In-situ stress simulation and integrity evaluation of underground gas storage: A case study of the Xiangguosi underground gas storage, Sichuan, SW China

-

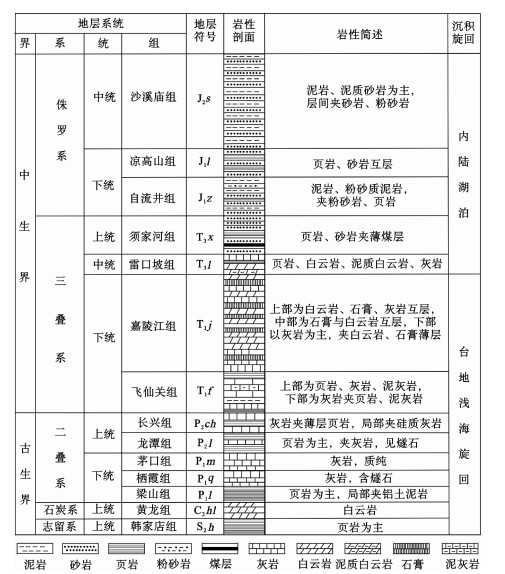

摘要: 为保障国家调峰保供需求,目前相国寺地下储气库(以下简称储气库)提出并正在进行扩压增量工程,为有效指导储气库运行上限压力优化,同时确保储气库长期安全运行,亟需对相国寺储气库开展地质体完整性评估。综合地质、地震、测井、动态监测资料以及各类室内岩芯实验数据,建立相国寺储气库三维静态及四维地质力学模型,分析了储气库地质体地质力学特征,分别对不同气藏孔隙压力特征下的盖层、底托层、断层稳定性进行应力应变模拟及评估。结果表明:梁山组盖层以及韩家店组底托层在储气库运行过程中产生的地层形变量小;5条控藏断层在储气库前期运行及现今注采条件下没有断层活化风险;模拟储气库注入压力高于原始气藏压力6 MPa时,储气库地质体完整性存在失稳风险。研究成果精细定量化评估了储气库在动态应力场影响下的运行安全,对优化储气库运行方案具有重要的指导意义。Abstract: To ensure the national demand for gas supply and peak shaving, a project of capacity expansion is proposed for the Xiangguosi underground gas storage (UGS). A geologic integrity evaluation is urgently needed to optimize the upper operating pressure and ensure the long-term safe operation. Thus, based on the geological, seismic, well logging, and dynamic monitoring data as well as the indoor core experimental data, 3D static and 4D geomechanical models were established for this UGS. Some geomechanical characteristics of the geological body were analyzed. The stability of the caprock, base, and fault under different reservoir pressure was individually simulated and evaluated as well. The results show that, both the caprock of the Liangshan Formation and the base of the Hanjiadian Formation may produce a little formation deformation during the operation; the five reservoir-controlling faults have no risk of fault activation during the early UGS operation under current stress conditions, and their sealing performance is good; when the reservoir pressure is higher than the original formation pressure of 6 MPa, the integrity of the Xiangguosi UGS is at risk of instability. This research accurately and quantitatively evaluate the operation safety of the Xiangguosi UGS under the influence of dynamic stress field, which has important guiding significance for the optimization of its operation plan.

-

图 4 三维地质力学模型建模流程及模型属性

a—三维地质力学模型建模流程;b—建模范围;c—静态泊松比属性;d—静态杨氏模量属性;e—内摩擦系数属性;f—最小水平主应力属性;g—最大水平主应力属性;h—孔隙压力属性

Figure 4. Modeling process and model attributes of the 3D geomechanical model

(a)3D geomechanical modeling process; (b)The modeling range; (c)Static Poisson′s ratio; (d)Static Young′s modulus; (e)Internal friction coefficient; (f)Minimum horizontal principal stress; (g)Maximum horizontal principal stress; (h)Pore pressure

图 7 梁山组地层最小主应力分布及拉张破坏风险分析图

a—梁山组盖层最小主应力随黄龙组孔隙压力变化图;b—梁山组盖层拉张破坏风险分析图

Figure 7. Analysis diagrams showing the minimum principal stress distribution and tensile failure risk in the Liangshan Formation

(a)Diagram showing the variation of minimum principal stress in the cap rock of the Liangshan Formation with pore pressure of the Huanglong Formation; (b)Diagram showing the tensile failure risk of the cap rock in the Liangshan Formation

图 8 梁山组地层不同注入压力Tau比值分布及不同部位剪切破坏对比分析图

a—梁山组盖层Tau比值随黄龙组孔隙压力变化图;b—梁山组盖层剪切破坏风险分析图

Figure 8. Comparative analysis of the Tau ratio distribution under different injection pressures and the shear failure in different parts of the Liangshan Formation

(a)Tau ratio of the cap rock in the Liangshan Formation varies with pore pressure in the Huanglong Formation; (b)Shear failure risk of the cap rock in the Liangshan Formation

图 9 5条主要断层开采初期和压力衰竭末期断层活动性分析图

a—1978年相国寺气田5条主要控藏断层断面Tau比值分布图;b—2012年相国寺储气库5条主要控藏断层断面Tau比值分布图

Figure 9. Diagram showing the fault activity of five major faults in the early mining stage and the late stage of pressure exhaustion

(a)Tau ratio distribution of five main reservoir-controlled faults in the Xiangguosi Gas Field in 1978;(b)Tau ratio distribution of five main reservoir-controlled faults in the Xiangguosi underground gas storage in 2012

表 1 不同岩石类型地层岩石力学参数正演数学模型

Table 1. Correlation statistics of rock mechanics parameters of different lithologies and strata

层位与岩性 VS/(km/s) 静态杨氏模量/GPa 静态泊松比 内聚力/MPa 内摩擦系数 上覆白云岩地层 0.3739×VP+0.7672 0.9×Edyn PRdyn 0.0018×e(3.7938×RHOB) tan(18.532×VP0.5148) 龙潭组页岩 0.5037×Vp+0.0521 0.45×Edyn 0.65×PRdyn 0.221×Esta0.712 tan{arcsin[(VP-1)/(VP+1)]}×0.7 上覆灰岩地层 -0.019×VP2+0.693×VP-0.416 0.9×Edyn PRdyn 0.0018×e(3.7938×RHOB) tan(18.532×VP0.5148) 梁山组页岩 0.5037×VP+0.0521 0.45×Edyn 0.65×PRdyn 1.65×Esta0.89 tan{arcsin[(VP-1)/(VP+1)]}×0.7 黄龙组白云岩 0.3696×VP+1.1682 0.9×Edyn PRdyn 96.62×e(-0.94×PHI) tan(18.532×VP0.5148) 韩家店组页岩 0.5037×VP+0.0521 0.45×Edyn 0.65×PRdyn 0.221×Esta0.712 tan{arcsin[(VP-1)/(VP+1)]}×0.7 注:VS—横波速度;VP—纵波速度;Esta—静态杨氏模量;Edyn—动态杨氏模量;PRdyn—动态泊松比;RHOB—岩石密度;PHI—孔隙度 -

BYERLEE J, 1978. Friction of rocks[J]. Pure and Applied Geophysics, 116(4-5): 615-626. doi: 10.1007/BF00876528 CHEN J S, LI J J, JING G, et al., 2018. Research progress of geomechanical evaluation system used for Jintan salt cavern gas storage[J]. Oil & Gas Storage and Transportation, 37(10): 1088-1096. (in Chinese with English abstract) CHEN N, WANG C H, CHEN Z P, et al., 2021. Re-analyzing the in-situ stress field in the right bank of the Baihetan hydroelectric power plant using the borehole breakout data[J]. Journal of Geomechanics, 27(3): 430-440. (in Chinese with English abstract) DING G S, 2011. Demand and challenges for underground gas storages in China[J]. Natural Gas Industry, 31(12): 90-93. (in Chinese with English abstract) DING G S, WANG J M, 2011. Key points in the reconstruction of an underground gas storage based on a depleted gas reservoir[J]. Natural Gas Industry, 31(5): 87-89. (in Chinese with English abstract) DONG S H, HAN Z C, FEI F, et al., 2013. Integrity management of oil & gas transmission stations and the related core technologies[J]. Natural Gas Industry, 33(12): 117-123. (in Chinese with English abstract) DONG S H, ZHANG H, 2018. Development status and prospect of safety insurance technologies for oil & gas reserves[J]. Oil & Gas Storage and Transportation, 37(3): 241-247. (in Chinese with English abstract) DOWNIE R, REESE S, AJAYI B, 2013. Investigating microseismic responses and interaction between offset hydraulic fracture treatments during horizontal well completions[C]//Proceedings of the SPE eastern regional meeting. Pittsburgh: SPE. DU A Q, JIANG J X, 2016. Study review of exhausted reservoir gas storages wellbore integrity[J]. Petrochemical Industry Technology, 23(4): 119. (in Chinese with English abstract) FAN W H, FENG B, LIU S B, et al., 2014. Wellbore seal integrity cementing technology of underground gas storage in Xiangguosi[J]. Fault-Block Oil & Gas Field, 21(1): 104-106. (in Chinese with English abstract) FU X F, WU T, LYU Y F, et al., 2018. Research status and development trend of the reservoir caprock sealing properties[J]. Oil & Gas Geology, 39(3): 454-471. (in Chinese with English abstract) HUANG J X, PENG S M, WANG X J, et al., 2006. Applications of imaging logging data in the research of fracture and ground stress[J]. Acta Petrolei Sinica, 27(6): 65-69. (in Chinese with English abstract) JAEGER J C, COOK N G W, 1976. Fundamentals of rock mechanics[M]. New York: Chapman and Hall. JIANG T W, ZHANG H, WANG H Y, et al., 2017. Effects of faults geomechanical activity on water invasion in Kela 2 Gasfield, Tarim Basin[J]. Natural Gas Geoscience, 28(11): 1735-1744. (in Chinese with English abstract) JIANG T W, ZHANG H, XU K, et al., 2020. Reservoir geomechanical characteristics and the influence on development in Keshen Gas Field[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 42(4): 1-12. (in Chinese with English abstract) LEI H, 2018. Opportunities and challenges of underground gas storage in China[J]. Oil & Gas Storage and Transportation, 37(7): 728-733. (in Chinese with English abstract) LIAO W, LIU G L, CHEN R H, et al., 2021. Evaluation on the dynamic sealing capacity of underground gas storages rebuilt from gas reservoirs: a case study of Xinjiang H underground gas storage[J]. Natural Gas Industry, 41(3): 133-141. (in Chinese with English abstract) LIN J P, JIA S P, LIU T H, et al., 2015. Comprehensive evaluation of sealing ability of mudstone cap rock for Xing 9 depleted gas reservoir in reconstructing underground gas storage[J]. Chinese Journal of Rock Mechanics and Engineering, 34(S2): 4100-4107. (in Chinese with English abstract) LIU W Z, 2017. Probe on and practice of well integrity technology for injection-production wells at Xiangguosi underground gas storage[J]. Drilling & Production Technology, 40(2): 27-30. (in Chinese with English abstract) LUO J H, LI L F, WANG J J, et al., 2019. The research progress on integrity technology of underground storage with gas reservoirs[J]. Petroleum Tubular Goods & Instruments, 5(2): 1-7. (in Chinese with English abstract) MA X H, ZHENG D W, SHEN R C, et al., 2018. Key technology and practice of gas storage construction in Complex geological conditions in China[J]. Petroleum Exploration and Development, 45(3): 489-499. (in Chinese with English abstract) MAO C Q, ZHENG Z Y, 2010. Site selection for underground gas storage rebuilt on the depleted Xiangguosi Carboniferous gas reservoirs in Sichuan and Chongqing areas[J]. Natural Gas Industry, 30(8): 72-75. (in Chinese with English abstract) MENG Z P, WANG Y H, ZHANG K, et al., 2019. Analysis of hydraulic fracturing cracks for coal reservoirs and in-situ stress direction in Southern Qinshui Basin[J]. Coal Science and Technology, 47(10): 216-222. (in Chinese with English abstract) RAMANATHAN V, BOSKOVIC D, ZHMODIK A, et al., 2014. Back to the future: shale 2.0-returning back to engineering and modelling hydraulic fractures in unconventionals with new seismic to stimulation workflows[C]//Proceedings of the SPE/CSUR unconventional resources conference. Calgary: SPE. REN H L, LIU C L, LIU W P, et al., 2020. Stress field simulation and fracture development prediction of the Wufeng Formation: Longmaxi Formation in the Fushun-Yongchuan Block, Sichuan Basin[J]. Journal of Geomechanics, 26(1): 74-83. (in Chinese with English abstract) WANG C H, GAO G Y, JIA J, et al., 2020. Variation of stress field and fault slip tendency induced by injection and production in the H underground gas storage[J]. Natural Gas Industry, 40(10): 76-85. (in Chinese with English abstract) WEI G Q, ZHENG Y L, QIU X S, et al., 2019. Geological theory and application of underground gas storage in China[J]. Acta Petrolei Sinica, 40(12): 1519-1530. (in Chinese with English abstract) WU J F, XIONG Y L, KONG L, et al., 2007. Risk assessment of reconstruction of gas storage in Xiangguosi, Carboniferous gas reservoir[J]. Natural Gas Exploration and Development, 30(1): 60-62, 71. (in Chinese with English abstract) WU J F, ZHONG B, FENG X, et al., 2012. Operation parameter design of the Xiangguosi underground gas storage based on the Carboniferous gas reservoir[J]. Natural Gas Industry, 32(2): 91-94. (in Chinese with English abstract) YU J, YAN R H, YE X Q, et al., 2013. A new integrated drilling and fracturing solution for tight oil exploration: a case study from central China[C]//Proceedings of the SPE/IADC middle east drilling technology conference & exhibition. Dubai: SPE. ZHANG G Q, ZENG D Q, FAN Z W, et al., 2021. Method and application of in-situ stress field to evaluate fault sealing of underground gas storage traps[J]. Natural Gas Geoscience, 32(6): 923-930. (in Chinese with English abstract) ZHANG G X, LI B, ZHENG D W, et al., 2017. Challenges to and proposals for underground gas storage (UGS) business in China[J]. Natural Gas Industry, 37(1): 153-159. (in Chinese with English abstract) ZHENG Y L, SUN J C, QIU X S, et al., 2020. Connotation and evaluation technique of geological integrity of UGSs in oil-gas fields[J]. Natural Gas Industry, 40(5): 94-103. (in Chinese with English abstract) ZHOU C S, GENG Y N, LEI Y, et al., 2020. Experimental research on distribution of in-situ stress of Bozhong 19-6 complex fault block structure[J]. Petrochemical Industry Application, 39(1): 84-89. (in Chinese with English abstract) ZOBACK M D, 2007. Reservoir geomechanics[M]. Cambridge: Cambridge University Press. 陈加松, 李建君, 井岗, 等, 2018. 金坛盐穴储气库地质力学评价体系研究进展[J]. 油气储运, 37(10): 1088-1096. https://www.cnki.com.cn/Article/CJFDTOTAL-YQCY201810003.htm 陈念, 王成虎, 陈平志, 等, 2021. 利用钻孔崩落数据再认识白鹤滩右岸地应力场特征[J]. 地质力学学报, 27(3): 430-440. doi: 10.12090/j.issn.1006-6616.2021.27.03.039 丁国生, 2011. 中国地下储气库的需求与挑战[J]. 天然气工业, 31(12): 90-93. doi: 10.3787/j.issn.1000-0976.2011.12.016 丁国生, 王皆明, 2011. 枯竭气藏改建储气库需要关注的几个关键问题[J]. 天然气工业, 31(5): 87-89. doi: 10.3787/j.issn.1000-0976.2011.05.023 董绍华, 韩忠晨, 费凡, 等, 2013. 输油气站场完整性管理与关键技术应用研究[J]. 天然气工业, 33(12): 117-123. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201312019.htm 董绍华, 张行, 2018. 石油及天然气储备库安全保障技术现状及展望[J]. 油气储运, 37(3): 241-247. https://www.cnki.com.cn/Article/CJFDTOTAL-YQCY201803001.htm 杜安琪, 蒋建勋, 2016. 枯竭型油气藏储气库井筒完整性研究综述[J]. 石化技术, 23(4): 119. doi: 10.3969/j.issn.1006-0235.2016.04.089 范伟华, 冯彬, 刘世彬, 等, 2014. 相国寺储气库固井井筒密封完整性技术[J]. 断块油气田, 21(1): 104-106. https://www.cnki.com.cn/Article/CJFDTOTAL-DKYT201401027.htm 付晓飞, 吴桐, 吕延防, 等, 2018. 油气藏盖层封闭性研究现状及未来发展趋势[J]. 石油与天然气地质, 39(3): 454-471. https://www.cnki.com.cn/Article/CJFDTOTAL-SYYT201803005.htm 黄继新, 彭仕宓, 王小军, 等, 2006. 成像测井资料在裂缝和地应力研究中的应用[J]. 石油学报, 27(6): 65-69. doi: 10.3321/j.issn:0253-2697.2006.06.014 江同文, 张辉, 王海应, 等, 2017. 塔里木盆地克拉2气田断裂地质力学活动性对水侵的影响[J]. 天然气地球科学, 28(11): 1735-1744. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201711013.htm 江同文, 张辉, 徐珂, 等, 2020. 克深气田储层地质力学特征及其对开发的影响[J]. 西南石油大学学报(自然科学版), 42(4): 1-12. https://www.cnki.com.cn/Article/CJFDTOTAL-XNSY202004001.htm 雷鸿, 2018. 中国地下储气库建设的机遇与挑战[J]. 油气储运, 37(7): 728-733. https://www.cnki.com.cn/Article/CJFDTOTAL-YQCY201807003.htm 廖伟, 刘国良, 陈如鹤, 等, 2021. 气藏型地下储气库动态密封性评价: 以新疆H地下储气库为例[J]. 天然气工业, 41(3): 133-141. doi: 10.3787/j.issn.1000-0976.2021.03.016 林建品, 贾善坡, 刘团辉, 等, 2015. 枯竭气藏改建储气库盖层封闭能力综合评价研究: 以兴9枯竭气藏为例[J]. 岩石力学与工程学报, 34(S2): 4100-4107. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2015S2057.htm 刘文忠, 2017. 相国寺储气库注采井完整性技术探索与实践[J]. 钻采工艺, 40(2): 27-30. doi: 10.3969/J.ISSN.1006-768X.2017.02.09 罗金恒, 李丽锋, 王建军, 等, 2019. 气藏型储气库完整性技术研究进展[J]. 石油管材与仪器, 5(2): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-SYYQ201902001.htm 马新华, 郑得文, 申瑞臣, 等, 2018. 中国复杂地质条件气藏型储气库建库关键技术与实践[J]. 石油勘探与开发, 45(3): 489-499. https://www.cnki.com.cn/Article/CJFDTOTAL-SKYK201803016.htm 毛川勤, 郑州宇, 2010. 川渝地区相国寺地下储气库库址选择[J]. 天然气工业, 30(8): 72-75. doi: 10.3787/j.issn.1000-0976.2010.08.019 孟召平, 王宇恒, 张昆, 等, 2019. 沁水盆地南部煤层水力压裂裂缝及地应力方向分析[J]. 煤炭科学技术, 47(10): 216-222. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201910028.htm 任浩林, 刘成林, 刘文平, 等, 2020. 四川盆地富顺—永川地区五峰组: 龙马溪组应力场模拟及裂缝发育区预测[J]. 地质力学学报, 26(1): 74-83. doi: 10.12090/j.issn.1006-6616.2020.26.01.008 王成虎, 高桂云, 贾晋, 等, 2020. H储气库注采诱发应力场及断层滑动趋势变化[J]. 天然气工业, 40(10): 76-85. doi: 10.3787/j.issn.1000-0976.2020.10.009 魏国齐, 郑雅丽, 邱小松, 等, 2019. 中国地下储气库地质理论与应用[J]. 石油学报, 40(12): 1519-1530. doi: 10.7623/syxb201912011 吴建发, 熊燕莉, 孔玲, 等, 2007. 相国寺石炭系气藏改建储气库风险评价[J]. 天然气勘探与开发, 30(1): 60-62, 71. doi: 10.3969/j.issn.1673-3177.2007.01.016 吴建发, 钟兵, 冯曦, 等, 2012. 相国寺石炭系气藏改建地下储气库运行参数设计[J]. 天然气工业, 32(2): 91-94. doi: 10.3787/j.issn.1000-0976.2012.02.022 张刚雄, 李彬, 郑得文, 等, 2017. 中国地下储气库业务面临的挑战及对策建议[J]. 天然气工业, 37(1): 153-159. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201701030.htm 张广权, 曾大乾, 范照伟, 等, 2021. 利用地应力评价地下储气库断层密封性方法及应用[J]. 天然气地球科学, 32(6): 923-930. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX202106015.htm 郑雅丽, 孙军昌, 邱小松, 等, 2020. 油气藏型储气库地质体完整性内涵与评价技术[J]. 天然气工业, 40(5): 94-103. https://www.cnki.com.cn/Article/CJFDTOTAL-TRQG202005015.htm 周长所, 耿亚楠, 雷杨, 等, 2020. 渤中19-6复杂断块构造地应力分布规律试验研究[J]. 石油化工应用, 39(1): 84-89. https://www.cnki.com.cn/Article/CJFDTOTAL-NXSH202001019.htm -

下载:

下载: