Prediction and analysis on large deformation of surrounding rocks in the Muzhailing Tunnel of the Weiyuan–Wudu Expressway under high in-situ stress

-

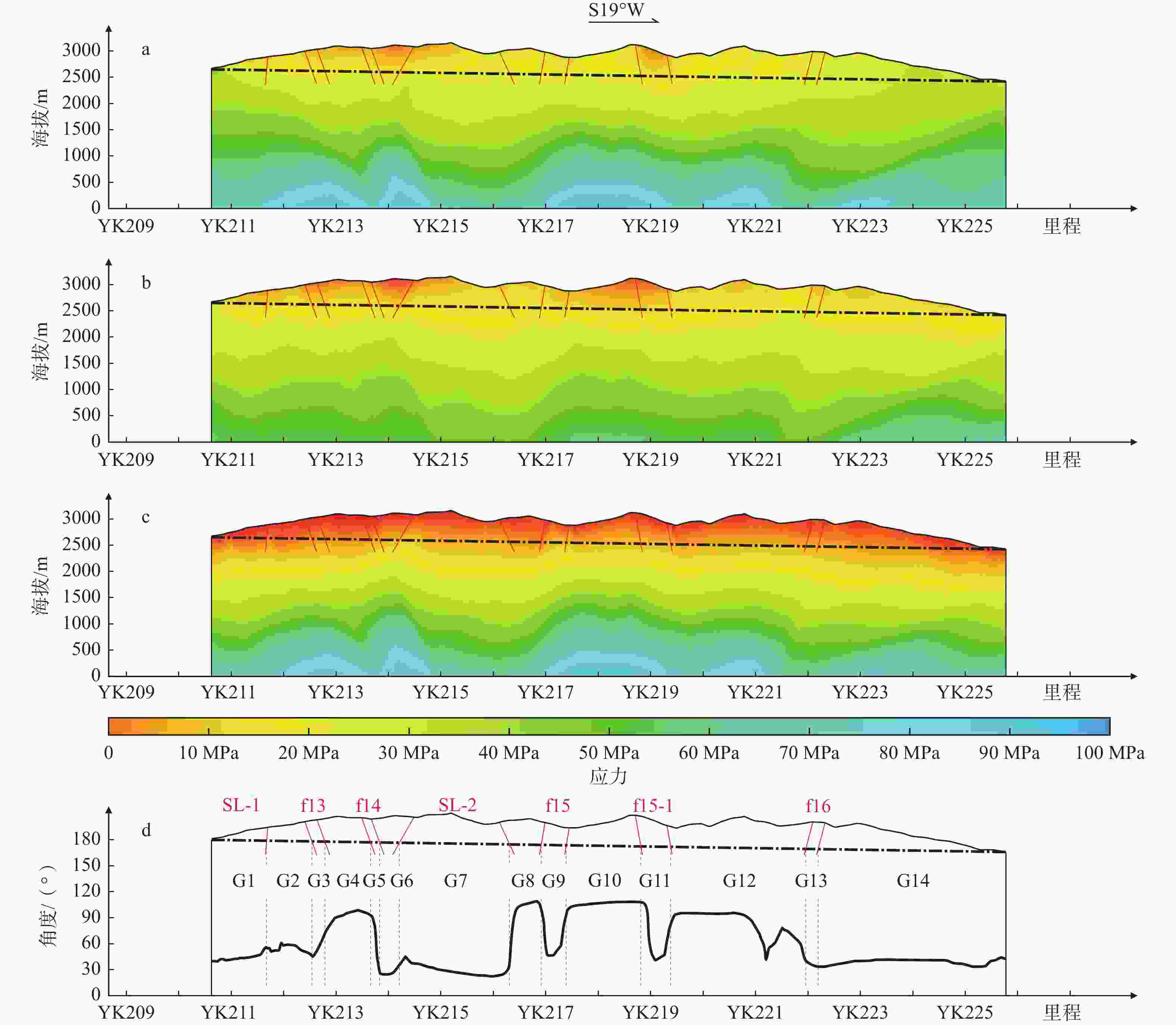

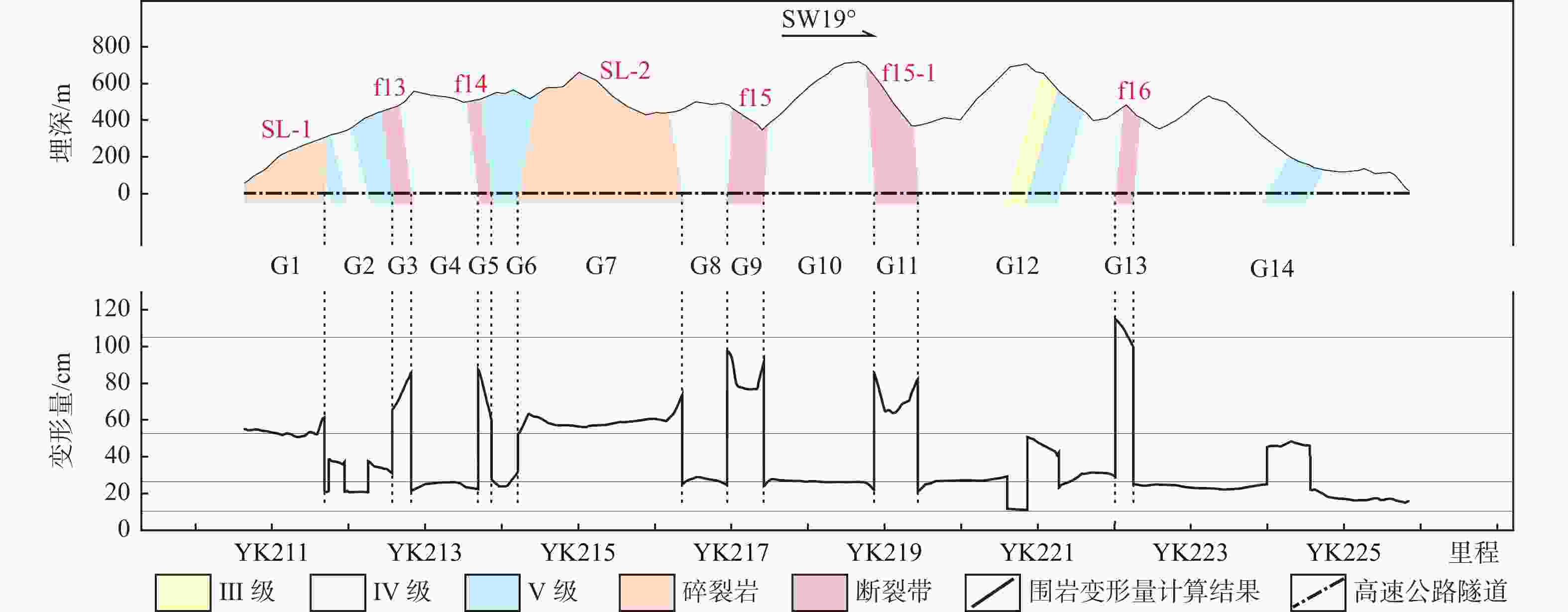

摘要: 为解决在建渭武高速木寨岭隧道施工过程中遇到的高地应力环境下软岩大变形问题,基于工程区已有地应力实测数据,利用ANSYS有限元软件建立三维地质模型,反演工程区地应力场,并结合Hoek围岩变形预测公式计算分析隧道围岩的变形量。结果表明:工程区的地应力场主要受断裂控制,其次还受到岩体强度和地形的双重影响,强构造变形区的水平主应力值普遍低于弱构造变形区,沿隧道轴线三向主应力大小关系为最大水平主应力(SH)>最小水平主应力(Sh)>垂直应力(SV),强构造变形区最大水平主应力值在G8区段最大,而在G6区段和G11区段最小;弱构造变形区的水平主应力值自G12区段开始逐渐增大,直至G14中段开始因埋深减小而逐渐降低。沿隧道轴线最大水平主应力方向总体为北东向,而在断裂间挤压构造带多偏转为北东东—近东西向。高速公路隧道围岩变形受岩体强度和地应力场的双重影响,其中,岩体强度占主导作用,围岩变形量主要集中在20~80 cm范围内,变形等级以中等和强烈为主。Abstract: This study aims to solve the significant deformation issue in the soft surrounding rocks under high in-situ stress encountered during the construction of the Muzhailing Tunnel on the Weiyuan–Wudu Expressway. We established a three-dimensional geological model to invert the in-situ stress field using ANSYS based on measured in-situ stress data in the engineering area. Then, we calculated and analyzed the deformation of the surrounding rocks by combining the inverted results with the Hoek deformation prediction formula. The result showed that the in-situ stress field in the engineering area was primarily controlled by faults, with secondary influences from rock strength and topography. In the intense tectonic deformation zone, horizontal principal stress values are generally lower than in the weak structural deformation zone. The relationship between the three principal stresses along the tunnel axis is SH>Sh>SV. The maximum horizontal principal stress in the intense tectonic deformation zone was the highest in the G8 section and the lowest in the G6 and G11 sections. In the weak structural deformation zone, horizontal principal stress gradually increases from the G12 section until it decreases due to reduced burial depth starting from the middle of the G14 section. The maximum horizontal principal stress orientation was generally in the NE direction, and the extruded structural belt between the faults was mostly deflected to the NEE –nearly EW direction. The deformation of the surrounding rocks was affected by rock mass strength and in-situ stress field, with rock mass strength playing a dominant role. The deformation of the surrounding rocks is mainly concentrated in the range of 20 to 80 cm, and the deformation levels are mainly moderate and intense.

-

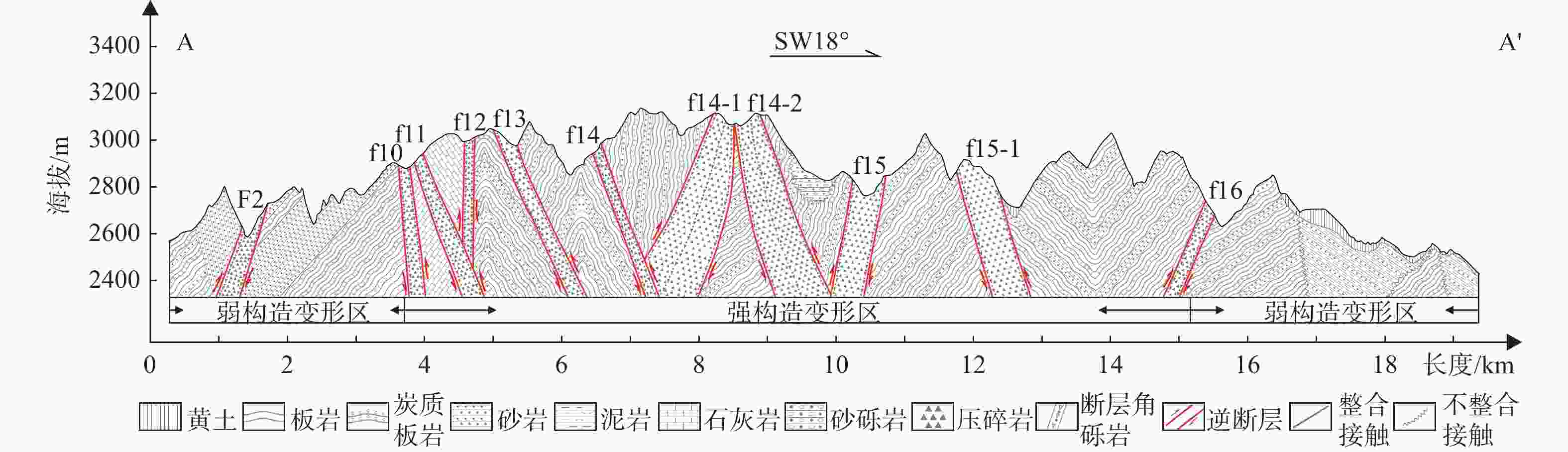

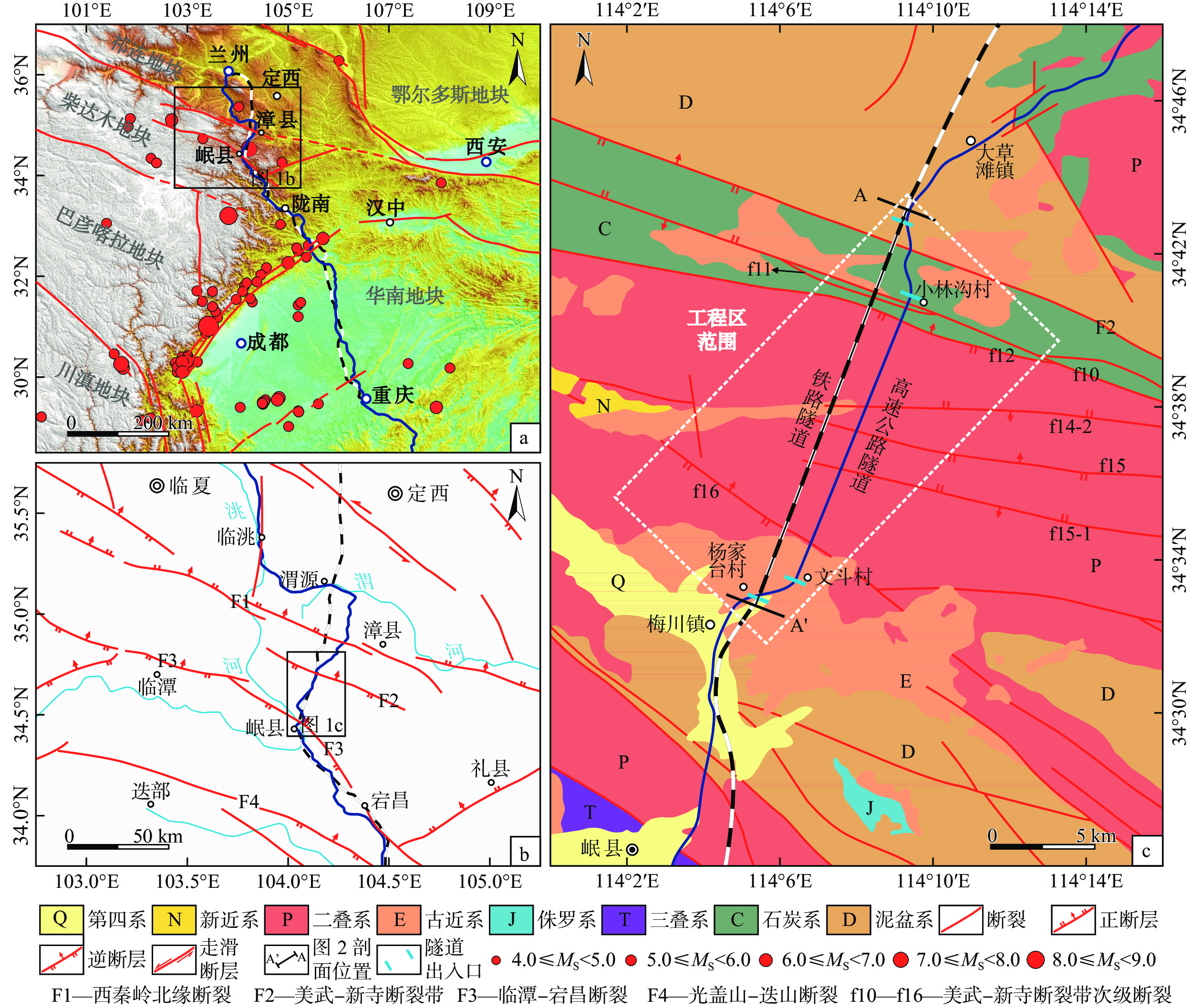

图 1 木寨岭工程区地质构造简图

a—西秦岭地区活动断裂分布图;b—工程区及邻区断裂分布图;c—工程区地质简图

Figure 1. Regional geological and structural diagram of the Muzhailing engineering area

(a) Distribution of active faults in the West Qinling area; (b) Geotectonic outline of the engineering area and adjacent areas; (c) Geological sketch of the engineering area

图 2 木寨岭工程区纵剖面图(剖面位置见图1)

F2—美武−新寺断裂带;f10—f16—美武−新寺断裂带次级断裂

Figure 2. Longitudinal section of the Muzhailing engineering area (The position of the longitudinal section is shown in Fig.1)

图 4 木寨岭工程区地应力场分布特征

a—SH云图;b—Sh云图;c—SV云图;d—海拔2400 m平面SH方向分布图;e—海拔2500 m平面SH方向分布图;f—海拔2600 m平面SH方向分布图

Figure 4. Characteristics of in-situ stress field in the Muzhailing engineering area

(a) Contours of SH; (b) Contours of Sh; (c) Contours of SV; (d) SH orientation distribution at an altitude of 2400 m; (e) SH orientation distribution at an altitude of 2500 m; (f) SH orientation distribution at an altitude of 2600 m

图 5 高速公路隧道轴线主应力云图及最大水平主应力方向

SL-1、SL-2—破碎岩带;f13—f16—美武−新寺断裂带次级断裂;G1—G14—变形区段编号a—隧道轴线纵剖面SH云图;b—隧道轴线纵剖面Sh云图;c—隧道轴线纵剖面SV云图;d—隧道轴线SH方向

Figure 5. Stress contours and orientation of SH along the highway tunnel axis

(a) SH cloud chart of longitudinal section of the tunnel axis; (b) Sh cloud chart of longitudinal section of the tunnel axis; (c) SV cloud chart of longitudinal section of the tunnel axis; (d) SH orientation of the tunnel axis

表 1 工程区已有地应力实测数据

Table 1. Measures in-situ stress data in the engineering area

钻孔编号 序号 埋深/m 实测值/MPa SH Sh SV SH方向 B1 1 245.8 26.22 15.73 6.50 NE42° 2 259.8 29.87 17.17 6.88 B2 3 243.2 23.98 14.66 6.44 NE40° 4 256.7 32.57 18.7 6.80 5 259.7 33.11 18.97 6.88 B3 6 221.5 37.69 21.09 5.87 NE53° 7 222.9 37.94 20.92 5.91 8 225.5 38.38 21.52 5.98 MSZ-01 9 294.9 24.95 14.95 7.97 NE34° 10 316 27.16 16.16 8.53 N1 11 434.5 26.22 16.28 11.51 NE43° 12 443.5 29.61 18.37 11.75 13 445.9 30.16 18.11 11.82 N3 14 444.5 34.98 20.63 11.78 NE55° 15 447.7 35.68 21.29 11.86 S-SK03 16 270.0 12.14 10.64 7.34 NE39.6° 17 300.0 11.37 10.83 8.16 18 365.0 14.84 11.34 9.93 19 397.0 16.28 14.05 10.8 20 427.0 18.76 15.64 11.61 表 2 岩体力学参数表

Table 2. Mechanical parameters of rock mass

围岩等级 岩性特征 密度/

(g·cm−3)弹性模量/

MPa泊松比 Ⅲ 砂岩 2.65 10000 0.25 Ⅳ 板岩夹炭质板岩 2.65 2200 0.30 Ⅴ 2.63 1300 0.35 碎裂岩带 压碎岩(原岩以板岩夹炭

质板岩为主)2.50 1100 0.37 断裂破碎带 断层角砾岩(原岩以板岩

夹砂岩夹炭质板岩为主)2.46 1000 0.40 表 3 地应力实测值与反演值比较

Table 3. Comparison of measured and regressive in-situ stress

编号 序号 埋深/m 实测值/MPa 反演值/MPa及相对误差δ/% SH Sh SV SH方向 SH δ(SH) Sh δ(Sh) SV δ(SV) SH方向 B1 1 245.8 26.22 15.73 6.50 NE42° 33.78 28.8 19.59 24.5 3.85 −40.9 NE47° 2 259.8 29.87 17.17 6.88 34.17 14.4 20.00 16.5 4.31 −37.4 B2 3 243.2 23.98 14.66 6.44 NE40° 30.59 27.6 18.45 25.9 4.70 −27.0 NE47° 4 256.7 32.57 18.70 6.80 33.97 4.3 19.85 6.1 5.14 −24.4 5 259.7 33.11 18.97 6.88 34.06 2.9 19.94 5.1 5.24 −23.9 B3 6 221.5 37.69 21.09 5.87 NE53° 35.06 −7.0 22.58 7.1 6.67 13.6 NE40° 7 222.9 37.94 20.92 5.91 35.06 −7.6 22.57 7.9 6.70 13.4 8 225.5 38.38 21.52 5.98 35.06 −8.7 22.56 4.8 6.77 13.2 MSZ-01 9 294.9 24.95 14.95 7.97 NE34° 24.35 −2.4 17.30 15.7 9.12 14.4 NE64° 10 316.0 27.16 16.16 8.53 24.58 −9.5 18.63 15.3 9.72 14.0 N1 11 434.5 26.22 16.28 11.51 NE43° 28.15 7.4 18.19 11.7 11.06 −3.9 NE68° 12 443.5 29.61 18.37 11.75 28.31 −4.4 18.44 0.4 11.40 −3.0 13 445.9 30.16 18.11 11.82 28.35 −6.0 18.51 2.2 11.49 −2.8 N3 14 444.5 34.98 20.63 11.78 NE55° 28.33 −19.0 17.25 −16.4 11.48 −2.5 NE70° 15 447.7 35.68 21.29 11.86 28.38 −20.5 17.33 −18.6 11.57 −2.4 S-SK03 16 270.0 12.14 10.64 7.34 NE39.6° 13.52 11.4 9.75 −8.4 7.04 −4.1 NE23° 17 300.0 11.37 10.83 8.16 13.45 18.3 10.46 −3.4 7.83 −4.0 18 365.0 14.84 11.34 9.93 15.85 6.8 12.02 6.0 9.54 −3.9 19 397.0 16.28 14.05 10.8 16.68 2.5 12.87 −8.4 10.44 −3.3 20 427.0 18.76 15.64 11.61 17.53 −6.6 13.81 −11.7 11.06 −4.7 表 4 高速公路隧道轴线位置地应力分段统计

Table 4. Sectional statistics of in-situ stress of the highway tunnel axis position

分区 分段 SH/MPa Sh/MPa SV/MPa SH方向 强构造变形区 G1 22.71~23.54 16.32~18.44 0~6.28 NE43.8°—56.2° G2 20.91~23.26 16.35~19.18 2.07~8.28 NE45.2°—61.1° G3 20.91~21.74 16.36~18.48 7.41~8.27 NE45.3°—73.7° G4 21.31~23.88 18.48~19.12 6.50~10.27 NE73.7°—98.6° G5 18.21~21.31 15.93~18.86 10.27~11.93 NE25.2°—92.7° G6 17.94~21.19 14.33~17.56 11.80~13.76 NE24.5°—34.4° G7 21.19~24.69 17.56~22.61 9.32~13.80 NE22.2°—46.6° G8 22.77~25.49 20.77~23.26 5.99~9.32 NE46.6°—109.2° G9 20.91~22.77 18.06~20.77 9.05~12.51 NE46.5°—100.6° G10 20.76~24.81 14.52~18.65 9.05~11.90 NE91.9°—108.4° G11 16.95~20.76 15.85~19.31 8.87~11.73 NE40.77°—108.0° G12 20.48~29.28 19.31~25.35 6.89~11.06 NE40.5°—95.6° G13 29.28~31.11 22.45~24.87 10.02~10.74 NE33.5°—41.0° 弱构造变形区 G14 27.92~38.27 15.76~22.45 1.28~10.02 NE32.8°—44.2° 表 5 围岩点荷载强度取值表

Table 5. Values of point load strength of tunnel surrounding rocks

岩性特征 围岩等级 IS(50)/MPa 砂岩 Ⅲ 4.5 板岩夹炭质板岩 Ⅳ 3.0 Ⅴ 2.4 压碎岩 碎裂岩带 2.0 断层角砾岩 断裂破碎带 1.7 表 6 高速公路隧道沿线围岩强度应力比

Table 6. Ratio of surrounding rock strength along the highway tunnel

分区 分段 Rc/σmax 强构造变形区 G1 1.76~2.03 G2 2.16~2.61 G3 1.57~1.88 G4 2.20~2.52 G5 1.54~2.03 G6 2.47~3.06 G7 1.55~1.99 G8 2.04~2.29 G9 1.43~1.70 G10 2.10~2.51 G11 1.56~1.93 G12 1.79~3.10 G13 1.27~1.41 弱构造变形区 G14 1.85~3.29 表 7 围岩大变形分级表

Table 7. Large deformation classification table

大变形等级 相对变形量(εt)/% 无 <1.0 轻微 1.0~2.5 中等 2.5~5.0 强烈 5.0~10.0 极强 >10.0 表 8 岩体强度计算参数估值表

Table 8. Estimation of rock mass strength calculation parameters

岩体条件 描述 围岩等级 mi GSI 取值依据 砂岩 薄层—中厚层状构造,节理裂隙较发育,将岩体切割成块状,部分接触面光滑 Ⅲ 15 35 Hoek and Marinos,2000

王建军和黄勇,2009

胡元芳等,2011板岩夹炭质板岩 以板岩为主,薄层板状构造,节理、裂隙发育,有黏性土充填,岩体破碎 Ⅳ 9 20 Ⅴ 7 20 压碎岩 成分以板岩为主,碎石状,强风化 碎裂岩带 7 10 断层角砾岩 以细角砾为主,其余为断层泥及砂粒充填,原岩以软质板岩为主,强风化 断裂破碎带 7 10 表 9 高速公路隧道围岩稳定性分析结果分段统计

Table 9. Sectional statistics of highway tunnel surrounding rock stability

分区 分段 围岩等级 Σt/cm 变形等级 强构造变形区 G1 SL-1 50.55~61.63 中等—强烈 G2 Ⅳ—Ⅴ 20.50~38.93 轻微—中等 G3 F13 66.09~85.21 强烈 G4 Ⅳ 21.57~26.17 轻微 G5 F14 59.21~87.96 强烈 G6 Ⅴ 23.70~32.14 中等 G7 SL-2 51.93~74.18 中等—强烈 G8 Ⅳ 24.70~29.01 轻微—中等 G9 f15 76.57~97.60 强烈 G10 Ⅳ 21.73~27.81 轻微—中等 G11 f15-1 63.69~85.86 强烈 G12 Ⅲ—Ⅴ 10.93~50.74 轻微—中等 G13 f16 99.15~114.75 强烈—极强 弱构造变形区 G14 Ⅳ—Ⅴ 14.76~48.38 轻微—中等 -

[1] ANAGNOSTOU G, 1993. A model for swelling rock in tunnelling[J]. Rock Mechanics and Rock Engineering, 26(4): 307-331. doi: 10.1007/BF01027115 [2] AYDAN Ö, AKAGI T, KAWAMOTO T, 1996. The squeezing potential of rock around tunnels: Theory and prediction with examples taken from Japan[J]. Rock Mechanics and Rock Engineering, 29(3): 125-143. doi: 10.1007/BF01032650 [3] CAO C Y, SHI C H, LEI M F, et al. , 2018. Squeezing failure of tunnels: a case study[J]. Tunnelling and Underground Space Technology, 77: 188-203. doi: 10.1016/j.tust.2018.04.007 [4] CHEN J X, LIU W W, CHEN L J, et al. , 2020. Failure mechanisms and modes of tunnels in monoclinic and soft-hard interbedded rocks: a case study[J]. KSCE Journal of Civil Engineering, 24(4): 1357-1373. doi: 10.1007/s12205-020-1324-3 [5] CHEN S J, XIAO M, CHEN J T, et al. , 2020. Disturbance law of faults to in-situ stress field directions and its inversion analysis method[J]. Chinese Journal of Rock Mechanics and Engineering, 39(7): 1434-1444. (in Chinese with English abstract) [6] FAN Y L, 2017. The measurement of in-situ stress in the typical project area of the Muzhailing Tunnel of Lanzhou-Chongqing railway and its engineering geological significance[D]. Beijing: China University of Geosciences (Beijing). (in Chinese with English abstract) [7] FANG X H, YANG Z, YANG J S, et al. , 2020. Large deformation characteristics and control measures of surrounding rock in altered granite stratum of high ground stress tunnel[J]. China Railway Science, 41(5): 92-101. (in Chinese with English abstract) [8] GOEL R K, JETHWA J L, PAITHANKAR A G, 1995. Tunnelling through the young Himalayas-A case history of the Maneri-Uttarkashi power tunnel[J]. Engineering Geology, 39(1-2): 31-44. doi: 10.1016/0013-7952(94)00002-J [9] HE M C, LV X J, JING H H, 2002. Characters of surrounding rockmass in deep engineering and its non-linear dynamic-mechanical design concept[J]. Chinese Journal of Rock Mechanics and Engineering, 21(8): 1215-1224. (in Chinese with English abstract) [10] HOEK E, MARINOS P, 2000. Predicting tunnel squeezing problems in weak heterogeneous rock masses[J]. Tunnels and Tunnelling International, 32(11): 45-51. [11] HOEK E, 2001. Big tunnels in bad rock[J]. Journal of Geotechnical and Geoenvironmental Engineering, 127(9): 726-740. doi: 10.1061/(ASCE)1090-0241(2001)127:9(726) [12] HU Y F, LIU Z Q, WANG J Y, 2011. Squeezing deformation prediction of soft rocks under high ground stress and its application[J]. Modern Tunnelling Technology, 48(3): 28-34. (in Chinese with English abstract) [13] HU Y F, WANG J Y, SONG Z, et al. , 2013. Predicting and controlling of the squeezing deformation in soft rock under high ground stress in Muzhailing Tunnel on Lanzhou-Chongqing Railway[C]//Proceedings of the 12th tunnel and underground engineering symposium across the strait. Emeishan: China Civil Engineering Society: 244-249. (in Chinese) [14] HUANG M L, ZHAO J M, TAN Z S, et al. , 2016. Analysis of the deformation and mechanical characteristics of the surrounding rock-Lining structure of the muzhailing tunnel[J]. Modern Tunnelling Technology, 53(6): 89-99, 107. (in Chinese with English abstract) [15] JETHWA J L, SINGH B, SINGH B, 1984. Estimation of ultimate rock pressure for tunnel linings under squeezing rock conditions-A new approach[C]//Proceedings of ISRM symposium on design and performance of underground excavations. Cambridge: ISRM Symposium, 231-238. [16] JIMENEZ R, RECIO D, 2011. A linear classifier for probabilistic prediction of squeezing conditions in Himalayan Tunnels[J]. Engineering Geology, 121(3-4): 101-109. doi: 10.1016/j.enggeo.2011.05.006 [17] JU X Q, 2010. Analysis on characteristics of ground stress in Muzhailing Tunnel around mountainous areas as well as its application[J]. Railway Investigation and Surveying, 36(2): 33-35. (in Chinese with English abstract) [18] LI B, ZHANG W, WEN R, 2022. Study on the hydraulic fracturing in-situ stress measurement in super-long highway tunnels in southern Shaanxi: Engineering geological significance[J]. Journal of Geomechanics, 28(2): 191-202. (in Chinese with English abstract) [19] LI J C, 2019. Optimization of excavation method for Muzhailing Tunnel in Weiwu expressway research on deformation control measures[D]. Lanzhou: Lanzhou Jiaotong University. (in Chinese with English abstract) [20] LI J Q, 2019. Study on construction deformation prediction and large deformation classification standard of Muzhailing Tunnel of Weiwu Expressway[D]. Lanzhou: Lanzhou Jiaotong University. (in Chinese with English abstract) [21] LI J W, LEI S Y, LI Z, et al. , 2012. Investigation on rheologic properties of carbonaceous slate in Muzhailing Tunnel[J]. Tunnel Construction, 32(1): 36-40. (in Chinese with English abstract) [22] LI P F, ZHAO Y, LIU J Y, 2014. Deformation characteristics and control method of tunnel with weak surrounding rock[J]. China Railway Science, 35(5): 55-61. (in Chinese with English abstract) [23] LI Y Z, GAO P, ZOU C, et al. , 2011. Deformation analysis and primary support parameter optimization: case study on Muzhailing Tunnel[J]. Tunnel Construction, 31(3): 320-324, 339. (in Chinese with English abstract) [24] LI Z J, GUO X X, MA Z W, et al. , 2020. Research status and high-strength pre-stressed primary (type) support system for tunnels with large deformation under squeezing conditions[J]. Tunnel Construction, 40(6): 769-782. (in Chinese with English abstract) [25] LIU Y R, TANG H M, 1999. Rockmass mechanics[M]. Wuhan: China University of Geosciences Press. (in Chinese) [26] Ministry of Housing and Urban-Rural Development of the People’s Republic of China, 2015. Standard for engineering classification of rock mass: GB/T 50218-2014[S]. Beijing: China Planning Press. (in Chinese) [27] PENG J B, CUI P, ZHUANG J Q, 2020. Challenges to engineering geology of Sichuan-Tibet railway[J]. Chinese Journal of Rock Mechanics and Engineering, 39(12): 2377-2389. (in Chinese with English abstract) [28] QI B S, ZHANG P, FENG C J, et al. , 2016. Current in-situ stress state and seismic risk in Sichuan-Gansu-Shaanxi border area[J]. Geology in China, 43(5): 1814-1827. (in Chinese with English abstract) [29] SAARI K, 1982. Analysis of plastic deformation (squeezing) of layers intersecting tunnels and shafts in rock[D]. Berkeley: University of California. [30] SHI Y, 2012. Formation and tectonic evolution of the eastern Qinling Orogen, Central China[D]. Nanjing: Nanjing University. (in Chinese with English abstract) [31] SINGH B, JETHWA J L, DUBE A K, et al. , 1992. Correlation between observed support pressure and rock mass quality[J]. Tunnelling and Underground Space Technology, 7(1): 59-74. doi: 10.1016/0886-7798(92)90114-W [32] SU S R, ZHU H H, WANG S T, et al. , 2002. The effect of fracture properties on stress field in the vicinity of a fracture[J]. Journal of Northwest University (Natural Science Edition), 32(6): 655-658. (in Chinese with English abstract) [33] SUN S F, 2012. Characteristics of soft rock tunnels and large deformation control technology in the Lanzhou-Chongqing railway[J]. Modern Tunnelling Technology, 49(3): 125-130. (in Chinese with English abstract) [34] SUN Y C, GAO B, XU Z L, et al. , 2012. Research on prediction method for squeezing deformation of surrounding rock of tunnel[J]. Journal of Railway Engineering Society, 29(2): 50-54. (in Chinese with English abstract) [35] TANIMOTO C, 1984. NATM-1[M]. Tokyo: Morikita Shuppan. [36] TAO Z G, LUO S L, KANG H W, et al. , 2020. Analysis of deformation law and creep characteristics of carbonaceous slate in highway tunnel[J]. Journal of China University of Mining & Technology, 49(5): 898-906. (in Chinese with English abstract) [37] TAPPONNIER P, ZHIQIN X, ROGER F, et al. , 2001. Oblique stepwise rise and growth of the Tibet Plateau[J]. Science, 294(5547): 1671-1677. doi: 10.1126/science.105978 [38] TERZAGHI K, 1946. Rock defects and loads on tunnel supports[C]//Introduction to rock tunnelling with steel support, RV proctor and TC white. Youngstown: Commercial Shearing and Stamping Company. [39] WANG C H, SHA P, HU Y F, et al. , 2011. Study of squeezing deformation problems during tunneling[J]. Rock and Soil Mechanics, 32(S2): 143-147. (in Chinese with English abstract) [40] WANG D, WANG J F, LI T B, et al. , 2021. Analysis of three-dimensional movement characteristics of rockfall: A case study at a railway tunnel entrance in the southwestern mountainous area, China[J]. Journal of Geomechanics, 27(1): 96-104. (in Chinese with English abstract) [41] WANG J J, HUANG Y, 2009. Engineering geological investigation report of Muzhailing Tunnel of Lanzhou-Chongqing Railway[R]. Xi’an: China Railway First Survey and Design Institute Group Co. , Ltd. (in Chinese) [42] WANG Y G, DING W Q, LIU Z Q, et al. , 2020. Classification standard of large deformation and construction time of second lining in Muzhailing Tunnel[J]. Chinese Journal of Underground Space and Engineering, 16(4): 1116-1122. (in Chinese with English abstract) [43] WOOD A M M, 1972. Tunnels for roads and motorways[J]. Quarterly Journal of Engineering Geology and Hydrogeology, 5(1-2): 111-126. doi: 10.1144/GSL.QJEG.1972.005.01.12 [44] YAN T Y, CUI Z, ZHANG Y H, et al. , 2018. Study of distribution characteristics of in-situ stress field in occurrence area of crossing active fault tunnel engineering[J]. Rock and Soil Mechanics, 39(S1): 378-386. (in Chinese with English abstract) [45] YANG S Q, CHEN M, JING H W, et al. , 2017. A case study on large deformation failure mechanism of deep soft rock roadway in Xin'An coal mine, China[J]. Engineering Geology, 217: 89-101. doi: 10.1016/j.enggeo.2016.12.012 [46] YANG Y,YAN Q H, YI J J, et al, 2021.Application of Integrated Geophysical Exploration Technology to the Survey of the Songshan Tunnel in Yanqing, Beijing[J].Geology and Exploration, 57(6):1374-1383. (in Chinese with English abstract) [47] YE K K, 2018. Dismantling and enlarging technology for ridge core section of Muzhailing Tunnel on Lanzhou-Chongqing Railway[J]. Tunnel Construction, 38(4): 640-648. (in Chinese with English abstract) [48] YU Y Y, CHEN Z M, LI G L, et al. , 2015. Three dimensional FE regression analysis of multivariate geo-stress field of Muzhailing Tunnel[J]. Journal of Lanzhou Jiaotong University, 34(1): 6-11. (in Chinese with English abstract) [49] ZHANG B, 2014. Study on deformation mechanism of slate in Muzhailing Tunnel[J]. Railway Engineering(5): 57-59. (in Chinese with English abstract) [50] ZHANG L C,ZHOU C,TANG J T,et al.,2022.Application of the Two-Component Wide-Field Electromagnetic Method to Engineering Survey of A Deep Tunnel [J].Geology and Exploration,58(4):857-865. (in Chinese with English abstract) [51] ZHANG P, SUN Z G, WANG Q N, et al. , 2017. In-situ stress measurement and stability analysis of surrounding rocks in the north section of deep buried tunnel in Muzhailing[J]. Journal of Geomechanics, 23(6): 893-903. (in Chinese with English abstract) [52] ZHANG P Z, WANG Q, MA Z J, 2002. GPS velocity field and active crustal blocks of contemporary tectonic deformation in continental China[J]. Earth Science Frontiers, 9(2): 430-441. (in Chinese with English abstract) [53] ZHANG Z D, 2003. Discussion and study on large deformation of tunnel in squeezing ground[J]. Modern Tunnelling Technology, 40(2): 5-12, 40. (in Chinese with English abstract) [54] ZHAO D A, LI G L, CHEN Z M, et al. , 2009. Three-dimensional FE regression analysis of multivariate geostress field of Wushaoling Tunnel[J]. Chinese Journal of Rock Mechanics and Engineering, 28(S1): 2687-2694. (in Chinese with English abstract) [55] ZHAO D,TIAN Q,HAO F J,2022.Study on Large Deformation Classification of Deep Buried Carbonaceous Slate Tunnels[J].Geology and Exploration, 58(6):1261-1271.(in Chinese with English abstract) [56] 陈世杰, 肖明, 陈俊涛, 等, 2020. 断层对地应力场方向的扰动规律及反演分析方法[J]. 岩石力学与工程学报, 39(7): 1434-1444. [57] 范玉璐, 2017. 兰渝铁路木寨岭隧道典型工程区地应力测量及工程地质意义[D]. 北京: 中国地质大学(北京). [58] 方星桦, 杨曾, 阳军生, 等, 2020. 高地应力隧道蚀变花岗岩地层围岩大变形特征及控制措施[J]. 中国铁道科学, 41(5): 92-101. [59] 何满潮, 吕晓俭, 景海河, 2002. 深部工程围岩特性及非线性动态力学设计理念[J]. 岩石力学与工程学报, 21(8): 1215-1224. [60] 胡元芳, 刘志强, 王建宇, 2011. 高地应力软岩条件下挤压变形预测及应用[J]. 现代隧道技术, 48(3): 28-34. [61] 胡元芳, 王建宇, 宋冶, 等, 2013. 兰渝线木寨岭隧道高地应力软岩挤压大变形预测及控制[C]//第十二届海峡两岸隧道与地下工程学术与技术研讨会论文集. 峨眉山: 中国土木工程学会: 244-249. [62] 黄明利, 赵建明, 谭忠盛, 等, 2016. 兰渝铁路木寨岭隧道岭脊段衬砌-围岩结构体系变形受力特征分析[J]. 现代隧道技术, 53(6): 89-99, 107. [63] 巨小强, 2010. 木寨岭隧道越岭区区域地应力特征分析及应用[J]. 铁道勘察, 36(2): 33-35. [64] 李彬, 张文, 文冉, 2022. 陕南特长公路隧道水压致裂法地应力测量结果及工程地质意义分析[J]. 地质力学学报, 28(2): 191-202. [65] 李佳琪, 2019. 渭武高速木寨岭隧道施工变形预测及大变形分级标准研究[D]. 兰州: 兰州交通大学. [66] 李剑超, 2019. 渭武高速木寨岭隧道开挖工法优化与变形控制措施研究[D]. 兰州: 兰州交通大学. [67] 李建伟, 雷胜友, 李振, 等, 2012. 木寨岭隧道炭质板岩流变力学特性研究[J]. 隧道建设, 32(1): 36-40. [68] 李鹏飞, 赵勇, 刘建友, 2014. 隧道软弱围岩变形特征与控制方法[J]. 中国铁道科学, 35(5): 55-61. [69] 李沿宗, 高攀, 邹翀, 等, 2011. 木寨岭隧道变形分析及初期支护参数优化研究[J]. 隧道建设, 31(3): 320-324, 339. [70] 李志军, 郭新新, 马振旺, 等, 2020. 挤压大变形隧道研究现状及高强预应力一次(型)支护体系[J]. 隧道建设(中英文), 40(6): 769-782. [71] 刘佑荣, 唐辉明, 1999. 岩体力学[M]. 武汉: 中国地质大学出版社. [72] 彭建兵, 崔鹏, 庄建琦, 2020. 川藏铁路对工程地质提出的挑战[J]. 岩石力学与工程学报, 39(12): 2377-2389. [73] 戚帮申, 张鹏, 丰成君, 等, 2016. 川甘陕交汇地区现今地应力环境与地震危险性[J]. 中国地质, 43(5): 1814-1827. [74] 时毓, 2012. 中国中部东秦岭造山带的形成和演化[D]. 南京: 南京大学. [75] 苏生瑞, 朱合华, 王士天, 等, 2002. 断裂物理力学性质对其附近地应力场的影响[J]. 西北大学学报(自然科学版), 32(6): 655-658. [76] 孙绍峰, 2012. 兰渝铁路软岩隧道特征及大变形控制技术[J]. 现代隧道技术, 49(3): 125-130. [77] 孙元春, 高波, 许再良, 等, 2012. 隧道围岩挤压变形预测方法研究[J]. 铁道工程学报, 29(2): 50-54. [78] 陶志刚, 罗森林, 康宏伟, 等, 2020. 公路隧道炭质板岩变形规律及蠕变特性研究[J]. 中国矿业大学学报, 49(5): 898-906. [79] 王成虎, 沙鹏, 胡元芳, 等, 2011. 隧道围岩挤压变形问题探究[J]. 岩土力学, 32(S2): 143-147. [80] 王栋, 王剑锋, 李天斌, 等, 2021. 西南山区某铁路隧道口高位落石三维运动特征分析[J]. 地质力学学报, 27(1): 96-104. [81] 王建军, 黄勇, 2009. 兰渝铁路木寨岭隧道工程地质勘察报告[R]. 西安: 中铁第一勘察设计院集团有限公司. [82] 王永刚, 丁文其, 刘志强, 等, 2020. 木寨岭隧道大变形分级标准与支护时机研究[J]. 地下空间与工程学报, 16(4): 1116-1122. [83] 颜天佑, 崔臻, 张勇慧, 等, 2018. 跨活动断裂隧洞工程赋存区域地应力场分布特征研究[J]. 岩土力学, 39(S1): 378-386. [84] 阳映, 闫清华, 衣骏杰, 等, 2021.综合物探技术在北京延庆松山隧道勘察中的应用[J].地质与勘探,57(6):1374-1383. [85] 叶康慨, 2018. 兰渝铁路木寨岭隧道岭脊核心段扩拆技术[J]. 隧道建设(中英文), 38(4): 640-648. [86] 余云燕, 陈志敏, 李国良, 等, 2015. 木寨岭隧道三维地应力场多元回归宏观拓展分析[J]. 兰州交通大学学报, 34(1): 6-11. doi: 10.3969/j.issn.1001-4373.2015.01.002 [87] 张波, 2014. 木寨岭隧道板岩变形机理研究[J]. 铁道建筑(5): 57-59. [88] 张林成, 周聪, 汤井田, 等, 2022.双分量广域电磁法在深埋隧洞工程勘察中的应用 [J].地质与勘探,58(4):857-865. [89] 张培震, 王琪, 马宗晋, 2002. 中国大陆现今构造运动的GPS速度场与活动地块[J]. 地学前缘, 9(2): 430-441. [90] 张鹏, 孙治国, 王秋宁, 等, 2017. 木寨岭深埋隧道北段地应力测量与围岩稳定性分析[J]. 地质力学学报, 23(6): 893-903. [91] 张祉道, 2003. 关于挤压性围岩隧道大变形的探讨和研究[J]. 现代隧道技术, 40 [92] 赵德安, 李国良, 陈志敏, 等, 2009. 乌鞘岭隧道三维地应力场多元有限元回归拓展分析[J]. 岩石力学与工程学报, 28(S1): 2687-2694. [93] 赵东, 田倩, 郝付军, 2022.深埋炭质板岩隧道的大变形分级研究[J].地质与勘探,58(6):1261-1271. [94] 中华人民共和国建设部, 2015. 工程岩体分级标准: GB/T 50218—2014[S]. 北京: 中国计划出版社. -

下载:

下载: