Determination of hydraulic fracture closure pressure based on total system stiffness method: Case studies

-

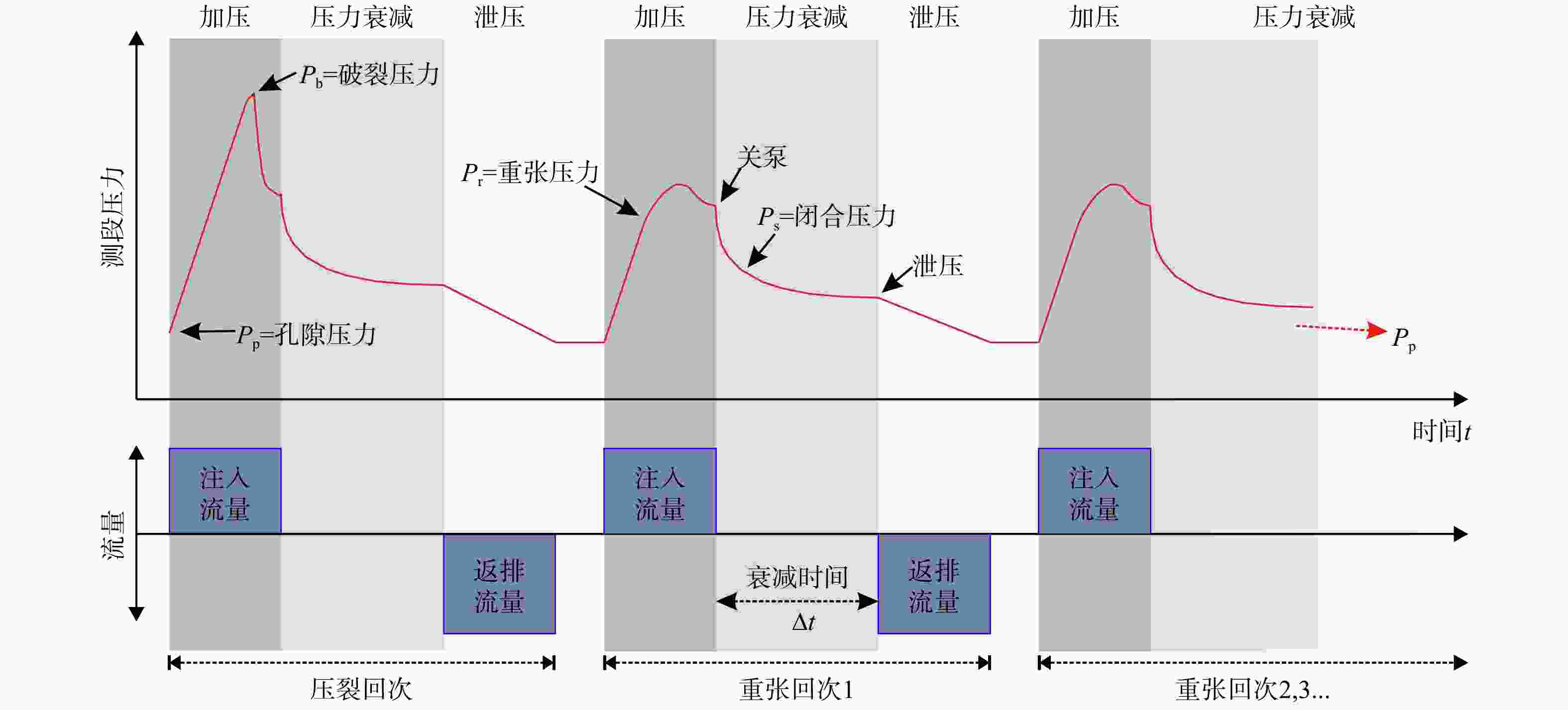

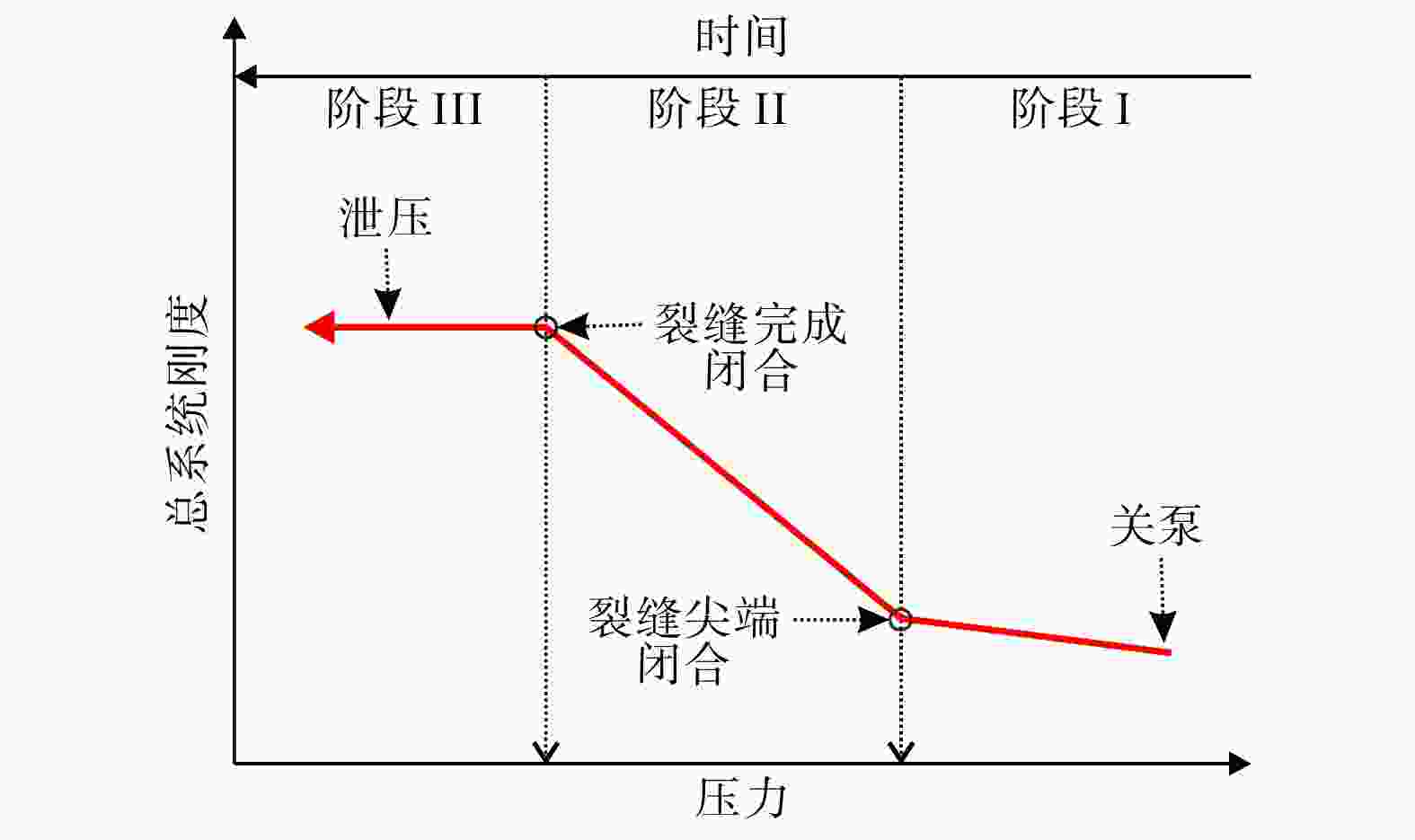

摘要: 水压致裂法是应用最为广泛的岩体原位应力测量方法之一,也是国际岩石力学学会推荐的地应力测试方法。基于压降曲线解释裂缝闭合压力以确定最小(水平)主应力是该技术的重要研究内容。然而,传统解释方法主要依赖于利用切线或最优拟合的方式分析压力衰减率,导致分析结果高度依赖数据时间窗口的范围,且无法识别出具有明确物理意义的压裂缝闭合过程,给闭合压力分析以及地应力测量结果带来一定不确定性。文章介绍了一种基于总系统刚度(TSS)演化特征确定闭合压力的新方法。该方法可将压力衰减曲线有效转换为总系统刚度曲线,从而更好地考虑压裂缝闭合的响应特征。利用TSS方法对多个来自不同钻孔、不同岩性和不同深度的水压致裂实测曲线进行严格分析,结果表明该方法具有较好的适用性。关泵后总系统刚度的演化可分为3个主要阶段,其特征可用于识别闭合压力的上下限,并评估压力曲线是否适用于获取原位应力信息。TSS方法的主要优势在于,其为裂缝闭合过程的开始和结束提供了明确的物理定义,因此与传统方法相比,该方法确定的闭合压力对时间窗口选择的敏感性降低。此外,TSS方法仅依赖于压力数据,无需任何拟合或外推。预期该方法在与水力压裂相关的原位应力分析中具有广阔的应用前景。Abstract:

Objective Hydraulic fracturing is one of the most widely used and ISRM-recommended techniques for in-situ stress measurement in rock masses, where a key step is determining closure pressure from the pressure-decay curve as a proxy for the minimum horizontal principal stress. Conventional interpretation methods mainly rely on tangents or best-fit lines to analyze the pressure-decay rate, making the result highly sensitive to the selected time window and lacking clear physical representation of fracture closure, which introduces uncertainties in closure pressure and stress evaluation. Methods This study proposes a method based on the evolution of Total System Stiffness (TSS), in which the pressure-decay curve after shut-in is transformed into a TSS curve to better capture fracture-closure behavior, and the method is applied to hydraulic-fracturing datasets from different boreholes, lithologies and depths. Results The evolution of TSS after shut-in can be divided into three main stages whose features can be used to identify upper and lower bounds of closure pressure and to evaluate whether the pressure curve is suitable for in-situ stress interpretation; closure pressures obtained in this way show reduced sensitivity to the choice of time window compared with conventional approaches. Conclusion The TSS method provides clear physical meanings for the beginning and end of fracture closure and determines closure pressure directly from pressure data, without fitting or extrapolation. [ Significance ] The method offers a practical tool for improving closure-pressure interpretation and is expected to be widely applicable in hydraulic-fracturing-based in-situ stress analysis. -

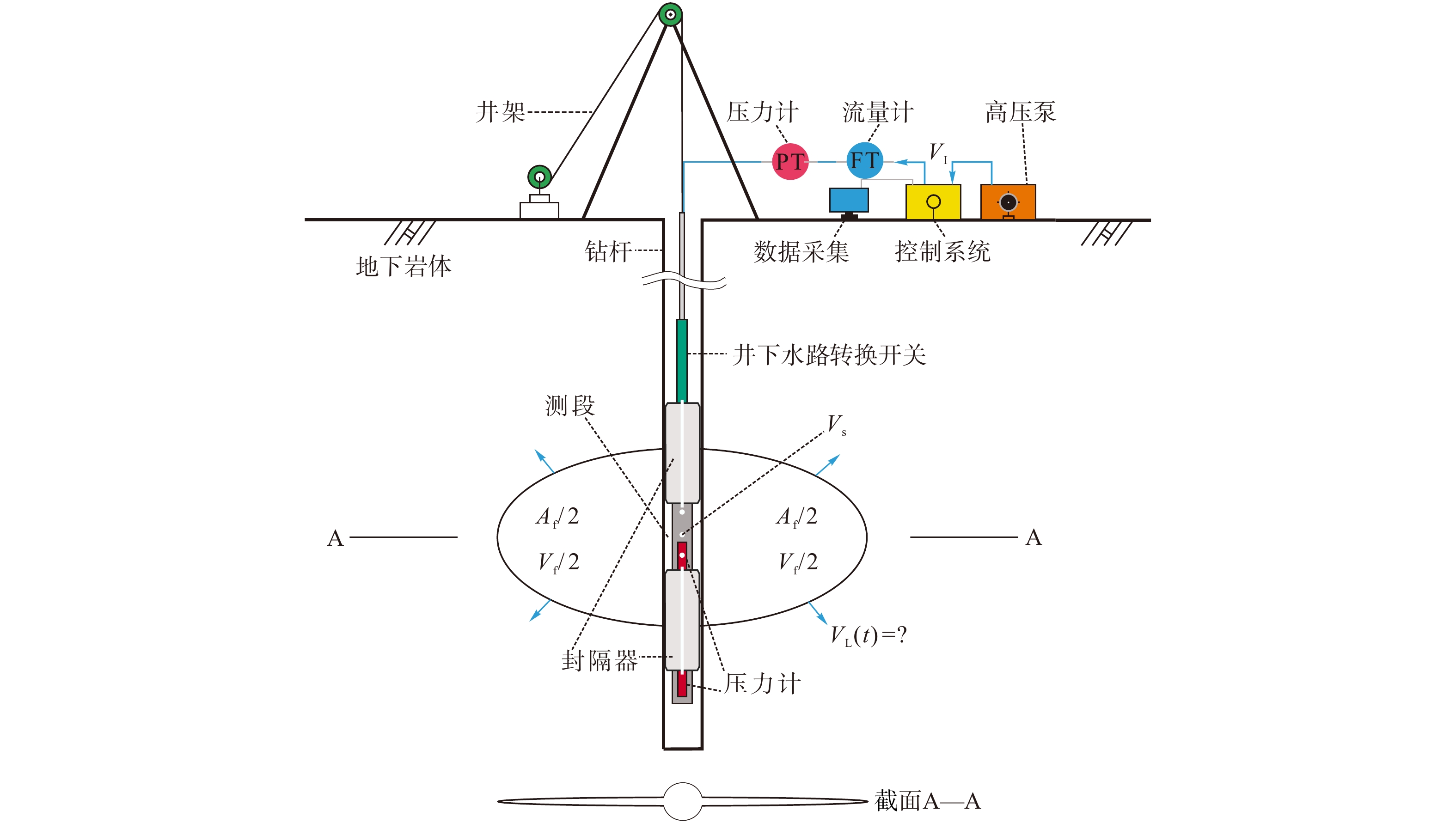

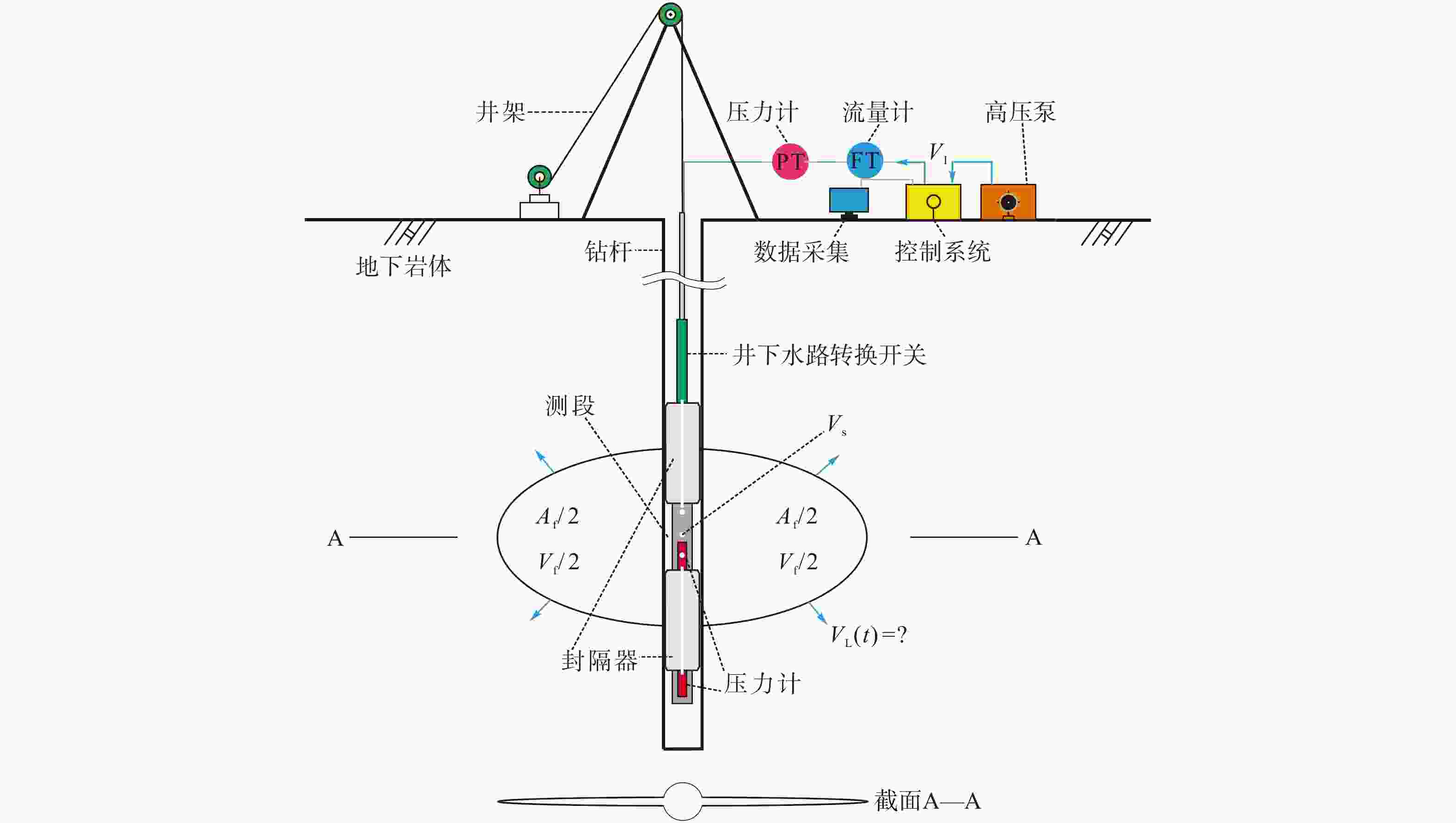

图 1 水压致裂测试设备及钻孔−压裂缝−地层系统的简化示意图

VI—累积注入流体体积;Vs—压裂段及钻杆的体积;Af—压裂缝的面积;Vf—压裂缝的体积;VL(t)—累积流体泄漏体积

Figure 1. A simplified sketch of HF test equipment setup and the borehole–fracture–formation system

VI—cumulative injected fluid volume; Vs—volume of the fracturing interval and drill string; Af—area of the hydraulic fracture; Vf—volume of the hydraulic fracture; VL(t)—cumulative fluid leakoff volume

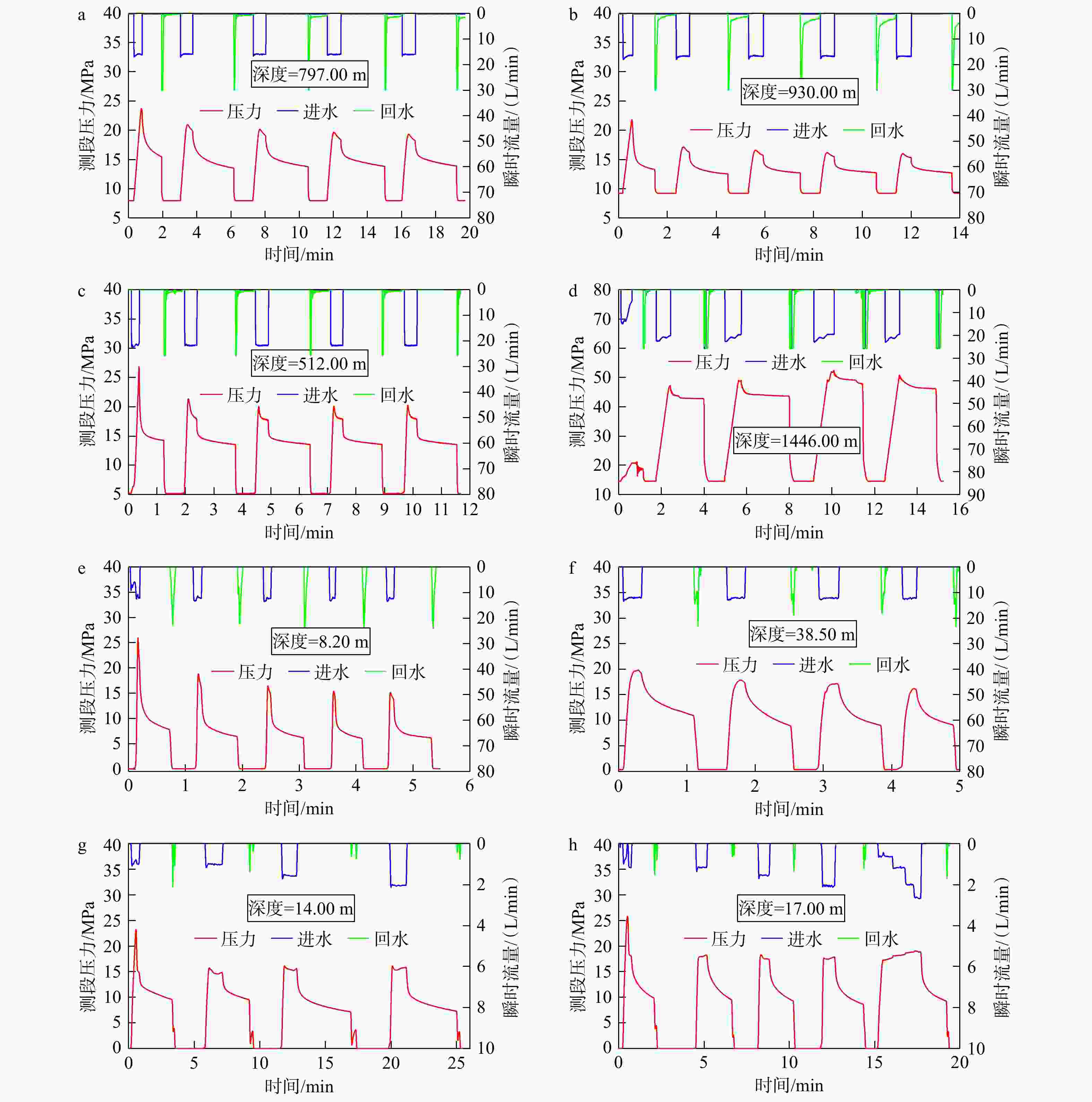

图 4 各测段水压致裂地应力测量压力和流量曲线

a—花岗岩,测深797.00 m;b—花岗岩,测深930.00 m;c—灰岩,测深512.00 m;d—硅质岩,测深1446.00 m;e—片麻岩,测深8.20 m;f—片麻岩,测深38.50 m;g—花岗岩,测深14.00 m(水平孔);h—花岗岩,测深17.00 m(水平孔)

Figure 4. Pressure and flowrate curves of hydraulic fracturing in situ stress measurements

(a) Granite, depth 797.00 m; (b) Granite, depth 930.00 m; (c) Limestone, depth 512.00 m; (d) Siliceous rock, depth 1446.00 m; (e) Gneiss, depth 8.20 m; (f) Gneiss, depth 38.50 m; (g) Granite, depth 14.00 m (horizontal borehole); (h) Granite, depth 17.00 m (horizontal borehole)

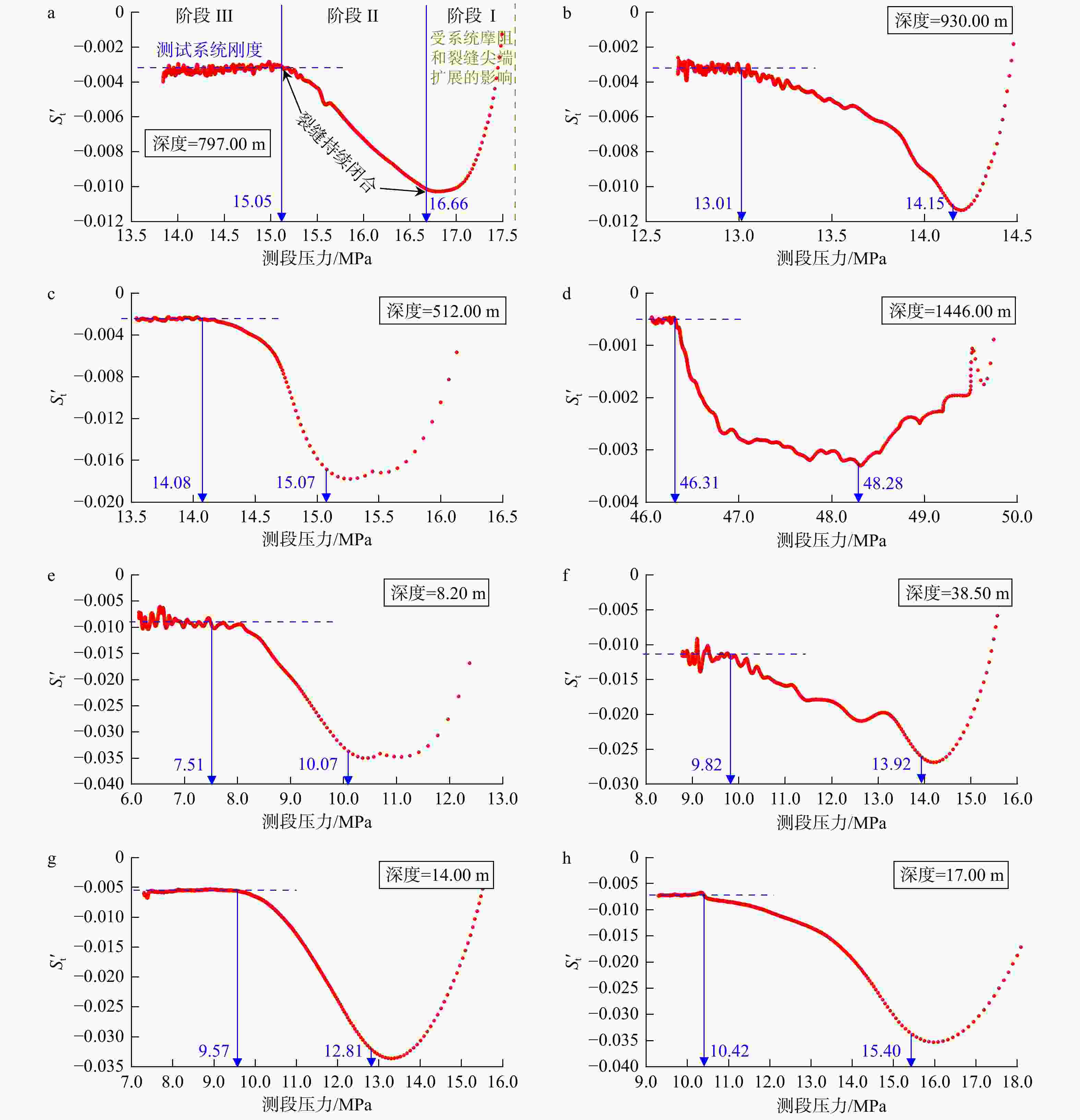

图 5 各水压致裂测段最后一个重张回次的TSS法分析结果

蓝色箭头代表识别闭合的特征拐点a—花岗岩,测深797.00 m;b—花岗岩,测深930.00 m;c—灰岩,测深512.00 m;d—硅质岩,测深1446.00 m;e—片麻岩,测深8.20 m;f—片麻岩,测深38.50 m;g—花岗岩,测深14.00 m(水平孔);h—花岗岩,测深17.00 m(水平孔)

Figure 5. The TSS method analysis results of the last re-opening cycle in each hydraulic fracturing measurement interval

(a) Granite, depth 797.00 m; (b) Granite, depth 930.00 m; (c) Limestone, depth 512.00 m; (d) Siliceous rock, depth 1446.00 m; (e) Gneiss, depth 8.20 m; (f) Gneiss, depth 38.50 m; (g) Granite, depth 14.00 m (horizontal borehole); (h) Granite, depth 17.00 m (horizontal borehole)The blue arrows indicate the inflection points for identifying fracture-closure behavior.

表 1 各水压致裂测段的基本信息

Table 1. Basic information of each hydraulic fracturing test interval

编号 钻孔位置 钻孔类型 孔口埋深/m 测深/m 岩性 压力计位置 流量计位置 孔隙压力/MPa a 甘肃酒泉 垂直孔 0.00 797.00 花岗岩 孔口+测段 孔口 7.97 b 930.00 9.30 c 湖南怀化 垂直孔 0.00 512.00 灰岩 孔口+测段 孔口 5.12 d 1446.00 硅质岩 14.46 e 辽宁抚顺 垂直孔 403.00 8.20 片麻岩 孔口 孔口 0.00 f 38.50 0.00 g 江西上饶 水平孔 830.00 14.00 花岗岩 孔口 孔口 0.00 h 17.00 0.00 -

[1] AMADEI B, STEPHANSSON O, 1997. Rock stress and its measurement[M]. Dordrecht: Springer. [2] BRUDY M, ZOBACK M D, FUCHS K, et al., 1997. Estimation of the complete stress tensor to 8 km depth in the KTB scientific drill holes: implications for crustal strength[J]. Journal of Geophysical Research: Solid Earth, 102(B8): 18453-18475. doi: 10.1029/96JB02942 [3] CHEN Q C, SUN D S, CUI J J, et al., 2019. Hydraulic fracturing stress measurements in Xuefengshan deep borehole and its significance[J]. Journal of Geomechanics, 25(5): 853-865. (in Chinese with English abstract) [4] CHENG Z Y, LIU R, ZHANG J F, et al., 2023. Study on Seepage Mechanism Characteristics of A Single Fracture Based on Fracture Deformation Under Different Confining Pressures[J]. Geoscience, 37 (4): 972-976. DOI:10.19657/j.geoscience.1000-8527.2023.059. (in Chinese with English abstract) [5] DONG S W, LI T D, GAO R, et al., 2010. International progress in probing the earth's lithosphere and deep interior: a review[J]. Acta Geologica Sinica, 84(6): 743-770. (in Chinese with English abstract) [6] ECONOMIDES M J, NOLTE K G, 2000. Reservoir stimulation[M]. 3rd ed. New York: Wiley. [7] FAN T Y, LU C X, LU G X. Analysis of Crustal Stress in Tectonic Ore-forming Processes: Research Status and Thought[J]. Geoscience, 2024, 38 (04) : 865-872. DOI: 10.19657/j.geoscience.1000-8527.2024.086. (in Chinese with English abstract) [8] FENG C J, CHEN Q C, WU M L, et al., 2012. Analysis of hydraulic fracturing stress measurement data—discussion of methods frequently used to determine instantaneous shut-in pressure[J]. Rock and Soil Mechanics, 33(7): 2149-2159. (in Chinese with English abstract) [9] GUO F, MORGENSTERN N R, SCOTT J D, 1993. Interpretation of hydraulic fracturing pressure: a comparison of eight methods used to identify shut-in pressure[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 30(6): 627-631. [10] HAIMSON B C, CORNET F H, 2003. ISRM suggested methods for rock stress estimation—part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF)[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7-8): 1011-1020. doi: 10.1016/j.ijrmms.2003.08.002 [11] HU C Y, LI C, YANG Z B, et al., 2024. Quantitative evaluation of maximum operating pressure and storage capacity for gas-top sandstone reservoir-type gas storage[J]. Journal of Geomechanics, 30(3): 419-426. (in Chinese with English abstract) [12] ITO T, EVANS K, KAWAI K, et al., 1999. Hydraulic fracture reopening pressure and the estimation of maximum horizontal stress[J]. International Journal of Rock Mechanics and Mining Sciences, 36(6): 811-826. doi: 10.1016/S0148-9062(99)00053-4 [13] MCCLURE M W, JUNG H, CRAMER D D, et al., 2016. The fracture-compliance method for picking closure pressure from diagnostic fracture-injection tests[J]. SPE Journal, 21(4): 1321-1339. doi: 10.2118/179725-PA [14] QIN X H, CHEN Q C, TAN C X, et al., 2013. Analysis of current geostress state and seismic risk in southwest segment of Longmenshan fracture belt[J]. Chinese Journal of Rock Mechanics and Engineering, 32(S1): 2870-2876. (in Chinese with English abstract) [15] RAAEN A M, SKOMEDAL E, KJØRHOLT H, et al., 2001. Stress determination from hydraulic fracturing tests: the system stiffness approach[J]. International Journal of Rock Mechanics and Mining Sciences, 38(4): 529-541. doi: 10.1016/S1365-1609(01)00020-X [16] RALEIGH C B, HEALY J H, BREDEHOEFT J D, 1976. An experiment in earthquake control at Rangely, Colorado[J]. Science, 191(4233): 1230-1237. doi: 10.1126/science.191.4233.1230 [17] SCHMITT D R, HAIMSON B, 2017. Hydraulic fracturing stress measurements in deep holes[M]//FENG X T. Rock mechanics and engineering volume 1. London: CRC Press. [18] SUN D S, FENG C J, XU H B, et al., 2015. In-situ stress measurement at deep borehole of Dataigou Iron Mine area and its application[J]. Journal of Central South University (Science and Technology), 46(4): 1384-1392. (in Chinese with English abstract) [19] TRINH N Q, HAGEN S A, STRØMSVIK H, et al., 2023. Two new methods for defining shut-in pressure in hydraulic fracturing tests[J]. Rock Mechanics and Rock Engineering, 56(4): 3055-3076. doi: 10.1007/s00603-022-03212-z [20] VOGLER D, SETTGAST R R, ANNAVARAPU C, et al., 2018. Experiments and simulations of fully hydro-mechanically coupled response of rough fractures exposed to high-pressure fluid injection[J]. Journal of Geophysical Research: Solid Earth, 123(2): 1186-1200. doi: 10.1002/2017JB015057 [21] WANG C H, SONG C K, XING B R, 2012. Compliance of drilling-rod system for hydro-fracturing in situ stress measurement and its effect on measurements at great depth[J]. Geoscience, 26(4): 808-816. (in Chinese with English abstract) [22] WANG H Y, SHARMA M M, 2017. New variable compliance method for estimating in-situ stress and leak-off from DFIT data[C]//Proceedings of SPE Annual Technical Conference and Exhibition. San Antonio: OnePetro: SPE-187348-MS. [23] YANG Y H, GAO G L, WANG F, et al., 2022. Layered in-situ stress measurement method for perforated interval of Nanpu Gas Storage, Jidong Oilfield[J]. Oil & Gas Storage and Transportation, 41(9): 1029-1035. (in Chinese with English abstract) [24] YANG Y H, SUN D S, MA X D, et al., 2025. A total system stiffness approach for determining shut-in pressure in hydraulic fracturing stress measurements[J]. International Journal of Rock Mechanics and Mining Sciences, 192: 106160. doi: 10.1016/j.ijrmms.2025.106160 [25] 陈群策, 孙东生, 崔建军, 等, 2019. 雪峰山深孔水压致裂地应力测量及其意义[J]. 地质力学学报, 25(5): 853-865. doi: 10.12090/j.issn.1006-6616.2019.25.05.070 [26] 程智余, 刘瑞, 张金锋, 等, 2023. 围压变化作用下基于水力开度变化的单裂隙渗流特性研究[J]. 现代地质, 37(4): 972-976. DOI: 10.19657/j.geoscience.1000-8527.2023.059. [27] 董树文, 李廷栋, 高锐, 等, 2010. 地球深部探测国际发展与我国现状综述[J]. 地质学报, 84(6): 743-770. [28] 范桃园, 吕承训, 吕古贤. 2024. 构造成矿作用的地应力分析: 研究现状与思考[J].现代地质, 38 (4) : 865-872. DOI: 10.19657/j.geoscience.1000-8527.2024.086. [29] 丰成君, 陈群策, 吴满路, 等, 2012. 水压致裂应力测量数据分析: 对瞬时关闭压力ps的常用判读方法讨论[J]. 岩土力学, 33(7): 2149-2159. doi: 10.16285/j.rsm.2012.07.017 [30] 胡彩云, 李聪, 杨智斌, 等, 2024. 气顶砂岩油藏型储气库运行上限压力和库容量定量评价研究[J]. 地质力学学报, 30(3): 419-426. doi: 10.12090/j.issn.1006-6616.2023075 [31] 秦向辉, 陈群策, 谭成轩, 等, 2013. 龙门山断裂带西南段现今地应力状态与地震危险性分析[J]. 岩石力学与工程学报, 32(S1): 2870-2876. [32] 孙东生, 丰成君, 许洪斌, 等, 2015. 大台沟矿区深孔水压致裂原地应力测量及应用[J]. 中南大学学报(自然科学版), 46(4): 1384-1392. [33] 王成虎, 宋成科, 邢博瑞, 2012. 水压致裂应力测量系统柔性分析及其对深孔测量的影响[J]. 现代地质, 26(4): 808-816. doi: 10.3969/j.issn.1000-8527.2012.04.024 [34] 杨跃辉, 高广亮, 王芳, 等, 2022. 冀东南堡储气库射孔段分层地应力测量方法[J]. 油气储运, 41(9): 1029-1035. doi: 10.6047/j.issn.1000-8241.2022.09.005 -

下载:

下载: