Research progress and prospects of deep stress measurement technology

-

摘要: 随着“向地球深部要资源、要安全、要空间”国家战略的实施,地应力引发的各类工程灾害在频率和强度上均显著增加,与此同时,在地下储气库和引水隧洞等工程领域,利用最小主应力准则确定上限运行压力,一定程度上可提高地下空间的储存能力或降低隧洞支护成本。总体而言,地应力在向地球深部进军进程中的重要性愈发突显。然而面向需求,深部应力测量技术尚存在探测能力不足和测量结果可靠性偏低等瓶颈问题,制约了地应力数据在解决构造活动、深部资源开发与地下空间利用等领域中的应用。文章在简要回顾地应力测量技术发展现状的基础上,重点介绍了团队近年来在地应力测量的理论研究、技术研发和应用实践等方面取得的进展与成效,指出了深部地应力测量在理论方法和技术层面面临的挑战,并结合正在承担的深地国家科技重大专项“深部应力探测关键技术与实验”项目,提出了深井应力探测的研究路线和攻关方向——研发高、精、尖的地应力测量技术与装备,构建覆盖震源深度空间的地应力观测技术体系。预期深井原位应力探测技术在地球动力学基础研究、深部资源勘查和灾害预测及防控等领域具有广阔的应用前景。Abstract:

Objective With the implementation of the national strategy of seeking resources, safety, and space from deep Earth, the frequency and intensity of various engineering disasters caused by in-situ stress have also significantly increased. At the same time, in engineering fields such as underground gas storage and water diversion tunnels, using the minimum principal stress criterion to determine the upper limit operating pressure can to some extent improve the storage capacity of underground space or reduce tunnel support costs. Overall, the importance of in-situ stress in the process of advancing towards the deep Earth is becoming increasingly prominent. However, there are still bottlenecks in the demand oriented deep stress measurement technology, such as insufficient detection capability and low reliability of measurement results, which restrict the application of in-situ stress data in solving scientific problems such as tectonic activity, deep resource development, and space utilization. Methods On the basis of a brief review of the current development status of in-situ stress measurement technology, this article focuses on the progress and achievements of the team in theoretical research, technical development, and application practice of in-situ stress measurement in recent years. Results It points out the challenges faced by deep in-situ stress measurement in terms of theoretical methods and technical aspects, and proposes a research route and direction for deep borehole stress detection in conjunction with the current national science and technology major project "Key Technologies and Experiments for Deep Stress Detection". Conclusion The goal is to develop high, precise, and advanced in-situ stress measurement technology and equipment, construct an in-situ stress observation technology system covering the depth space of the hypocenter source. [ Significance ] Deep borehole in-situ stress detection technology holds significant potential for applications in geodynamics research, deep resource exploration, and disaster prediction and prevention. -

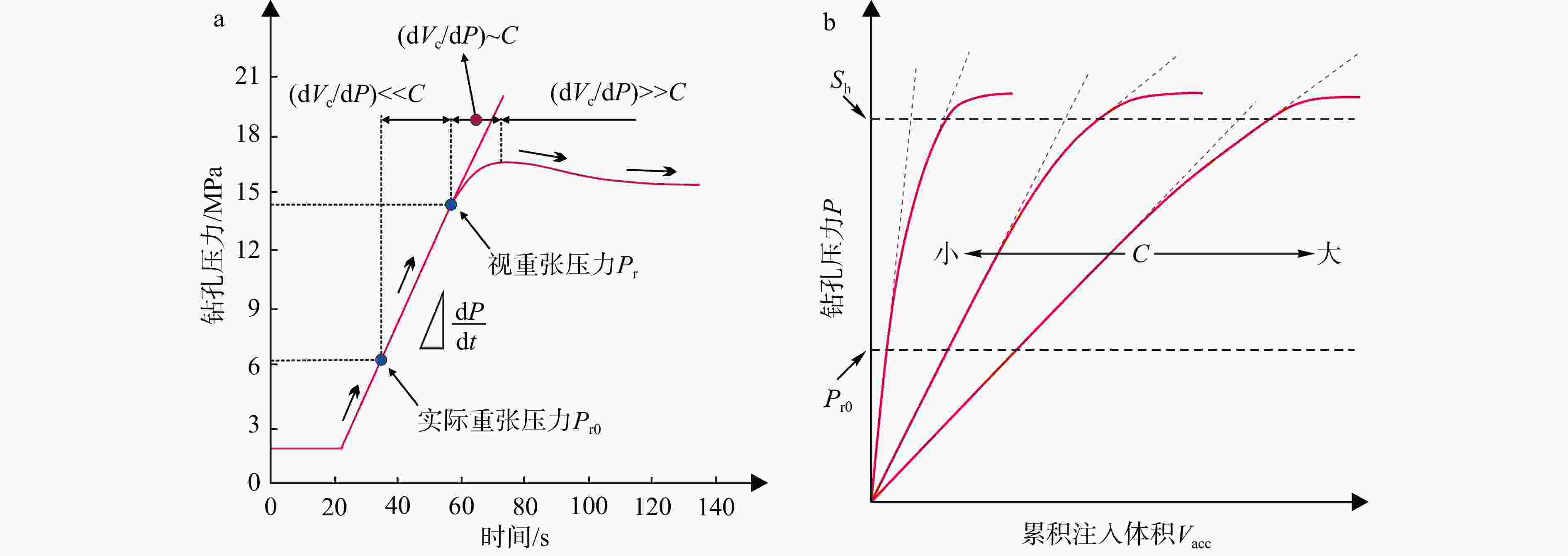

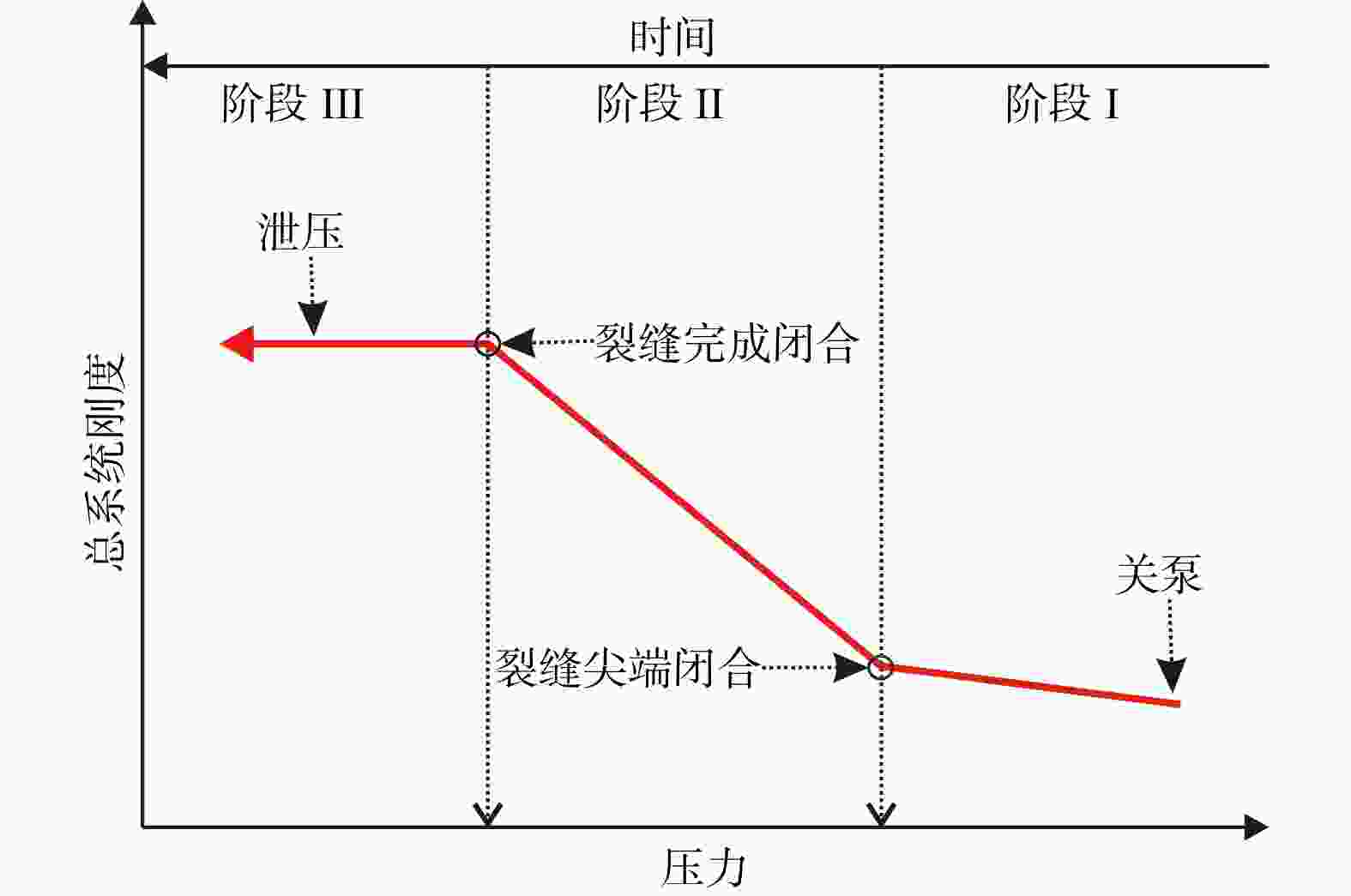

图 2 系统柔度对重张压力影响示意图(杨跃辉等,2024)

C—系统柔度;Vc—裂缝张开引起的水体体积变化;dVc/dP—单位压力下裂缝张开对应的体积变化;Sh—最小水平主应力(a)重张过程中的系统柔度随时间变化;(b)系统柔度与重张压力关系曲线

Figure 2. Schematic diagram of the effect of system compliance on reopening pressure (Yang et al., 2024)

(a) The system compliance changes over time during the reopening process; (b) Schematic diagram of the relationship between system compliance and reopening pressureC—system compliance; Vc—water volume change induced by fracture opening; dVc/dP—volume change per unit pressure change due to fracture opening

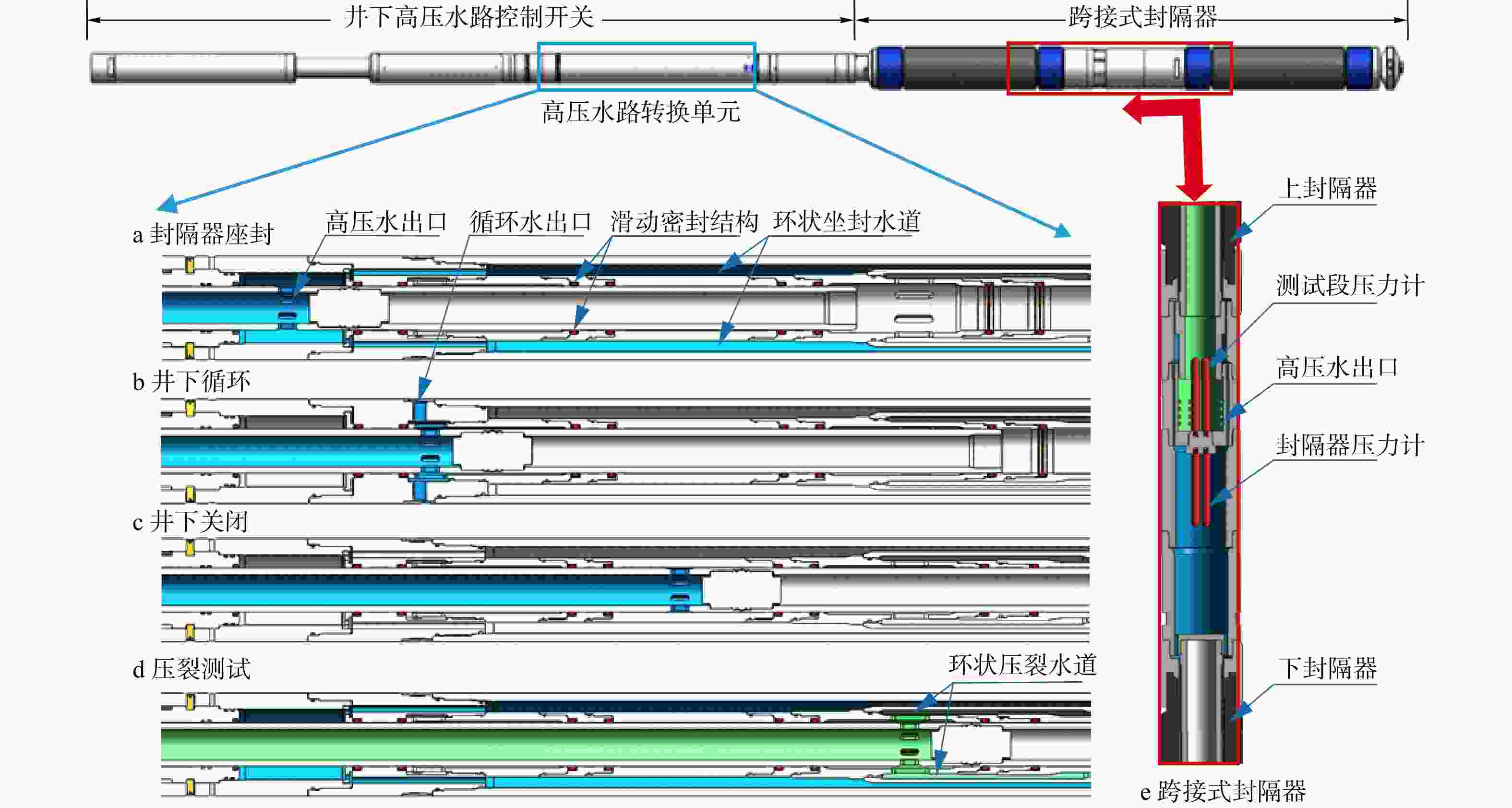

图 3 新一代深孔水压致裂地应力测试井下工具(蓝色为座封水路过流空间,绿色为测试水路过流空间)

a—封隔器坐封水路;b—井下循环水路;c—井下关闭水路;d—压裂测试水路;e—跨接式封隔器

Figure 3. New generation downhole tool for deep in-situ stress measurement of hydraulic fracturing method (Blue denotes the packer-setting flow path; green denotes the testing flow path.)

(a) Straddle packers inflation waterflow; (b) Circulation waterflow; (c) Shut in waterflow; (d) Test interval injection waterflow; (e) Bridge plug

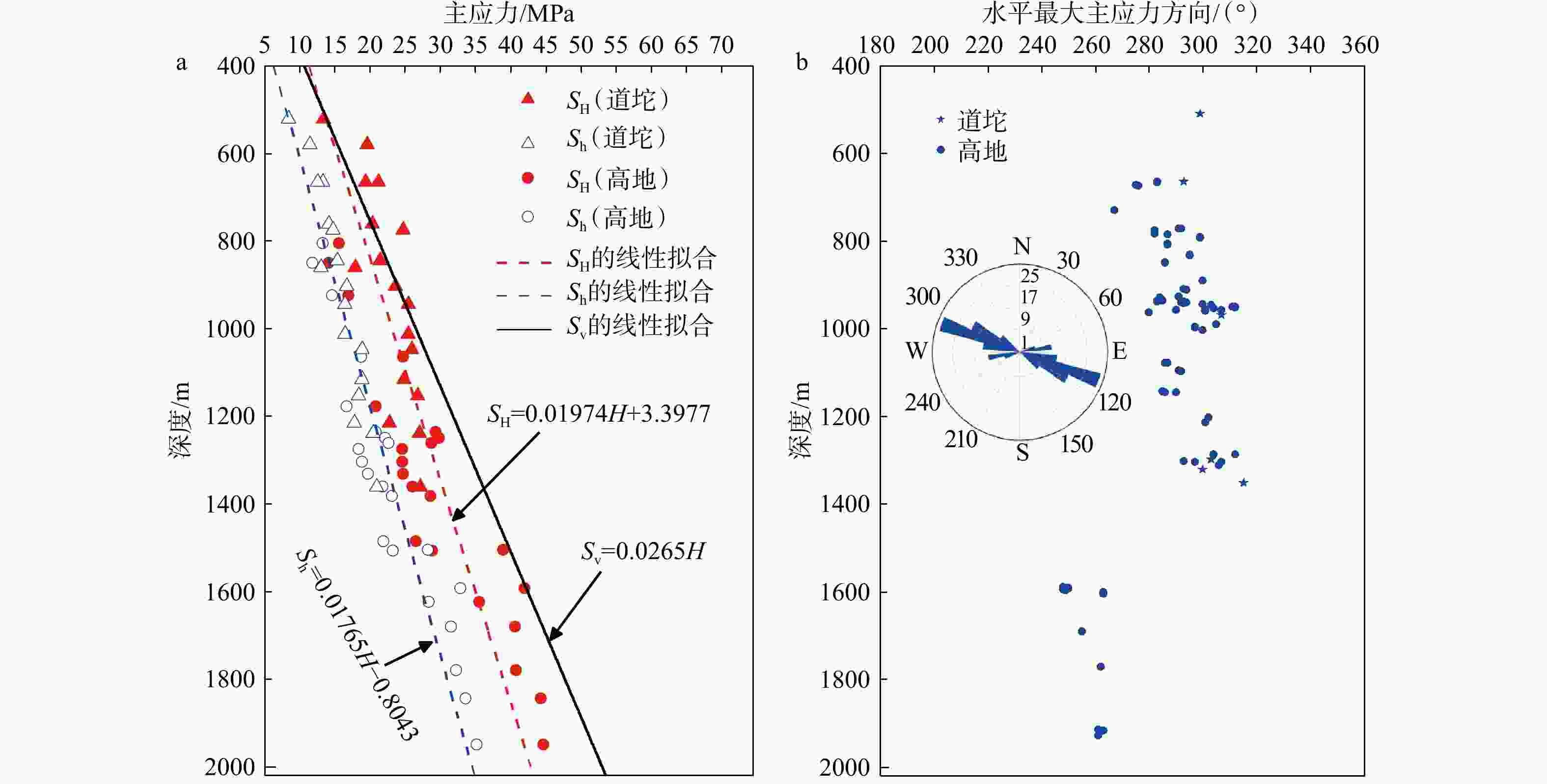

图 5 贵州省松桃锰矿集区实测主应力量值和方向随深度变化规律

a—主应力量值随深度变化;b—最大水平主应力方向随深度变化

Figure 5. The variation law of measured principal stress values and directions with depth in Songtao manganese ore area, Guizhou Province

(a) The magnitude of principal stress varies with depth; (b) The direction of maximum horizontal principal stress varies with depth

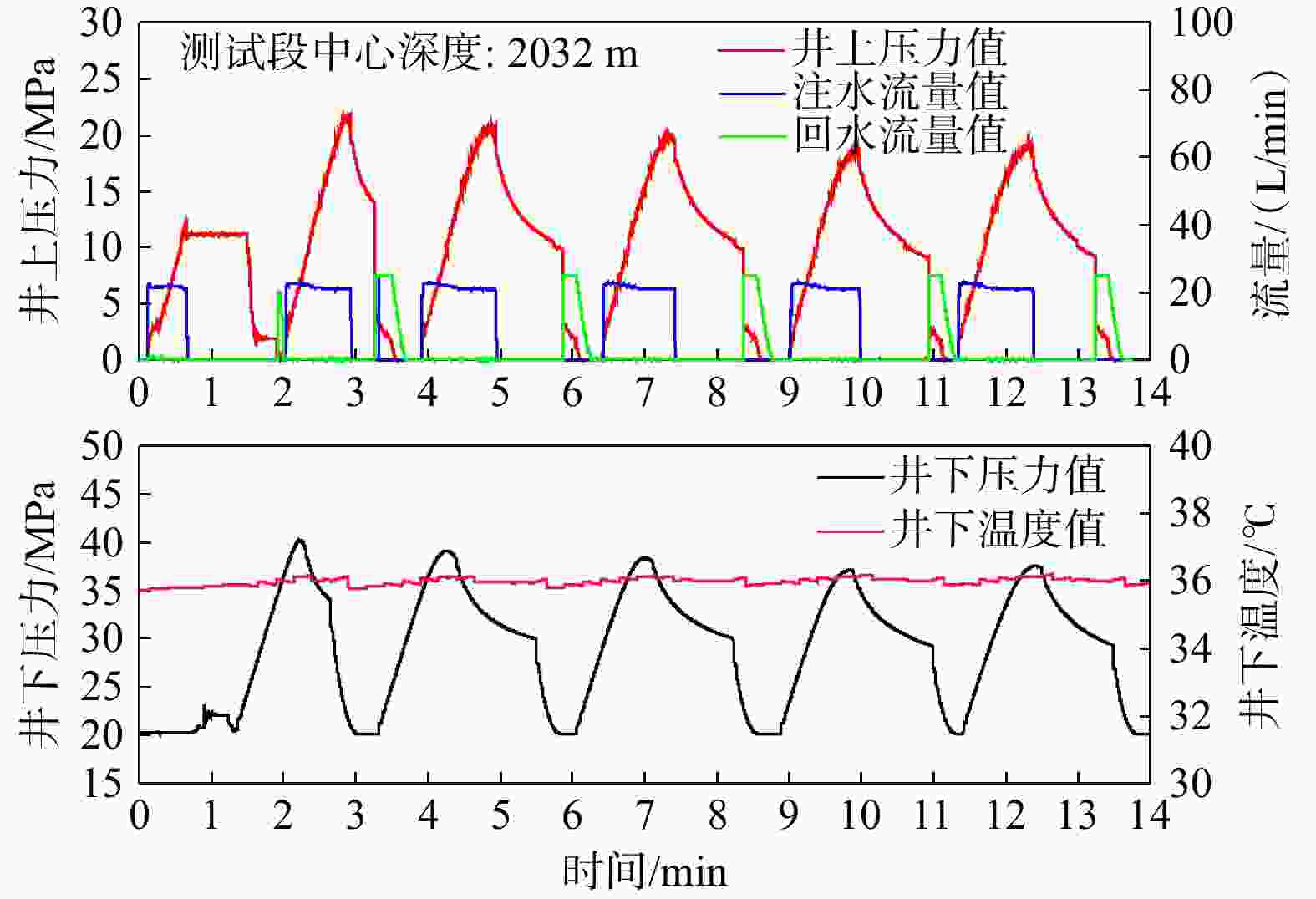

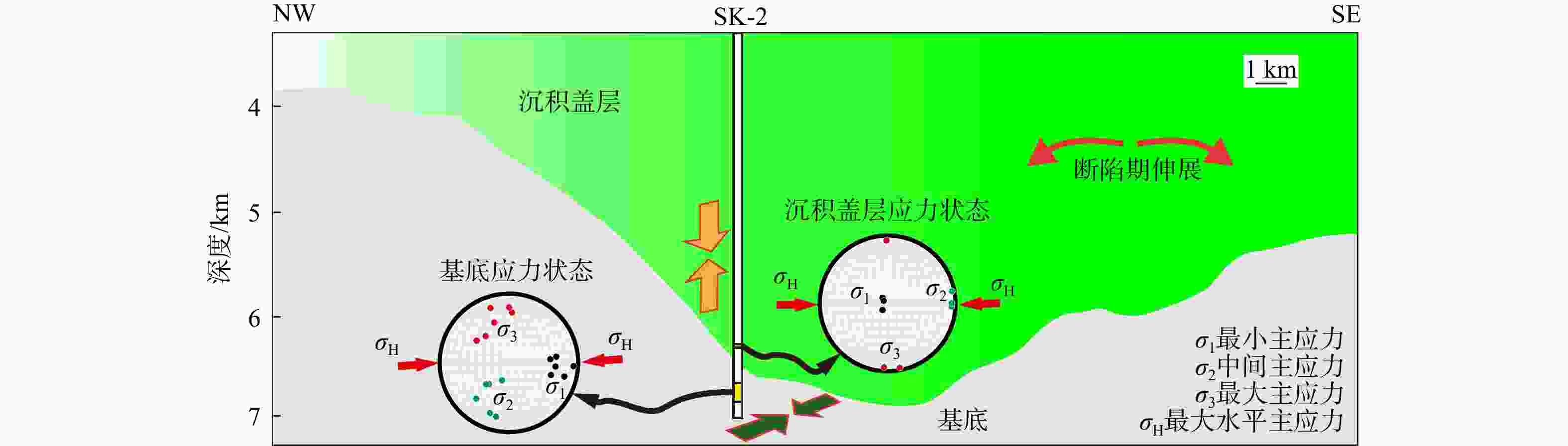

图 7 松辽盆地沉积盖层和基底实测三维地应力状态(Wang et al., 2020;王斌等,2024)

Figure 7. Three dimensional in-situ stress state of sedimentary cover and basement measured in Songliao Basin (Wang et al., 2020; 2024)

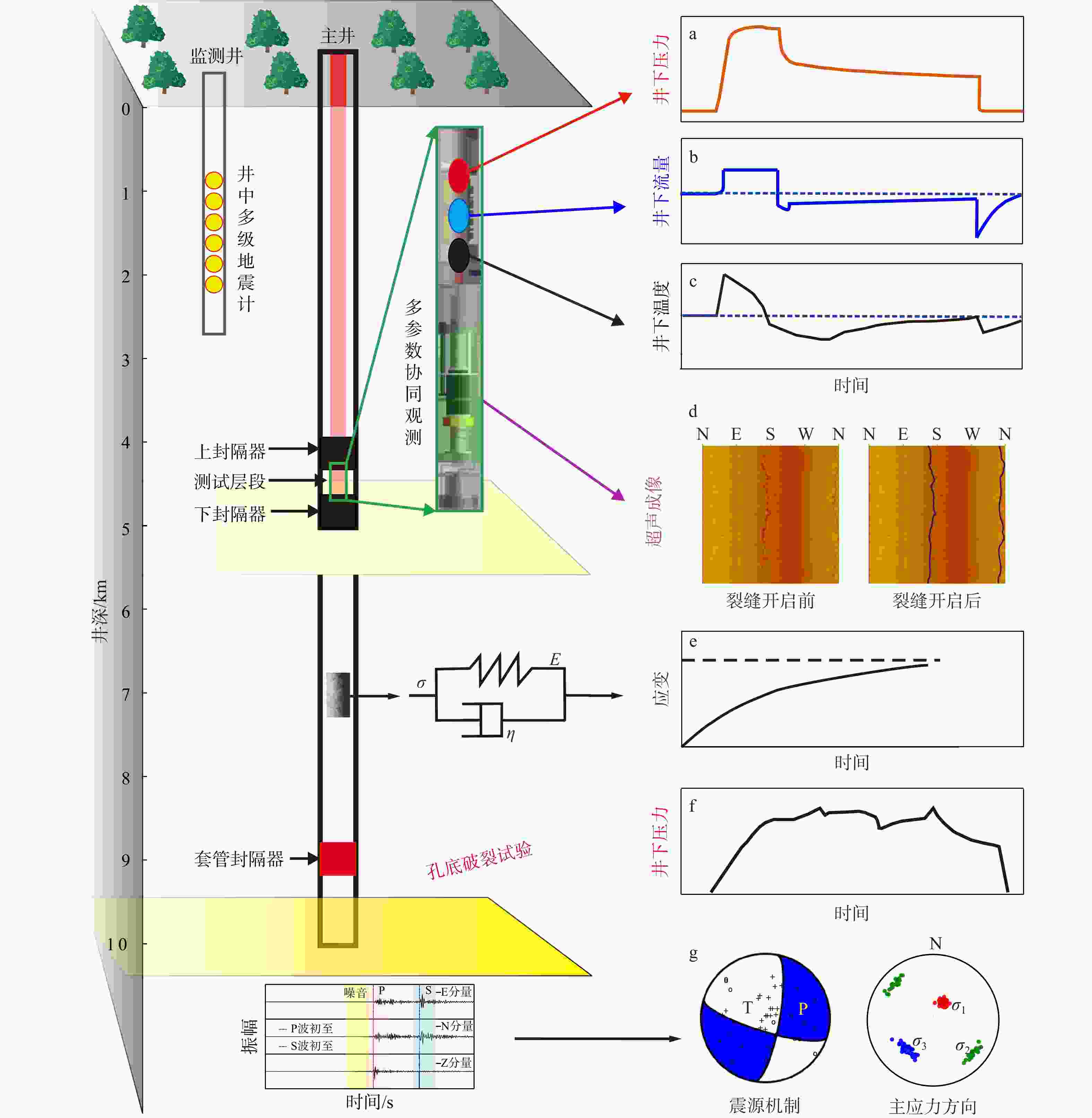

图 8 深部应力探测技术路线示意图

a—井下压力时间曲线;b—井下流量时间曲线;c—井下温度时间曲线;d—压力缝井壁图像;e—岩芯滞弹性应变恢复曲线;f—井底破裂试验曲线;g—基于地震波的应力场反演

Figure 8. Schematic diagram of deep stress detection

(a) Downhole pressure vs. time curve; (b) Downhole flowrate vs. time curve; (c) Downhole temperature vs. time curve; (d) Image logging of test interval; (e) Anelastic strain recovery curve of rock core; (f) Bottom hole fracturing test curve; (g) Stress inversion based on seismic waves

表 1 研发前后井下设备参数对比

Table 1. Comparison of downhole equipment parameters before and after development

设备类型 适用孔径 推拉行程 过水通道 无阻流量 耐差压力 耐温 传统井下工具 75~130 mm 5~10 cm 小孔 20 L/min 35 MPa 80 ℃ 新一代井下工具 60~230 mm 30~50 cm 环状空间 100 L/min 50 MPa 120 ℃ -

[1] AMADEI B, STEPHANSSON O, 1997. Rock stress and its measurement[M]. Dordrecht: Springer: 1-505. [2] BAUMGÄRTNER J, RUMMEL F, ZOBACK M D, 1990. Hydraulic fracturing in situ stress measurements to 3 km depth in the KTB pilot hole VB: a summary of a preliminary data evaluation[M]//BRAM K, DRAXLER J K, KESSELS W, et al. KTB report 90-6a: grundlagenforschung und bohrlochgeophysik (bericht 10); Langzeitmeß- und testprogramm in der KTB-Oberpfalz VB. Hannover: Projektleitung Kontinentales Tiefbohrprogramm der Bundesrepublik Deutschland im Niedersächsischen Landesamt für Bodenforschung: 353-399. [3] BREDEHOEFT J D, WOLFF R G, KEYS W S, et al., 1976. Hydraulic fracturing to determine the regional in situ stress field, Piceance Basin, Colorado[J]. Geological Society of America Bulletin, 87(2): 250-258. doi: 10.1130/0016-7606(1976)87<250:HFTDTR>2.0.CO;2 [4] BRUDY M, ZOBACK M D, FUCHS K, et al., 1997. Estimation of the complete stress tensor to 8 km depth in the KTB scientific drill holes: implications for crustal strength[J]. Journal of Geophysical Research: Solid Earth, 102(B8): 18453-18475. doi: 10.1029/96JB02942 [5] CHEN Q C, SUN D S, CUI J J, et al., 2019. Hydraulic fracturing stress measurements in Xuefengshan deep borehole and its significance[J]. Journal of Geomechanics, 25(5): 853-865. (in Chinese with English abstract) [6] CHENG Z Y, LIU R, ZHANG J F, et al., 2023. Study on SeepageMechan-ism Characteristics of A Single Fracture Based on Fracture DeformationUnder Different Confining Pressures[J]. Geoscience, 37 (4): 972-976.DOI:10.19657/j.geoscience.1000-8527.2023.059. (in Chinese with English abstract) [7] CUI J W, LIN W R, WANG L J, et al. , 2014. Determination of three-dimensional in situ stresses by anelastic strain recovery in Wenchuan Earthquake Fault Scientific Drilling Project Hole-1 (WFSD-1)[J]. Tectonophysics, 619-620: 123-132. [8] DONG S W, LI J H, GAO R, et al., 2023. Intraplate lithospheric extension revealed by seismic reflection profiling of South China[J]. Earth and Planetary Science Letters, 609: 118100. doi: 10.1016/j.jpgl.2023.118100 [9] FAIRHURST C, 1964. Measurement of in situ rock stresses with particular references to hydraulic fracturing[J]. Rock Mechanics and Engineering Geology, 2: 129-147. [10] FAIRHURST C, 2017. Some challenges of deep mining[J]. Engineering, 3(4): 527-537. doi: 10.1016/J.ENG.2017.04.017 [11] HAIMSON B C, FAIRHURST C, 1967. Initiation and extension of hydraulic fractures in rocks[J]. Society of Petroleum Engineers Journal, 7(3): 310-318. doi: 10.2118/1710-PA [12] HAIMSON B C, FAIRHURST C, 1969. In-situ stress determination at great depth by means of hydraulic fracturing[C]//The 11th U. S. symposium on rock mechanics (USRMS). Berkeley: OnePetro: ARMA-69-0559. [13] HAIMSON B C, 1972. Earthquake related stresses at Rangely, Colorado[C]//The 14th U. S. symposium on rock mechanics (USRMS). University Park: OnePetro: ARMA-72-0689. [14] HAIMSON B C, 1978. Crustal stress in the Michigan basin[J]. Journal of Geophysical Research: Solid Earth, 83(B12): 5857-5863. doi: 10.1029/JB083iB12p05857 [15] HAIMSON B C, CORNET F H, 2003. ISRM Suggested Methods for rock stress estimation: part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF)[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7-8): 1011-1020. doi: 10.1016/j.ijrmms.2003.08.002 [16] HARDY M P, ASGIAN M I, 1989. Fracture reopening during hydraulic fracturing stress determinations[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 26(6): 489-497. [17] HE M C, WU Y Y, GAO Y B, et al., 2024. Research progress of rock mechanics in deep mining[J]. Journal of China Coal Society, 49(1): 75-99. (in Chinese with English abstract) [18] HU C Y, LI C, YANG Z B, et al., 2024. Quantitative evaluation of maximum operating pressure and storage capacity for gas-top sandstone reservoir-type gas storage[J]. Journal of Geomechanics, 30(3): 419-426. (in Chinese with English abstract) [19] HUBBERT M K, WILLIS D G, 1957. Mechanics of hydraulic fracturing[J]. Transactions of the AIME, 210(1): 153-168. doi: 10.2118/686-G [20] ITO T, EVANS K, KAWAI K, et al., 1999. Hydraulic fracture reopening pressure and the estimation of maximum horizontal stress[J]. International Journal of Rock Mechanics and Mining Sciences, 36(6): 811-826. doi: 10.1016/S0148-9062(99)00053-4 [21] ITO T, YOKOYAMA T, 2021. Effect of system compliance on pressure-time curve at reopening and new standard in Japan[C]//Proceedings of the 55th U. S. rock mechanics/geomechanics symposium. Houston: OnePetro: ARMA-2021-2069. [22] Japanese Geotechnical Society (JGS), 2017. Method for initial stress measurement by hydraulic fracturing technique: JGS3761-2017[S]. Osaka: Japanese Geotechnical Society. [23] KLEE G, RUMMEL F, 1993. Hydrofrac stress data for the European HDR research project test site Soultz-Sous-Forets[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 30(7): 973-976. [24] LI F Q, ZHAI Q S, BI S X, et al., 1986. In-situ stress measurement by hydraulic fracturing and preliminary results[J]. ACTA Seismologica Sinica, 8(4): 431-438. (in Chinese with English abstract) [25] LI X B, GONG F Q, 2021. Research progress and prospect of deep mining rock mechanics based on coupled static-dynamic loading testing[J]. Journal of China Coal Society, 46(3): 846-866. (in Chinese with English abstract) [26] LIN S Y, JI J Q, SU J, 2019. Statistical analysis of global earthquake focal depth and distribution of seismic layer[J]. Chinese Journal of Geology, 54(4): 1167-1184. (in Chinese with English abstract) [27] LIN W R, KWAŚNIEWSKI M, IMAMURA T, et al., 2006. Determination of three-dimensional in situ stresses from anelastic strain recovery measurement of cores at great depth[J]. Tectonophysics, 426(1-2): 221-238. doi: 10.1016/j.tecto.2006.02.019 [28] MARTIN C D, CHANDLER N A, 1993. Stress heterogeneity and geological structures[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 30(7): 993-999. [29] MATSUKI K, 2008. Anelastic strain recovery compliance of rocks and its application to in situ stress measurement[J]. International Journal of Rock Mechanics and Mining Sciences, 45(6): 952-965. doi: 10.1016/j.ijrmms.2007.10.005 [30] MENG W, TIAN T, SUN D S, et al., 2022. Research on stress state in deep shale reservoirs based on in-situ stress measurement and rheological model[J]. Journal of Geomechanics, 28(4): 537-549. (in Chinese with English abstract) [31] National Mine Safety Administration, 2024. Specification for general survey of hidden disaster-causing factors in mines Part 3: metal & nonmetal mines and tailings ponds: KA/T 22.3-2024[S]. (in Chinese) [32] National Technical Committee on Petroleum Drilling Engineering of Standardization Administration of China, 2012. Terms of petroleum and natural gas drilling engineering: GB/T 28911–2012. Beijing: Standards Press of China. [33] PINE R J, LEDINGHAM P, MERRIFIELD C M, 1983. In situ stress measurement in the Carnmenellis granite: II. Hydrofracture tests at Rosemanowes Quarry to depths of 2000 m[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 20(2): 63-72. [34] QIN X H, ZHANG P, FENG C J, et al., 2014. In-situ stress measurements and slip stability of major faults in Beijing region, China[J]. Chinese Journal of Geophysics, 57(7): 2165-2180. (in Chinese with English abstract) [35] Raleigh C B, Healy J H, Bredehoeft J D, 1972. Faulting and crustal stress at Rangely, Colorado[J]. Flow and fracture of rocks, 16: 275-284 [36] RALEIGH C B, HEALY J H, BREDEHOEFT J D, 1976. An experiment in earthquake control at Rangely, Colorado[J]. Science, 191(4233): 1230-1237. doi: 10.1126/science.191.4233.1230 [37] RANJITH P G, ZHAO J, JU M H, et al., 2017. Opportunities and challenges in deep mining: a brief review[J]. Engineering, 3(4): 546-551. doi: 10.1016/J.ENG.2017.04.024 [38] RÖCKEL T, NATAU O, 1995. Rock mechanics[M]//EMMERMANN R, ALTHAUS E, GIESE P, et al. KTB report 95-2: KTB Hauptbohrung; Results of geoscientific investigation in the KTB field laboratory; Final report: 0 - 9101 m. Stuttgart: Schweitzerbart: E1-E9. [39] RUMMEL F, ZOBACK M D, 1993. Hydrofrac stress profile in the KTB boreholes VB and HB[M]//EMMERMANN R, LAUTERJUNG J, UMSONST T. KTB report 93-2: contributions to the 6. Annual KTB-colloquium, geoscientific results; Giessen 1. -2. April 1993. Potsdam: Deutsches GeoForschungsZentrum GFZ: 191-194. [40] RUTQVIST J, TSANG C F, STEPHANSSON O, 2000. Uncertainty in the maximum principal stress estimated from hydraulic fracturing measurements due to the presence of the induced fracture[J]. International Journal of Rock Mechanics and Mining Sciences, 37(1-2): 107-120. doi: 10.1016/S1365-1609(99)00097-0 [41] SCHETELIG K, AZZAM R, KLÄSENER R, 1993. Borehole break-outs and their relation to mechanical and physical properties of KTB core samples[M]//EMMERMANN R, LAUTERJUNG J, UMSONST T. KTB report 93-2: contributions to the 6. Annual KTB-colloquium, geoscientific results; Giessen 1. -2. April 1993. Potsdam: Deutsches GeoForschungsZentrum GFZ: 183-186. [42] SHANGGUAN S T, SUN D S, ZHANG G B, et al., 2021. In-situ stress measurement and fault stability analysis within a depth of 3~4 km in the Tangshan area[J]. Acta Geologica Sinica, 95(12): 3915-3925. (in Chinese with English abstract) [43] SONE H, ZOBACK M D, 2014. Viscous relaxation model for predicting least principal stress magnitudes in sedimentary rocks[J]. Journal of Petroleum Science and Engineering, 124: 416-431. doi: 10.1016/j.petrol.2014.09.022 [44] SUN D S, LIN W R, CUI J W, et al., 2014. Three-dimensional in situ stress determination by anelastic strain recovery and its application at the Wenchuan Earthquake Fault Scientific Drilling Hole-1 (WFSD-1)[J]. Science China Earth Sciences, 57(6): 1212-1220. doi: 10.1007/s11430-013-4739-6 [45] SUN D S, SONE H, LIN W R, et al., 2017. Stress state measured at ~7 km depth in the Tarim Basin, NW China[J]. Scientific Reports, 7(1): 4503. doi: 10.1038/s41598-017-04516-9 [46] SUN D S, LV H T, WANG L J, et al., 2018. Determination of the in-situ stress state at 7 km depth under Tarim Basin by ASR and DITH methods[J]. Chinese Journal of Rock Mechanics and Engineering, 37(2): 383-391. (in Chinese with English abstract) [47] SUN D S, CHEN Q C, ZHANG Y Q, 2020a. Analysis on the Application Prospect of ASR in-situ stress measurement method in underground mine[J]. Journal of Geomechanics, 26(1): 33-38. (in Chinese with English abstract) [48] SUN D S, PANG F, LI A W, et al., 2020b. In-situ stress profile prediction based on the rheological model: a case study of Well AY-1 in the Qianbei area of Guizhou province[J]. Natural Gas Industry, 40(3): 58-64. (in Chinese with English abstract) [49] TOWNEND J, ZOBACK M D, 2000. How faulting keeps the crust strong[J]. Geology, 28(5): 399-402. doi: 10.1130/0091-7613(2000)28<399:HFKTCS>2.0.CO;2 [50] TRZECIAK M, SONE H, 2024. Polyaxial failure criteria for in situ stress analysis using borehole breakouts: review of existing methods and development of an empirical alternative[J]. International Journal of Rock Mechanics and Mining Sciences, 182: 105864. doi: 10.1016/j.ijrmms.2024.105864 [51] WANG B, SUN D S, CHEN Q C, et al., 2020. Stress-state differences between sedimentary cover and basement of the Songliao Basin, NE China: in-situ stress measurements at 6-7 km depth of an ICDP Scientific Drilling borehole (SK-II)[J]. Tectonophysics, 777: 228337. doi: 10.1016/j.tecto.2020.228337 [52] WANG B, SUN D S, LI A W, et al., 2024. In situ stress state of deep basement in the Songliao Basin: evidence from in situ stress measurement in SK-2 borehole[J]. Earth Science Frontiers, 31(2): 377-390. (in Chinese with English abstract) [53] WANG C H, SONG C K, XING B R, 2012. Compliance of drilling-rod system for hydro-fracturing in situ stress measurement and its effect on measurements at great depth[J]. Geoscience, 26(4): 808-816. (in Chinese with English abstract) [54] WANG C H, 2014. Brief review and outlook of main estimate and measurement methods for in-situ stresses in rock mass[J]. Geological Review, 60(5): 971-996. (in Chinese with English abstract) [55] WANG L J, CUI J W, ZHANG X W, et al., 2006. In-situ stress state in the main borehole of the Chinese continental scientific drilling[J]. Earth Science: Journal of China University of Geosciences, 31(4): 505-512. (in Chinese with English abstract) [56] WANG L J, SUN D S, LIN W R, et al., 2012. Anelastic strain recovery method to determine in-situ stress and application example[J]. Chinese Journal of Geophysics, 55(5): 1674-1681. (in Chinese with English abstract) [57] XIE H P, GAO F, JU Y, 2015. Research and development of rock mechanics in deep ground engineering[J]. Chinese Journal of Rock Mechanics and Engineering, 34(11): 2161-2178. (in Chinese with English abstract) [58] XIE H P, LI C B, GAO M Z, et al., 2021. Conceptualization and preliminary research on deep in situ rock mechanics[J]. Chinese Journal of Rock Mechanics and Engineering, 40(2): 217-232. (in Chinese with English abstract) [59] XIE H P, ZHANG R, ZHANG Z T, et al., 2023. Reflections and explorations on deep earth science and deep earth engineering technology[J]. Journal of China Coal Society, 48(11): 3959-3978. (in Chinese with English abstract) [60] XU J D, ZHANG C Y, LI A W, et al., 2024. In-situ stress measurements in hot dry rock, Qinghai Gonghe Basin and simulation analysis of reservoir fracture modification. Earth Science Frontiers, 31(6): 130-144. (in Chinese with English abstract) [61] YANG Y H, SUN D S, QIN X H, et al., 2024. Error analysis and discussion of determining the maximum horizontal principal stress by hydraulic fracturing based on the compliance analysis of testing system[J]. Chinese Journal of Rock Mechanics and Engineering, 43(S1): 3385-3396. (in Chinese with English abstract) [62] YANG Y H, SUN D S, MA X D, et al., 2025. A total system stiffness approach for determining shut-in pressure in hydraulic fracturing stress measurements[J]. International Journal of Rock Mechanics and Mining Sciences, 192: 106160. doi: 10.1016/j.ijrmms.2025.106160 [63] YANG Y H, SUN D S, QIN X H, et al. , 2025. Determination of hydraulic fracture closure pressure based on total system stiffness method and case study[J]. Journal of Geomechanics, 28(4): this issue. (in Chinese with English abstract) [64] ZANG A, STEPHANSSON O, 2010. Stress field of the earth’s crust[M]. Dordrecht: Springer. [65] ZHANG C S, 2009. Design criteria for concrete-lining high pressure hydropower tunnel and high pressure permeability test on rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 28(7): 1305-1311. (in Chinese with English abstract) [66] ZHANG X L, YING L, ZHAO D A, 2024. Application of in-situ stress measurement technology of ultra deep survey borehole ASR method[J]. Journal of Jilin University (Earth Science Edition), 54(1): 198-207. (in Chinese with English abstract) [67] ZHAO K, LIU Y X, LI Y P, et al, 2022. Feasibility analysis of salt cavern gas storage in extremely deep formation: a case study in China[J]. Journal of Energy Storage, 47: 103649. doi: 10.1016/j.est.2021.103649 [68] ZHENG Y L, SUN J C, QIU X S, et al., 2020. Connotation and evaluation technology of geological integrity of reservoir-type gas storage [J]. Gas industry, 40 (5): 94-101.(in Chinese with English abstract) [69] ZHENG Z X, SUN Q Q, 2017. Tunnel engineering of Sichuan-Tibet railway[J]. Tunnel Construction, 37(8): 1049-1054. (in Chinese) [70] ZOBACK M D, TSUKAHARA H, HICKMAN S, 1980. Stress measurements at depth in the vicinity of the San Andreas fault: implications for the magnitude of shear stress at depth[J]. Journal of Geophysical Research: Solid Earth, 85(B11): 6157-6173. doi: 10.1029/JB085iB11p06157 [71] ZOBACK M D, HEALY J H, 1992. In situ stress measurements to 3.5 km depth in the Cajon Pass scientific research borehole: implications for the mechanics of crustal faulting[J]. Journal of Geophysical Research: Solid Earth, 97(B4): 5039-5057. doi: 10.1029/91JB02175 [72] ZOBACK M D, APEL R, BAUMGÄRTNER J, et al., 1993. Upper-crustal strength inferred from stress measurements to 6 km depth in the KTB borehole[J]. Nature, 365(6447): 633-635. doi: 10.1038/365633a0 [73] ZOBACK M D, HARJES H P, 1997. Injection-induced earthquakes and crustal stress at 9 km depth at the KTB deep drilling site, Germany[J]. Journal of Geophysical Research: Solid Earth, 102(B8): 18477-18491. doi: 10.1029/96JB02814 [74] ZOBACK M D, 2007. Reservoir geomechanics[M]. Cambridge: Cambridge University Press: 167-223. [75] 陈群策, 孙东生, 崔建军, 等, 2019. 雪峰山深孔水压致裂地应力测量及其意义[J]. 地质力学学报, 25(5): 853-865. doi: 10.12090/j.issn.1006-6616.2019.25.05.070 [76] 程智余, 刘瑞, 张金锋, 等, 2023. 围压变化作用下基于水力开度变化的单裂隙渗流特性研究[J]. 现代地质, 37(4): 972-976. DOI: 10.19657/j.geoscience.1000-8527.2023.059 [77] 国家矿山安全监察局, 2024. 矿山隐蔽致灾因素普查规范 第3部分: 金属非金属矿山及尾矿库: KA/T 22.3-2024[S]. [78] 何满潮, 武毅艺, 高玉兵, 等, 2024. 深部采矿岩石力学进展[J]. 煤炭学报, 49(1): 75-99. [79] 胡彩云, 李聪, 杨智斌, 等, 2024. 气顶砂岩油藏型储气库运行上限压力和库容量定量评价研究[J]. 地质力学学报, 30(3): 419-426. [80] 李方全, 翟青山, 毕尚煦, 等, 1986. 水压致裂法原地应力测量及初步结果[J]. 地震学报, 8(4): 431-438. [81] 李夕兵, 宫凤强, 2021. 基于动静组合加载力学试验的深部开采岩石力学研究进展与展望[J]. 煤炭学报, 46(3): 846-866. doi: 10.13225/j.cnki.jccs.YT21.0176 [82] 林士扬, 季建清, 苏君, 2019. 全球地震震源深度统计分析与地震层分布[J]. 地质科学, 54(4): 1167-1184. doi: 10.12017/dzkx.2019.066 [83] 孟文, 田涛, 孙东生, 等, 2022. 基于原位地应力测试及流变模型的深部泥页岩储层地应力状态研究[J]. 地质力学学报, 28(4): 537-549. [84] 秦向辉, 张鹏, 丰成君, 等, 2014. 北京地区地应力测量与主要断裂稳定性分析[J]. 地球物理学报, 57(7): 2165-2180. [85] 全国石油钻井工程标准化委员会, 2012. 石油天然气钻井工程术语: GB/T 28911—2012[S]. 北京: 中国标准化出版社. [86] 上官拴通, 孙东生, 张国斌, 等, 2021. 唐山地区3~4 km深部地应力测量及断层稳定性分析[J]. 地质学报, 95(12): 3915-3925. [87] 孙东生, 吕海涛, 王连捷, 等, 2018. ASR和DITF法综合确定塔里木盆地7km深部地应力状态[J]. 岩石力学与工程学报, 37(2): 383-391. [88] 孙东生, 陈群策, 张延庆, 2020a. ASR法在井下矿山地应力测试中的应用前景分析[J]. 地质力学学报, 26(1): 33-38. [89] 孙东生, 庞飞, 李阿伟, 等, 2020b. 基于流变模型的地应力剖面预测: 以贵州黔北地区安页1井为例[J]. 天然气工业, 40(3): 58-64. doi: 10.3787/j.issn.1000-0976.2020.03.007 [90] 王斌, 孙东生, 李阿伟, 等, 2024. 松辽盆地深部基底地应力状态: 来自松科2井地应力实测数据的证据[J]. 地学前缘, 31(2): 377-390. doi: 10.13745/j.esf.sf.2023.11.38 [91] 王成虎, 宋成科, 邢博瑞, 2012. 水压致裂应力测量系统柔性分析及其对深孔测量的影响[J]. 现代地质, 26(4): 808-816. doi: 10.3969/j.issn.1000-8527.2012.04.024 [92] 王成虎, 2014. 地应力主要测试和估算方法回顾与展望[J]. 地质论评, 60(5): 971-996. [93] 王连捷, 崔军文, 张晓卫, 等, 2006. 中国大陆科学钻主孔现今地应力状态[J]. 地球科学: 中国地质大学学报, 31(4): 505-512. [94] 王连捷, 孙东生, 林为人, 等, 2012. 地应力测量的非弹性应变恢复法及应用实例[J]. 地球物理学报, 55(5): 1674-1681. doi: 10.6038/j.issn.0001-5733.2012.05.024 [95] 谢和平, 高峰, 鞠杨, 2015. 深部岩体力学研究与探索[J]. 岩石力学与工程学报, 34(11): 2161-2178. [96] 谢和平, 李存宝, 高明忠, 等, 2021. 深部原位岩石力学构想与初步探索[J]. 岩石力学与工程学报, 40(2): 217-232. doi: 10.13722/j.cnki.jrme.2020.0317 [97] 谢和平, 张茹, 张泽天, 等, 2023. 深地科学与深地工程技术探索与思考[J]. 煤炭学报, 48(11): 3959-3978. doi: 10.13225/j.cnki.jccs.2023.0989 [98] 许家鼎, 张重远, 张浩, 等, 2024. 青海共和盆地干热岩地应力测量及其储层压裂改造意义分析[J]. 地学前缘, 31(6): 130-144. [99] 杨跃辉, 孙东生, 秦向辉, 等, 2024. 基于测试系统柔度分析的水压致裂法确定最大水平主应力误差分析与讨论[J]. 岩石力学与工程学报, 43(S1): 3385-3396. [100] 杨跃辉, 孙东生, 吴邦宸, 等, 2025. 总系统刚度法在水力裂缝闭合压力测定中的应用[J]. 地质力学学报. DOI: 10. 12090 / j. issn. 1006-6616. 2025099 [101] 张春生, 2009. 混凝土衬砌高压水道的设计准则与岩体高压渗透试验[J]. 岩石力学与工程学报, 28(7): 1305-1311. doi: 10.3321/j.issn:1000-6915.2009.07.002 [102] 张小林, 应黎, 赵冬安, 2024. 超深勘察钻孔ASR法地应力测试技术应用[J]. 吉林大学学报(地球科学版), 54(1): 198-207. doi: 10.13278/j.cnki.jjuese.20220118 [103] 郑雅丽, 孙军昌, 邱小松, 等, 2020. 油气藏型储气库地质体完整性内涵与评价技术[J]. 天然气工业, 40(5): 94-101. [104] 郑宗溪, 孙其清, 2017. 川藏铁路隧道工程[J]. 隧道建设, 37(8): 1049-1054. -

下载:

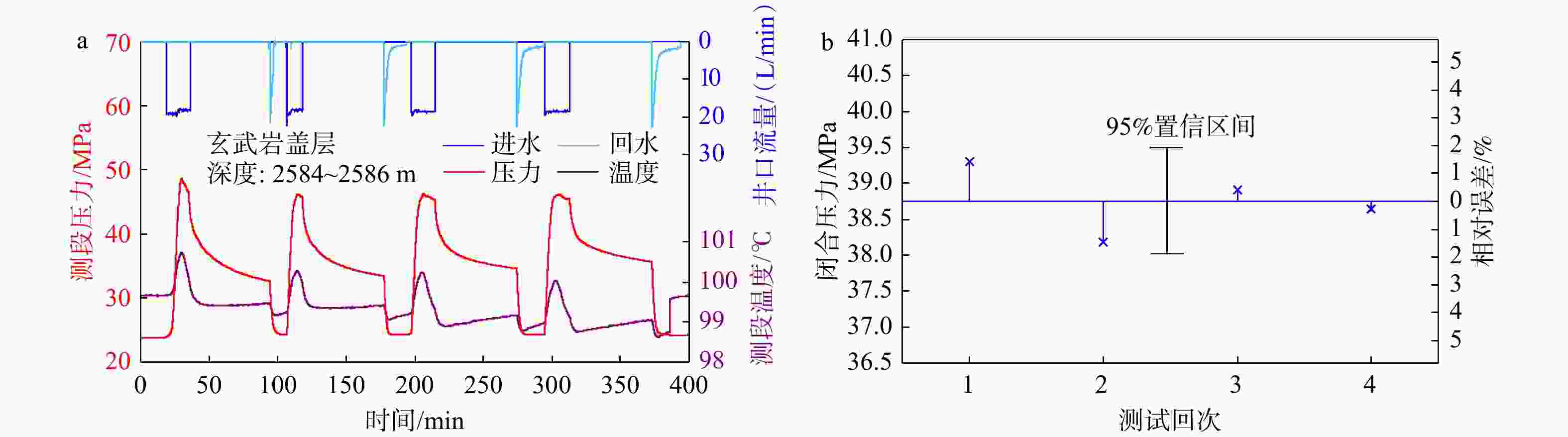

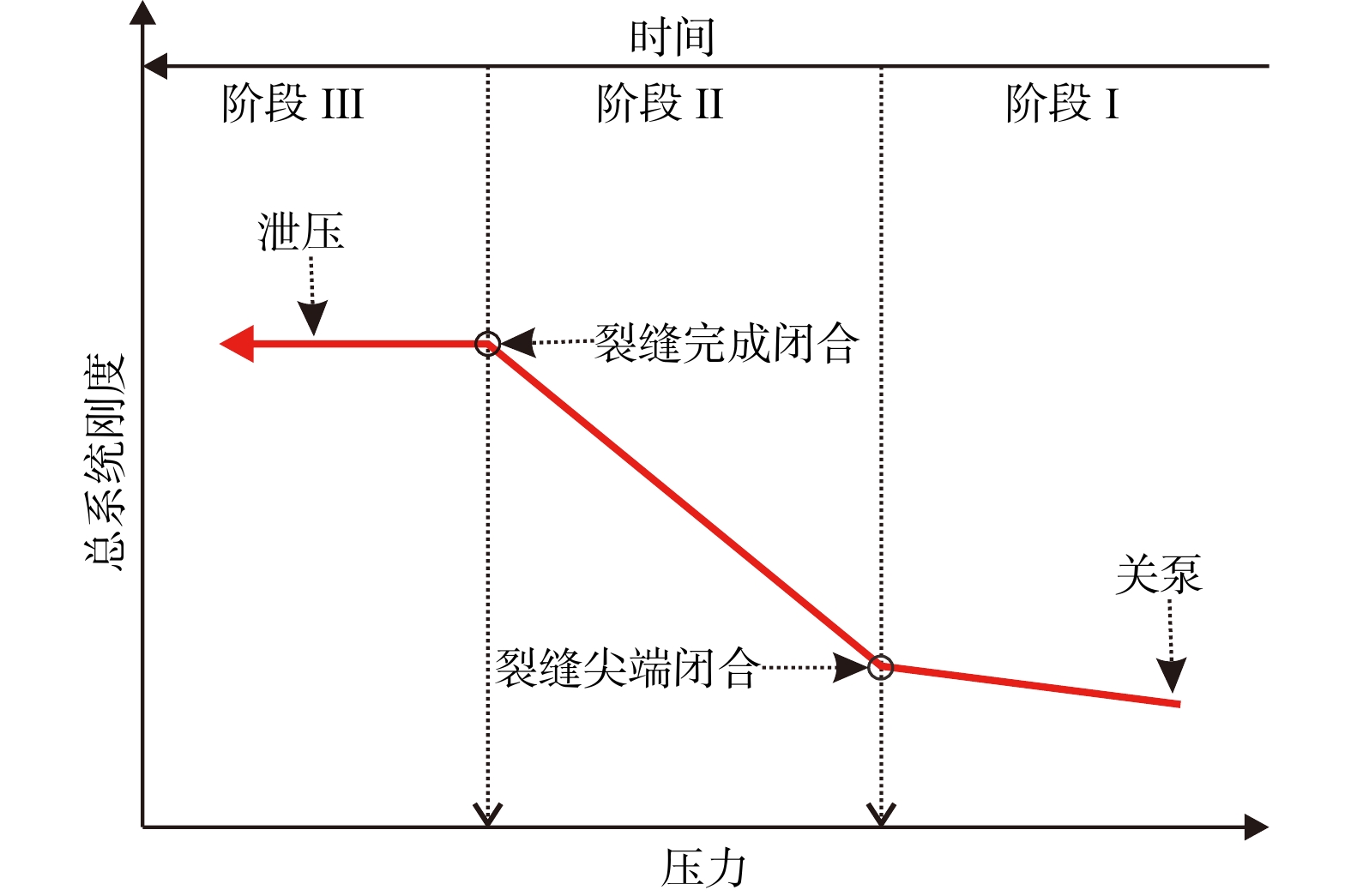

下载: