Quantitative evaluation of maximum operating pressure and storage capacity for gas-top sandstone reservoir-type gas storage

-

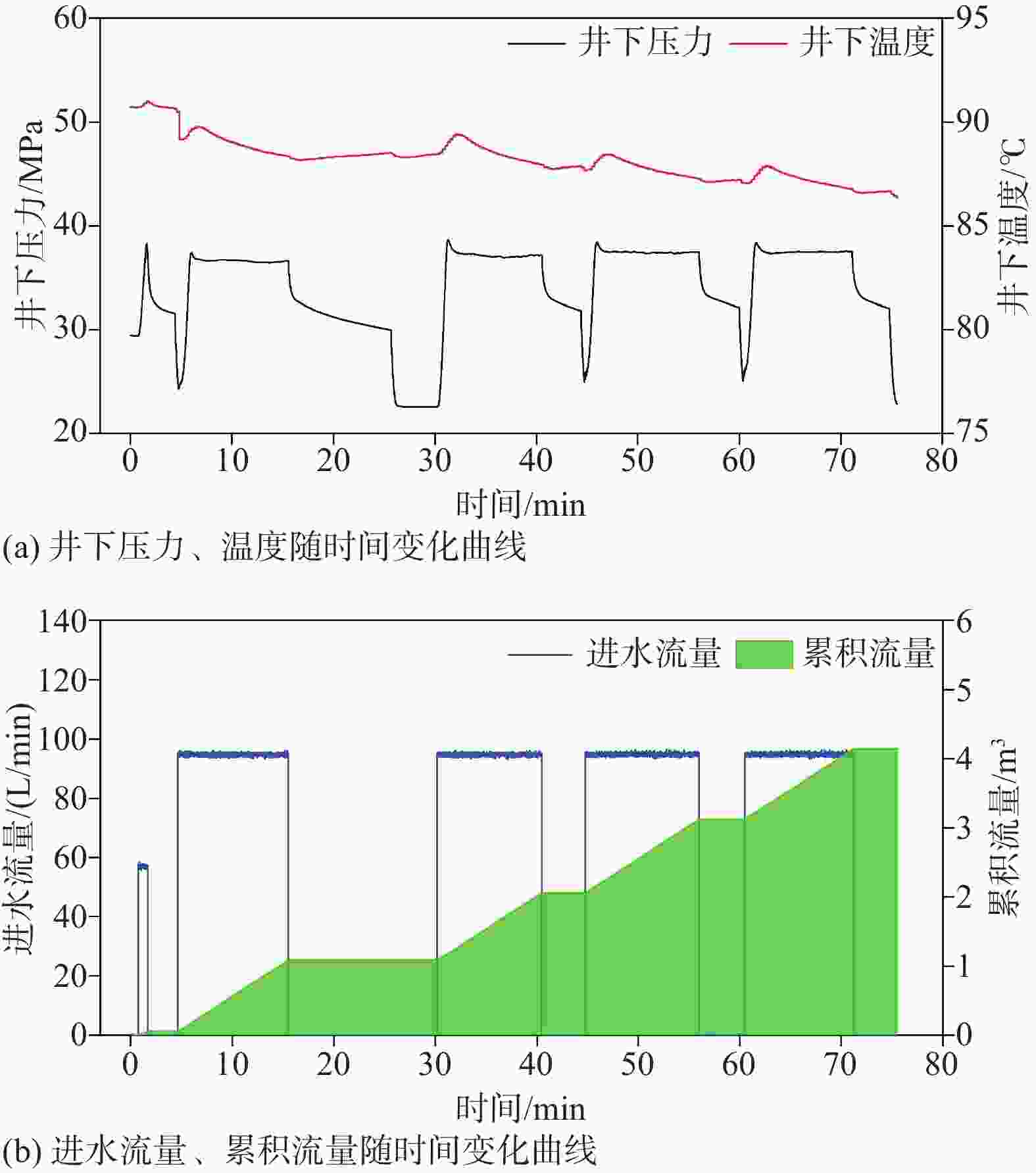

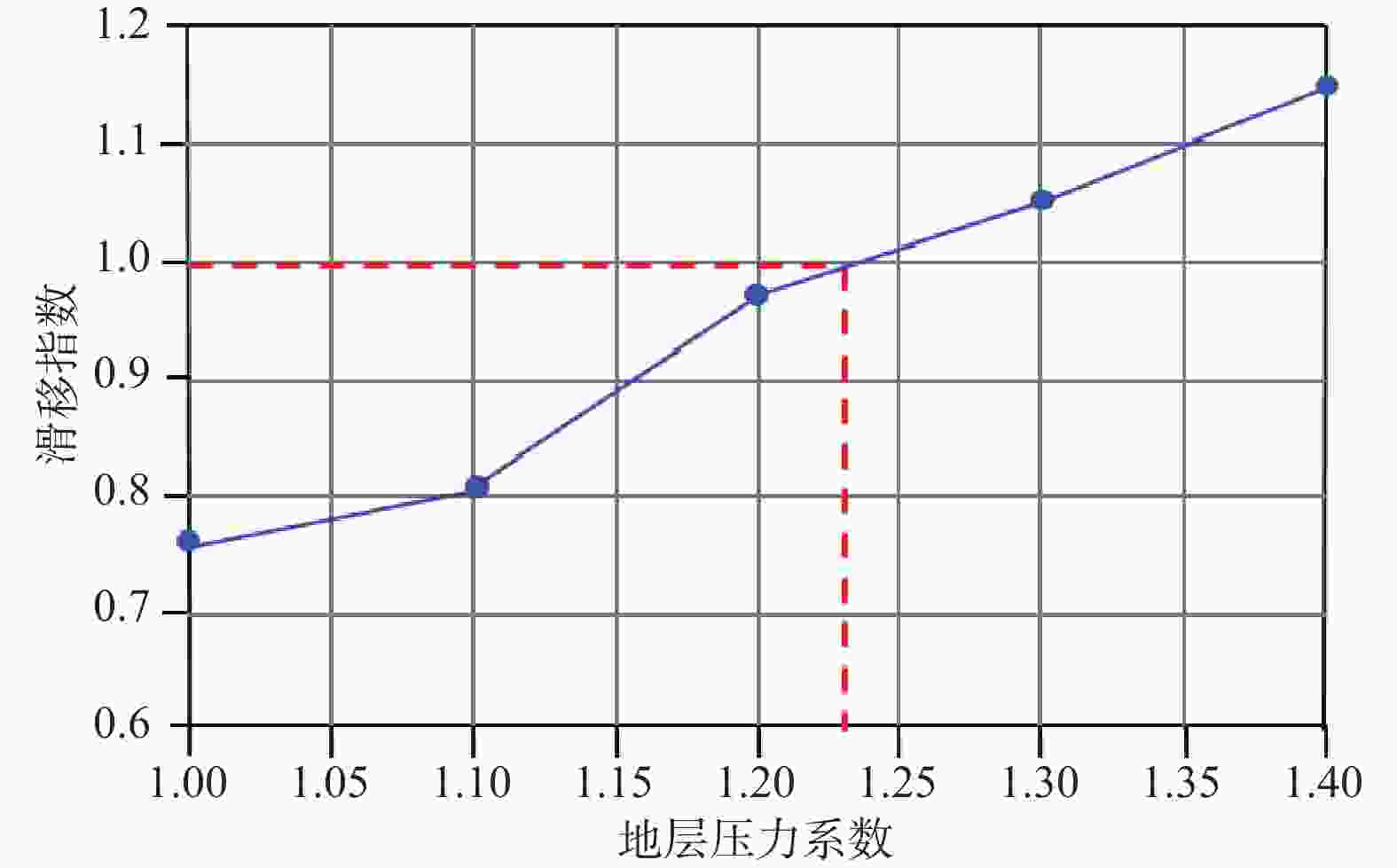

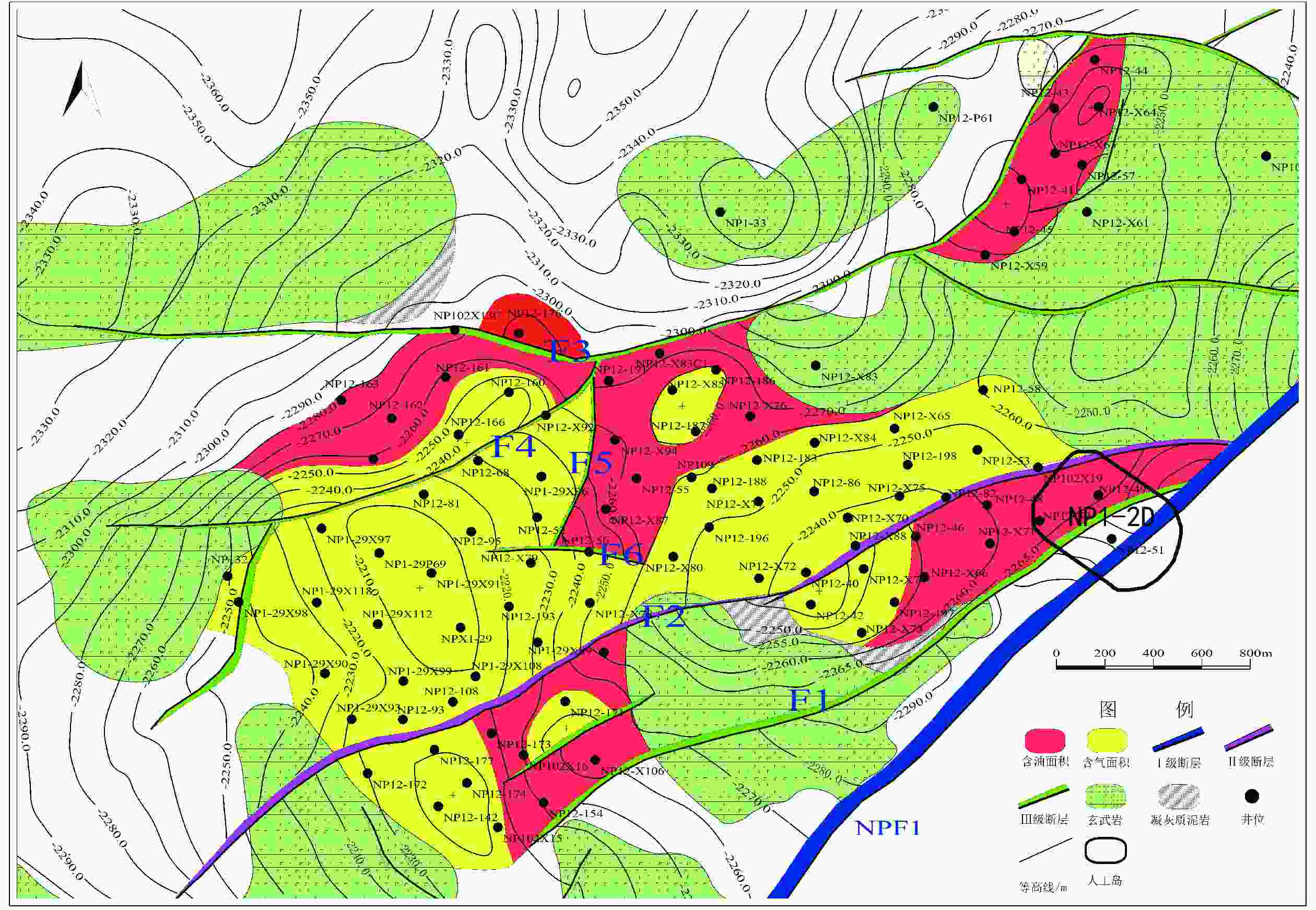

摘要: 提高运行上限压力是增加储气库工作气量最直接、最有效且综合效益最优的方案。通过在矿场井中原位实测得到的最小主应力,对冀东南堡油田1-29气顶砂岩油藏型储气库的运行上限压力和库容量进行了定量评价,研究结果表明:基于最小主应力准则,盖层发生拉张破坏对应的上限压力最低,即根据实测最小主应力确定南堡油田1-29储气库的运行上限压力为27.2 MPa。基于有效库容计算模型,综合考虑气层含水量、残余水和边缘孔隙以及油层的波及系数、气驱液效率和含油空间利用率等因素,将上限压力从原始地层压力22.5 MPa提升到27.2 MPa,储气库的有效库容从15.46×108 m3增加到18.14×108 m3,库容量增加约17.3%,预期可显著提升储气库的经济效益。研究成果对其他地下储气库运行上限压力和库容量定量评价具有一定参考价值。

-

关键词:

- 南堡1-29气顶砂岩油藏 /

- 地下储气库 /

- 地应力 /

- 上限压力 /

- 库容

Abstract:Objective The maximum operating pressure for underground gas storage facilities designed for oil and gas reservoirs, both constructed and under construction in China, is currently set at the original formation pressure. There have yet to be successful cases of overpressure operation, which significantly impacts the economic benefits of converting depleted oil and gas reservoirs into underground gas storage facilities. This article aims to evaluate the maximum operating pressure and storage capacity of the Nanpu 1-29 gas storage facility from the perspective of the ultimate bearing capacity of cap layers and faults, with the goal of effectively enhancing the construction benefits of the facility. Methods The evaluation of the maximum operating pressure for the Nanpu 1-29 gas storage facility in eastern Hebei is based on the minimum principal stress measured in situ in the mining wells. Different effective porosity calculation methods are employed to quantitatively evaluate the effective storage capacity of gas and oil reservoirs, as well as the incremental capacity after pressure boosting operation, based on their development differences. Results The evaluation of the maximum operating pressure for the Nanpu 1-29 gas storage facility indicates that the minimum principal stress of the cap layers determined by the in-situ measurements in the mining wells is 34.00 MPa. Based on the tensile failure criteria determined by the minimum principal stress, the maximum operating pressure for the tensile failure of the cap layer is 27.20 MPa. Combined with the maximum safe injection pressure corresponding to shear failure of the cap layer (30.60 MPa) and the maximum safe injection pressure corresponding to unstable slip of the fault (27.60 MPa), the final maximum operating pressure for the Nanpu 1-29 gas storage facility is determined to be 27.20 MPa. Based on the effective storage capacity calculation model, considering factors such as the water content of the gas reservoir, residual water and edge porosity as well as the coefficient of influence, the efficiency of gas-driven fluid, and the utilization rate of oil-containing space, the maximum operating pressure increased from the original formation pressure of 22.50 MPa to 27.20 MPa. The practical storage capacity of the gas storage facility increased from 15.46×108 m3 to 18.14×108 m3, an increase of approximately 17.3%. Conclusion (1) The construction of gas storage facilities can be re-evaluated for the maximum operating pressure based on the minimum principal stress measured in situ in the mining wells, and overpressure design can be conducted under appropriate conditions. (2) Overpressure design can effectively increase storage capacity and improve the economic benefits of reservoir construction. Significance The research results have a certain reference value for the quantitative evaluation of the maximum operating pressure and storage capacity of other underground gas storage facilities, and are expected to significantly improve the economic benefits of overpressure-designed reservoir-type gas storage facilities in China. -

表 1 冀东南堡油田1-29储气库运行上限压力评价

Table 1. Evaluation results of the maximum operating pressure in Gas Storage 1-29, Nanpu Oilfield, eastern Hebei

动态密封性 破坏类型 评价方法 最大安全

注气压力运行上

限压力盖层拉张破坏 矿场地应力测试 ≤27.2 MPa 27.20 MPa 盖层剪切破坏 库伦−摩尔准则 ≤30.6 MPa 断层承载能力 断层滑移指数 ≤27.6 MPa 表 2 气层自由气库容量评价结果

Table 2. Evaluation results of free air capacity in gas reservoir

断块 气层原始含气

孔隙/×104 m3气层含水量/

×104 m3残余水孔隙/

×104 m3侧缘孔隙/

×104 m3有效储气孔隙/

×104 m3气体波及体积系数 库容/×108 m3 常压22.5 MPa

压力系数1.0超压27.2 MPa

压力系数1.2常压22.5 MPa

压力系数1.0超压27.2 MPa

压力系数1.2南堡1-29 246.45 32.84 13.36 8.26 224.83 0.00454 0.00387 4.96 5.82 南堡109 121.04 29.70 12.09 7.07 101.88 0.00454 0.00387 2.24 2.63 合计 367.49 62.54 25.45 15.33 326.71 − − 7.20 8.45 表 3 油层自由气库容量评价结果

Table 3. Evaluation results of free gas capacity in oil reservoir

断块 油层原始含油

孔隙/×

104 m3波及系

数/%气驱液

效率/%含油空间

利用率/%有效含气孔隙

体积/×104 m3气体波及体积系数 库容/×108 m3 常压22.5 MPa

压力系数1.0超压27.2 MPa

压力系数1.2常压22.5 MPa

压力系数1.0超压27.2 MPa

压力系数1.2南堡1-29 261.81 65 71.6 46.54 121.8 0.00454 0.00387 2.68 3.15 南堡109 412.34 65 71.6 46.54 191.9 0.00454 0.00387 4.23 4.96 南堡12-X66 111.31 65 71.6 46.54 61.19 0.00454 0.00387 1.35 1.58 合计 785.45 − − − 374.94 − − 8.26 9.69 -

[1] ANYADIEGWU C I C, 2012. Estimation of storage capacity of an underground gas storage reservoir[J]. International Journal of Academic Research, 4(4): 11-15. doi: 10.7813/2075-4124.2012/4-4/A.2 [2] BARREE R D, BARREE V L, CRAIG D P, 2009. Holistic fracture diagnostics: consistent interpretation of Prefrac injection tests using multiple analysis methods[J]. SPE Production & Operations, 24(3): 396-406. [3] BÉREST P, BROUARD B, FAVRET F, et al 2015. Maximum pressure in gas storage caverns[C]//Solution Mining Research Institute spring 2015 technical conference. New Work: Solution Mining Research Institute: 1-17. [4] BRUNO M S, DEWOLF G, FOH S, 2000. Geomechanical analysis and decision analysis for delta pressure operations in gas storage reservoirs[C]//Paper presented at the American gas association operations conference. Denver. [5] CHEN Q C, SUN D S, CUI J J, et al, 2019. Hydraulic fracturing stress measurements in Xuefengshan deep borehole and its significance[J]. Journal of Geomechanics, 25(5): 853-865. (in Chinese with English abstract [6] CHEN S M, 2016. Energy consumption and natural gas emission reduction potential in the Beijing-Tianjin-Hebei region[J]. Resources Economization & Environmental Protection, 31(4): 1, 3. (in Chinese) [7] CHEN Z W, YANG X T, WANG G, et al, 2014. Analytical technique of horizontal maximum principal stress for petroleum engineering[J]. Journal of Geomechanics, 20(1): 94-102. (in Chinese with English abstract [8] COFFIN P, LEBAS G, 2007. Converting the Pecorade oil field into an underground gas storage[C]//International petroleum technology conference. Dubai: OnePetro. [9] DIETERT J, PURSELL D, 2008. Underground natural gas storage, Simmons and company international. 5000 Bank of America Houston, Texas 77002. [10] DING G S, LI W Y, 2002. Foreign and domestic underground gas storage tanks: current situation and development trends[J]. International Petroleum Economics, 10(6): 23-26. (in Chinese with English abstract [11] DING G S, WANG J M, 2011. Key points in the reconstruction of an underground gas storage based on a depleted gas reservoir[J]. Natural Gas Industry, 31(5): 87-89. (in Chinese with English abstract [12] DOU S J, ZHAO P Q, 2010. Application of fault-sealing in oilfield development[J]. Fault-Block Oil & Gas Field, 17(1): 28-31. (in Chinese with English abstract [13] HAIMSON B C, CORNET F H. 2003. ISRM suggested methods for rock stress estimation: part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF)[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7-8): 1011-1020. [14] HU X L, LÜ Y F, FU G, et al, 2019. Quantitative evaluation of fault vertical sealing ability of 1st structure in Nanpu Sag[J]. Earth Science, 44(11): 3882-3893. (in Chinese with English abstract [15] LI J, ZHANG J J, 2013. Design of reservoir capacity for building reservoirs in unconfined gas reservoirs[J]. Broken block oil and gas field, 20(3): 359-361. (in Chinese with English abstract [16] LIU J Y, WANG L D, MA Z X. 2008. Comparison of two algorithms for the calculation of reserves out of the volumetric method[J]. Marine Geology Dynamics, 24(3): 40-42. (in Chinese with English abstract [17] LIU W, CHEN M, LV Z H, et al, 2011. Classification and development trend of underground gas storage[J]. Oil-Gas Field Surface Engineering, 30(12): 100-101. (in Chinese) [18] MA X M, YU B B, MA D B, et al, 2010. Project design and matching technologies for underground gas storage based on a depleted sandstone gas reservoir[J]. Natural Gas Industry, 30(8): 67-71. (in Chinese with English abstract [19] MALAKOOTI R, AZIN R, 2011. The optimization of underground gas storage in a partially depleted gas reservoir[J]. Petroleum Science and Technology, 29(8): 824-836. doi: 10.1080/10916460903486742 [20] PAN J R, LI L, ZHANG Y Q, et al , 2019. Research on the development of natural gas storage and peak shaving facilities in China[C]//China gas operation and safety seminar (10th) & gas branch of China Civil Engineering Society. Shanghai: Gas Branch of China Civil Engineering Society: 159-162. (in Chinese) [21] REINHARD R, STAUDTMEISTERK, ZANDER-SCHI-EBENHOFER D, 1998. Rock mechanical determination of the maximum internal pressure for gas storage caverns in rack salt[S]. Hannover: Solution Mining Research Instit-ute: 1-20. [22] SAWYER W K, ZUBER M D, BUES A D, 1998. Reservoir simulation and analysis of the Sciota aquifer gas storage pool[C]//SPE eastern regional meeting. Pittsburgh: SPE. [23] SUN J C, XU H C, WANG J M, et al, 2018. Injection-production mechanisms and key evaluation technologies for underground gas storages rebuilt from gas reservoirs[J]. Natural Gas Industry, 38(4): 138-144. (in Chinese with English abstract [24] SUN L L, ZHANG M G, HU Z H, 2019. The analysis on influencing factors and relation of Beijing-Tianjin-Hebei natural gas market[J]. Urban Gas(7): 24-29. (in Chinese with English abstract [25] TANG L G, WANG J M, BAI F J, et al, 2014. Inventory forecast in underground gas storage based on modified material balance equation[J]. Petroleum Exploration and Development, 41(4): 480-484. (in Chinese with English abstract [26] WANG J M, JIANG F G, 2007. A method for calculating underground gas storage capacity reconstructed from sand gas-cap reservoir at the late water-driving stage[J]. Natural Gas Industry, 27(11): 97-99. (in Chinese with English abstract [27] XU H C, WANG J M, QU P, et al, 2015. A prediction model of storage capacity parameters of a geologically-complicated reservoir-type underground gas storage (UGS)[J]. Natural Gas Industry, 35(1): 103-108. (in Chinese with English abstract [28] YANG Y H, GAO G L, WANG F, et al, 2022. Layered in-situ stress measurement method for perforated interval of Nanpu gas storage, Jidong oilfield[J]. Oil & Gas Storage and Transportation, 41(9): 1029-1035. (in Chinese with English abstract [29] ZHAO Q S, YU L Z, 2013. Study on reservoir characteristics of Guantao Formation in No. 1 and No. 2 structures of Nanpu oilfield[J]. Journal of Oil and Gas Technology, 35(7): 38-43. (in Chinese with English abstract [30] ZHAO Y C, LUO Y, LI L X, et al, 2022. In-situ stress simulation and integrity evaluation of underground gas storage: a case study of the Xiangguosi underground gas storage, Sichuan, SW China[J]. Journal of Geomechanics, 28(4): 523-536. (in Chinese with English abstract [31] ZHENG D W, XU H C, WANG J M, et al, 2017. Key evaluation techniques in the process of gas reservoir being converted into underground gas storage[J]. Petroleum Exploration and Development, 44(5): 794-801. (in Chinese with English abstract [32] ZHENG Y L, SUN J C, QIU X S, et al, 2020. Connotation and evaluation technique of geological integrity of UGSs in oil-gas fields[J]. Natural Gas Industry, 40(5): 94-103. (in Chinese with English abstract [33] ZHONG C, QIN Q R, ZHOU J L, et al, 2018. Study on fault sealing of organic-rich shale by present stress: a case study of Longmaxi Formation in Dingshan Area, southeast Sichuan[J]. Journal of Geomechanics, 24(4): 452-464. (in Chinese with English abstract [34] 陈群策,孙东生,崔建军,等,2019. 雪峰山深孔水压致裂地应力测量及其意义[J]. 地质力学学报,25(5):853-865. doi: 10.12090/j.issn.1006-6616.2019.25.05.070 [35] 陈思敏,2016. 京津冀地区的能源消费和天然气的减排潜力[J]. 资源节约与环保,31(4):1,3. [36] 陈朝伟,杨向同,王刚,等,2014. 石油工程水平最大地应力分析技术[J]. 地质力学学报,20(1):94-102. doi: 10.3969/j.issn.1006-6616.2014.01.009 [37] 丁国生,李文阳,2002. 国内外地下储气库现状与发展趋势[J]. 国际石油经济,10(6):23-26. doi: 10.3969/j.issn.1004-7298.2002.06.004 [38] 丁国生,王皆明,2011. 枯竭气藏改建储气库需要关注的几个关键问题[J]. 天然气工业,31(5):87-89. doi: 10.3787/j.issn.1000-0976.2011.05.023 [39] 窦松江,赵平起,2010. 断层封闭性在油田开发中的应用[J]. 断块油气田,17(1):28-31. [40] 胡欣蕾,吕延防,付广,等,2019. 南堡凹陷1号构造断层垂向封闭能力定量评价[J]. 地球科学,44(11):3882-3893. [41] 李季,张吉军,2013. 不封闭气藏建库库容设计[J]. 断块油气田,20(3):359-361,383. [42] 刘吉余,王立东,马志欣,2008. 容积法储量计算的两种算法比较[J]. 海洋地质动态,24(3):40-42. doi: 10.3969/j.issn.1009-2722.2008.03.009 [43] 刘炜,陈敏,吕振华,等,2011. 地下储气库的分类及发展趋势[J]. 油气田地面工程,30(12):100-101. doi: 10.3969/j.issn.1006-6896.2011.12.051 [44] 马小明,余贝贝,马东博,等,2010. 砂岩枯竭型气藏改建地下储气库方案设计配套技术[J]. 天然气工业,30(8):67-71. doi: 10.3787/j.issn.1000-0976.2010.08.018 [45] 潘季荣,李乐,张永清,等,2019. 我国天然气储气调峰设施发展研究[C]//中国燃气运营与安全研讨会(第十届)暨中国土木工程学会燃气分会2019年学术年会论文集(上册). 上海:中国土木工程学会燃气分会:159-162. [46] 孙军昌,胥洪成,王皆明,等,2018. 气藏型地下储气库建库注采机理与评价关键技术[J]. 天然气工业,38(4):138-144. doi: 10.3787/j.issn.1000-0976.2018.04.016 [47] 孙莉莉,张明光,胡周海,2019. 京津冀天然气市场影响因素及关联度分析[J]. 城市燃气(7):24-29. [48] 唐立根,王皆明,白凤娟,等,2014. 基于修正后的物质平衡方程预测储气库库存量[J]. 石油勘探与开发,41(4):480-484. doi: 10.11698/PED.2014.04.14 [49] 王皆明,姜凤光,2007. 砂岩气顶油藏改建储气库库容计算方法[J]. 天然气工业,27(11):97-99. doi: 10.3321/j.issn:1000-0976.2007.11.030 [50] 胥洪成,王皆明,屈平,等,2015. 复杂地质条件气藏储气库库容参数的预测方法[J]. 天然气工业,35(1):103-108. doi: 10.3787/j.issn.1000-0976.2015.01.014 [51] 杨跃辉,高广亮,王芳,等,2022. 冀东南堡储气库射孔段分层地应力测量方法[J]. 油气储运,41(9):1029-1035. [52] 赵其生,于连忠,2013. 南堡油田南堡1、2号构造馆陶组储层特征研究[J]. 石油天然气学报,35(7):38-43. doi: 10.3969/j.issn.1000-9752.2013.07.009 [53] 赵昱超,罗瑜,李隆新,等,2022. 地下储气库地应力模拟研究与地质完整性评估:以相国寺为例[J]. 地质力学学报,28(4):523-536. doi: 10.12090/j.issn.1006-6616.2021138 [54] 郑得文,胥洪成,王皆明,等,2017. 气藏型储气库建库评价关键技术[J]. 石油勘探与开发,44(5):794-801. doi: 10.11698/PED.2017.05.15 [55] 郑雅丽,孙军昌,邱小松,等,2020. 油气藏型储气库地质体完整性内涵与评价技术[J]. 天然气工业,40(5):94-103. doi: 10.3787/j.issn.1000-0976.2020.05.012 [56] 钟城,秦启荣,周吉羚,等,2018. 现今地应力对富有机质页岩断层封闭性的研究:以川东南丁山地区龙马溪组为例[J]. 地质力学学报,24(4):452-464. doi: 10.12090/j.issn.1006-6616.2018.24.04.047 -

下载:

下载: