Sh), which means the maximum horizontal stress at the measuring point is the maximum principal stress and is in the strike-slip stress state. Its lateral pressure coefficient Kav is between 0.92 and 1.09, reflecting that the tectonic action in the engineering area is not intense. In the range of 330–506 meters, the saturated uniaxial compressive strength of the two boreholes is betwwen 35 and 107 MPa, with an average of 63.79 MPa, and the ratio of the saturated strength to the maximum principal stress (

\begin{document}$ {{R}_{\mathrm{b}}} $\end{document} /σm) is between 3.54 and 5.81, belonging to the medium–high stress level. The direction of the maximum horizontal principal stress in the project area is NE 43° to NE 70.5°, and the average is NE 59.5°, consistent with the regional focal mechanism solution and GPS displacement data. From the perspective of in-situ stress orientation, the average direction of the maximum principal stress in the engineering area is NE 59.5°, and the direction of the long axis of the underground powerhouse is between NE 29.5° and NE 89.5°, which is conducive to the stability of the surrounding rock of the powerhouse. The maximum water head PH of the underground hub project is about 4.62 MPa (i.e., PH <σ3). Based on the hydraulic splitting criterion, it can be seen that the rock mass can resist the maximum internal water pressure, and the reinforced concrete lining of the water transmission tunnel can satisfy the stability of the water transmission tunnel. The research results can be widely used in investigating and designing pumped storage power station projects.

-

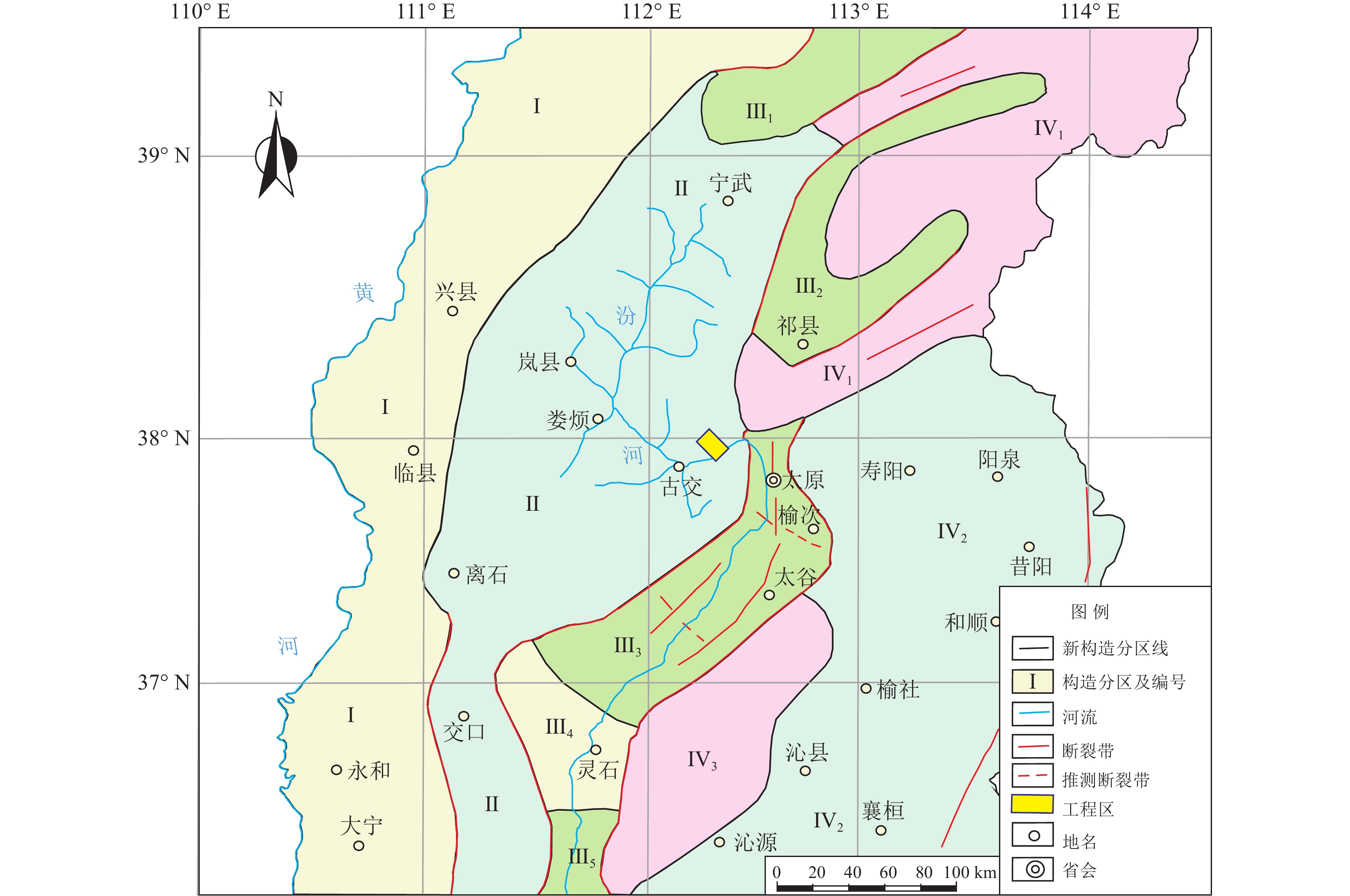

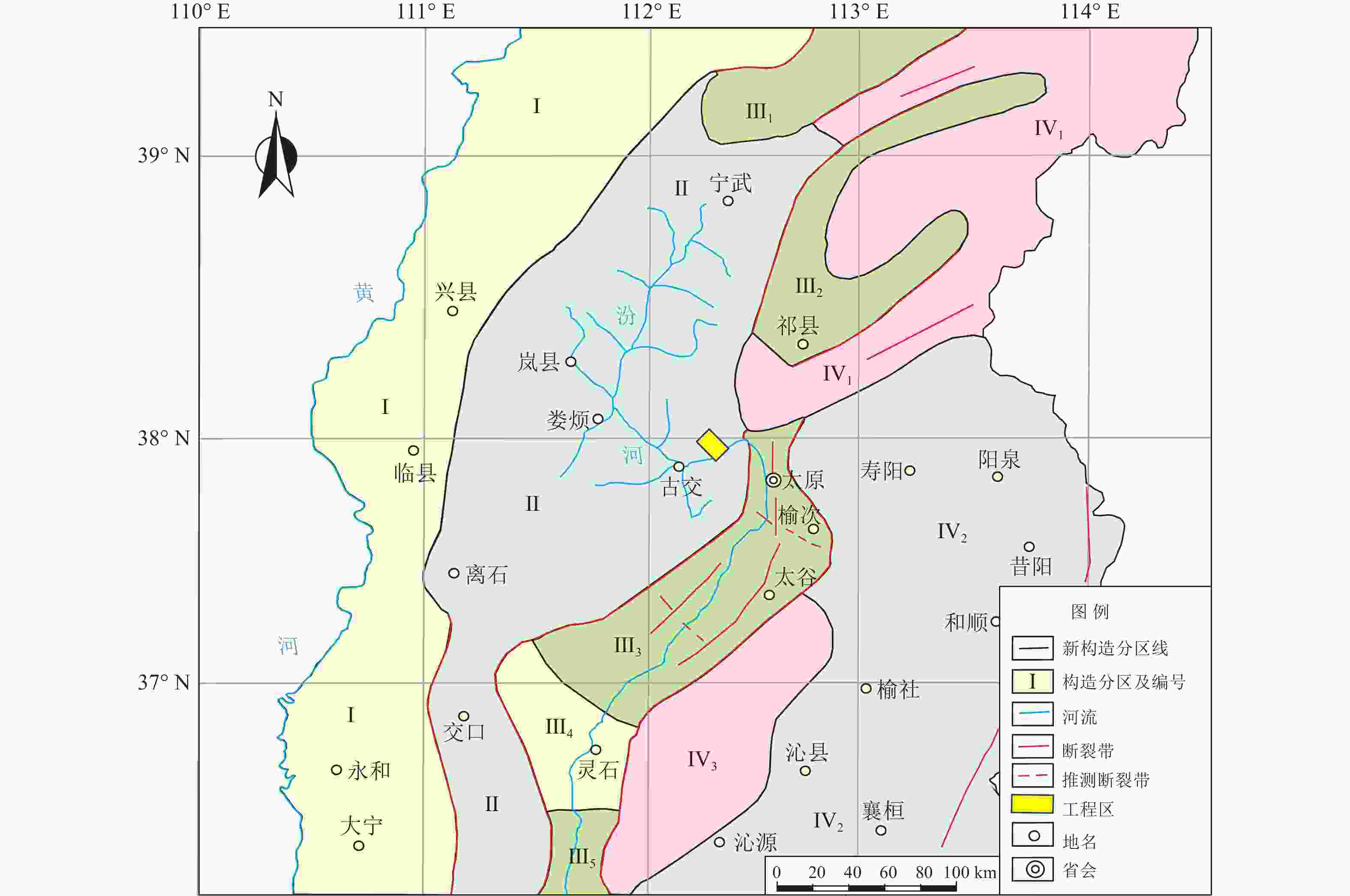

图 1 工程区及其周缘区域地质构造特征

Ⅰ—鄂尔多斯断块隆起区;Ⅱ—吕梁山断块隆起区,Ⅲ—汾渭断陷带;Ⅲ1—大同断陷盆地;Ⅲ2—忻定断陷盆地;Ⅲ3—晋中新裂陷−太原断陷盆地;Ⅲ4—韩侯岭横向隆起;Ⅳ—太行山断块隆起区;Ⅳ1—恒山、五台山隆起区;Ⅳ2—晋东南太行山隆起区;Ⅳ3—太岳山隆起区;Ⅲ5—临汾断陷盆地

Figure 1. Geological and tectonic characteristics of the project area and its surrounding area

Ⅰ–Erdos block upwarping; Ⅱ–Lyuliangshan block upwarping, Ⅲ–Fenwei fault depression basin; Ⅲ1–Datong fault basin; Ⅲ2–Xining fault basin; Ⅲ3–New Rift zone–Taiyuan fault basin in central Shanxi; Ⅲ4–Hanhouling transverse uplift; Ⅳ–Taihangshan fault block upwarping; Ⅳ1–Hengshan–Wutaishan uplift zone; Ⅳ2–Taihangshan uplift zone in southeastern Shanxi; Ⅳ3 –Taiyueshan uplift area; Ⅲ5–Linfen fault basin

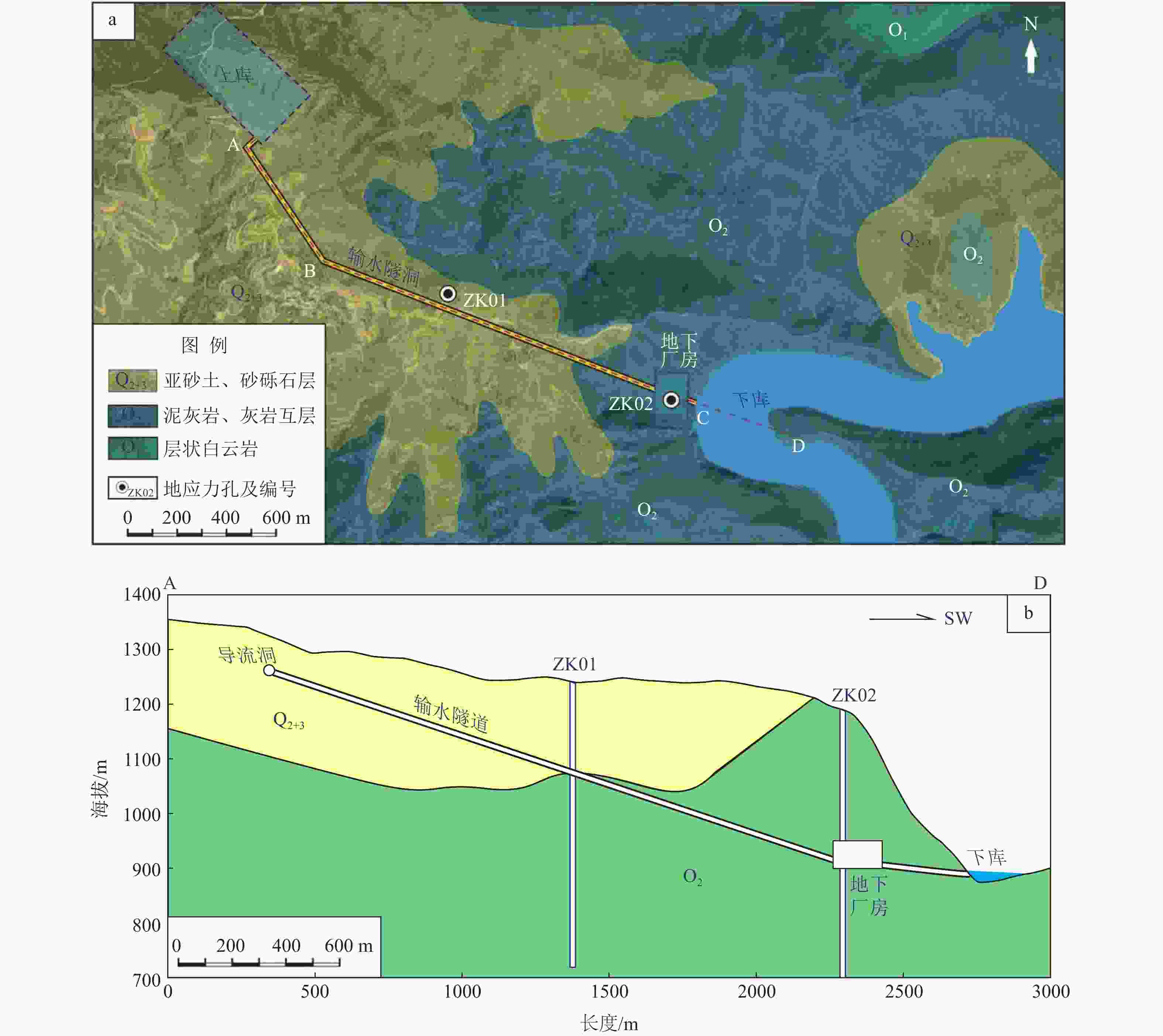

图 2 抽水蓄能电站工程区地层岩性及枢纽设施布设示意图

a—抽水蓄能电站工程区地层岩性示意图;b—抽水蓄能电站工程枢纽设施布设示意图

Figure 2. Schematic diagram of formation lithology and layout of hub facilities in the engineering area of pumped storage power station

(a) Schematic diagram of stratum lithology in the project area of the pumped storage power station; (b) Schematic diagram of the pivot facility layout of the pumped storage power station

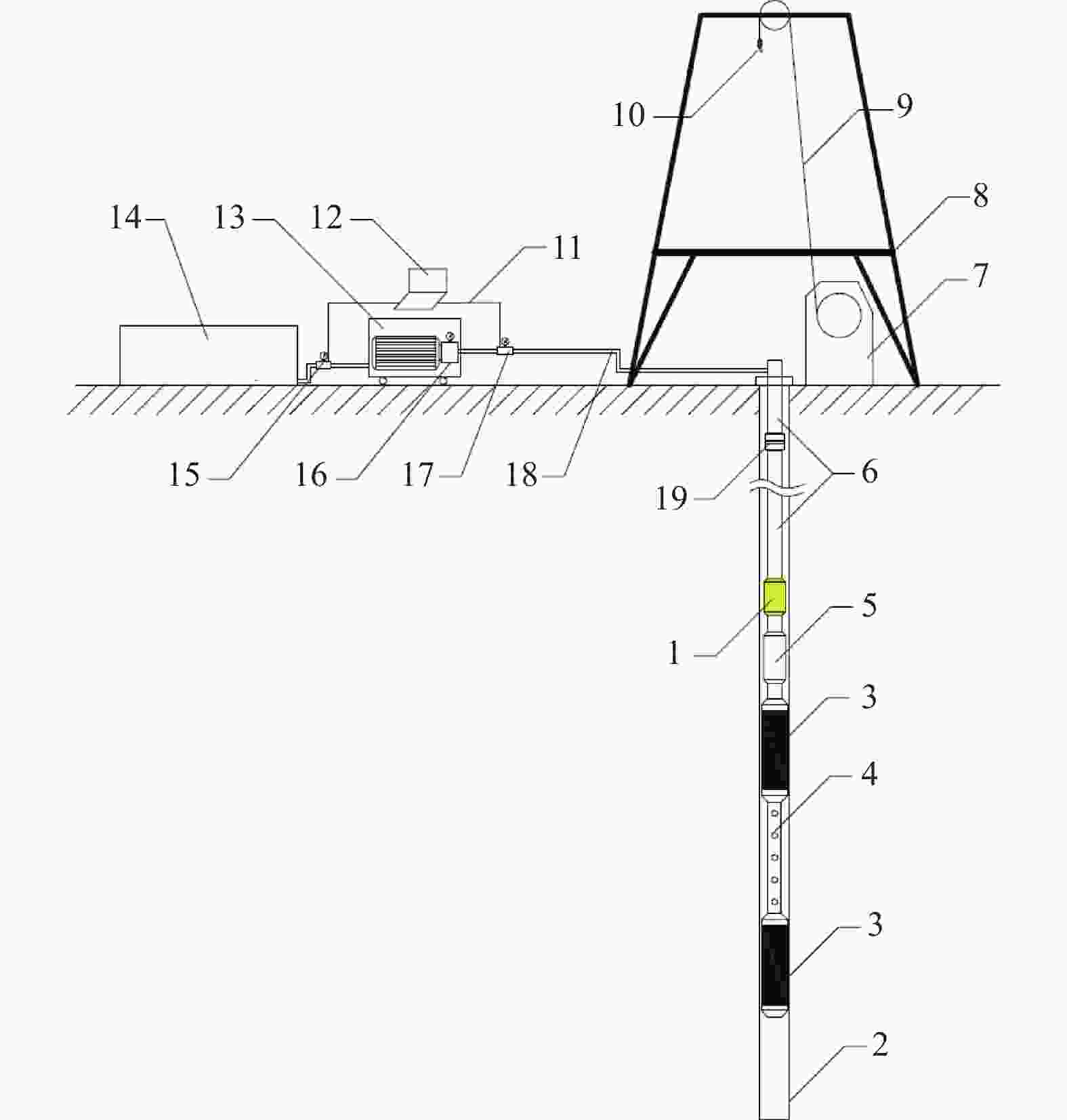

图 3 单回路水压致裂地应力测试系统示意图

1—封隔栓塞组件卸压装置;2—无水钻孔;3—封隔栓塞组件;4—压裂测试段;5—推拉开关;6—钻杆;7—钻机;8—钻塔;9—钢丝绳;10—提升器;11—数据线;12—笔记本电脑;13—高压泵;14—水箱;15—电子流量计;16—高压泵泵头、压力表;17—数字压力计;18—高压管路;19—钻杆接头

Figure 3. Schematic diagram of single-loop hydraulic fracturing in-situ stress test system

1−pressure relief device for packers; 2−waterless borehole; 3−packers; 4−fracturing test section; 5−push-pull switch; 6−drill pipe; 7−drill rig; 8−drill tower; 9−steel wire rope; 10−hoist; 11−data line; 12−laptop; 13−pump; 14−water tank; 15−flowmeter; 16−pump head/pressure gauge; 17−digital pressure gauge; 18−pipeline; 19−drill pipe connector

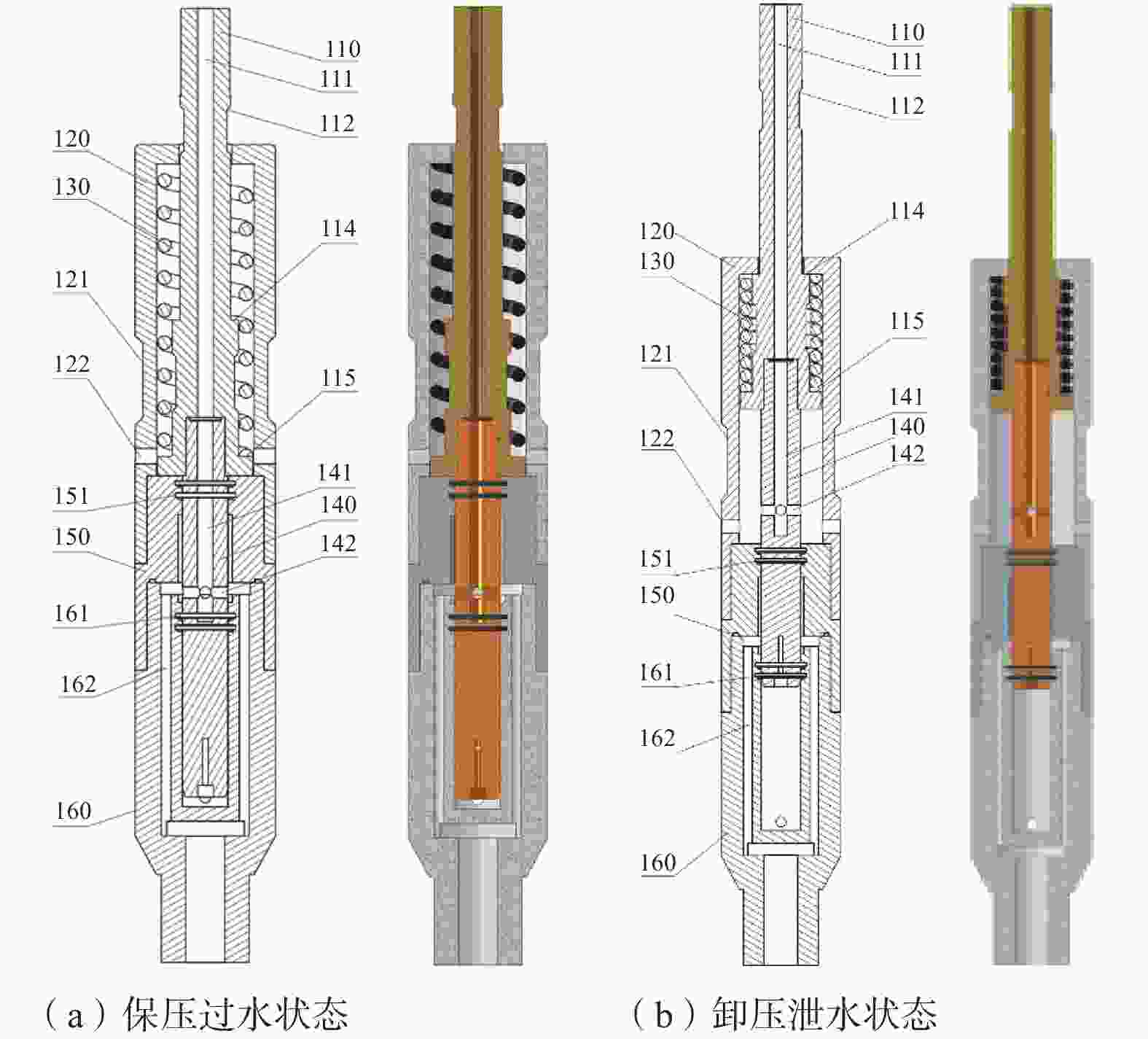

图 4 干孔水压致裂地应力测试卸压装置结构示意图

110—过水支撑端子;111—轴向过水孔;112—紧固卡台;114—中部环形限位台阶;115—底部环形支撑台阶;120—上限位套筒;121—扳手卡台;122—无螺纹泄水孔;130—承重弹簧;140—镀铬芯轴;141—轴向过水孔;142—径向过水孔;150—中间连接件;151—“O”型密封圈;160—下部过水连接件;161—“O”型密封圈;162—过水孔

Figure 4. Schematic diagram of the pressure relief device structure for dry pore hydraulic fracturing stress test

110–water-through support terminal; 111–axial water-through hole; 112–fastening card; 114–middle ring limit step; 115–bottom ring support step; 120–upper limit sleeve; 121–wrench clip; 122–threadless drain hole; 130–load-bearing spring; 140–chrome mandrel; 141–axial water-through hole; 142–radial water-through hole; 150–middle connector; 151–“O”-type seal ring; 160–lower water-through connector; 161–“O”-type seal ring. 162–water-through hole

图 7 侧压系数随深度变化曲线(据杨树新等,2012修改)

Figure 7. Lateral pressure coefficient with depth (modified from Yang et al. 2012)

表 1 地应力测试结果

Table 1. In-situ stress test results

孔号 测段位置/m 主应力值/MPa 最大水平与垂直

主应力比值KHv最小水平与垂直

主应力比值Khv最大与最小水平

主应力比值KHh侧压系数

Kav最大水平

主应力SH方向最大水平

主应力SH最小水平

主应力Sh垂直主应力

SvZK01 355.7 10.98 6.79 9.61 1.14 0.71 1.62 0.92 370.5 12.17 7.13 10.01 1.22 0.71 1.71 0.96 NE43° 388.9 12.73 7.61 10.51 1.21 0.72 1.67 0.97 453.6 17.05 9.75 12.26 1.39 0.80 1.75 1.09 472.2 17.03 10.13 12.76 1.33 0.79 1.68 1.06 NE65° 480.2 18.09 10.01 12.97 1.39 0.77 1.80 1.08 ZK02 421.5 12.12 8.42 11.39 1.06 0.74 1.44 0.90 438.6 14.49 8.89 11.86 1.22 0.75 1.63 0.99 467.4 15.48 9.38 12.63 1.23 0.74 1.65 0.98 493.5 15.54 9.54 13.34 1.17 0.72 1.63 0.94 NE70.5° 497.3 16.67 10.17 13.44 1.24 0.76 1.64 1.00 502.1 17.62 11.32 13.57 1.30 0.83 1.56 1.07 表 2 岩体应力分级表

Table 2. Initial stress classification of rock mass

应力分级 最大主应力值σm/MPa 岩石强度应力比Rb/σm 极高地应力 σm≥40 <2 高地应力 20≤σm<40 2~4 中等地应力 10≤σm<20 4~7 低地应力 σm<10 >7 注:Rb为岩石饱和单轴抗压强度,MPa;σm为最大主应力,MPa 表 3 工程区地应力水平综合评判结果

Table 3. Evaluation results of in-situ stress level in the project area

测段深度/m 岩性 σm/MPa 地应力水平 $ \overline{{R}_{\mathrm{b}}} $/MPa Rb/σm 地应力水平 综合地应力水平 355.7 灰岩 10.98 中等地应力 63.79 5.81 中等地应力 中等地应力 370.5 灰岩 12.17 中等地应力 63.79 5.24 中等地应力 中等地应力 388.9 灰岩 12.73 中等地应力 63.79 5.01 中等地应力 中等地应力 453.6 灰岩 17.05 中等地应力 63.79 3.74 高地应力 高地应力 472.2 灰岩 17.03 中等地应力 63.79 3.75 高地应力 高地应力 480.2 灰岩 18.01 中等地应力 63.79 3.54 高地应力 高地应力 421.5 灰岩 12.12 中等地应力 63.79 5.26 中等地应力 中等地应力 438.6 灰岩 14.49 中等地应力 63.79 4.40 中等地应力 中等地应力 467.4 灰岩 15.48 中等地应力 63.79 4.12 中等地应力 中等地应力 493.5 灰岩 15.54 中等地应力 63.79 4.10 中等地应力 中等地应力 497.3 灰岩 16.67 中等地应力 63.79 3.83 高地应力 高地应力 502.1 灰岩 17.62 中等地应力 63.79 3.62 高地应力 高地应力 -

[1] BAI J P, PENG H, MA X M, et al. , 2013. Hollow inclusion strain gauge geostress measuring instrument in deep borehole and its application example[J]. Chinese Journal of Rock Mechanics and Engineering, 32(5): 902-908. (in Chinese with English abstract) [2] BAO L H, DU Y, GUO Q L, et al. , 2017. In-situ stress measurement and research on tectonic stress field distribution law of Chengdu-Lanzhou railway[J]. Journal of Geomechanics, 23(5): 734-742. (in Chinese with English abstract) [3] BROWN E T, HOEK E, 1978. Trends in relationships between measured in-situ stresses and depth[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 15(4): 211-215. [4] CAI M F, QIAO L, LI H B, 1995. Rock-stress measurement principles and techniques[M]. Beijing: Science Press: 1-27. (in Chinese) [5] CAI M F, PENG H, MA X M, et al. , 2009. Evolution of the in situ rock strain observed at Shandan Monitoring Station during the M8.0 earthquake in Wenchuan, China[J]. International Journal of Rock Mechanics and Mining Sciences, 46(5): 952-955. doi: 10.1016/j.ijrmms.2008.12.004 [6] CHAI B, GUO J J, GUO X J, et al. , 2022. Engineering geological survey report on the pre-feasibility study stage of Taiyuan (Gujiao) pumped Storage Power Station[R]. Taiyuan: Shanxi Water Conservancy and Hydropower Survey, Design and Research Institute Co. , Ltd. (in Chinese) [7] CHEN D D, NIU Z W, 2017. Selection of lining form for diversion system of a pumped storage power station[J]. Small Hydro Power(4): 35-39. (in Chinese) [8] CHEN Q C, AN Q M, SUN D S, et al. , 2010. Current In-situ stress state of Shanxi basin and analysis of earthquake risk[J]. Acta Geoscientica Sinica, 31(4): 541-548. (in Chinese with English abstract) [9] FANG L, WANG S, XU K, et al. , 2018. Characteristics of current in-situ stress of Qinshui Basin[J]. Fault-Block Oil & Gas Field, 25(4): 413-418. (in Chinese with English abstract) [10] FENG C J, LI B, LI H, et al. , 2022. Estimation of in-situ stress field surrounding the Namcha Barwa region and discussion on the tectonic stability[J]. Journal of Geomechanics, 28(6): 919-937. (in Chinese with English abstract) [11] GUO Q L, AN Q M, ZHAO S G, 2002. Application of hydraulic fracturing test in the design of Guangzhou pump storage project[J]. Chinese Journal of Rock Mechanics and Engineering, 21(6): 828-832. (in Chinese with English abstract) [12] GUO X Y, JIANG C S, WANG X S, et al. , 2017. Characteristics of small to moderate focal mechanism solutions stress field of the circum-Ordos block[J]. Journal of Geodesy and Geodynamics, 37(7): 675-685. (in Chinese) [13] HAIMSON B C, CORNET F H, 2003. ISRM suggested methods for rock stress estimation-part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF)[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7-8): 1011-1020. doi: 10.1016/j.ijrmms.2003.08.002 [14] HAN D, ZHAO Z H, YAN B Z, et al. , 2022. Status and prospect of China’s pumped storage development in 2021[J]. Water Power, 48(5): 1-4, 104. (in Chinese with English abstract) [15] JING F, SHENG Q, ZHANG Y H, et al. , 2007. Research on distribution rule of shallow crustal geostress in China mainland[J]. Chinese Journal of Rock Mechanics and Engineering, 26(10): 2056-2062. (in Chinese with English abstract) [16] JING F, LIANG H C, BIAN Z H, et al. , 2008. Review of geo-stress measurement method and study[J]. Journal of North China Institute of Water Conservancy and Hydroelectric Power, 29(2): 71-75. (in Chinese with English abstract) [17] KANG H P, LIN J, ZHANG X, et al. , 2010. In-situ stress measurements and distribution laws in Lu’an underground coal mines[J]. Rock and Soil Mechanics, 31(3): 827-831, 844. (in Chinese with English abstract) [18] LI A W, CHEN Q C, SUN D S, et al. , 2019-08-30. Emergency discharge module for hydraulic fracturing measuring device: CN, 110185441A[P]. (in Chinese) [19] LI B, ZHANG W, WEN R, 2022. Study on the hydraulic fracturing in-situ stress measurement in super-long highway tunnels in southern Shaanxi: Engineering geological significance[J]. Journal of Geomechanics, 28(2): 191-202. (in Chinese with English abstract) [20] LI P E, LIAO L, LIU P, 2017. Numerical simulation of relationship between stress field evolution and historical strong earthquakes in Taiyuan basin[J]. Earth Science, 42(9): 1623-1636. (in Chinese with English abstract) [21] LI Y S, YIN J M, AI K, et al. , 2006. Measurement and analysis of geostress for underground engineering design of Shenzhen pumped storage plant[J]. Chinese Journal of Rock Mechanics and Engineering, 25(S2): 3965-3970. (in Chinese with English abstract) [22] LIU L J, TIAN Z Y, ZHENG Y B, et al. , 2016. Study of site selection of deep underground powerhouse in Huanggou pumped storage power station[J]. Resources Environment & Engineering, 30(1): 96-99. (in Chinese with English abstract) [23] LUO C W, LI H B, LI J R, et al. , 2018-01-19. Dry hole pressure relief valve and hydraulic fracturing in-situ stress testing device: CN, 206905955U[P]. (in Chinese) [24] LYU C T, 2020. Analysis of in-situ stress and rock burst in surrounding rock of underground powerhouse of Langjiang pumped-storage power station[J]. Guangdong Water Resources and Hydropower(12): 57-61. (in Chinese with English abstract) [25] MENG W, GUO C B, MAO B Y, et al. , 2021. Tectonic stress field and engineering influence of China-Nepal Railway Corridor[J]. Geoscience, 35(1): 167-179. (in Chinese with English abstract) [26] MENG W, TIAN T, SUN D S, et al. , 2022. Research on stress state in deep shale reservoirs based on in-situ stress measurement and rheological model[J]. Journal of Geomechanics, 28(4): 537-549. (in Chinese with English abstract) [27] National Standard of the People's Republic of China, 2006. Code for hydropower engineering geological investigation: GB 50287-2006[S]. Beijing: China Planning Press. (in Chinese) [28] PENG H, MA X M, JIANG J J, 2009. Process analysis of in-situ strain during the MS8.0 Wenchuan earthquake-data from the stress monitoring station at Shandan[J]. Acta Geologica Sinica, 83(4): 754-766. doi: 10.1111/j.1755-6724.2009.00099.x [29] QIAO E W, PENG H, MA X M, 2019. The surrounding rock condition exploration and construction method analysis of cross-Bohai strait passage[J]. Journal of Geomechanics, 25(4): 563-573. (in Chinese with English abstract) [30] SUN D S, CHEN Q C, LI Q, et al. , 2019-09-06. A water level pressure difference control valve: CN, 110206509A[P]. (in Chinese) [31] WANG X W, YANG G H, 2017. Analysis of horizontal deformation along the Shanxi fault zone by GPS measurement[J]. Journal of Geodesy and Geodynamics, 37(11): 1101-1104. (in Chinese with English abstract) [32] WANG Y H, CUI X F, HU X P, et al. , 2012. Study on the stress state in upper crust of China mainland based on in-situ stress measurements[J]. Chinese Journal of Geophysics, 55(9): 3016-3027. (in Chinese with English abstract) [33] WANG Y, ZHU J F, 2012. Leakage treatment of steel lining in diversion system of Baoquan pumped storage power station[C]//Collection of papers on the construction of pumped storage power station. Beijing: China Power Press: 328-331. (in Chinese) [34] WU M L, SUN L, 2019-06-21. Water discharge device and ground stress measurement system of double-pipe hydraulic fracturing: CN, 109915100A[P]. (in Chinese) [35] XIE F R, CUI X F, ZHAO J T, et al. , 2004. Regional division of the recent tectonic stress field in China and adjacent areas[J]. Chinese Journal of Geophysics, 47(4): 654-662. (in Chinese with English abstract) [36] XIE F R, CHEN Q C, CUI X F, et al. , 2007. Fundamental database of crustal stress environment in continental China[J]. Progress in Geophysics, 22(1): 131-136. (in Chinese with English abstract) [37] YANG S X, YAO R, CUI X F, et al. , 2012. Analysis of the characteristics of measured stress in Chinese mainland and its active blocks and North-South seismic belt[J]. Chinese Journal of Geophysics, 55(12): 4207-4217. (in Chinese with English abstract) [38] YE G Q, FANG D, JIANG Y L, et al. , 2015. Underground powerhouse location and axis selection design of Baihetan hydropower station[J]. Zhejiang Hydrotechnics, 43(6): 46-51. (in Chinese with English abstract) [39] YIN J M, GUO X F, AI K, et al. , 2008. Analysis of in-situ stress measurement and high pressure tunnel’s design verification for Qingyuan pumped storage plant[J]. Journal of Yangtze River Scientific Research Institute, 25(5): 43-45, 83. (in Chinese with English abstract) [40] YU Z Y, SHEN X Z, LIANG H, et al. , 2022. The characteristics of major faults and stress field in Weihe-Yuncheng basin constrained by seismic activity and focal mechanism solutions[J]. Seismology and Geology, 44(2): 395-413. (in Chinese with English abstract) [41] ZHANG C Y, DU S H, HE M C, et al. , 2022. Characteristics of in-situ stress on the western margin of the eastern Himalayan syntaxis and its influence on stability of tunnel surrounding rock[J]. Chinese Journal of Rock Mechanics and Engineering, 41(5): 954-968. (in Chinese with English abstract) [42] ZHANG N, LAN H X, LI L P, et al. , 2022. Characteristics and implications of in-situ stresses in Southeastern Tibetan Plateau[J]. Journal of Engineering Geology, 30(3): 696-707. (in Chinese with English abstract) [43] ZHANG S L, LIU R C, WANG X, et al. , 2017. The variation characteristics of stress field of the Taiyuan Basin before and after the Wenchuan earthquake[J]. Earthquake Research in China, 33(1): 46-55. (in Chinese with English abstract) [44] ZHANG X L, ZHANG G Z, LIU Y, et al. , 2021-06-04. A rapid discharge device suitable for ultra-low water level hydraulic fracturing method: CN, 213360088U[P]. (in Chinese) [45] ZHAO D A, CHEN Z M, CAI X L, et al. , 2007. Analysis of distribution rule of geostress in China[J]. Chinese Journal of Rock Mechanics and Engineering, 26(6): 1265-1271. (in Chinese with English abstract) [46] ZHAO X Y, GAN J, SONG X W, et al. , 2022. In-situ stress measurement and high-pressure water pressure test report in the pre-feasibility study stage of Taiyuan (Gujiao) pumped storage power station in Shanxi province[R]. Beijing: Beijing Engineering Corporation Limited. (in Chinese) [47] 白金朋, 彭华, 马秀敏, 等, 2013. 深孔空心包体法地应力测量仪及其应用实例[J]. 岩石力学与工程学报, 32(5): 902-908. [48] 包林海, 杜义, 郭啟良, 等, 2017. 成兰铁路地应力测量与构造应力场分布规律研究[J]. 地质力学学报, 23(5): 734-742. [49] 蔡美峰, 乔兰, 李华斌, 1995. 地应力测量原理和技术[M]. 北京: 科学出版社: 1-27. [50] 柴宝, 郭俊君, 郭晓娟, 等, 2022. 太原(古交)抽水蓄能电站工程预可研阶段工程地质勘察报告[R]. 太原: 山西省水利水电勘测设计研究院有限公司 [51] 陈冬冬, 牛正威, 2017. 某抽水蓄能电站引水系统衬砌形式的选择[J]. 小水电(4): 35-39. [52] 陈群策, 安其美, 孙东生, 等, 2010. 山西盆地现今地应力状态与地震危险性分析[J]. 地球学报, 31(4): 541-548. [53] 房璐, 王硕, 徐珂, 等, 2018. 山西沁水盆地现今地应力特征[J]. 断块油气田, 25(4): 413-418. [54] 丰成君, 李滨, 李惠, 等, 2022. 南迦巴瓦地区地应力场估算与构造稳定性探讨[J]. 地质力学学报, 28(6): 919-937. [55] 郭启良, 安其美, 赵仕广, 2002. 水压致裂应力测量在广州抽水蓄能电站设计中的应用研究[J]. 岩石力学与工程学报, 21(6): 828-832. [56] 郭祥云, 蒋长胜, 王晓山, 等, 2017. 鄂尔多斯块体周缘中小地震震源机制及应力场特征[J]. 大地测量与地球动力学, 37(7): 675-685. [57] 韩冬, 赵增海, 严秉忠, 等, 2022. 2021年中国抽水蓄能发展现状与展望[J]. 水力发电, 48(5): 1-4, 104. [58] 景锋, 盛谦, 张勇慧, 等, 2007. 中国大陆浅层地壳实测地应力分布规律研究[J]. 岩石力学与工程学报, 26(10): 2056-2062. [59] 景锋, 梁合成, 边智华, 等, 2008. 地应力测量方法研究综述[J]. 华北水利水电学院学报, 29(2): 71-75. [60] 康红普, 林健, 张晓, 等, 2010. 潞安矿区井下地应力测量及分布规律研究[J]. 岩土力学, 31(3): 827-831, 844. [61] 李阿伟, 陈群策, 孙东生, 等, 2019-08-30. 一种水压致裂测量装置用紧急泄水组件: 中国, 110185441A[P]. [62] 李彬, 张文, 文冉, 2022. 陕南特长公路隧道水压致裂法地应力测量结果及工程地质意义分析[J]. 地质力学学报, 28(2): 191-202. [63] 李平恩, 廖力, 刘盼, 2017. 太原盆地应力场演化与强震关系的数值模拟研究[J]. 地球科学, 42(9): 1623-1636. [64] 李永松, 尹健民, 艾凯, 等, 2006. 深圳抽水蓄能电站地应力测试分析及其在地下硐室设计中的应用[J]. 岩石力学与工程学报, 25(S2): 3965-3970. [65] 刘录君, 田作印, 郑以宝, 等, 2016. 荒沟抽水蓄能电站深埋地下厂房位置研究[J]. 资源环境与工程, 30(1): 96-99. [66] 罗超文, 李海波, 李俊如, 等, 2018-01-19. 干孔泄压阀及水压致裂地应力测试装置: 中国, 206905955U[P]. [67] 吕城腾, 2020. 浪江抽水蓄能电站地下厂房地应力及硐室围岩岩爆分析[J]. 广东水利水电(12): 57-61. [68] 孟文, 郭长宝, 毛邦燕, 等, 2021. 中尼铁路交通廊道现今构造应力场及其工程影响[J]. 现代地质, 35(1): 167-179. [69] 孟文, 田涛, 孙东生, 等, 2022. 基于原位地应力测试及流变模型的深部泥页岩储层地应力状态研究[J]. 地质力学学报, 28(4): 537-549. [70] 乔二伟, 彭华, 马秀敏, 2019. 渤海海峡跨海通道围岩条件探查与施工方法分析[J]. 地质力学学报, 25(4): 563-573. [71] 孙东生, 陈群策, 李全, 等, 2019-09-06. 一种水位压差控制阀: 中国, 110206509A[P]. [72] 王秀文, 杨国华, 2017. 利用GPS资料研究山西裂谷带的水平形变[J]. 大地测量与地球动力学, 37(11): 1101-1104. [73] 王艳华, 崔效锋, 胡幸平, 等, 2012. 基于原地应力测量数据的中国大陆地壳上部应力状态研究[J]. 地球物理学报, 55(9): 3016-3027. [74] 王洋, 朱建峰, 2012. 宝泉抽水蓄能电站引水系统钢衬渗漏处理[C]//抽水蓄能电站工程建设文集. 北京: 中国电力出版社: 328-331. [75] 吴满路, 孙林, 2019-06-21. 泄水装置及双管水压致裂地应力测量系统: 中国, 109915100A[P]. [76] 谢富仁, 崔效锋, 赵建涛, 等, 2004. 中国大陆及邻区现代构造应力场分区[J]. 地球物理学报, 47(4): 654-662. [77] 谢富仁, 陈群策, 崔效锋, 等, 2007. 中国大陆地壳应力环境基础数据库[J]. 地球物理学进展, 22(1): 131-136. [78] 杨树新, 姚瑞, 崔效锋, 等, 2012. 中国大陆与各活动地块、南北地震带实测应力特征分析[J]. 地球物理学报, 55(12): 4207-4217. [79] 叶更强, 方丹, 江亚丽, 等, 2015. 白鹤滩水电站地下厂房位置及轴线选择设计[J]. 浙江水利科技, 43(6): 46-51. [80] 尹健民, 郭喜峰, 艾凯, 等, 2008. 清远抽水蓄能电站地应力测试分析与高压隧洞设计验证[J]. 长江科学院院报, 25(5): 43-45, 83. [81] 余占洋, 沈旭章, 梁浩, 等, 2022. 基于地震活动性和震源机制解研究渭河-运城盆地主要断裂带的特征及应力场分布[J]. 地震地质, 44(2): 395-413. [82] 张重远, 杜世回, 何满潮, 等, 2022. 喜马拉雅东构造结西缘地应力特征及其对隧道围岩稳定性的影响[J]. 岩石力学与工程学报, 41(5): 954-968. [83] 张宁, 兰恒星, 李郎平, 等, 2022. 青藏高原东南缘实测地应力特征及意义分析[J]. 工程地质学报, 30(3): 696-707. [84] 张淑亮, 刘瑞春, 王霞, 等, 2017. 汶川地震前后太原盆地应力场变化特征研究[J]. 中国地震, 33(1): 46-55. [85] 张小林, 张广泽, 刘毅, 等, 2021-06-04. 一种适用于超低水位水压致裂法急速泄水装置: 中国, 213360088U[P]. [86] 赵德安, 陈志敏, 蔡小林, 等, 2007. 中国地应力场分布规律统计分析[J]. 岩石力学与工程学报, 26(6): 1265-1271. doi: 10.3321/j.issn:1000-6915.2007.06.024 [87] 赵晓阳, 甘俊, 宋宪文等, 2022. 山西省太原(古交)抽水蓄能电站预可行性研究阶段地应力测量及高压压水试验报告[R]. 北京:中国电建集团北京勘测设计研究院有限公司. [88] 中华人民共和国住房和城乡建设部, 2016. 水力发电工程地质勘察规范: GB 50287-2016 [S]. 北京: 中国计划出版社. -

下载:

下载: