Fracture network complexity of tight sandstone and its influencing factors

-

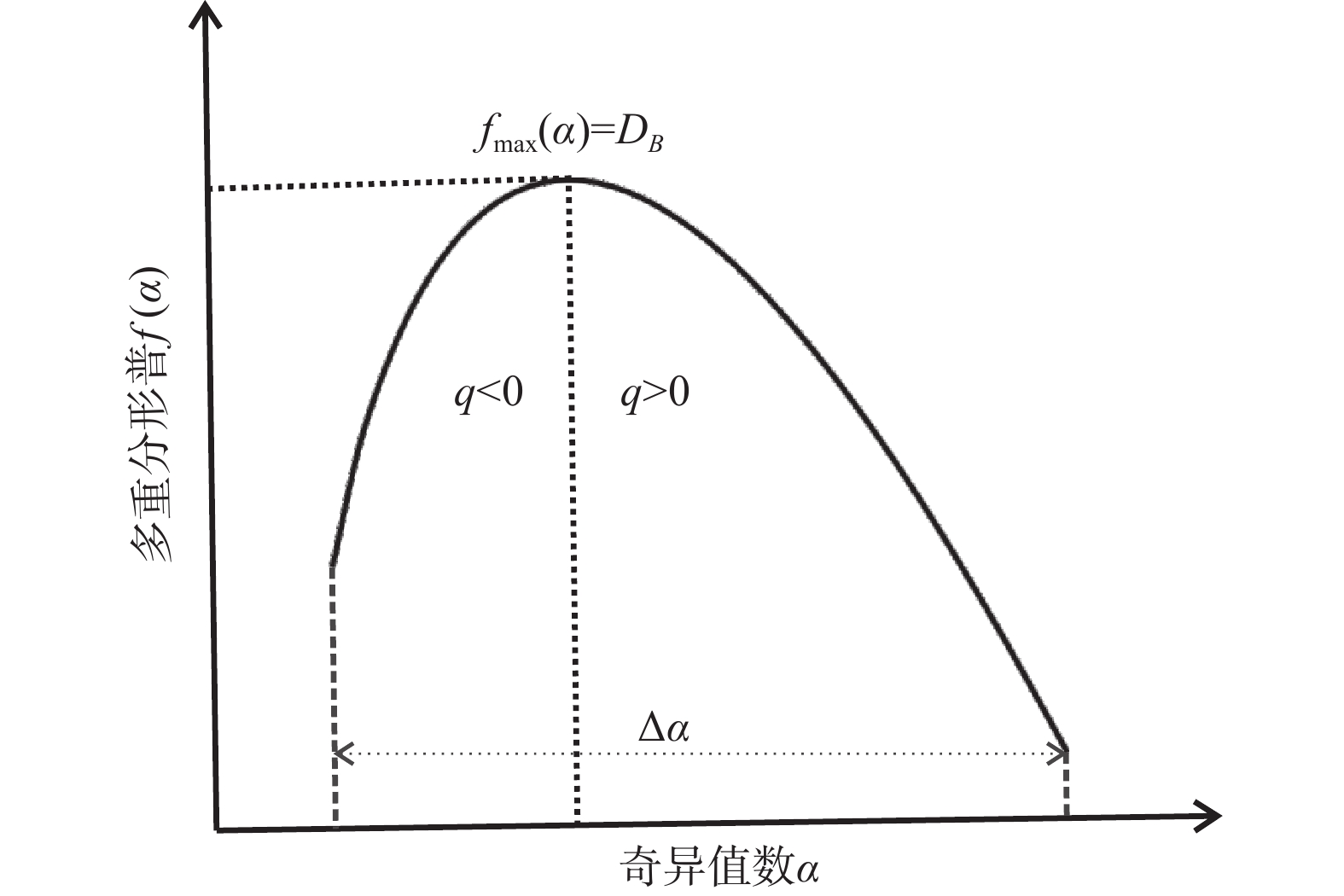

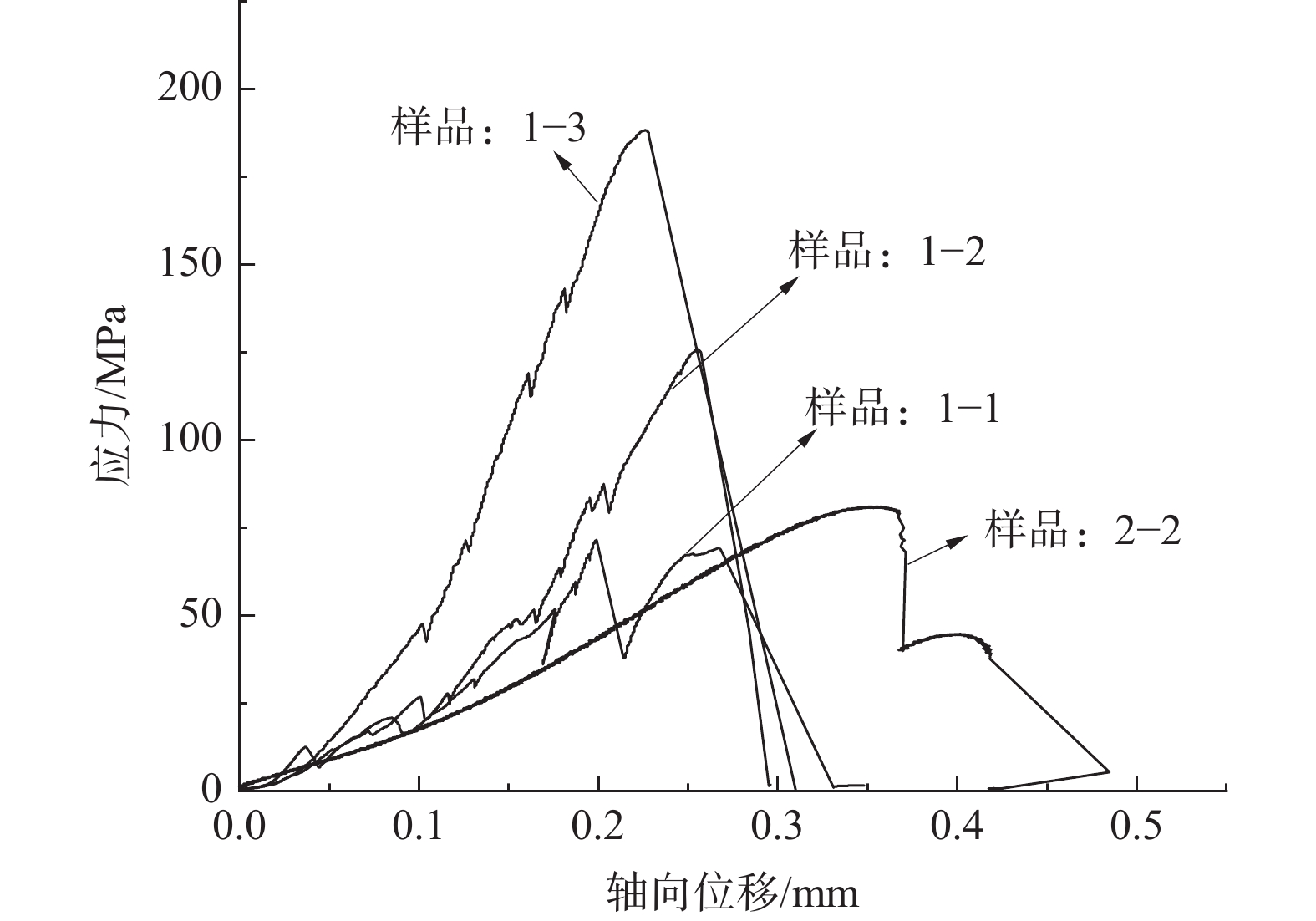

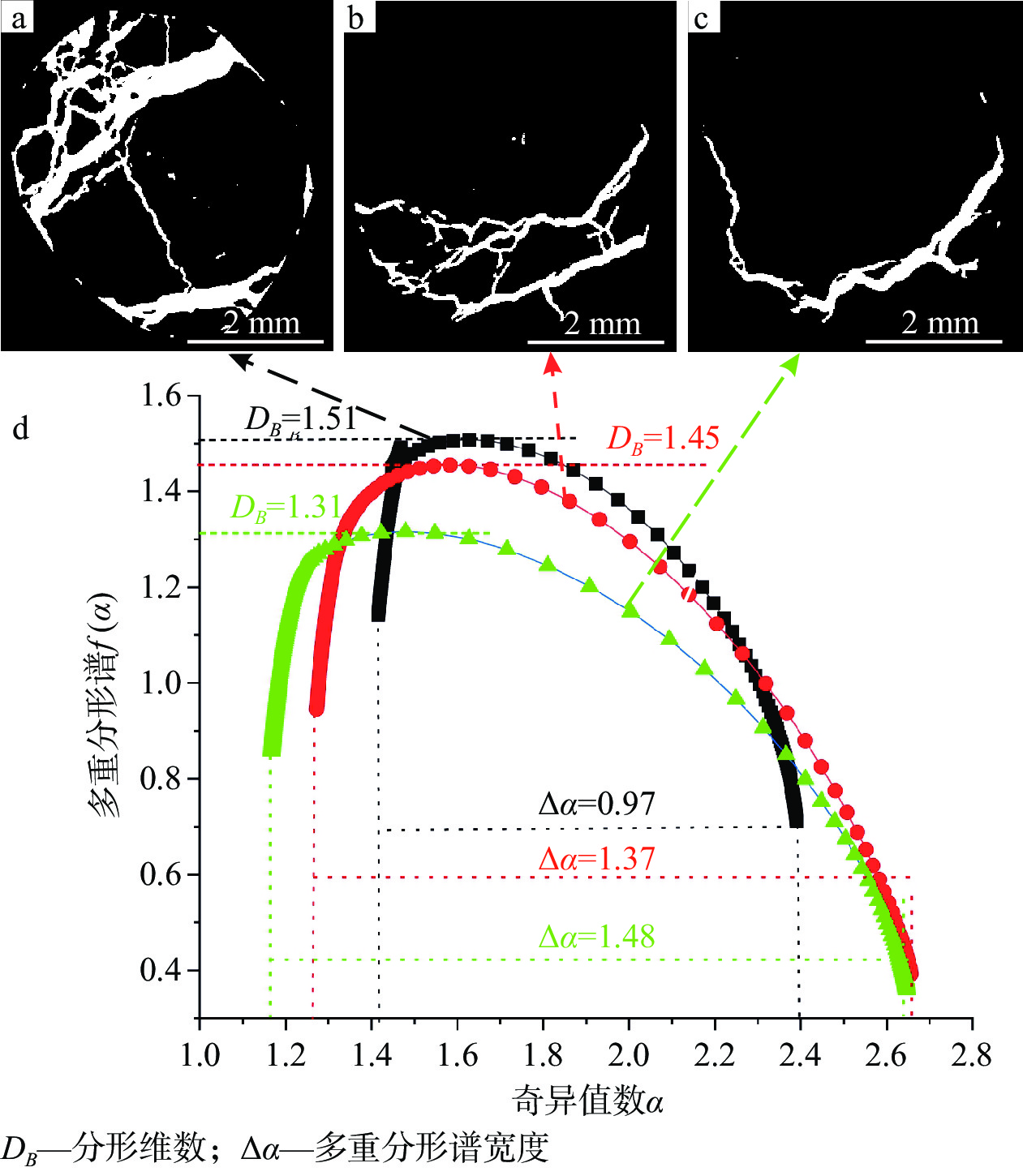

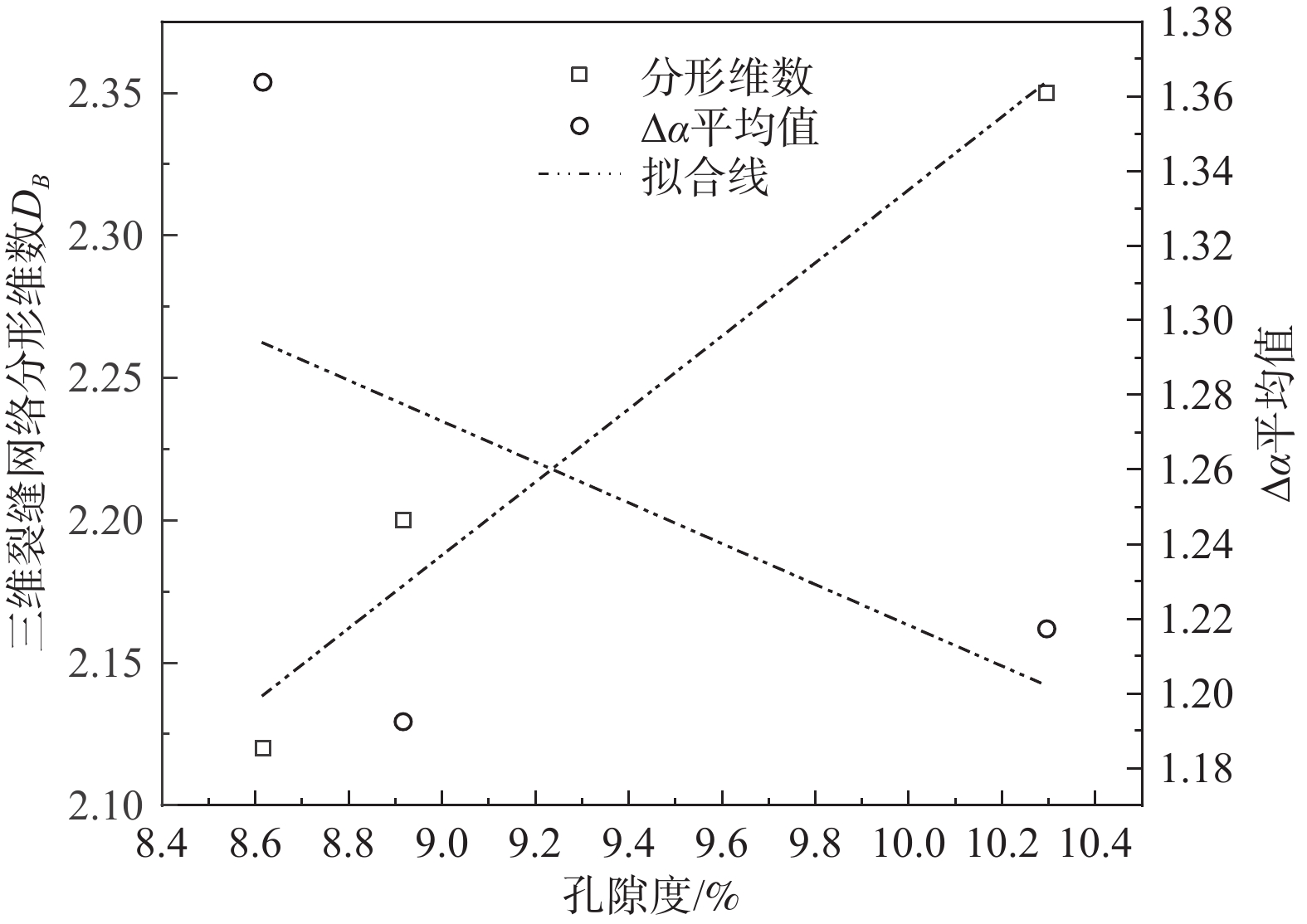

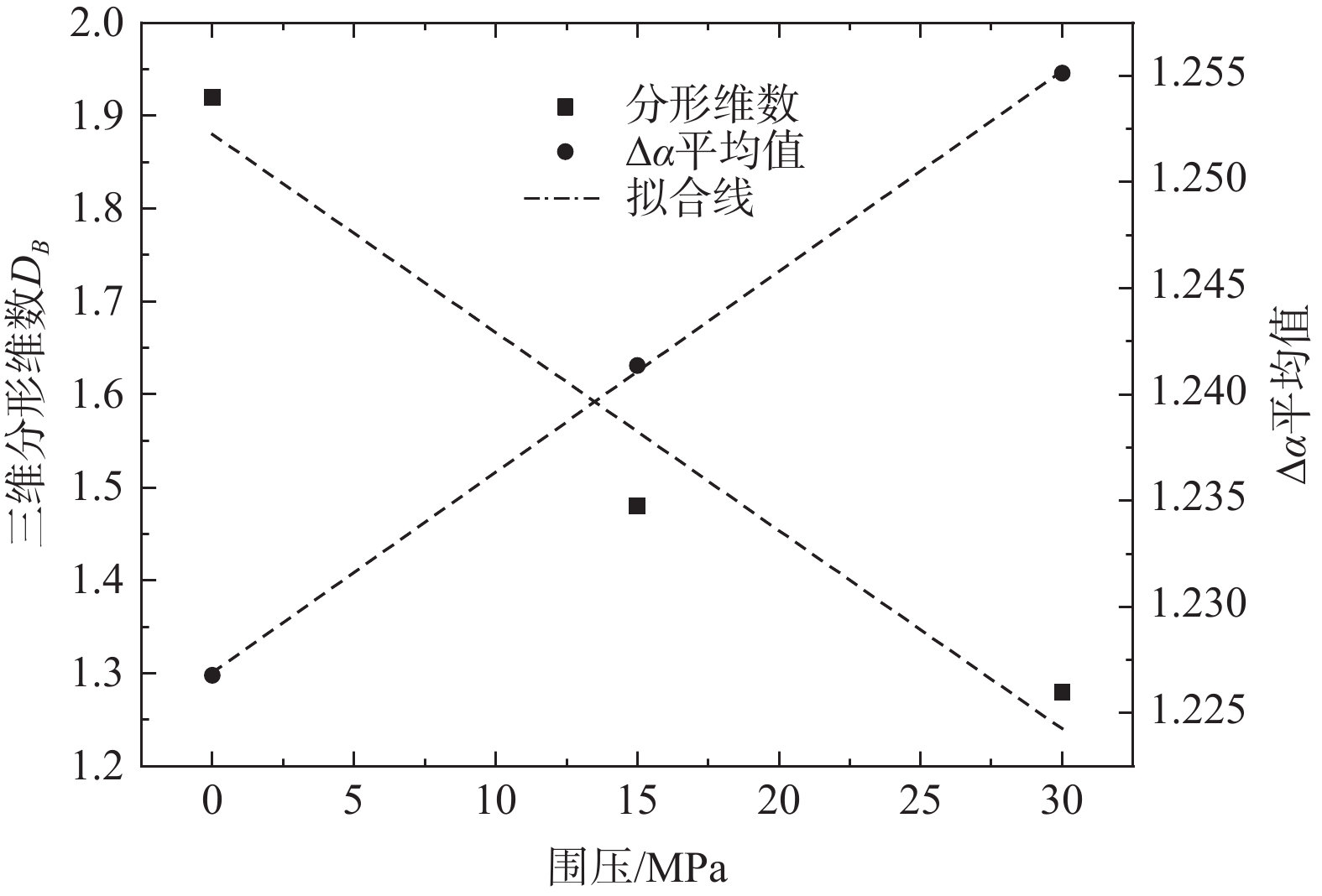

摘要: 裂缝网络分析在油气藏勘探开发过程中发挥着着重要作用,致密砂岩裂缝网络复杂性分析对水力压裂优化、裂缝网络预测、裂缝建模等具有重要意义。文章结合致密砂岩复杂的裂缝网络动态演化的实验研究,明确了裂缝网络的分形和多重分形谱特征,深入分析了裂缝网络的复杂性及其主控因素。通过岩石力学和X射线CT扫描实验确定了岩石力学和裂缝网络特征;通过扫描电镜实验、裂缝网络的分形分析定量化表征了致密砂岩微观组构和裂缝网络的分形特征。研究结果表明:致密砂岩的石英含量为 28.08~52.88%,黏土含量为11.54~25.45%,粒度为61.18~184.55 μm,孔隙度为8.125%~10.296%;单轴抗压强度介于69.09~188.33 MPa,弹性模量介于31.69~92.76 GPa;分形维数(DB)为1.28~2.35,谱宽(Δα)平均值为1.0851~1.3638。裂缝的萌生、扩展贯穿于应力–应变的全过程,裂缝网络的复杂性主要受控于致密砂岩的微观组构特征,并且具有明显的围压和尺度效应。三维裂缝网络的分形维数、多重分形谱的谱宽平均值可分别表征裂缝空间分布的复杂性和非均质性,两者之间具有相对的独立性。砂岩中石英、长石等脆性矿物含量越高、储层孔隙度越大、砂岩组成粒度越小裂缝网络分形维数越大,谱宽平均值越小;无围压情况下,样品裂缝网络的复杂性主要受控于微观组构特征,且随着轴向压力的增加而增加;存在围压的情况下,围压起主导作用,围压越大分形维数越小,谱宽平均值越大。而黏土矿物不利于复杂裂缝的形成;小尺度样品的分形维数和谱宽平均值大于尺度大样品的分形维数和谱宽平均值。砂岩的弹性模量和抗压强度与分形维数和谱宽平均值具有一定的正相关性。Abstract:

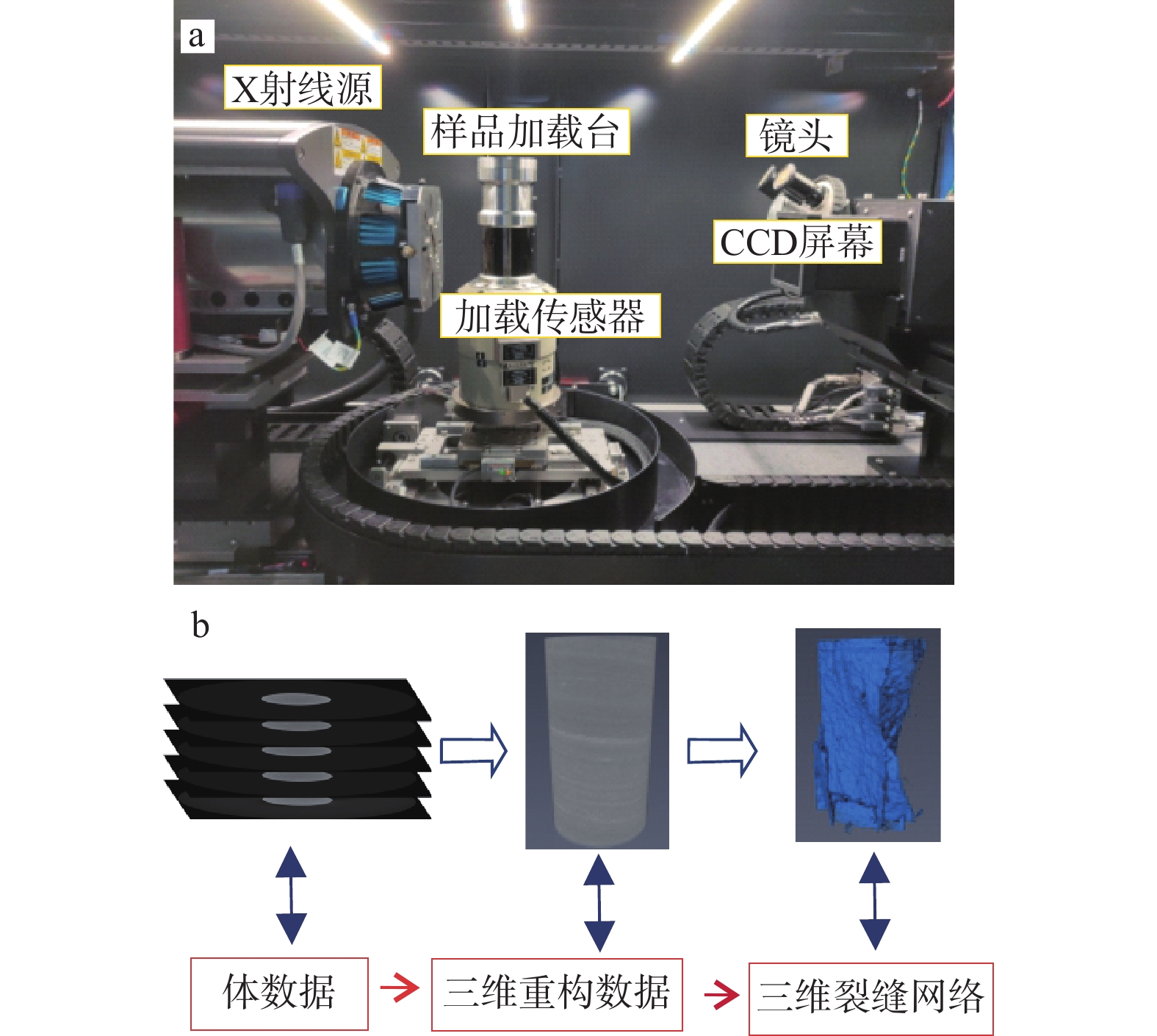

Objective Fracture network analysis plays an important role in oil and gas exploration and development. However, complexity analysis of tight sandstone fracture networks and their control factors is relatively lagging. Based on an experimental study of the dynamic evolution of the complex fracture network in tight sandstone, the fractal and multifractal spectral characteristics of the fracture network were defined, and the complexity and main controlling factors of the fracture network were analyzed. Fracture network complexity analysis of tight sandstone plays an important role in hydraulic fracturing optimization, fracture network prediction, and fracture modeling. Methods Rock mechanics and X-ray computed tomography scan experiments determined the characteristics of rock mechanics and fracture networks . The microstructure and fracture network fractal characteristics of tight sandstone were quantitatively characterized by SEM and fracture network fractal analysis. Results The results showed that the quartz content of tight sandstone ranges from 28.08 to 52.88%, clay content ranges from 11.54 to 25.45%, particle size ranges from 61.18 to 184.55 μm, and porosity ranges from 8.125 to 10.296%. Uniaxial compressive strength ranges from 69.09 to 188.33 MPa, and the elastic modulus ranges from 31.69 to 92.76 GPa. The fractal dimension (DB) ranges from 1.28 to 2.35 and average spectral width (Δα) ranges from 1.0851 to 1.3638. Conclusion The initiation and propagation of fractures extend through the entire stress–strain process. The complexity of the fracture network of tight sandstone is mainly controlled by microscopic fabric characteristics, and has obvious confining pressure as well as scale effects. The DB of the three-dimensional fracture network and average Δα of the multifractal spectrum represents the complexity and heterogeneity of the fracture spatial distribution, respectively, and are relatively independent. As the content of quartz, feldspar, and other brittle minerals in sandstone increases, the porosity of the reservoir increases, particle size of the sandstone decreases, DB of the fracture network increases, and average Δα decreases. In the absence of confining pressure, the complexity of the sample fracture network is mainly controlled by the microscopic fabric characteristics, and the complexity increases with increase of axial pressure. When present confining pressure plays a leading role; the higher it is, the lower the DB value, and the higher the mean Δα value. Clay minerals are unconducive to complex fractures formation. The mean values of DB and Δα of small-scale samples are greater than those of large-scale samples. The elastic modulus and compressive strength of sandstone are positively correlated with DB and mean Δα. -

Key words:

- tight sandstone /

- fracture network /

- fractal dimension /

- multifractal spectrum /

- rock mechanics

-

0. 引言

中国是矿业大国,矿产资源开发利用为国民经济和社会发展做出了巨大贡献。与此同时也应当清醒地认识到,矿产资源长期大规模和超强度开采,不同程度破坏了矿山及其周边环境。因矿业开发引起的地面塌陷、土地损毁、山体崩塌、滑坡、泥石流等矿山地质灾害,严重影响了人民生命财产安全和正常生活秩序,不同程度地制约了经济社会的健康可持续发展,引起了国家和社会的高度关注。大力推进生态文明建设,加强和改进矿业领域生态文明,必须牢固树立科学发展的理念,以人为本,高度重视矿产资源开发过程中的环境问题及其对经济社会发展的影响。

随着卫星遥感技术的快速发展,基于高分辨率卫星遥感影像数据的矿山开采状况及环境影响分析已经可以满足日常管理工作的实际需求。以高分辨率遥感影像为基础,可以提供准确、客观、实时的矿山开发和环境信息,进而有针对性地对矿产资源开发利用问题进行研究与科学决策,以实现矿产资源高效利用与环境保护协调发展[1]。

1. 遥感技术在矿山地质环境调查中应用

遥感影像可以使各种生态环境因素得到充分的体现,根据各类要素在不同条件下的光谱特性、成像特性进行数字图像处理,在信息提取、分类的基础上进行污染现状调查与环境要素研究,并结合遥感影像上各种信息对主要污染源及其分布、污染扩散路径等进行分析。例如:根据水体在一定遥感波段上不同的光谱特征(反射率、亮度、颜色等)可以对其受污染状况做出评价;根据矿区不同时期遥感影像的地表信息(高程、颜色、纹理、亮度等)可以获取矿山土地塌陷、土地污染等方面的信息[2]。在遥感图像处理的基础上可以获得矿山生态环境全面、实时、丰富的信息源,进而可为矿山地质环境治理与恢复提供决策支持,并对治理后效果进行评价。

不同分辨率的遥感影像为建立矿山监测信息系统提供多源、多平台、多时相、多层次、多领域的实时、丰富、准确、可靠的信息,并可定期进行信息更新,具有成本低、效率高、时间快的显著特点,在矿山地质环境调查中具有广阔的应用前景[3]。

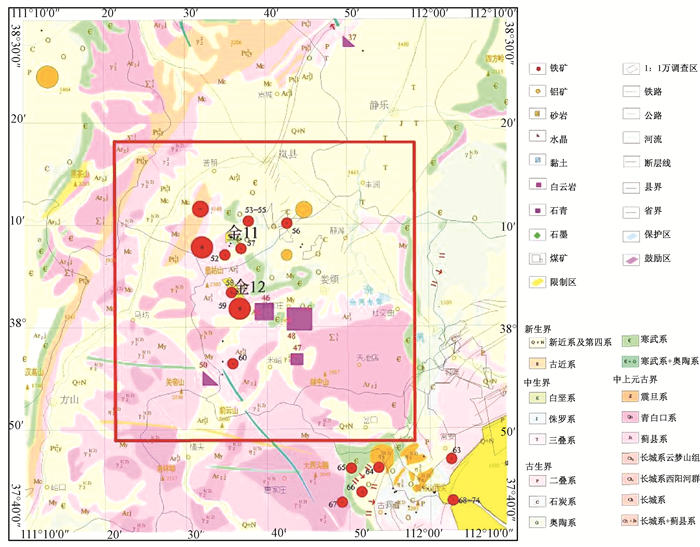

2. 研究区概况

山西省是中国重要的铁矿资源产地,探明储量居全国前列,分布相对集中,具有规模大、铁含量较低、地表露头或近地表、易选磁铁矿为主的特点,主要分布在娄烦—岚县、五台—恒山等地区。娄烦矿区位于吕梁山中部,独特的地质条件使得矿产资源异常丰富,不仅矿种多,分布广,且开采历史悠久,是山西省著名的铁矿石产地。

娄烦尖山铁矿在山西省已知铁矿中规模最大,该矿区铝土矿资源亦十分丰富,在省内居于首位,具有储量大、品位高的特点,开采方式分为露天开采和硐采两种。由于该地区具有较强的典型性和代表性,故作为此次调查的研究区(见图 1)。

3. 遥感调查方法

3.1 数据源

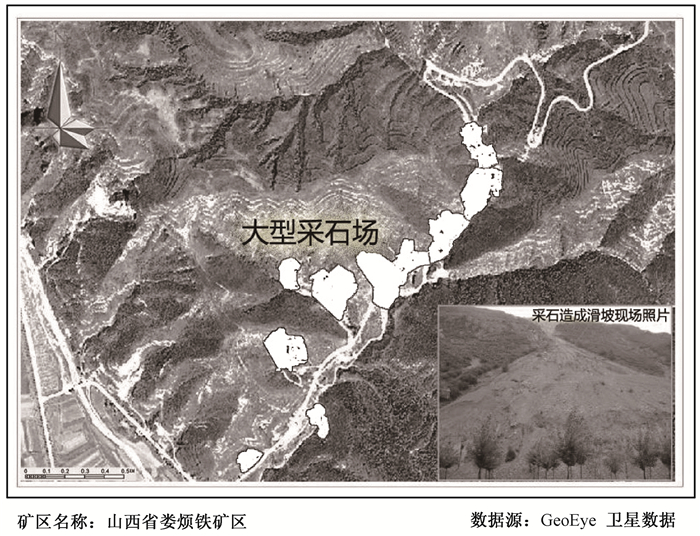

考虑到遥感卫星数据来源、分辨率等因素,本文采用GeoEye-1遥感数据资料,成像时间2010年7月。数据范围:111°21′22.78″,38°18′08.85″;111°58′29.51″,38°17′57.68″;111°16′50.34″,37°48′56.17″;111°58′05.29″,37°48′43.24″。面积2945 km2。遥感数据组合为4 m分辨率多光谱数据及1 m分辨率全色数据。数据获取范围内局部有少量云覆盖,对遥感解译影响不大,数据质量总体较好,满足监测要求(见图 2)。

3.2 数据处理

获取数据后,将GeoEye-1图像进行了纠正处理。GeoEye-1数据全色分辨率为0.41 m,多光谱数据分辨率为1.65 m,数据纠正融合后,重采样分辨率为1.00 m。

3.2.1 图像纠正

遥感图像在成像过程中由于传感器的性能差异、卫星飞行高度和姿态变化及地面高低起伏不同会造成图像的各种几何畸变。为了消除几何畸变并把图像转换到需要的地图投影上去,需要对GeoEye-1数据进行几何纠正。以1:10000地形图或部分1:50000地形图(针对没有1:10000地形图的地区)和相应的DEM为基准进行正射纠正。纠正时仍采用高斯-克吕格3度带投影,校正后的图面中误差(1:50000尺度)一般不大于0.5 mm,最大不大于1.0 mm,控制点拟合精度误差0.3 mm以内[4]。

3.2.2 图像镶嵌

工作区涉及两景以上卫星数据时,需进行镶嵌处理。镶嵌时除了满足拼接线处相邻影像的细节在几何上一一对接外,相邻影像的色调要保持一致,并且达到层次丰富、色调均匀、反差适中、清晰的效果。

3.2.3 图像信息增强

为了在影像图上准确识别各类目标地物,解译前需要对遥感影像图进行一定的图像处理,根据矿区的实际特点选择有效的增强方法,数据融合为基本方法之一。

3.2.4 图像分类

主要针对多光谱数据进行,对不同的矿山地物类型将尝试采用不同的分类方法,高分辨率图像分类主要以目视为主。

3.3 信息提取

此次工作的信息提取在MAPGIS6.7平台进行,提取的目标物有:① 正在开采的地下、露天矿山的矿区、开采面、排土场等范围;② 已经闭坑的矿山状况及范围;③ 露天开采的石灰石矿等;④ 矿山地质环境现状(包括地质灾害、矿山污染等)。

3.4 实地调查

实地调查内容包括煤矿、铁矿、铝土矿等金属矿产资源开发状况及相关地物(开采面、排石场、排土场等)的类型、占地等,并对有界外开采嫌疑的图斑进行验证。

4. 调查区环境相关数据分析

4.1 矿山开发占用土地情况

遥感解译及统计数据显示,山西娄烦调查区矿山开发占地总面积为1057.73 hm2,生产矿山占地318.34 hm2(其中,采石场开采占地104.44 hm2),固体废弃物占地646.84 hm2,闭坑矿山占地92.55 hm2,其面积比例约为3:6:1,固体废弃物及闭坑矿山占矿山开采占地总面积的70%。合法开采与违规开采占用土地比例约为1:5,违规开采占用土地问题十分突出(见表 1、表 2)。

表 1 调查区矿山开采占用土地统计(按开采阶段)Table 1. Statistics survey area of land occupied by mining (Mining stage classification)开发状况 矿种 个数 占地面积/ha 合计 生产矿山(地下开采) 煤矿 25 25.86 25.86 铁矿 14 生产矿山(露天开采) 铝土矿 4 3.82 292.48 铁矿 14 184.22 石材 112 104.44 固体废弃物占地 排土场 219 300.65 646.84 尾矿库 133 214.21 废铁矿石堆 234 131.98 闭坑矿山 铝土矿 6 19.92 92.55 铁矿 143 72.63 表 2 调查区矿山开采占用土地统计(按矿种)Table 2. Statistics of land occupied by mining in the survey area according to mineral commodity矿种 开采面 矿山建筑 固体废弃物 合法开采 违规开采 小计 煤矿 14.63 11.23 25.86 25.86 铝土矿 3.82 3.82 8.13 铁矿 45.78 138.44 184.22 638.71 采石场 104.44 104.44 合计 49.6 242.88 292.48 25.86 646.84 4.2 矿山开发引起的次生地质灾害情况

通过遥感解译及数据分析得出,该监测区域范围内,主要地质灾害有地面沉降、滑坡、地裂缝等。因开采石材,引发山体崩塌、滑坡等地质灾害,造成道路阻塞,损毁交通,共有9处隐患点,地质灾害面积约6.95 hm2(见图 3)。

4.3 矿山开发导致粉尘污染

调查区内局部地区密集开采石材矿,其特点是规模小、布点密,整体布局比较零乱,采石场粉尘的随意排放严重影响大气环境和周围生态环境。露天堆放的石料导致整个矿区粉尘满天飞,采石场沿途不断有拉满石料的车辆开过,扬起的尘土使整个空间能见度极低,部分石料还从车上散落下来,造成二次污染,导致该地区粉尘污染非常严重。

粉尘弥漫在空气当中,降低了空气质量,影响了日常生活,长期身处粉尘污染的环境会引起多种疾病,严重影响人们身体健康;粉尘污染使矿区土壤质量变坏、硬化,植被遭到破坏,长期积下的粉尘还污染了农作物,并引起农作物减产。

5. 结论与建议

5.1 矿山开发占地严重,恢复治理工作亟待开展

通过研究发现,随着区域矿业活动的加剧,矿山开发占地规模逐步加大,矿山开采引发了一系列的环境问题,造成了区域生态环境的恶化。矿山闭坑后,未能得到及时的恢复治理,造成长期闲置,大量可开采矿产资源长期裸露在外,造成了资源浪费,还严重破坏了周边的生态环境,长此以往,势必影响当地资源开发与经济社会的可持续发展[5]。

建议:① 节约集约利用土地,提高建设用地利用效率,减少矿山土地占用;② 针对不同类型、不同阶段的矿山地质环境问题,区别对待,制定不同的预防与治理恢复措施。在矿山开采过程中,推广应用充填开采等技术,切实减少地面塌陷,减少废弃物堆放造成的土地损毁。同时,采矿权人在开采矿产资源的同时,认真执行矿山地质环境保证金制度,积极承担起治理责任和义务;对于历史遗留的矿山地质环境问题,各级政府部门应当严格制定并实施规划,加大投入,认真做好矿山地质环境恢复治理工作。

5.2 矿山开采引发地质灾害隐患不容忽视

据统计,地质灾害成因大多是人为原因所造成。调查区内采石场众多,且比较分散,设置规模小,设备简易,石材的粗放式开采极易造成山体崩塌和道路阻塞、损毁。尤其是在雨季等极端气候下引发山体崩塌、滑坡、泥石流等地质灾害的频率极高。建议相关部门应当引起足够重视,加强排查、监管与综合治理,推进地质灾害群测群防体系建设,减少地质灾害隐患点,确保人民生命和财产安全。确有必要的地区,实施搬迁避让工程,对受滑坡、泥石流影响的居民所在地进行搬迁治理,提早预防、及早治理。

5.3 部分矿产开发无序,亟待建立科学规范的矿山开发秩序

从驱动因素上分析,经济快速增长导致的资源过度、无序开采是该地区矿山地质环境不断恶化的重要决定性因素[6]。然而长久以来,粗放式开采造成的环境问题与日俱增,按照新形势下科学开采的新要求,迫切需要发展绿色矿业,建设绿色矿山。将绿色矿业理念贯穿于矿产资源开发利用全过程,转变以往单纯以消耗资源、破坏生态为代价的开发利用方式,实现资源开发的经济效益、生态效益、环境效益和社会效益的协调统一。

-

图 3 砂岩样品的扫描电镜图像和矿物分析(2个样品的粒度有显著的差异)

a—样品1-1背散射图像;b—样品1-2背散射图像;c—样品1-1AMICS矿物分析图;d—样品1-2AMICS矿物分析图

Figure 3. Backscattering image and mineral analysis diagram of sandstone sample.

(a) Sample 1-1 backscatter image; (b) Sample 1-2 backscatter images; (c) Sample 1-1AMICS mineral analysis diagram; (d) Sample 1-2AMICS mineral analysis diagram (there is a significant difference in particle size between the two samples)

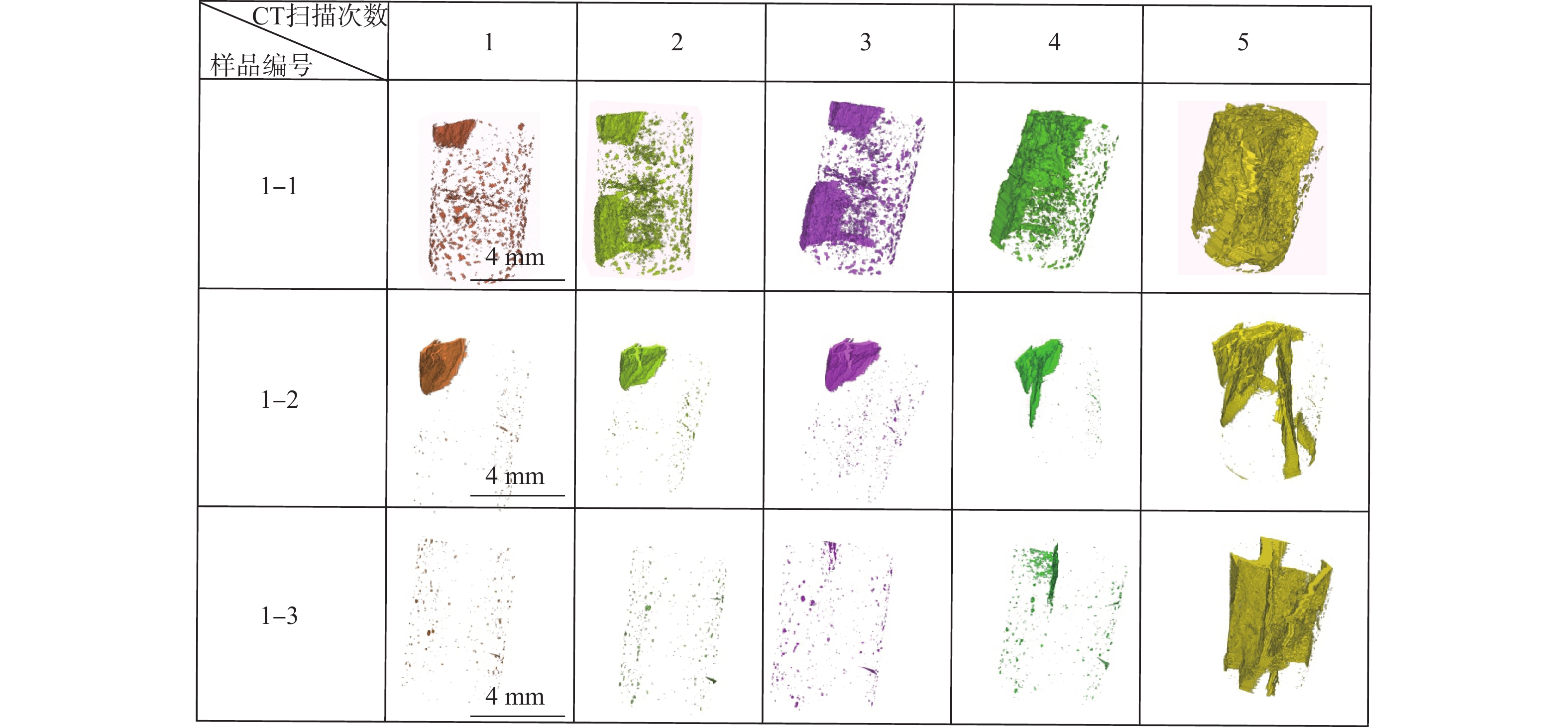

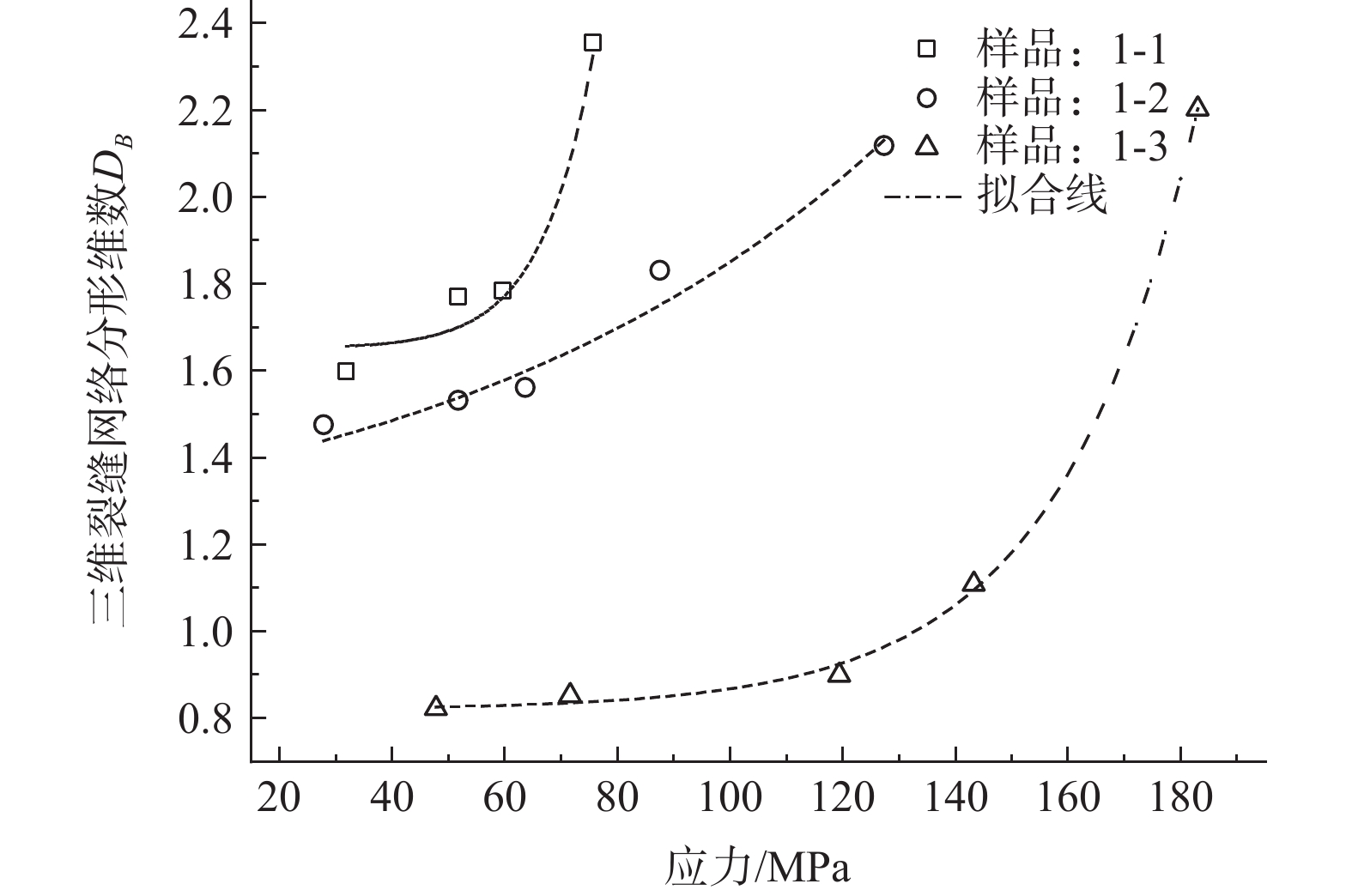

图 6 QXY组样品不同载荷下的三维裂缝网络(CT扫描后经过数据处理得到三维裂缝网络,用颜色区分不同的扫描次数。次数1—4为破裂前扫描,次数5为破裂后扫描)

Figure 6. Three-dimensional crack network of QXY group samples under different loads(3D fracture network is obtained through data processing after CT scan, and the colors represent different scan times. digits 1-4 were scanned before rupture and digits 5 is scanned after rupture).

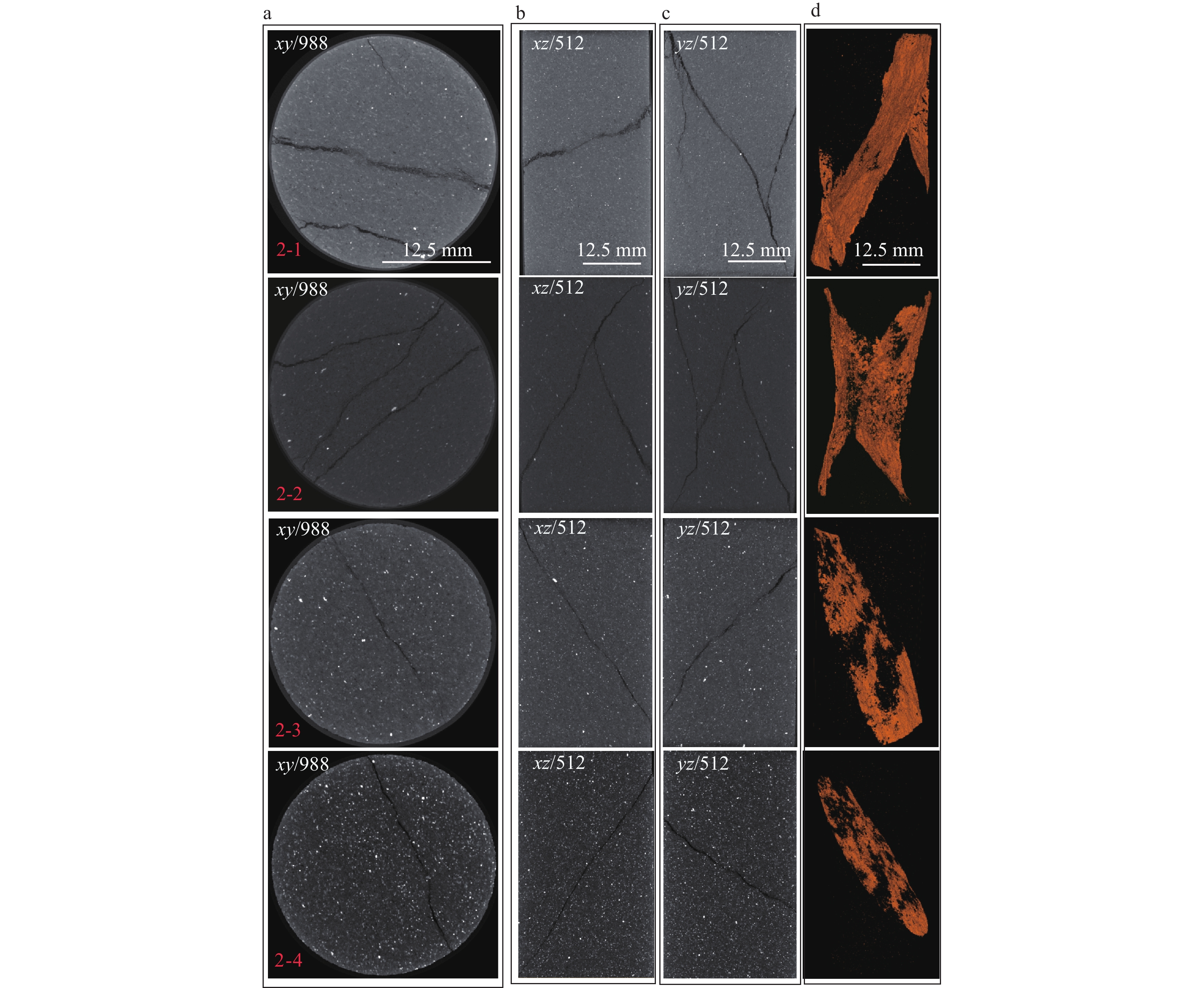

图 7 QDY组砂岩样品破裂后的二维CT切片和三维裂缝网络(图中x、y、z为坐标,数字代表切片位置)

a—xy方向的CT切片;b—xz方向的CT切片;c—yz方向的CT切片;d—三维裂缝网络

Figure 7. Two-dimensional CT slices and three-dimensional fracture network of sandstone samples of QDY formation after fracture

(a) xy direction CT section; (b) xz direction CT section; (c) yz direction CT section; (d) 3D crack network (x, y and z are coordinates, and the numbers represent slice positions)

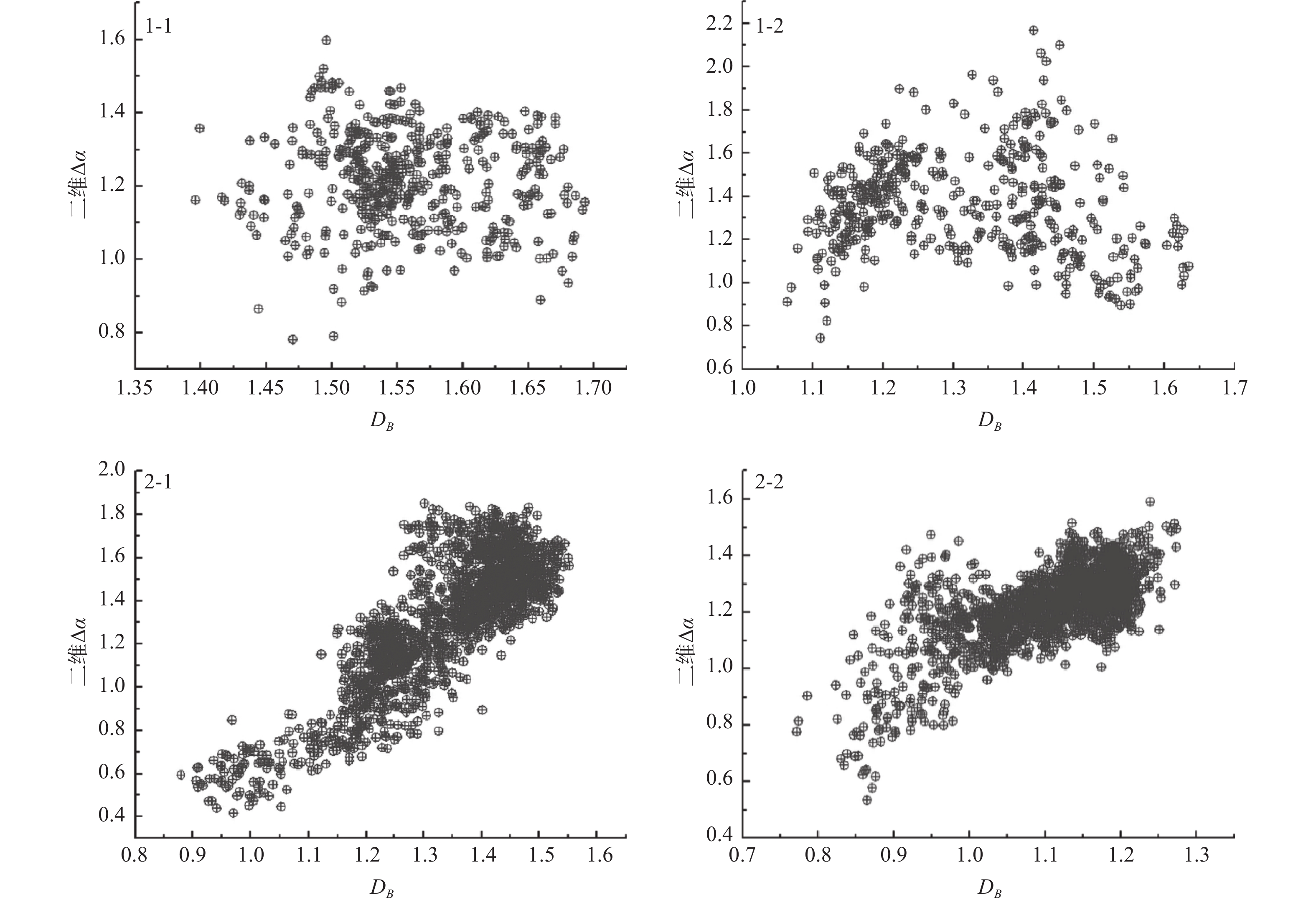

图 8 砂岩样品的二维裂缝网络和对应的多重分形谱

a—最大分形维数为1.51的二维裂缝网络; b—最大分形维数为1.45的二维裂缝网络;c—最大分形维数为1.31的二维裂缝网络;d—多重分形谱

Figure 8. Two-dimensional fracture network and corresponding multifractal spectrum of sandstone samples.

(a) Two-dimensional fracture network with a maximum fractal dimension of 1.51; (b) Two-dimensional fracture network with a maximum fractal dimension of 1.45; (c) Two-dimensional fracture network with a maximum fractal dimension of 1.31; (d) Multifractal spectrum

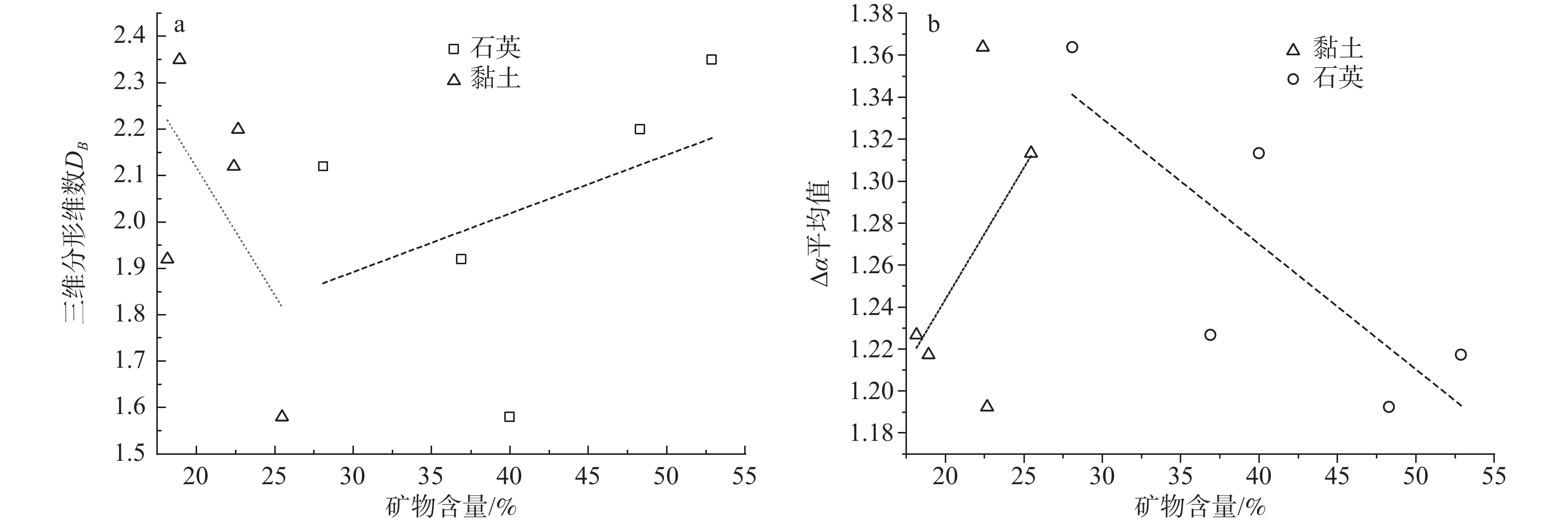

图 10 矿物含量与三维分形维数(DB)、谱宽(Δα)平均值之间的关系(单轴压缩样品的数据)

a—三维分形维数与矿物含量; b—谱宽平均值与矿物含量

Figure 10. Relationship between mineral content and three-dimensional fractal dimension as well as mean spectral width (uniaxial compression sample data)

(a) Three-dimensional fractal dimension and mineral content; (b) Average spectral width and mineral content;

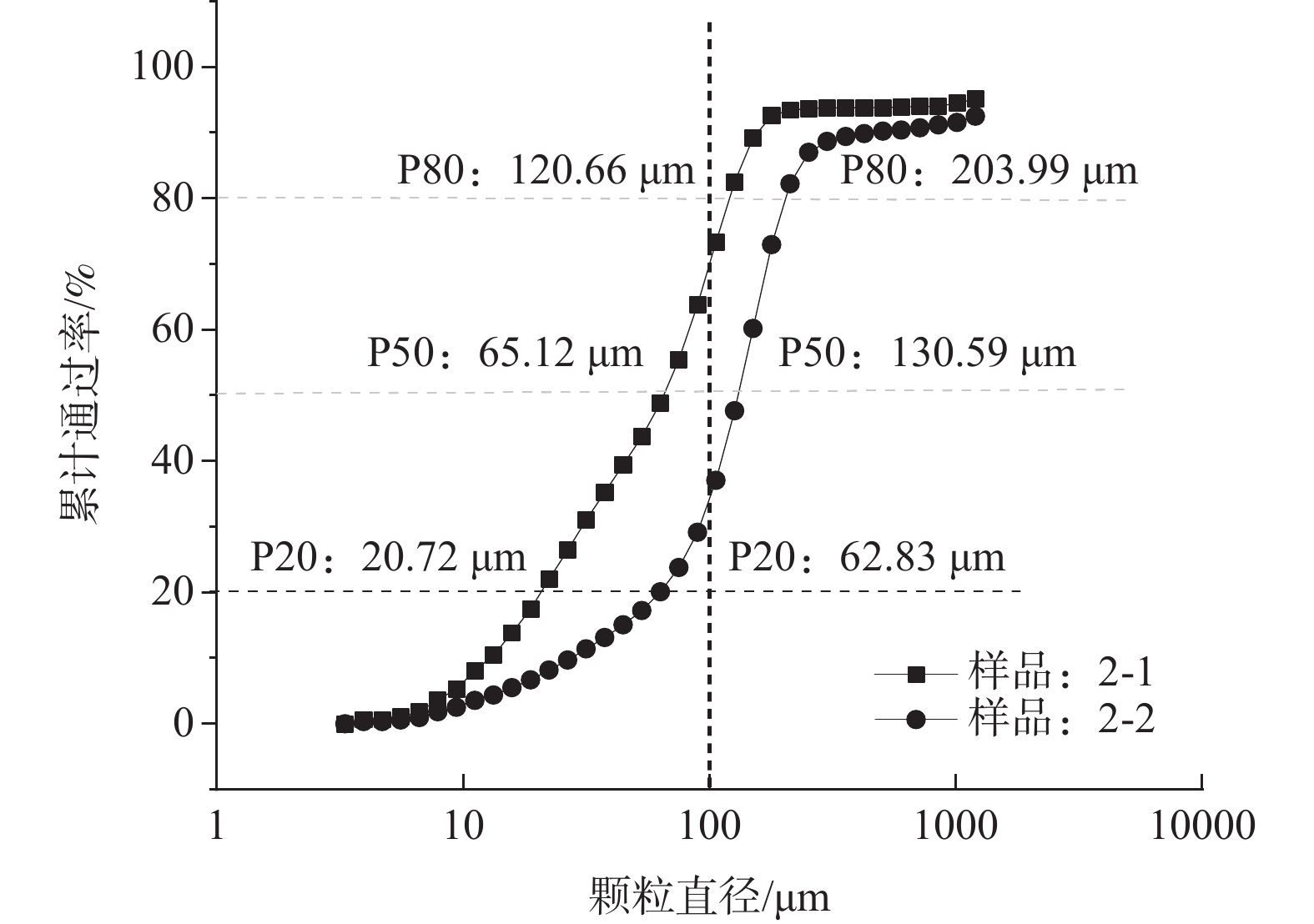

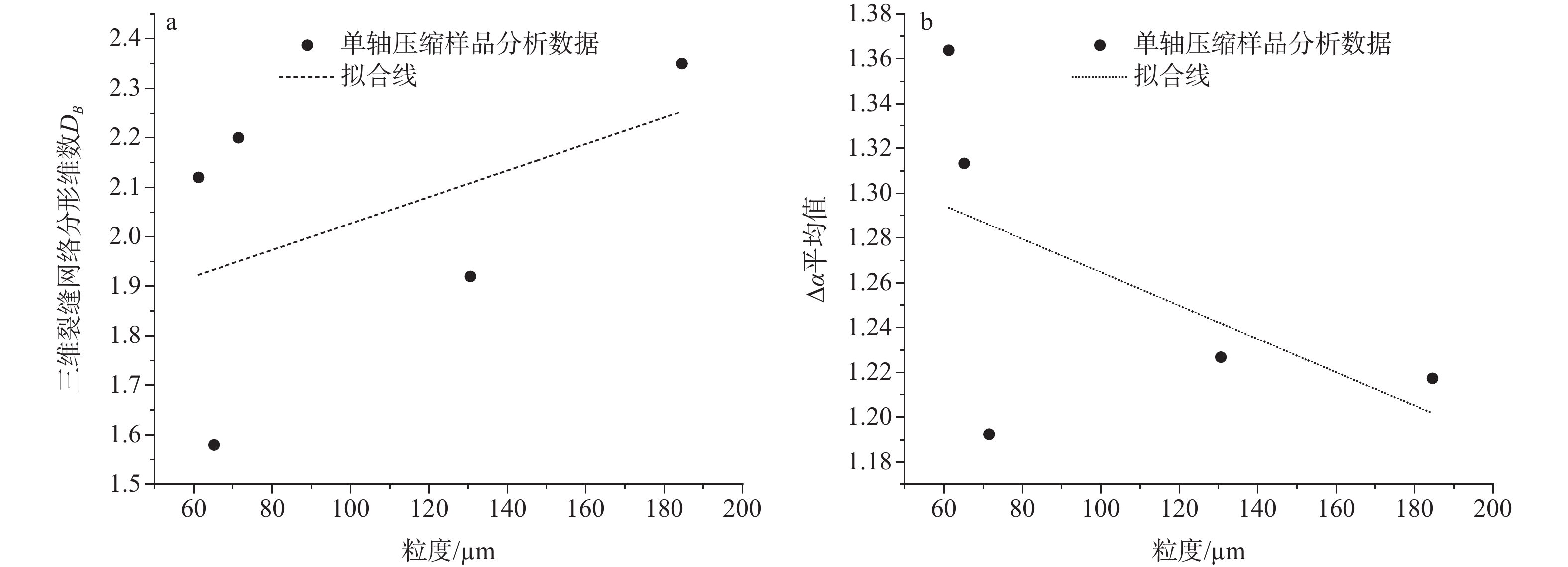

图 13 砂岩平均粒径与三维裂缝网络分形维数(DB)、谱宽(Δα)平均值之间的关系(单轴压缩样品的数据)

a—三维裂缝网络分形维数与粒度; b—谱宽平均值与粒度

Figure 13. Relation shaps between average particle size of sandstone and fractal dimension as well as average spectral width of three-dimensional fracture network (data of uniaxial compression sample)

(a) Fractal dimension of three-dimensional fracture network and particle size; (b) Average spectral width and particle size

表 1 致密砂岩试样矿物含量及粒度特征

Table 1. Mineral content and particle size characteristics of tight sandstone samples

样品组 样品编号 石英/% 长石/% 黏土/% 其他/% 粒度平均值/μm QXY 1-1 52.88 15.19 11.54 20.39 184.55 1-2 28.08 6.65 22.38 32.89 61.18 1-3 45.37 15.05 14.90 20.68 71.42 QDY 2-1 39.99 21.09 25.45 13.47 65.12 2-2 36.90 34.93 18.15 10.02 130.59 2-3 37.77 28.12 14.85 19.26 79.08 2-4 46.18 26.61 24.98 2.23 110.23 表 2 致密砂岩的裂缝网络体积和孔隙度

Table 2. Volume and porosity of 3D fracture network

样品组 样品编号 孔隙度/% 孔隙体积/‰ QXY 1-1 10.296 3.54E+09 1-2 8.516 3.26E+09 1-3 8.917 3.43E+09 QDY 2-1 8.125 1.96E+12 2-2 8.288 1.84E+12 2-3 8.654 1.97E+12 2-4 8.123 1.68E+12 表 3 致密砂岩试样基本物理力学参数

Table 3. Basic physical and mechanical parameters of tight sandstone samples

样品组 样品编号 直径/mm 高度/mm 围压/MPa 抗压强度/MPa 弹性模量/GPa 泊松比 QXY 1-1 4.00 8.12 0 69.09 31.69 / 1-2 4.00 7.92 0 125.79 67.47 / 1-3 4.00 8.06 0 188.33 92.76 / QDY 2-1 25.00 49.97 0 110.77 22.03 0.279 2-2 25.00 50.01 0 80.97 14.29 0.260 2-3 25.00 50.11 15 187.95 25.81 0.259 2-4 25.00 50.07 30 234.27 27.98 0.288 表 4 裂缝网络分形特征参数

Table 4. Fractal characteristic parameters of fracture network

样品组 样品编号 二维Δα平均值 三维分形维数DB QXY 1-1 1.2173 2.35 1-2 1.3638 2.12 1-3 1.1924 2.20 QDY 2-1 1.3133 1.59 2-2 1.2267 1.92 2-3 1.0066 1.48 2-4 1.0851 1.28 -

[1] BARTON C C, 1995. Fractal analysis of scaling and spatial clustering of fractures[M]. In: Fractals in the Earth Sciences. Springer, 141–178. [2] BERKOWITZ B. , HADAD A, 1997. Fractal and multifractal measures of natural and synthetic fracture networks[J]. Journal Of Geophysical Research-solid Earth 102: 12205–12218 [3] BIENIAWSKI Z T, 1967. Mechanism of brittle fracture of rock: Part II-experimental studies[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 4(4): 407-423. [4] CAI M, KAISER P K, TASAKA Y, et al., 2004. Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations[J]. International Journal of Rock Mechanics and Mining Sciences, 41(5): 833-847. doi: 10.1016/j.ijrmms.2004.02.001 [5] CAI M, MORIOKA H, KAISER P K, et al., 2007. Back-analysis of rock mass strength parameters using AE monitoring data[J]. International Journal of Rock Mechanics and Mining Sciences, 44(4): 538-549. doi: 10.1016/j.ijrmms.2006.09.012 [6] CHEN X, MA L T, SHI C L, et al., 2022. Water occurrence and identification method of the water-bearing degree of tight sandstone reservoirs in the Linxing block[J]. Geology and Exploration, 58(6): 1331-1340. (in Chinese with English abstract [7] DERSHOWITZ W S, HERDA H H, et al. , 1992. Interpretation of fracture spacing and intensity[C]. In: The 33th Us Symposium on Rock Mechanics. USRMS, American Rock. Mechanics Association. [8] DING C D, ZHANG Y, YANG X T, et al., 2019. Permeability evolution of tight sandstone under high confining pressure and high pore pressure and its microscopic mechanism[J]. Rock and Soil Mechanics, 40(9): 3300-3308. (in Chinese with English abstract [9] DUAN M K, JIANG C B, GAN Q, et al., 2020. Experimental investigation on the permeability, acoustic emission and energy dissipation of coal under tiered cyclic unloading[J]. Journal of Natural Gas Science and Engineering, 73: 103054. doi: 10.1016/j.jngse.2019.103054 [10] DUNCAN P M, EISNER L, 2010. Reservoir characterization using surface microseismic monitoring[J]. Geophysics, 75(5): 75A139-75A146. doi: 10.1190/1.3467760 [11] EBERHARDT E, STIMPSON B, STEAD D, 1999. Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures[J]. Rock Mechanics and Rock Engineering, 32(2): 81-99. doi: 10.1007/s006030050026 [12] FAN J M, CHEN X D, LEI Z D, et al., 2019. Characteristics of natural and hydraulic fractures in tight oil reservoir in Ordos Basin and its implication to field development[J]. Journal of China University of Petroleum, 43(3): 98-106. (in Chinese with English abstract [13] GAO C Y, ZHAO F H, GAO L F, et al., 2023. The methods of fracture prediction based on structural strain analysis and its application[J]. Journal of Geomechanics, 29(1): 21-33. (in Chinese with English abstract [14] GHASEMI S, KHAMEHCHIYAN M, TAHERI A, et al., 2020. Crack evolution in damage stress thresholds in different minerals of granite rock[J]. Rock Mechanics and Rock Engineering, 53(3): 1163-1178. doi: 10.1007/s00603-019-01964-9 [15] GRIFFITH A A, 1924. The theory of rupture[C]. In: Proceedings of the First International Congress for Applied Mechanics, 55-63. [16] GRIFFITH A. A., 1920. The Phenomena of Rupture and Flow in Solids[J]. Phil Trans Roy Soc(London), A221: 162-198. [17] GUO Y H, 2018. Experimental study on the effect of particle size on the mechanical properties of sandstone[D]. Qingdao: Shandong University of Science and Technology. (in Chinese with English abstract [18] HOU B, ZHANG R X, ZENG Y J, et al., 2018. Analysis of hydraulic fracture initiation and propagation in deep shale formation with high horizontal stress difference[J]. Journal of Petroleum Science and Engineering, 170: 231-243. doi: 10.1016/j.petrol.2018.06.060 [19] JARVIE D M, HILL R J, RUBLE T E, et al., 2007. Unconventional shale-gas systems: the Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment[J]. AAPG Bulletin, 91(4): 475-499. doi: 10.1306/12190606068 [20] LI B, LI J L, WANG P, et al., 2023. Confining pressure effect and quantitative characterization of rock shear strength parameters[J]. China Mining Magazine, 32(2): 157-164. (in Chinese with English abstract [21] LI M, GUO Y H, WANG H C, et al., 2020. Effects of mineral composition on the fracture propagation of tight sandstones in the Zizhou area, east Ordos Basin, China[J]. Journal of Natural Gas Science and Engineering, 78: 103334. doi: 10.1016/j.jngse.2020.103334 [22] LI S Y, HE T M, YIN X C, 2010. Introduction of rock fracture mechanics[M]. Hefei: University of Science and Technology of China Press. (in Chinese) [23] LI Y W, YANG S, ZHAO W C, et al., 2018. Experimental of hydraulic fracture propagation using fixed-point multistage fracturing in a vertical well in tight sandstone reservoir[J]. Journal of Petroleum Science and Engineering, 171: 704-713. doi: 10.1016/j.petrol.2018.07.080 [24] LING J M, 1993. Study on the mesoscopical characteristics of rock damage under compressive loading[J]. Journal of Tongji University, 21(2): 219-226. (in Chinese with English abstract [25] LIU F Y, YANG T H, ZHANG P H, et al., 2018. Dynamic inversion of rock fracturing stress field based on acoustic emission[J]. Rock and Soil Mechanics, 39(4): 1517-1524. (in Chinese with English abstract [26] LIU J S, DING W L, XIAO Z K, et al., 2019. Advances in comprehensive characterization and prediction of reservoir fractures[J]. Progress in Geophysics, 34(6): 2283-2300. (in Chinese with English abstract [27] LIU S X, WANG Z X, ZHANG L Y, 2018. Experimental study on the cracking process of layered shale using X-ray microCT[J]. Energy Exploration & Exploitation, 36(2): 297-313. [28] LIU S X, WANG Z X, ZHANG L Y, et al., 2018. Micromechanics properties analysis of shale based on nano-indentation[J]. Journal of Experimental Mechanics, 33(6): 957-968. (in Chinese with English abstract [29] LIU S X, WANG Z X, ZHANG L Y, et al., 2019. Effects of microstructure characteristics of shale on development of complex fracture network[J]. Journal of Mining and Safety Engineering, 36(2): 420-428. (in Chinese with English abstract [30] MA S W, WEI L, WANG Y J, et al., 2022. Characterization and evaluation of microscopic pore structures of tight sandstone reservoir in the 8th member of Shihezi Formation in southern Ordos Basin[J]. Geology and Exploration, 58(6): 1321-1330. (in Chinese with English abstract [31] MANDELBROT B B, 1982. The Fractal Geometry of Nature, vol. 1. WH freeman, New York. Matsumoto, N., Yomogida, K., Honda, S., 1992. Fractal analysis of fault systems in Japan and the Philippines[J]. Geophys. Res. Lett, 19: 357-360. doi: 10.1029/92GL00202 [32] MIAO S Y, ZHANG H J, CHEN Y K, et al. , 2019. Surface microseismic monitoring of shale gas hydraulic fracturing based on microseismic location and tomography[J]. Geophysical Prospecting for Petroleum, 58(2): 262-271, 284. (in Chinese with English abstract [33] NASSERI M H, RAO K S, RAMAMURTHY T, 1997. Failure mechanism in schistose rocks[J]. International Journal of Rock Mechanics and Mining Sciences, 34(3-4): 219. e1-219. e15. [34] PAN L Y, HAO L H, LIU K X, et al., 2023. Fracture Propagation Law of Hydraulic Fracturing in High-Salinity Reservoir of Fengcheng Formation in Mahu[J]. Xinjiang Oil & Gas, 19(4): 20-28 [35] PESTMAN B J, VAN MUNSTER J G, 1996. An acoustic emission study of damage development and stress-memory effects in sandstone[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 33(6): 585-593. [36] RENARD F, MCBECK J, CORDONNIER B, et al., 2019. Dynamic in situ three-dimensional imaging and digital volume correlation analysis to quantify strain localization and fracture coalescence in sandstone[J]. Pure and Applied Geophysics, 176(3): 1083-1115. doi: 10.1007/s00024-018-2003-x [37] SHANG C J, KANG Y S, DENG Z, et al., 2019. The influence mechanism of filled natural fractures on the variation law of shale permeability in loading process[J]. Journal of Geomechanics, 25(3): 382-391. (in Chinese with English abstract [38] SHI X, PAN J, HOU Q, et al. , 2018. Micrometer-scale fractures in coal related to coal rank based on micro-ct scanning and fractal theory[J]. Fuel 212: 162–172. [39] TAN Y L, WANG Z X, FENG X Q, et al., 2021. Structural preservation conditions analysis of oil and gas in complex structural area: A case study of structural analysis in the Well Wanjingdi-1, Anhui, China[J]. Journal of Geomechanics, 27(3): 441-452. (in Chinese with English abstract [40] THIELE S T, GROSE L, SAMSU A, MICKLETHWAITE S, et al. , 2017. Rapid, semi-automatic fracture and contact mapping for point clouds, images and geophysical data[J]. Solid Earth 8: 1241–1253. [41] WANG D K, ZENG F C, WEI J P, et al., 2021. Quantitative analysis of fracture dynamic evolution in coal subjected to uniaxial and triaxial compression loads based on industrial CT and fractal theory[J]. Journal of Petroleum Science and Engineering, 196: 108051. doi: 10.1016/j.petrol.2020.108051 [42] WANG L S, SUN D S, ZHENG X H, et al., 2017. Size effect experiment of uniaxial compressive strength of three typical rocks[J]. Journal of Geomechanics, 23(2): 327-333. (in Chinese with English abstract [43] WANG S, XU Y, ZHANG Y B, et al., 2023. Effects of sandstone mineral composition heterogeneity on crack initiation and propagation through a microscopic analysis technique[J]. International Journal of Rock Mechanics and Mining Sciences, 162: 105307. doi: 10.1016/j.ijrmms.2022.105307 [44] WANG Y, WANG H M, ZHU H B, 2021. Preliminary study on physical experimental simulation of hydraulic fracturing[J]. Progress in Geophysics, 36(3): 1130-1137. (in Chinese with English abstract [45] WEIBULL W, 1939. A statistical theory of the strength of materials[M]. Stockholm: Generalstabens Litografiska Anstalts Förlag: 1-29. [46] WEN X L, KONG M W, LUO Y, et al., 2021. Study and Application of Fracturing Technology for Tight Reservoir With HPHT Closure Stress in the Southern Margin of Junggar Basin[J]. Xinjiang oil & Gas, 17(4): 15-20. [47] WEN S S, YIN C, SHI X W, et al., 2023. Multi-scale rupture characteristics dominated by pre-existing fractures of Longmaxi shale during hydraulic fracturing in Luzhou block[J]. Progress in Geophysics, 38(5): 2172-2181. (in Chinese with English abstract [48] WU F Q, QIAO L, GUAN S G, et al., 2021. Uniaxial compression test study on size effect of small size rock samples[J]. Chinese Journal of Rock Mechanics and Engineering, 40(5): 865-873. (in Chinese with English abstract [49] WU H, ZHOU Y, YAO Y, et al., 2019. Imaged based fractal characterization of microfracture structure in coal[J]. Fuel, 239: 53-62. doi: 10.1016/j.fuel.2018.10.117 [50] WU N, SHI S, ZHENG S Q, et al., 2022. Formation pressure calculation of tight sandstone gas reservoir based on material balance inversion method[J]. Coal Geology & Exploration, 50(9): 115-121. (in Chinese with English abstract [51] WU S T, YANG Z, PAN S Q, et al., 2020. Three-dimensional imaging of fracture propagation in tight sandstones of the Upper Triassic Chang 7 member, Ordos Basin, Northern China[J]. Marine and Petroleum Geology, 120: 104501. doi: 10.1016/j.marpetgeo.2020.104501 [52] XIE H P, CHEN Z D, 1989. Analysis of rock fracture micro-mechanism[J]. Journal of China Coal Society(2): 57-66. (in Chinese with English abstract [53] XING H T, ZHANG X L, HE J X, et al., 2022. Mineral composition characteristics and petroleum geological significance of tight sandstone of Longtan Formation in Weixin area, eastern Yunnan[J]. Coal Geology & Exploration, 50(4): 52-60. (in Chinese with English abstract [54] XIONG L F, 2021. Mechanisms and factors of the localized deformation in porous rocks[D]. Beijing: University of Science and Technology Beijing. (in Chinese with English abstract [55] XIONG L F, 2022. Study on deformation and failure mechanism of porous rock and its influencing factors [ D ]. Beijing University of Science and Technology. [56] YANG F, MEI W B, LI L, et al., 2023. Propagation of hydraulic fractures in thin interbedded tight sandstones[J]. Coal Geology & Exploration, 51(7): 61-71. (in Chinese with English abstract [57] YANG S Q, SU C D, XU W Y, 2005. Experimental and theoretical study of size effect of rock material[J]. Engineering Mechanics, 22(4): 112-118. (in Chinese with English abstract [58] YU X, LI G, CHEN Z, et al., 2021. Experimental study on physical and mechanical characteristics of tight sandstones in the Xujiahe Formation in western Sichuan after high-temperature exposure[J]. Journal of Geomechanics, 27(1): 1-9. (in Chinese with English abstract [59] ZENG L B, LYU W Y, LI J, et al., 2016. Natural fractures and their influence on shale gas enrichment in Sichuan Basin, China[J]. Journal of Natural Gas Science and Engineering, 30: 1-9. doi: 10.1016/j.jngse.2015.11.048 [60] ZHANG D M, WANG P, ZANG D G, et al., 2023. Pre-stack reservoir prediction of tight sandstone of the fifth member of Xujiahe Formation in the Wubaochang area of northeastern Sichuan[J]. Geology and Exploration, 59(6): 1356-1365. (in Chinese with English abstract [61] ZHANG H, KANG Y L, CHEN J S, et al., 2007. Experimental study on mechanical properties of dense sandstone under different confining pressures[J]. Chinese Journal of Rock Mechanics and Engineering, 26(S2): 4227-4231. (in Chinese with English abstract [62] ZHANG Y F, NIU S Y, DU Z M, et al., 2020. Dynamic fracture evolution of tight sandstone under uniaxial compression in high resolution 3D X-ray microscopy[J]. Journal of Petroleum Science and Engineering, 195: 107585. doi: 10.1016/j.petrol.2020.107585 [63] ZHAO C, LIU F M, TIAN J Y, et al., 2016. Study on single crack propagation and damage evolution mechanism of rock-like materials under uniaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering, 35(S2): 3626-3632. (in Chinese with English abstract [64] ZHAO N, WANG L, ZHANG L, et al. , 2022. Mechanical properties and fracturing characteristics of tight sandstones based on granularity classification: a case study of Permian Lower Shihezi Formation, Ordos Basin[J]. Petroleum Geology & Experiment, 44(4): 720-729, 738. (in Chinese with English abstract [65] ZHONG J H, LIU S X, MA Y S, et al., 2015. Macro-fracture mode and micro-fracture mechanism of shale[J]. Petroleum Exploration and Development, 42(2): 242-250. (in Chinese with English abstract [66] ZHOU J, SHEN Z Z, 2021. The effect of grain size on the mechanical properties of sandstone[J]. China Petroleum and Chemical Standard and Quality, 41(18): 81-82. (in Chinese with English abstract [67] ZHU H Y, SONG Y J, LEI Z D, et al., 2022a. 4D-stress evolution of tight sandstone reservoir during horizontal wells injection and production: A case study of Yuan 284 block, Ordos Basin, NW China[J]. Petroleum Exploration and Development, 49(1): 156-169. doi: 10.1016/S1876-3804(22)60012-0 [68] ZHU W W, HE X P, LI Y T, et al., 2022b. Impacts of fracture properties on the formation and development of stimulated reservoir volume: a global sensitivity analysis[J]. Journal of Petroleum Science and Engineering, 217: 110852. doi: 10.1016/j.petrol.2022.110852 [69] ZHU W W, LEI G, HE X P, et al., 2022c. Fractal and multifractal characterization of stochastic fracture networks and real outcrops[J]. Journal of Structural Geology, 155: 104508. doi: 10.1016/j.jsg.2021.104508 [70] ZHU W W, LEI G, HE X P, et al., 2022d. Can we infer the percolation status of 3D fractured media from 2D outcrops?[J]. Engineering Geology, 302: 106648. doi: 10.1016/j.enggeo.2022.106648 [71] 陈鑫,马立涛,史长林,等,2022. 临兴区块致密砂岩储层水赋存状态及气层含水程度识别方法[J]. 地质与勘探,58(6):1331-1340. [72] 丁长栋,张杨,杨向同,等,2019. 致密砂岩高围压和高孔隙水压下渗透率演化规律及微观机制[J]. 岩土力学,40(9):3300-3308. [73] 樊建明,陈小东,雷征东,等,2019. 鄂尔多斯盆地致密油藏天然裂缝与人工裂缝特征及开发意义[J]. 中国石油大学学报(自然科学版),43(3):98-106. doi: 10.3969/j.issn.1673-5005.2019.03.011 [74] 高晨阳,赵福海,高莲凤,等,2023. 基于构造应变分析的裂缝预测方法及其应用[J]. 地质力学学报,29(1):21-33. doi: 10.12090/j.issn.1006-6616.2022089 [75] 郭宇航,2018. 粒度对红砂岩力学性质的影响规律试验研究[D]. 青岛:山东科技大学. [76] 李斌,李佳伦,王鹏,等,2023. 岩石抗剪强度参数的围压效应与定量表征[J]. 中国矿业,32(2):157-164. [77] 李世愚,和泰名,尹祥础,2010. 岩石断裂力学导论[M]. 合肥:中国科学技术大学出版社. [78] 凌建明,1993. 压缩荷载条件下岩石细观损伤特征的研究[J]. 同济大学学报,21(2):219-226. [79] 刘飞跃,杨天鸿,张鹏海,等,2018. 基于声发射的岩石破裂应力场动态反演[J]. 岩土力学,39(4):1517-1524. [80] 刘敬寿,丁文龙,肖子亢,等,2019. 储层裂缝综合表征与预测研究进展[J]. 地球物理学进展,34(6):2283-2300. doi: 10.6038/pg2019CC0290 [81] 刘圣鑫,王宗秀,张林炎,等,2019. 页岩微观组构特征对复杂裂缝网络形成的影响[J]. 采矿与安全工程学报,36(2):420-428. [82] 马尚伟,魏丽,王一军,等,2022. 鄂尔多斯盆地南部盒8段致密砂岩储层微观孔隙结构表征与评价[J]. 地质与勘探,58(6):1321-1330. doi: 10.12134/j.dzykt.2022.06.016 [83] 缪思钰,张海江,陈余宽,等,2019. 基于微地震定位和速度成像的页岩气水力压裂地面微地震监测[J]. 石油物探,58(2):262-271,284. doi: 10.3969/j.issn.1000-1441.2019.02.012 [84] 潘丽燕,郝丽华,刘凯新,等,2023. 玛湖风城组高含盐储层水力压裂裂缝扩展规律[J]. 新疆石油天然气,19(4):20-28 doi: 10.12388/j.issn.1673-2677.2023.04.003 [85] 尚春江,康永尚,邓泽,等,2019. 充填天然裂缝对页岩受载过程中渗透率变化规律影响机理分析[J]. 地质力学学报,25(3):382-391. [86] 谭元隆,王宗秀,冯兴强,等,2021. 复杂构造区油气构造保存条件分析:来自皖泾地1井的构造解析[J]. 地质力学学报,27(3):441-452. doi: 10.12090/j.issn.1006-6616.2021.27.03.040 [87] 王连山,孙东生,郑秀华,等,2017. 三种典型岩石单轴抗压强度的尺寸效应试验研究[J]. 地质力学学报,23(2):327-333. [88] 王瑜,王辉明,朱海波,2021. 水力压裂物理实验模拟初探[J]. 地球物理学进展,36(3):1130-1137. doi: 10.6038/pg2021EE0258 [89] 文贤利,孔明炜,罗垚,等,2021,准噶尔盆地南缘高温高压高闭合应力致密储层改造技术研究及应用[J]. 新疆石油天然气,17(4):15-20 [90] 文山师,尹陈,石学文,等,2023. 天然裂缝主导模式下泸州龙马溪组页岩水力压裂多尺度破裂特征[J]. 地球物理学进展,38(5):2172-2181. [91] 伍法权,乔磊,管圣功,等,2021. 小尺寸岩样单轴压缩试验尺寸效应研究[J]. 岩石力学与工程学报,40(5):865-873. [92] 武男,石石,郑世琪,等,2022. 基于物质平衡反演法的致密砂岩气藏地层压力计算[J]. 煤田地质与勘探,50(9):115-121. doi: 10.12363/issn.1001-1986.21.12.0801 [93] 谢和平,陈至达,1989. 岩石断裂的微观机理分析[J]. 煤炭学报(2):57-66. [94] 邢慧通,张晓丽,何金先,等,2022. 滇东威信地区龙潭组致密砂岩矿物组成特征及其油气地质意义[J]. 煤田地质与勘探,50(4):52-60. doi: 10.12363/issn.1001-1986.21.07.0403 [95] 熊良锋,2021. 孔隙岩石变形破坏机制及其影响因素研究[D]. 北京:北京科技大学. [96] 熊良锋,2022. 孔隙岩石变形破坏机制及其影响因素研究[D]. 北京科技大学. [97] 杨帆,梅文博,李亮,等,2023. 薄互层致密砂岩水力压裂裂缝扩展特征研究[J]. 煤田地质与勘探,51(7):61-71. doi: 10.12363/issn.1001-1986.22.10.0788 [98] 杨圣奇,苏承东,徐卫亚,2005. 岩石材料尺寸效应的试验和理论研究[J]. 工程力学,22(4):112-118. doi: 10.3969/j.issn.1000-4750.2005.04.022 [99] 于鑫,李皋,陈泽,等,2021. 川西须家河组致密砂岩高温后的物理力学特征参数试验研究[J]. 地质力学学报,27(1):1-9. [100] 张德明,王鹏,臧殿光,等,2023. 川东北五宝场地区须五段致密砂岩叠前储层预测[J]. 地质与勘探,59(6):1356-1365. doi: 10.12134/j.dzykt.2023.06.020 [101] 张浩,康毅力,陈景山,等,2007. 变围压条件下致密砂岩力学性质实验研究[J]. 岩石力学与工程学报,26(S2):4227-4231. [102] 赵程,刘丰铭,田加深,等,2016. 基于单轴压缩试验的岩石单裂纹扩展及损伤演化规律研究[J]. 岩石力学与工程学报,35(S2):3626-3632. [103] 钟建华,刘圣鑫,马寅生,等,2015. 页岩宏观破裂模式与微观破裂机理[J]. 石油勘探与开发,42(2):242-250. [104] 周婧,沈振振,2021. 粒度对砂岩力学性质的作用[J]. 中国石油和化工标准与质量,41(18):81-82. 期刊类型引用(2)

1. 潘雨梁,张小东,韩磊,张硕,冀海军. 沁南郑庄区块煤层气直井压裂曲线特征及其成因. 中国矿业. 2025(03): 225-235 .  百度学术

百度学术2. 叶美娜,仲海书,张震,李保珠,田向盛,张英. 甘肃早子沟金矿典型岩石微观结构特征及其渗透性研究. 地质与勘探. 2024(06): 1142-1152 .  百度学术

百度学术其他类型引用(0)

-

下载:

下载:

下载:

下载:

百度学术

百度学术