DISCRETE ELEMENT SIMULATION OF SAND CONFINED COMPRESSION TEST BASED ON MatDEM

-

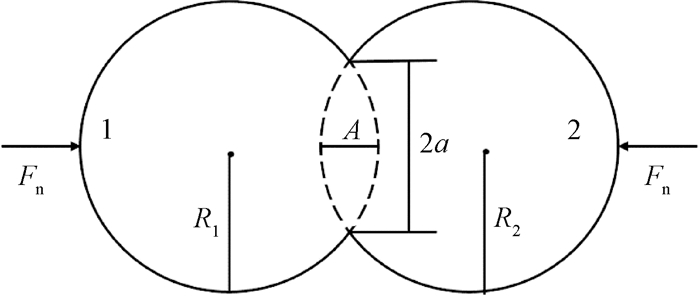

摘要: 离散元法基于非连续介质力学理论,尤其适用于砂土等离散介质体的数值模拟研究。利用岩土体离散元模拟软件MatDEM的二次开发功能,研发了砂土侧限压缩试验三维离散元模拟器。对三个不同级配砂土试样进行了侧限压缩试验,并且进行了与之相对应的数值模拟,通过分析对比试验结果与数值模拟结果验证了所开发模拟器的有效性。模拟结果表明:离散元法可以很好地反应砂土压缩过程中的配位数变化;每个模拟样品中,粒径较小的单元受到较大的平均压力,导致平均位移较大;数值计算结果的主要误差是由离散元颗粒自身的泊松比引起的。研究突破了常规土力学研究方法的局限性,为今后岩土工程离散元模拟研究提供了参考。Abstract: Discrete element method is suitable for numerical simulation of discrete mesoporous media such as sand, because discrete element method is based on discontinuous medium mechanics theory. A 3D discrete element simulator for sand confined compression test was developed by the discrete element simulation software MatDEM. Confined compression tests for 3 different graded sands were carried out, and the numerical simulation matched with the test was carried out. The validity of the developed simulator was verified by the comparison between the test and numerical simulation results. The results show that DEM can well reflect the change of the coordination number in the compression process of sand; in each sample, the elements with smaller size are subjected to greater average pressure, which leads to a larger average displacement; the main error of numerical simulation was caused by the Poisson's ratio of the discrete element particle. This study overcomes the limitations of the conventional soil mechanics research methods, and provides a reference for the study of the discrete element simulation of geotechnical engineering in the future.

-

Key words:

- sand /

- confined compression test /

- DEM /

- numerical simulation /

- error analysis

-

表 1 模拟与试验砂样物理参数对比

Table 1. Comparison of physical parameters of the simulated sand and the tested sand

砂样编号 类型 粒组/mm 总质量/g 各粒组质量比 孔隙比 单元数量/个 1号 试验 0.4~0.6/1~1.2 85 1:1 0.8303 模拟 0.4~0.6/1~1.2 1.002:1 0.8670 323750 2号 试验 0.4~0.6/0.6~0.8 86 1:1 0.8209 模拟 0.4~0.6/0.6~0.8 1:1 0.8670 403699 3号 试验 0.4~0.6/0.6~0.8/1~1.2 89 1:1:1 0.8121 模拟 0.4~0.6/0.6~0.8/1~1.2 1:1.024:0.983 0.8591 236192 表 2 模型微观力学参数

Table 2. Micromechanical parameters of the model

类型 法向刚度/(N/m) 切向刚度/(N/m) 断裂位移/m 抗剪力/N 摩擦系数 试算值 1.3139×106 4.1931×105 0 44.3733 0 解析值 1.1254×106 4.0193×105 0 39.9360 0 -

[1] 李爽, 刘洋, 吴可嘉.砂土直剪试验离散元数值模拟与细观变形机理研究[J].长江科学院院报, 2017, 34(4):104~110, 116. http://d.old.wanfangdata.com.cn/Periodical/cjkxyyb201704025LI Shuang, LIU Yang, WU Kejia. Exploring mesoscopic deformation mechanism of sand in direct shear test by numerical simulation using discrete element method[J]. Journal of Yangtze River Scientific Research Institute, 2017, 34(4):104~110, 116. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/cjkxyyb201704025 [2] 王玉锁, 王明年, 童建军, 等.砂类土体隧道围岩压缩模量的试验研究[J].岩土力学, 2008, 29(6):1607~1612, 1617. doi: 10.3969/j.issn.1000-7598.2008.06.033WANG Yusuo, WANG Mingnian, TONG Jianjun, et al. Test research on compression modulus of sandy soil tunnel surrounding rock[J]. Rock and Soil Mechanics, 2008, 29(6):1607~1612, 1617. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2008.06.033 [3] Ghayoomi M, Suprunenko G, Mirshekari M. Cyclic triaxial test to measure strain-dependent shear modulus of unsaturated sand[J]. International Journal of Geomechanics, 2017, 17(9):1~11. [4] 扈萍, 黄茂松, 马少坤, 等.粉细砂的真三轴试验与强度特性[J].岩土力学, 2011, 32(2):465~470. doi: 10.3969/j.issn.1000-7598.2011.02.024HU Ping, HUANG Maosong, MA Shaokun, et al. True triaxial tests and strength characteristics of silty sand[J]. Rock and Soil Mechanics, 2011, 32(2):465~470. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2011.02.024 [5] Desrues J, Chambon R, Mokni M, et al. Void ratio evolution inside shear bands in triaxialsand specimens studied by computed tomography[J]. Géotechnique, 1996, 46(3):529~546. doi: 10.1680/geot.1996.46.3.529 [6] Oda M, Takemura T, Takahashi M. Microstructure in shear band observed by microfocus X-ray computed tomography[J]. Géotechnique, 2015, 54(8):539~542. http://cn.bing.com/academic/profile?id=2af4c8c8d498bea7613ae90790782d8a&encoded=0&v=paper_preview&mkt=zh-cn [7] 曹亮, 刘文白, 李晓昭, 等.基于数字图像的砂土压缩变形模式的试验研究[J].岩土力学, 2012, 33(4):1018~1024. doi: 10.3969/j.issn.1000-7598.2012.04.009CAO Liang, LIU Wenbai, LI Xiaozhao, et al. Experimental study of compression deformation patterns in sands based on digital image analysis[J]. Rock and Soil Mechanics, 2012, 33(4):1018~1024. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2012.04.009 [8] Cundall P A, Strack O D L. A discrete numerical mode for granular assemblies[J]. Géotechnique, 1979, 29(1):47~65. doi: 10.1680/geot.1979.29.1.47 [9] Naeij M, Mirghasemi A A. Study of anisotropies evolution in direct shear test using discrete element method[A]. Yang Q. Constitutive Modeling of Geomaterials[M]. Boca Raton, Fla: SSGG, 2013, 451~460. [10] 蒋明镜, 王富周, 朱合华.单粒组密砂剪切带的直剪试验离散元数值分析[J].岩土力学, 2010, 31(1):253~257, 298. doi: 10.3969/j.issn.1000-7598.2010.01.043JANG Mingjing, WANG Fuzhou, ZHU Hehua. Shear band formation in ideal dense sand in direct shear test by discrete element analysis[J]. Rock and Soil Mechanics, 2010, 31(1):253~257, 298. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2010.01.043 [11] Tong Z X, Zhang L W, Zhou M. DEM simulation of biaxial compression experiments of inherently anisotropic granular materials and the boundary effects[J]. Journal of Applied Mathematics, 2013, 2013:394372. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0232215620 [12] Yan G, Yu H S, McDowell G. Simulation of granular material behaviour using DEM[J]. Procedia Earth and Planetary Science, 2009, 1(1):598~605. doi: 10.1016/j.proeps.2009.09.095 [13] 史旦达, 周健, 贾敏才, 等.考虑颗粒破碎的砂土高应力一维压缩特性颗粒流模拟[J].岩土工程学报, 2007, 29(5):736~742. doi: 10.3321/j.issn:1000-4548.2007.05.017SHI Danda, ZHOU Jian, JIA Mincai, et al. Numerical simulations of particle breakage property of sand under high pressure 1D compression condition by use of particle flow code[J]. Chinese Journal of Geotechnical Engineering, 2007, 29(5):736~742. (in Chinese with English abstract) doi: 10.3321/j.issn:1000-4548.2007.05.017 [14] Ueda T, Matsushima T, Yamada Y. DEM simulation on the one-dimensional compression behavior of various shaped crushable granular materials[J]. Granular Matter, 2013, 15(5):675~684. doi: 10.1007/s10035-013-0415-y [15] 陈铖, 刘小清, 罗正东, 等.颗粒级配对粗粒土强度与变形特性影响的研究[J].工程地质学报, 2016, 24(6):1191~1198. http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201606022CHEN Cheng, LIU Xiaoqing, LUO Zhengdong, et al. Study of strength and deformation characteristic of unbound granual material with different grain composition[J]. Journal of Engineering Geology, 2016, 24(6):1191~1198. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/gcdzxb201606022 [16] 朱俊高, 郭万里, 徐佳成, 等.级配和密实度对粗粒土三轴试验影响离散元分析[J].重庆交通大学学报(自然科学版), 2017, 36(6):70~74. doi: 10.3969/j.issn.1674-0696.2017.06.11ZHU Jungao, GUO Wanli, XU Jiacheng, et al. DEM analysis on impact of gradation and compactness on coarse-grained soil in tri-axial test[J]. Journal of Chongqing Jiaotong University (Natural Science), 2017, 36(6):70~74. (in Chinese with English abstract) doi: 10.3969/j.issn.1674-0696.2017.06.11 [17] 孔亮, 季亮亮, 曹杰峰.应力路径和颗粒级配对砂土变形影响的细观机制[J].岩石力学与工程学报, 2013, 32(11):2334~2341. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201311020KONG Liang, JI Liangliang, CAO Jiefeng. Deformation mesomechanism of sands with different grain gradations under different stress paths[J]. Chinese Journal of Rock Mechanics & Engineering, 2013, 32(11):2334~2341. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201311020 [18] 孙其诚, 王光谦.颗粒物质力学导论[M].北京:科学出版社, 2009, 15~17.SUN Qicheng, WANG Guangqian. Introduction to particulate matter mechanics[M]. Beijing:Science Press, 2009, 15~17. (in Chinese) [19] 刘春, 施斌, 顾凯, 等.岩土体大型三维离散元模拟系统的研发与应用[J].工程地质学报, 2014, 22(S1):551~557. http://d.old.wanfangdata.com.cn/Conference/8502179LIU Chun, SHI Bin, GU Kai, et al. Development and application of large-scale discrete element simulation system for rock and soil[J]. Journal of Engineering Geology, 2014, 22(S1):551~557. (in Chinese with English abstract) http://d.old.wanfangdata.com.cn/Conference/8502179 [20] Liu C, Xu Q, Shi B, et al. Mechanical properties and energy Conversion of 3D close-packed lattice model for brittle rocks[J]. Computers & Geosciences, 2017, 103:12~20. http://cn.bing.com/academic/profile?id=b42c208c2bc50a32e70363bb4a43f69d&encoded=0&v=paper_preview&mkt=zh-cn -

下载:

下载: