Integrated determination of principal stress and tensile strength of rock based on the laboratory and field hydraulic fracturing tests

-

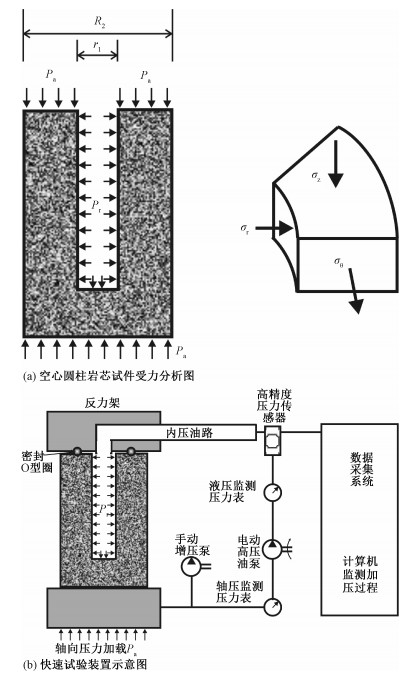

摘要: 钻杆式水压致裂原地应力测试系统的柔性会影响最大水平主应力的计算精度。利用空心岩柱液压致裂试验获得的岩石抗拉强度来取代重张压力计算最大水平主应力是降低钻杆式测试系统柔性的负面影响的重要途径。在福建某隧道深度为65 m的钻孔内开展了8段的高质量水压致裂原地应力测试,随后利用钻孔所揭露的完整岩芯开展了17个岩样的空心岩柱液压致裂试验。利用空心岩柱液压致裂所得的抗拉强度平均值为8.40 MPa,与经典水压致裂法确定的岩体抗拉强度8.22 MPa接近。对于20 m的范围内8个测段的原地应力量值,最小水平主应力平均值为8.41 MPa,基于重张压力Pr的最大水平主应力平均值为16.70 MPa;基于空心岩柱抗拉强度的最大水平主应力量值平均值为16.88 MPa,两种方法获得的最大水平主应力平均值基本一致。最大最小水平主应力与垂直主应力之间的关系表现为σH > σV > σh,这种应力状态有利于区域走滑断层活动。通过对比分析可知,对于钻杆式水压致裂原地应力测试系统,当测试深度小且测试系统柔性小时,基于重张压力和基于空心岩柱抗拉强度得到的最大水平主应力量值差别不大,这说明基于空心岩柱的岩石抗拉强度完全可以用于水压致裂最大水平主应力的计算,同时基于微小系统柔性的水压致裂测试系统获得的现场岩体强度也是可靠的。Abstract: The compliance of the drilling-rod hydraulic fracturing in-situ stress measurement can affect the determination accuracy of the maximum horizontal principal stress. Utilizing tensile strengths based on the hollow cylinder hydraulic fracturing test to replace reopening pressures to calculate maximum horizontal principal stresses is a very promising option to cut down the negative effects from the drilling-rod test system. Eight hydraulic fracturing in-situ stress measurement tests were conducted in a 65 m-deep borehole in an under-construction railway tunnel in Fujian Province. Seventeen hollow cylinders made from the cores recovered from the same borehole were fractured hydraulically in laboratory. The average tensile strength based on the hollow cylinder hydraulic fracturing test is 8.40 MPa, which is close to 8.22 MPa, that determined by the classic hydraulic fracturing in-situ stress measurement. For the 8 in-situ stress measurements within a very narrow depth range of 20 m, the average value of the minimum horizontal principal stress is 8.41 MPa, and the average value of the maximum horizontal principal stress based on the hollow-cylinder tensile strength is 16.88 MPa, which is close to 16.70 MPa, the average value that calculated by the reopening pressure. The relationship between the three major principal stresses is σH > σV > σh, which is favorable for the strike-slip faulting. Based on the comparative analysis, for the drilling-rod hydraulic fracturing test system, when the test depth is shallow and the system compliance is minor, there are no marked differences in the calculated maximum principal stresses between based on the reopening pressures and the hollow-cylinder-test tensile strengths, which proves that the tensile strengths based on the hollow-cylinder test can be utilized to calculate the maximum horizontal principal stress during the hydraulic fracturing in-situ stress measurement; at the same time, the tensile strength of rock mass in the test interval, determined by the field hydraulic fracturing test with minor test system compliance, is definitely reliable for use.

-

表 1 水压致裂原地应力测量成果表

Table 1. Summary of hydraulic fracturing stress measurements

深度

/mPb Pr Ps P0 T σH σh σV σH

方向/MPa 21.7~22.3 15.74 7.04 7.41 0.41 8.70 14.78 7.41 11.39 80° 23.7~24.3 15.30 8.47 8.57 0.43 6.83 16.81 8.57 11.44 97° 25.7~26.3 17.87 9.87 8.82 0.45 8.00 16.14 8.82 11.49 27.7~28.3 19.88 8.71 9.30 0.47 11.17 18.72 9.30 11.55 29.7~30.3 16.69 7.75 8.39 0.49 8.94 16.93 8.39 11.60 31.7~32.3 16.02 8.49 7.57 0.51 7.53 13.71 7.57 11.66 39.7~40.3 13.39 8.46 9.69 0.59 4.93 20.02 9.69 11.87 41.7~42.3 18.33 8.68 9.11 0.60 9.65 18.05 9.11 11.93 表 2 基于两种方法计算的水压致裂原地应力测量成果表

Table 2. Summary of hydraulic fracturing stress measurements based on two methods

隧道内测试

深度/m自然

埋深/mσh/

MPaσV/

MPa①σH1/

MPa②σH2/

MPa③平均差

系数21.73~22.28 422.01 7.41 11.39 14.78 14.28 1% 23.73~24.28 424.01 8.57 11.44 16.81 18.18 5% 25.73~26.28 426.01 8.82 11.49 16.14 16.34 1% 27.73~28.28 428.01 9.30 11.55 18.72 15.75 8% 29.73~30.28 430.01 8.39 11.60 16.93 16.19 2% 31.73~32.28 432.01 7.57 11.66 13.71 14.38 3% 39.73~40.28 440.01 9.69 11.87 20.02 23.29 8% 41.73~42.28 442.01 9.11 11.93 18.05 16.61 4% ①—基于公式(5)计算,Pr采用经典水压致裂法利用P-t曲线确定;②—基于公式(3)计算,岩石抗拉强度T采用空心岩柱液压致裂试验确定;③—平均差系数采用常用的统计学公式计算,以每个测试段的两个值σH1、σH2为样本进行计算 -

AMADEI B, STEPHANSSON O, 1997. Rock stress and its measurement[M]. Dordrecht: Springer. CHANG C D, JO Y, OH Y, et al., 2014. Hydraulic fracturing in situ stress estimations in a potential geothermal site, Seokmo Island, South Korea[J]. Rock Mechanics and Rock Engineering, 47(5): 1793-1808. doi: 10.1007/s00603-013-0491-7 CHEN Q C, SUN D S, CUI J J, et al., 2019. Hydraulic fracturing stress measurements in xuefengshan deep borehole and its significance[J]. Journal of Geomechanics, 25(5): 853-865, doi: 10.12090/j.issn.1006-6616.2019.25.05.070. (in Chinese with English abstract) COVIELLO A, LAGIOIA R, NOVA R, 2005. On the measurement of the tensile strength of soft rocks[J]. Rock Mechanics and Rock Engineering, 38(4): 251-273. doi: 10.1007/s00603-005-0054-7 CUISIAT F D, HAIMSON B C, 1992. Scale effects in rock mass stress measurements[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 29(2): 99-117. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=40cfdc0171e6a052312aa03354fab8df DANESHY A A, 1973. A study of inclined hydraulic fractures[J]. Society of Petroleum Engineers Journal, 13(2): 61-68. http://www.researchgate.net/publication/220010473_a_study_of_inclined_hydraulic_fractures HAIMSON B C, CORNET F H, 2003. ISRM suggested methods for rock stress estimation-part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF)[J]. International Journal of Rock Mechanics and Mining Sciences, 40(7-8): 1011-1020. doi: 10.1016/j.ijrmms.2003.08.002 HAIMSON B C, ZHAO Z L, 1991. Effect of borehole size and pressurization rate on hydraulic fracturing breakdown pressure[C]//Proceedings of the the 32nd U.S. symposium on rock mechanics. Norman: American Rock Mechanics Association. HUDSON J A, 1970. A critical examination of indirect tensile strength tests for brittle rocks[D]. Minneapolis: University of Minnesota. HUDSON J A, HARDY M P, FAIRHURST C, 1973. The failure of rock beams: Part Ⅱ-Experimental studies[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 10(1): 69-82. http://d.old.wanfangdata.com.cn/Conference/WFHYXW629059 Institute of China Seismological Bureau Crustal Stress, CRIEPI, 1999. Study on the formation and propagation of hydrostatic cracking[M]. Beijing: Earthquake Press. (in Chinese) Institute of Crustal Dynamics, China Earthquake Administration, 2013. "Data acquisition and processing code for hydraulic fracturing in-situ stress measurement system." Abbreviated as DADPC for HF: No. 2013SR122558[CP]. 2013-08-30[2013-11-09]. ITO T, EVANS K, KAWAI K, et al., 1999. Hydraulic fracture reopening pressure and the estimation of maximum horizontal stress[J]. International Journal of Rock Mechanics and Mining Sciences, 36(6): 811-826. doi: 10.1016/S0148-9062(99)00053-4 ITO T, IGARASHI A, KATO H, et al., 2006. Crucial effect of system compliance on the maximum stress estimation in the hydrofracturing method: Theoretical considerations and field-test verification[J]. Earth, Planets And Space, 58(8): 963-971. doi: 10.1186/BF03352601 ITO T, SATOH T, KATO H, 2010. Deep rock stress measurement by hydraulic fracturing method taking account of system compliance effect[C]//Proceedings of ISRM international symposium on in-situ rock stress. Beijing: International Society for Rock Mechanics and Rock Engineering. JAEGER J C, COOK N G, ZIMMERMAN R W, 2007. Fundamentals of rock mechanics[M]. 4th ed. London: Wiley-Blackwell. PERRAS M A, DIEDERICHS M S, 2014. A review of the tensile strength of rock: concepts and testing[J]. Geotechnical and Geological Engineering, 32(2): 525-546. doi: 10.1007/s10706-014-9732-0 TAN C X, ZHANG P, LU S L, et al., 2019. Significance and role of in-situ crustal stress measuring and real-time monitoring in earthquake prediction research[J]. Journal of Geomechanics, 25(5): 866-876, doi: 10.12090/j.issn.1006-6616.2019.25.05.071. (in Chinese with English abstract) WANG C H, 2014. Brief review and outlook of main estimate and measurement methods for in-situ stresses in rock mass[J]. Geological Review, 60(5): 971-996. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzlp201405003 WANG C H, SONG C K, XING B R, 2012. Compliance of drilling-rod system for hydro-fracturing in situ stress measurement and its effect on measurements at great depth[J]. Geoscience, 26(4): 808-816. (in Chinese with English abstract) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xddz201204024 WANG C H, WANG R T, WANG C Q, 2017. Development of multiple-diameter core hydraulic fracturing machine to test tensile strength of rocks[J]. Chinese Journal of Rock Mechanics and Engineering, 36(S1): 3321-3331. (in Chinese with English abstract) http://www.researchgate.net/publication/320537052_Development_of_multiple-diameter_core_hydraulic_fracturing_machine_to_test_tensile_strength_of_rocks WANG C H, WANG X J, HOU Y H, et al., 2014-04-09. High-pressure fluid control panel for hydraulic fracturing in-situ stress measurement system: CN201320624928.8[P]. WANG C H, WANG X J, MAO J Z, et al., 2016-01-22. Data acquisition instrument for hydraulic fracturing in-situ stress measurement system: CN201310471715.0[P]. YAMASHITA F, MIZOGUCHI K, FUKUYAMA E, et al., 2010. Reexamination of the present stress state of the Atera fault system, central Japan, based on the calibrated crustal stress data of hydraulic fracturing tests obtained by measuring the tensile strength of rocks[J]. Journal of Geophysical Research, 115(B4): B04409. ZOBACK M D, POLLARD D D, 1978. Hydraulic fracture propagation and the interpretation of pressure-time records for in-situ stress determinations[C]//Proceedings of the 19th U.S. symposium on rock mechanics. Stateline, Reno: American Rock Mechanics Association: 14-22. 陈群策, 孙东生, 崔建军, 等, 2019.雪峰山深孔水压致裂地应力测量及其意义[J].地质力学学报, 25(5): 853-865, doi: 10.12090/j.issn.1006-6616.2019.25.05.070. 谭成轩, 张鹏, 路士龙, 等, 2019.原位地应力测量与实时监测在地震预报研究中的作用和意义[J].地质力学学报, 25(5): 866-876, doi: 10.12090/j.issn.1006-6616.2019.25.05.071. 王成虎, 宋成科, 邢博瑞, 2012.水压致裂应力测量系统柔性分析及其对深孔测量的影响[J].现代地质, 26(4): 808-816. doi: 10.3969/j.issn.1000-8527.2012.04.024 王成虎, 2014.地应力主要测试和估算方法回顾与展望[J].地质论评, 60(5): 971-996. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzlp201405003 王成虎, 王显军, 侯砚和, 等, 2014-04-09.水压致裂原地应力测量高压流体控制系统: CN201320624928.8[P]. 王成虎, 王显军, 包林海, 等, 2016-01-22.水压致裂法原地应力测量数据采集系统: CN201310471715.0[P]. 王成虎, 王仁涛, 王春权, 2017.多直径岩芯液压致裂岩石抗拉强度快速试验机研发[J].岩石力学与工程学报, 36(S1): 3321-3331. http://www.cnki.com.cn/Article/CJFDTotal-YSLX2017S1023.htm 中国地震局地壳应力研究所, 日本电力中央研究所, 1999.水压致裂裂缝的形成和扩展研究[M].北京:地震出版社. 中国地震局地壳应力研究所, 2013.水压致裂原地应力测量数据采集与分析系统[简称: 水压致裂测试数采分析系统, V1.0]: 2013SR122558 [CP]. 2013-08-30[2013-11-09]. -

下载:

下载: